Ordering, Design, Manufacturing and Assembly Instructions for Cap:¶

- Part contains a Two Custom Coils which I estimated using Trial and error.

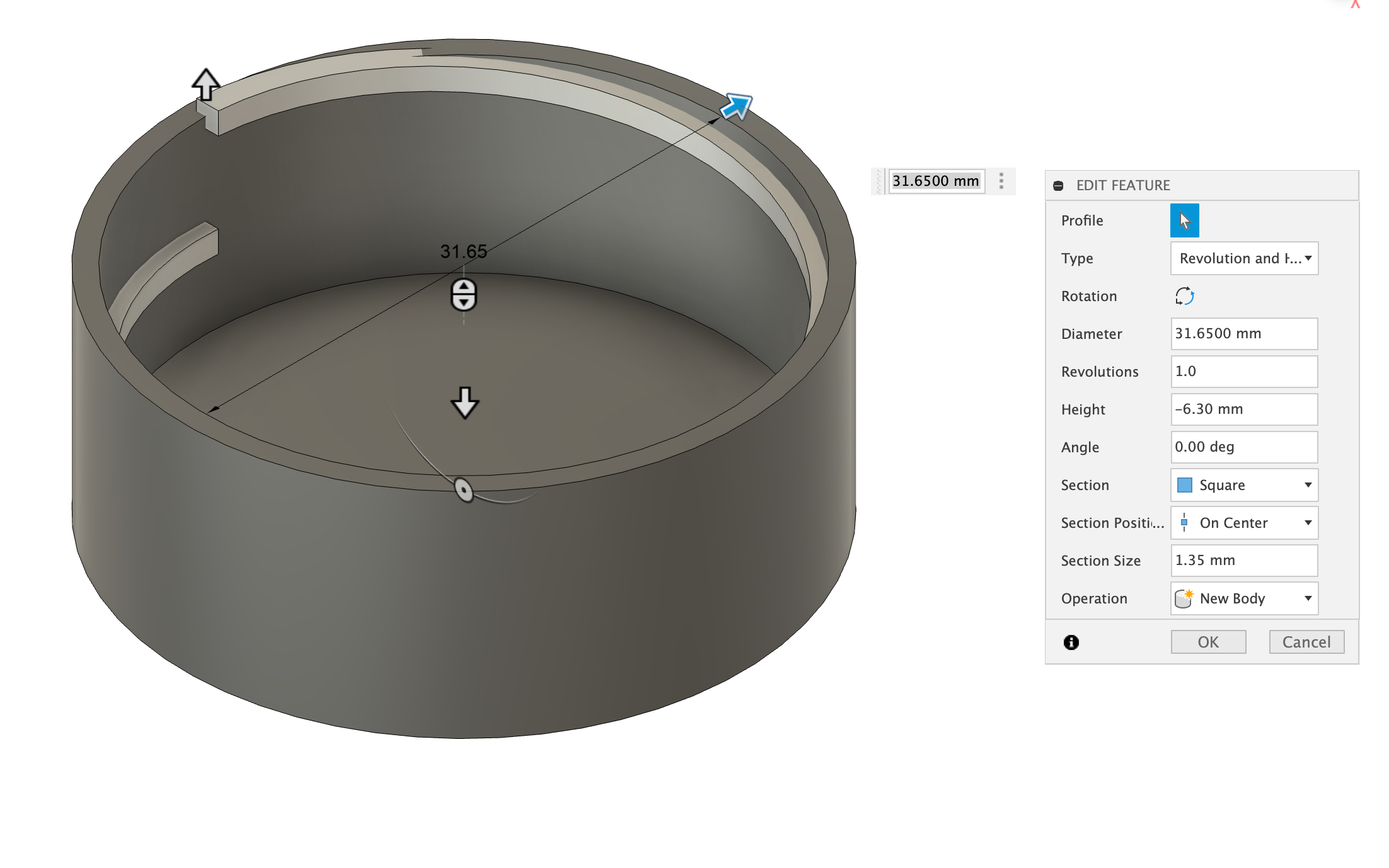

- The Two Coils Are 180 Degrees apart. The Screenshot should give you the dimensions of the first coil.

- I then moved these coils and fillet them before fusing them with the main body in the Model.

- The F3D File should have the complete design history.

- I have also provided Intermediate Versions of the STEP file to help if you don't have Autodesk Fusion.

- The Two Coils Are 180 Degrees apart. The Screenshot should give you the dimensions of the first coil.

- You can also modify the design to make a two port version.

- One of the Sketches in the F3D file should allow you to make the two port version.

- I ordered these parts from RapidDirect

- CNC Machining / Aluminum 6061-T6 / As machined (Ra1.6)

- I orderd both: As Machined and Anodized parts.

- I recommend anodizing since you can autoclave the parts if necessary.

- Anodizing Type II (Black, Glossy)

- General tolerance: ISO2768M

- Tightest tolerance: ISO2768F

- Threads and tapped holes: Standard threads

- In the notes please do mention: 1/4-28 UNF 1B(Loose Fit) is needed.

- I've also included a Drawing document but did not mention details of the Custom Thread. Please do include the Dimensions of the Custom Coils in the Notes

- You can also send them the intermediate files and the Screenshot with the Dimensions of the Coils to RapidDirect.

- Cost

- I ordered 60 Caps and the total came to about 11 USD per cap including shipping in May 2024.

- Commercial Versions of these reservoirs cost about 120 USD or more. I recommend having them made with these CAD files to save money.

- Finished Part Videos. You can watch videos of the Machined Finished Parts here:

- Anodized Version

- As-Machined Version

- Both Parts Work Equally Well. But I recommend getting the Anodized version.

- 30 Anodized Caps should be enough for one ChronoSeq device.

- Adding Gasket/O-Ring

- O-Ring Gasket Was Ordered from Primal23Industrial

- Place this O-Ring at the Bottom of the Cap so it seals the Gap between the 50ml Falcon Tube and the CNC Machined Cap.

- You can also order from Amazon

- E12534116-100 1 1/4 OD X 3/4 ID X 1/16 Thickness Neoprene Rubber Washers - Endeavor Series Select Pack Quantity: 100 Pack. Cost about 20$.

- Additional Parts:

- To Block one of the Ports you can use a Delrin Plug.

- You can Connect Pneumatic Tubing Using a Barb.

- You can connect 1/16" OD tubing to the CAP using a Nut and Ferrule.

- Leak Test Video:

- In this Video the Fully Assembled Part was Submerged in Water and there were no leaks when pressurized to 2 Bar.

- Optional Additive Manufacturing Version:

- You can also print these parts using an FDM Printer but removing supports can be tricky.

- You can use a toolkit like this to help with support removal.

- SLA (Resin) Prints with a 50μm layer height is recommended.

- In addition you will need to add another O-Ring in the 1/4-28 UNF Ports to prevent gas leaks, especially for the FDM Printed Version.

- Oil-Resistant Soft Buna-N O-Rings, 1/16 Fractional Width, Dash Number 004, Packs of 100

- The Ferrule should be in contact with the additional O-Ring to Prevent Leaks for the FDM Version.

- You can also print these parts using an FDM Printer but removing supports can be tricky.

- Tolerance Compensation for FDM and SLA Prints

- Tolerance compensation was needed for the FDM Version of the CAP. I used a XY Tolerance Compensation of 0.15mm

- The 3MF File and was printed on a Bambu Lab X1 Carbon.

- You can load the 3MF File into the Orca Slicer directly to inherit the print settings.

- For the Bambu Lab X1 Carbon we had:

- 0.4mm Nozzle

- Textured PEI Plate

- For the Resin Prints Tolerance compensation might also be needed. But I haven't tried it. Instead I:

- Used a Tap and Tap Wrench to shave off excess plastic from the print.