Instructions for Assembling LG16-1000D Sensirion Flow Sensor¶

Brief Description and Working Principle¶

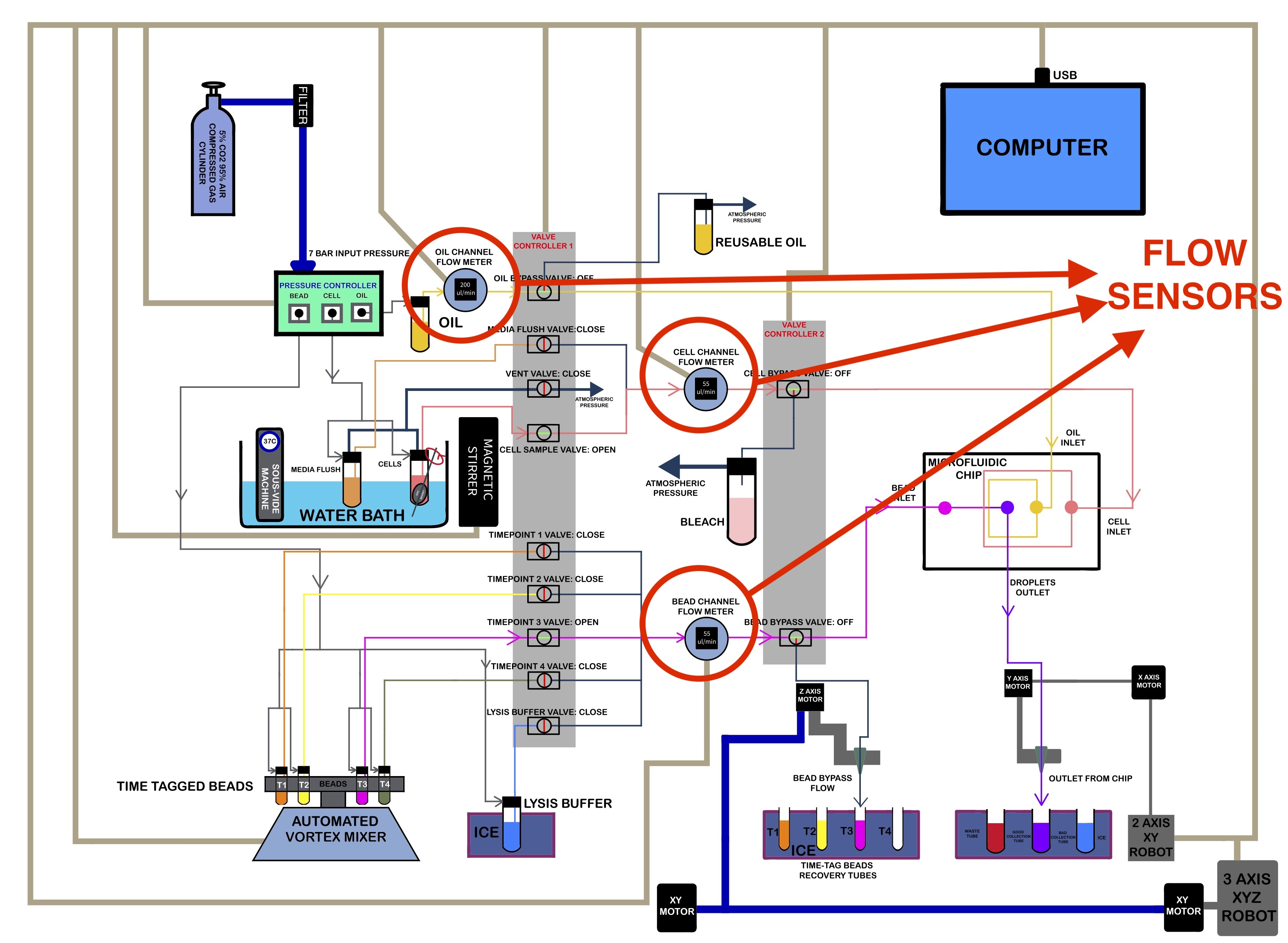

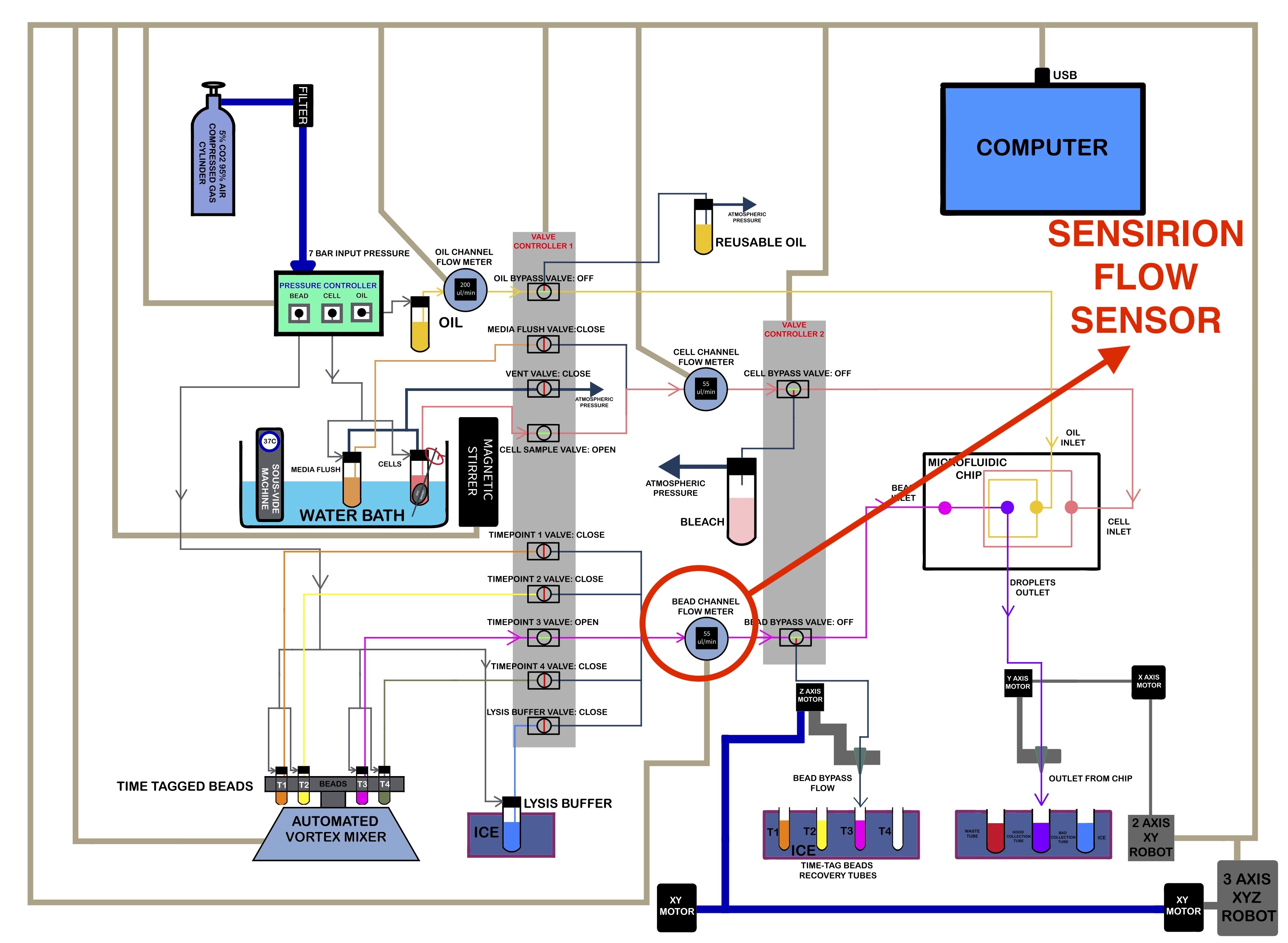

- We need precise control of Flow Rates going into our Microfluidic Chip for Droplet Generation.

- Flow Rates can be changed by Changing the Gas Pressure in each Channel.

- Flow Rates are measured using Flow Sensors/Flow Meters.

- We need 3 Flow Meters for each injection Channel: Bead, Cell and Oil Channels.

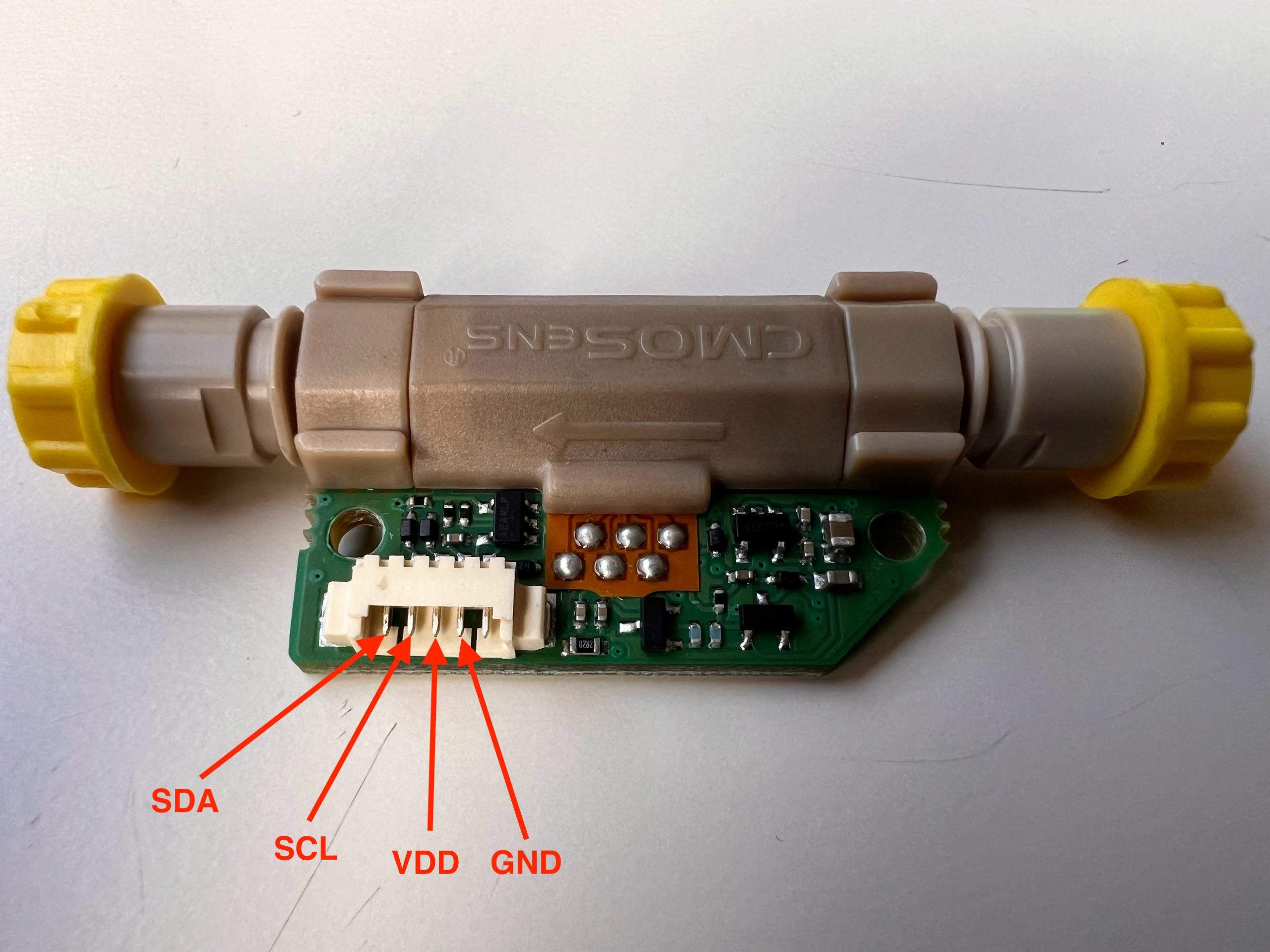

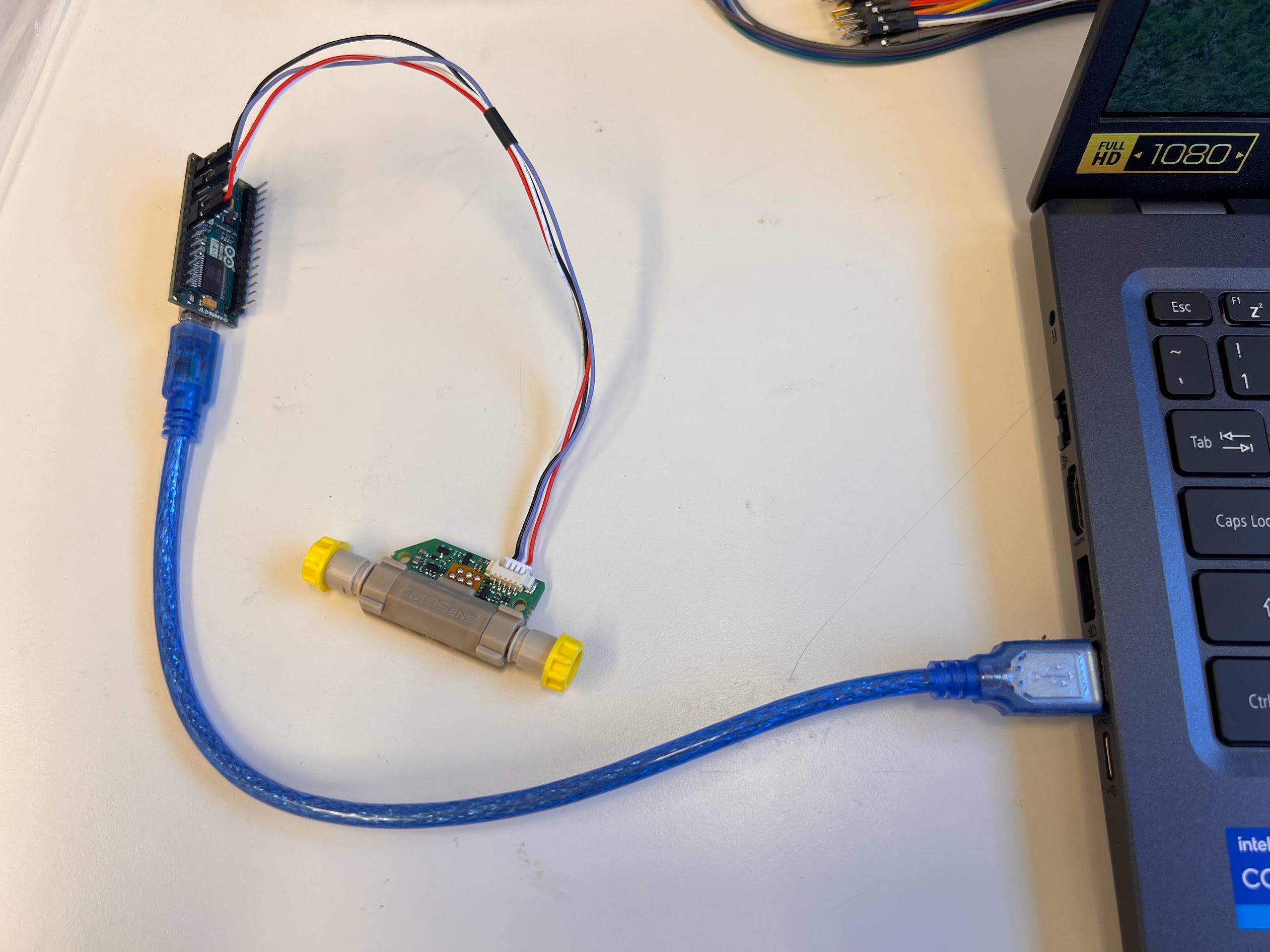

- The Sensirion LG16-1000D Flow Sensor tells us Flow rates in the 0-1000μl range.

- The Flow Sensor works by measuring heat transfer.

- This heat transfer can vary depending on the Dissolved Chemicals or Fluid Being used, therefore this sensor needs to be Calibrated before use.

- We have already calculated some Calibration values for this Sensor but it might be useful to Check the Calibration.

- We will learn how to check this Calibration in a separate notebook.

- We use the Sensirion Flow Sensor for the Bead Channel Only.

- There is a Thin Glass Capillary inside the Flow Sensor, overtightening can cause this to break. Please follow any precautions mentioned in the datasheet.

| Location of Flow Sensors in Schematic | Location of Sensirion Flow Sensor in Schematic |

|---|---|

|

|

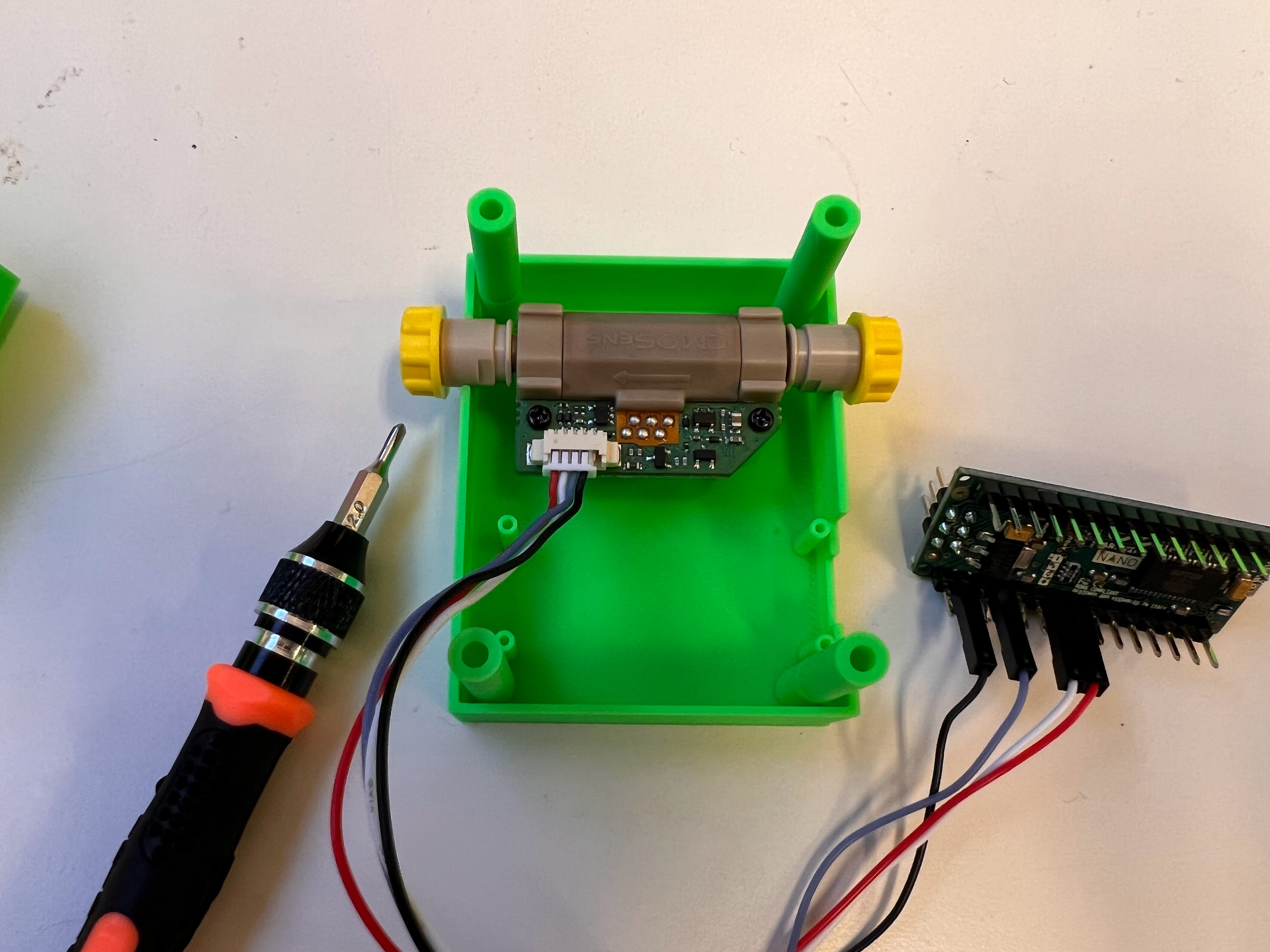

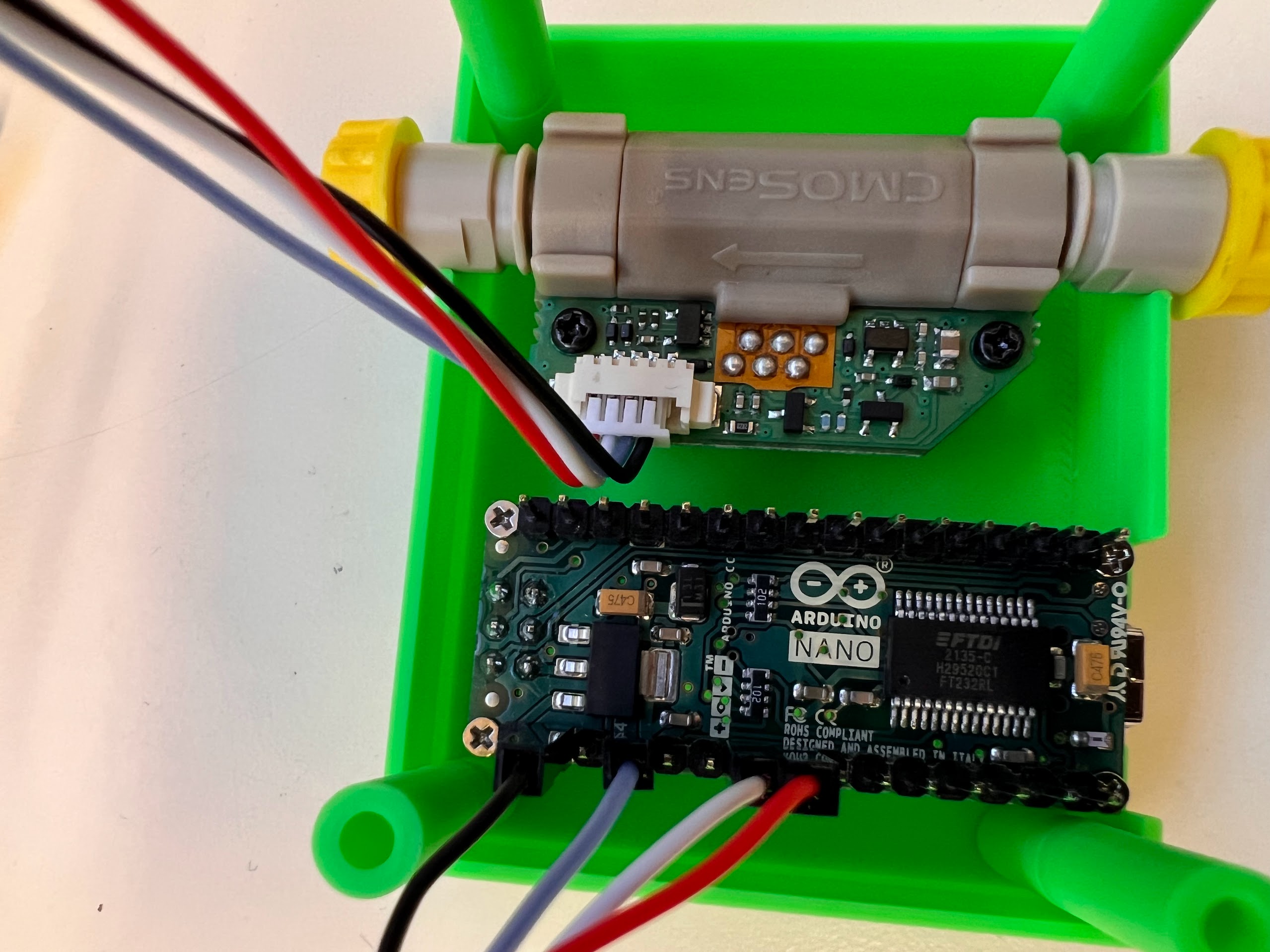

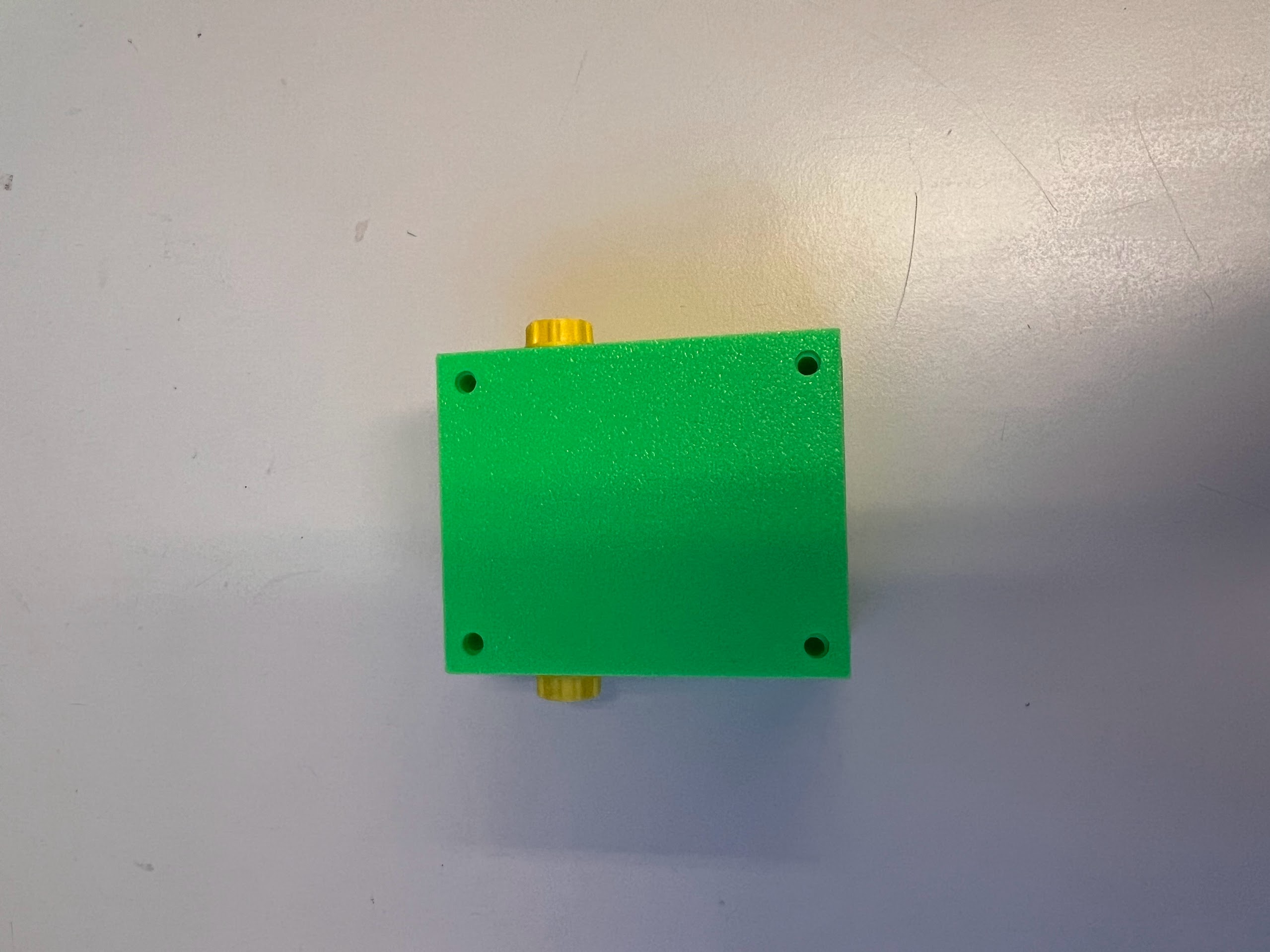

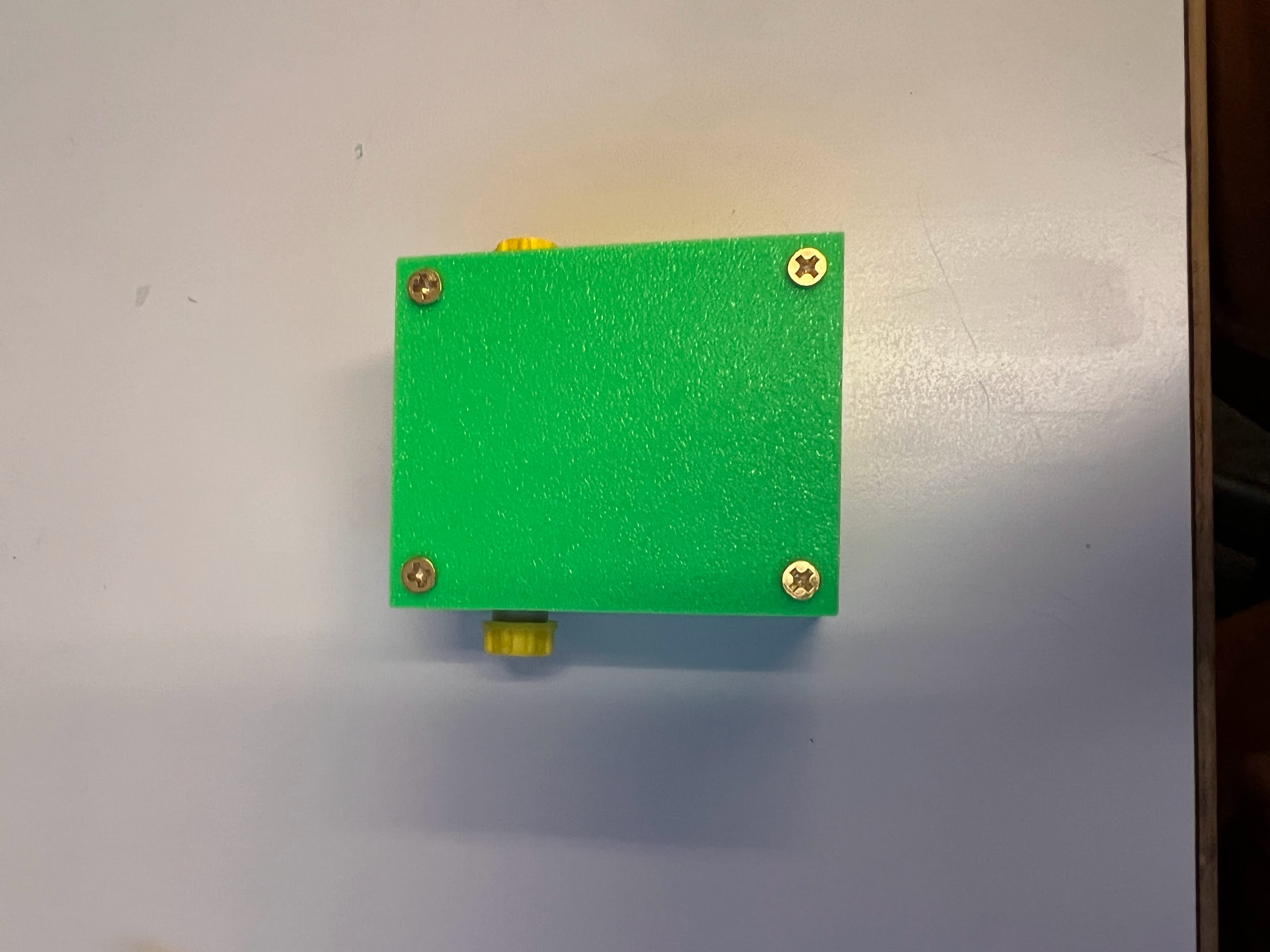

3D Printing Sensor Housing¶

- We used a Bambu Lab X1 Carbon to print the Housing.

- 0.4mm Nozzle

- Textured PEI Plate

- We generated a 3MF File with all the Settings we used for the Print. You can open this file on the Orca Slicer.

- The Original STEP Files and F3D Files can be found in this directory.

- We recommend getting a 3D Printing Accessories Kit if you haven't purchased one already.

- Its extremely helpful in removing supports and cleaning up the print.

- You can watch the Timelapse Video Below: