Instructions for Assembling Valve Controller V2¶

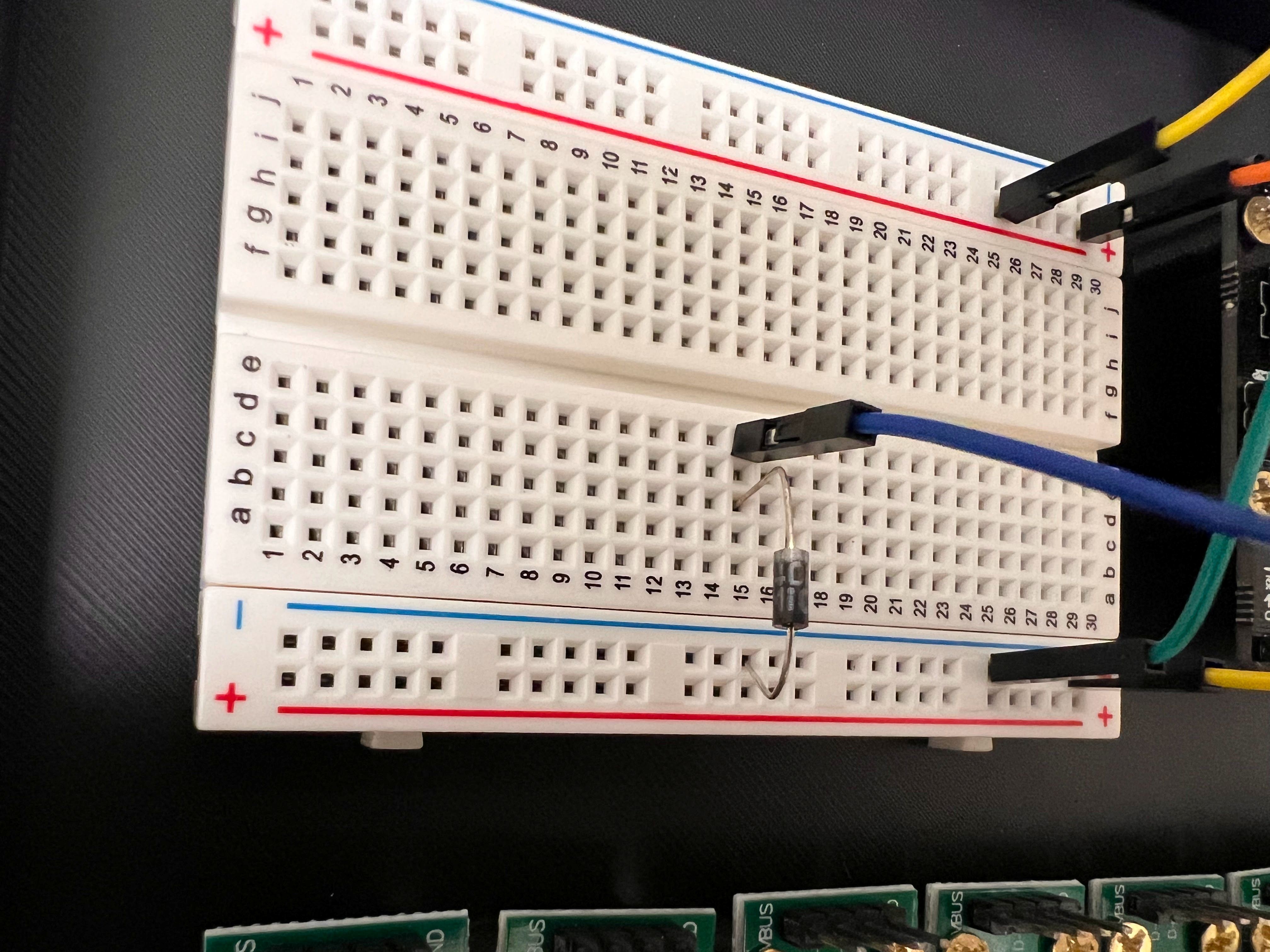

- We updated the instructions to add a Flyback diode for the Solenoid Valves.

Brief Description of Purpose and Working Principles:¶

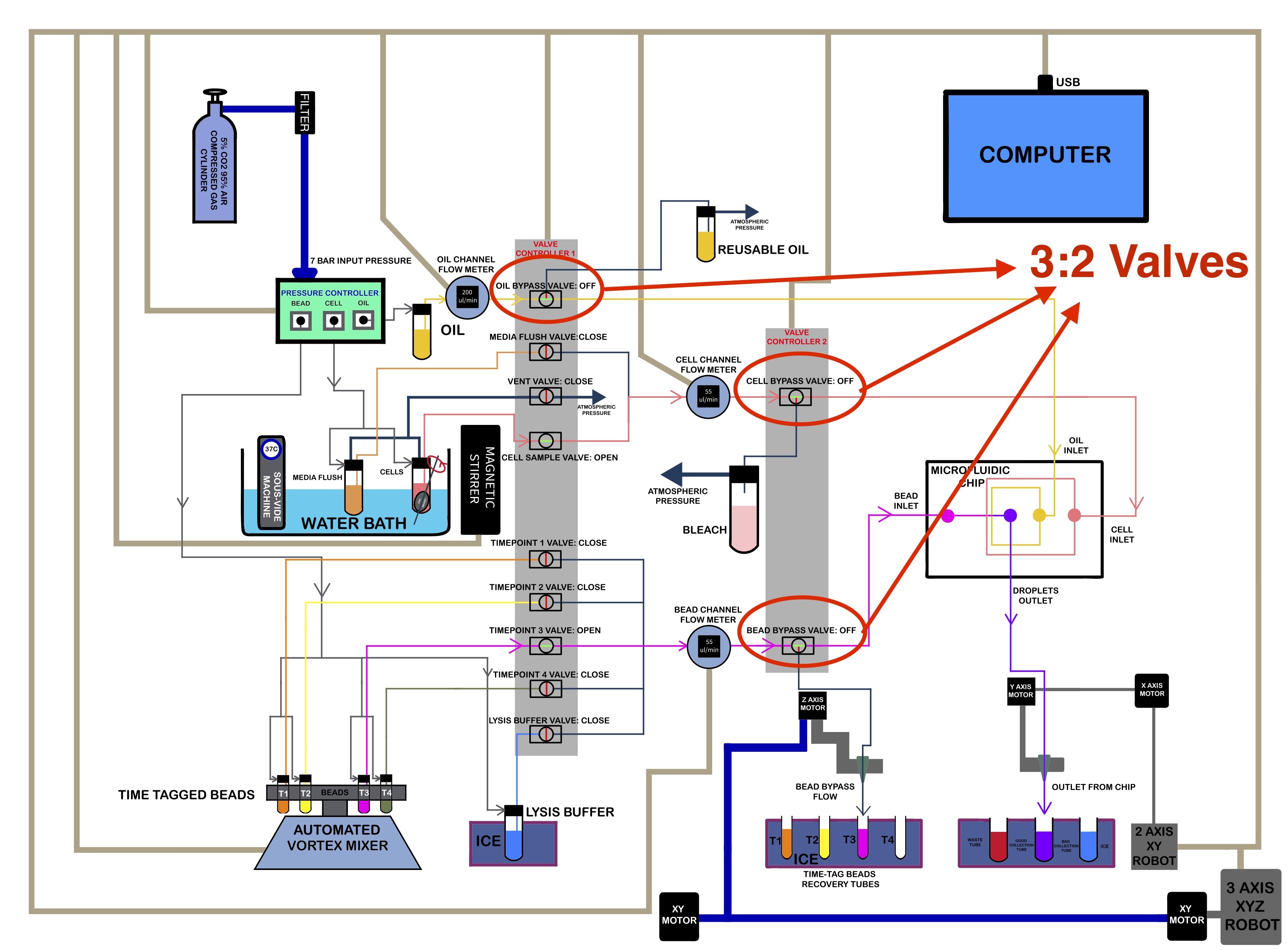

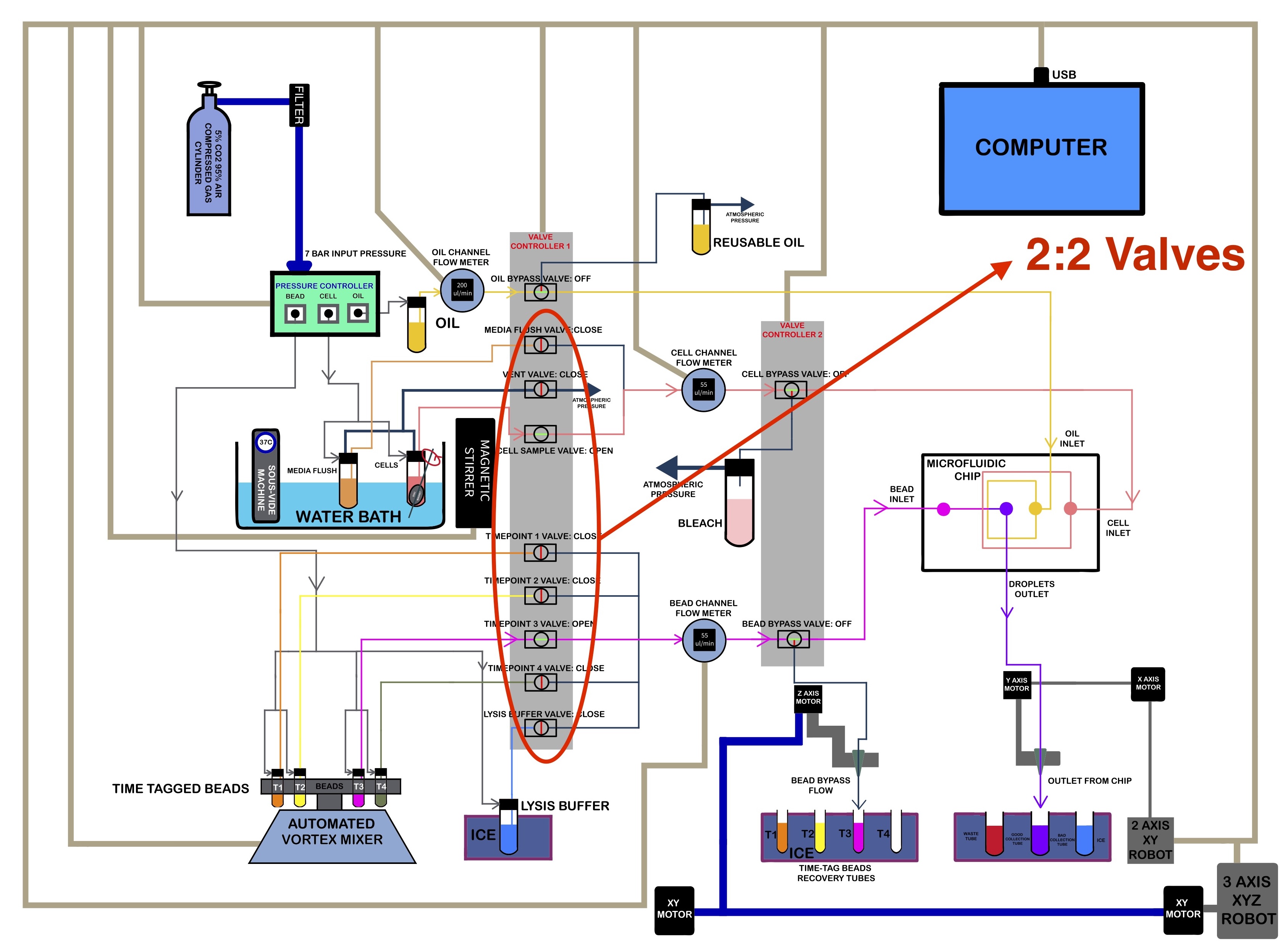

- We need to a way to control the flow of liquid through the ChronoSeq Device by shutting down or redirecting flow.

- To help control the flow with our computer we need to build a Valve Controller that can switch specific valves ON or OFF when it receives a command from the computer.

- The SMC Valves we have selected for our device can be 2:2 Valves or 3:2 Valves.

- 2:2 Valves Turn Flow ON or OFF. Most of these will be used to control flow from Individual Reservoirs.

- 3:2 Valves Redirect Flow from the Input Port to the Main or Bypass Port. We use these as Bypass Valves for Controlling flow into the Microfluidic Chip for each Channel: Cells, Beads and Oil.

- The 2:2 SMC Valves we have purchased are Normally Closed (NC). Meaning liquid will only flow through them when they are powered ON.

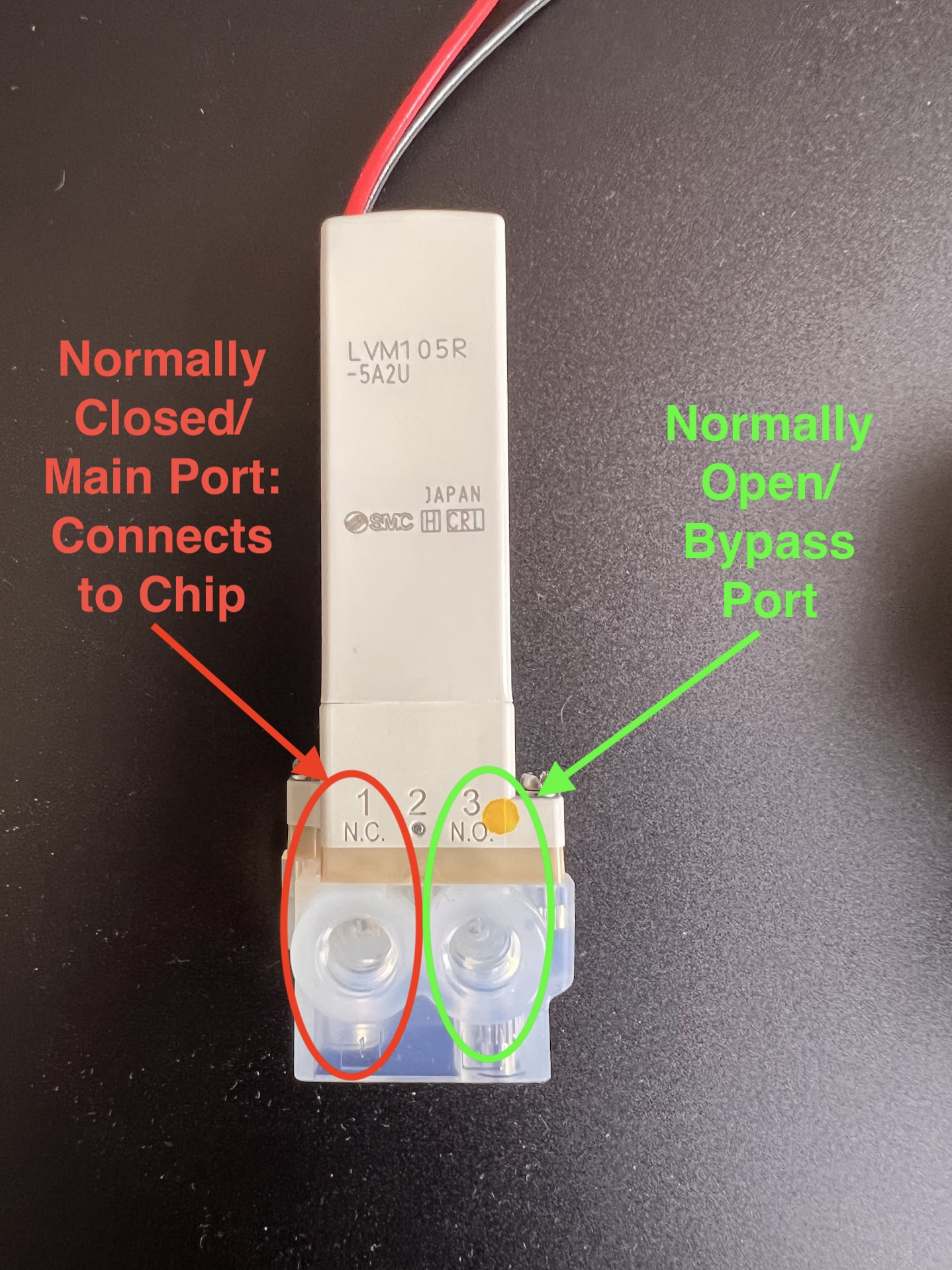

- The 3:2 Valves allow flow from:

- The Input Port to the Bypass port when powered OFF. The Bypass port is therefore called the Normally Open (NO) Port.

- You can identify the NO Port by Looking for the NO Symbol on the Valve near the Port.

- The Valve allows flow from the Input port to the Main port only when powered ON. This port is therefore called the Normally Closed (NC) Port.

- You can identify the NC Port by Looking for the NC Symbol on the Valve near the Port.

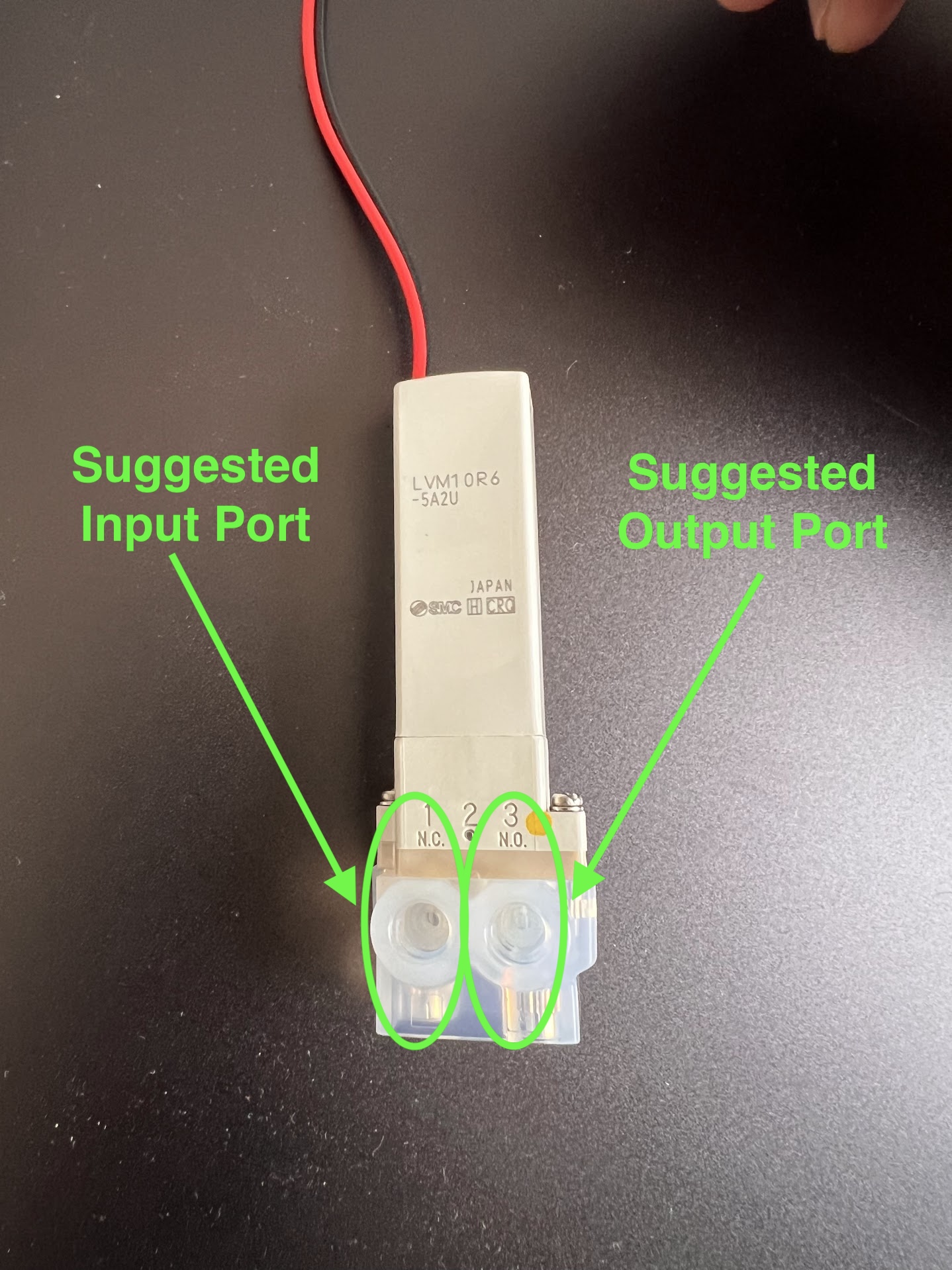

- The 3:2 Valves can be converted into 2:2 NC or 2:2 NO Valves by blocking either the NC or NO Port using a Delrin Plug.

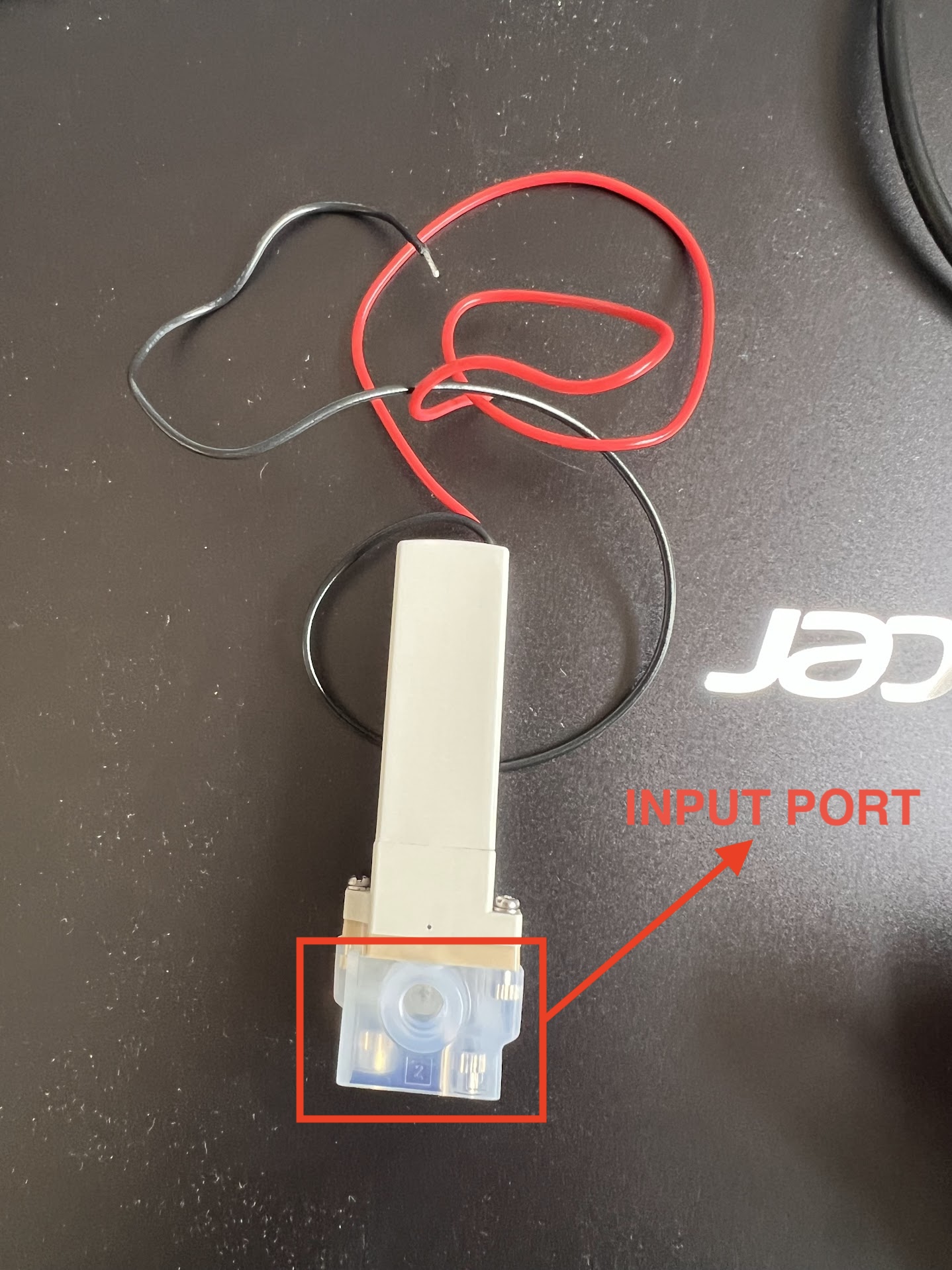

| 3:2 Valve Input Port | 3:2 NC and NO Port Locations | 2:2 Valve Suggested Input and Output Ports |

|---|---|---|

|

|

|

| Location of 3:2 Bypass Valves in Schematic | Location of 2:2 Valves in Schematic |

|---|---|

|

|

Ordering Information for SMC Valves¶

- SMC Valves are Highly Configurable and the exact product number represents this configuration.

- For Example this website allows you to generate a product number before ordering.

- Make sure the Chemicals being used for your application are compatible with the Wetted materials in your Valve Configuration.

- We will be ordering the LVM10 Series of Valves.

- The Following product numbers and Quantities were ordered for the two types for Valves:

- 2:2 Valves: LVM10R6-5A2U . Quantity : 30 Units

- 22 Units are needed in the Version of the ChronoSeq Device with 16 Timepoint Reservoirs.

- The remaining 8 were kept as backup replacements.

- You can order only 22 Valves if you want to save some money.

- Only 18 Valves are necessary if your device has 12 Timepoint Reservoirs.

- 3:2 Valves: LVM105R-5A2U . Quantity : 5 Units

- 3 Units are needed in the Current Version of the ChronoSeq Device.

- The remaining 2 were kept as backup replacements.

- You can order only 3 Valves if you want to save some money.

- 2:2 Valves: LVM10R6-5A2U . Quantity : 30 Units

- SMC has many global suppliers and your local supplier might vary.

- Different suppliers offer different prices.

- Its best to find the most competitive local supplier for your area.

- You can use this website to help you locate a supplier.

- We ordered our valves from Bay Advanced Technologies located in Orange County, CA.

- Its best to call them to place an order. Their number is +1 714-241-1031 .

- You should also email Monica(mgparra@bayat.com) or Derek(dloe@bayat.com) if they still work there.

- You can also call (+1 213-476-3863) or email Colby(cchristy@bayat.com), a local account Manager in San Diego.

- We payed by providing our Credit Card Number over the phone.

- Both the 3:2 and 2:2 Valves Cost 81.60USD Each in April 2024.

Overview of Valve Controller Design¶

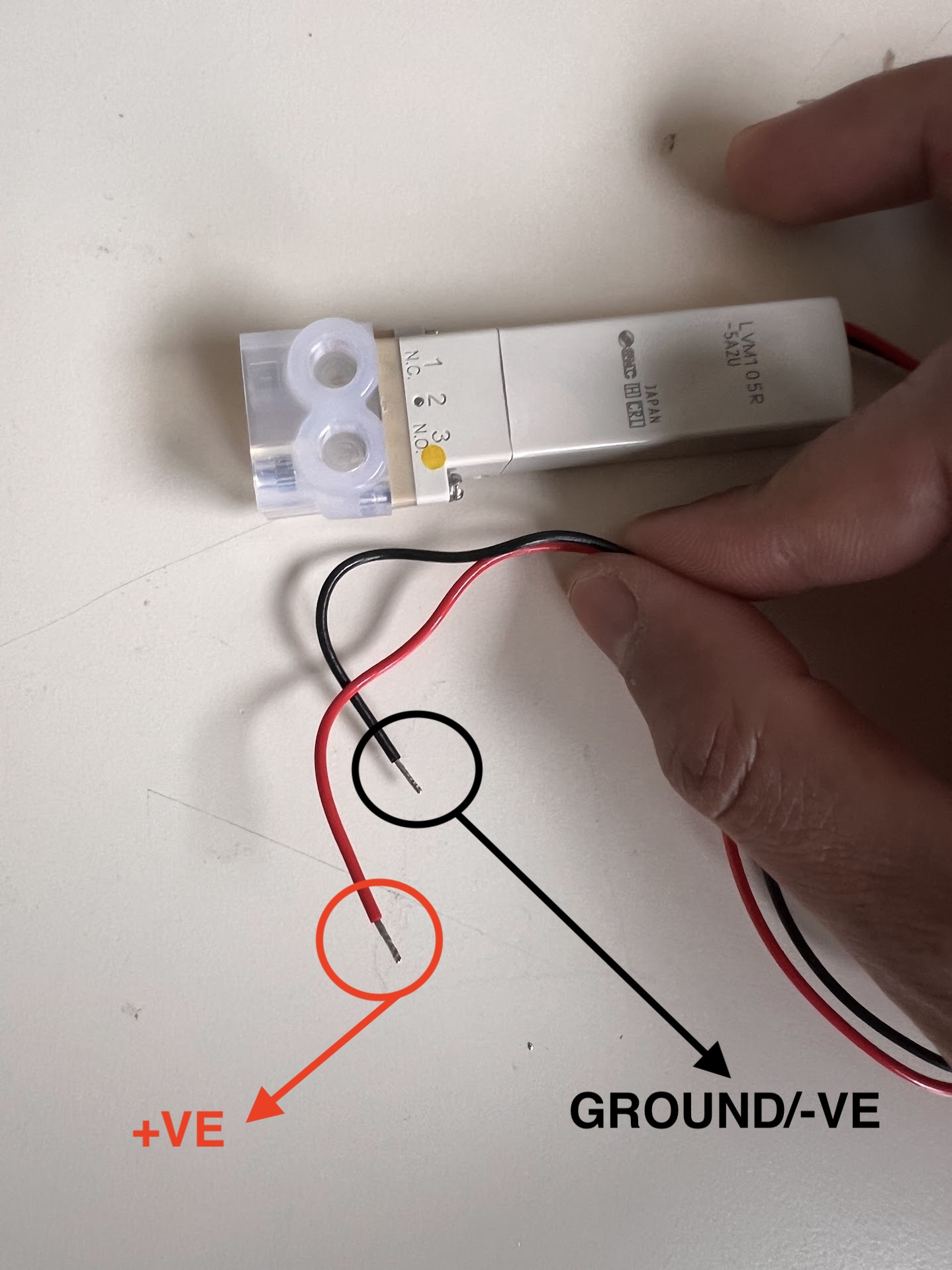

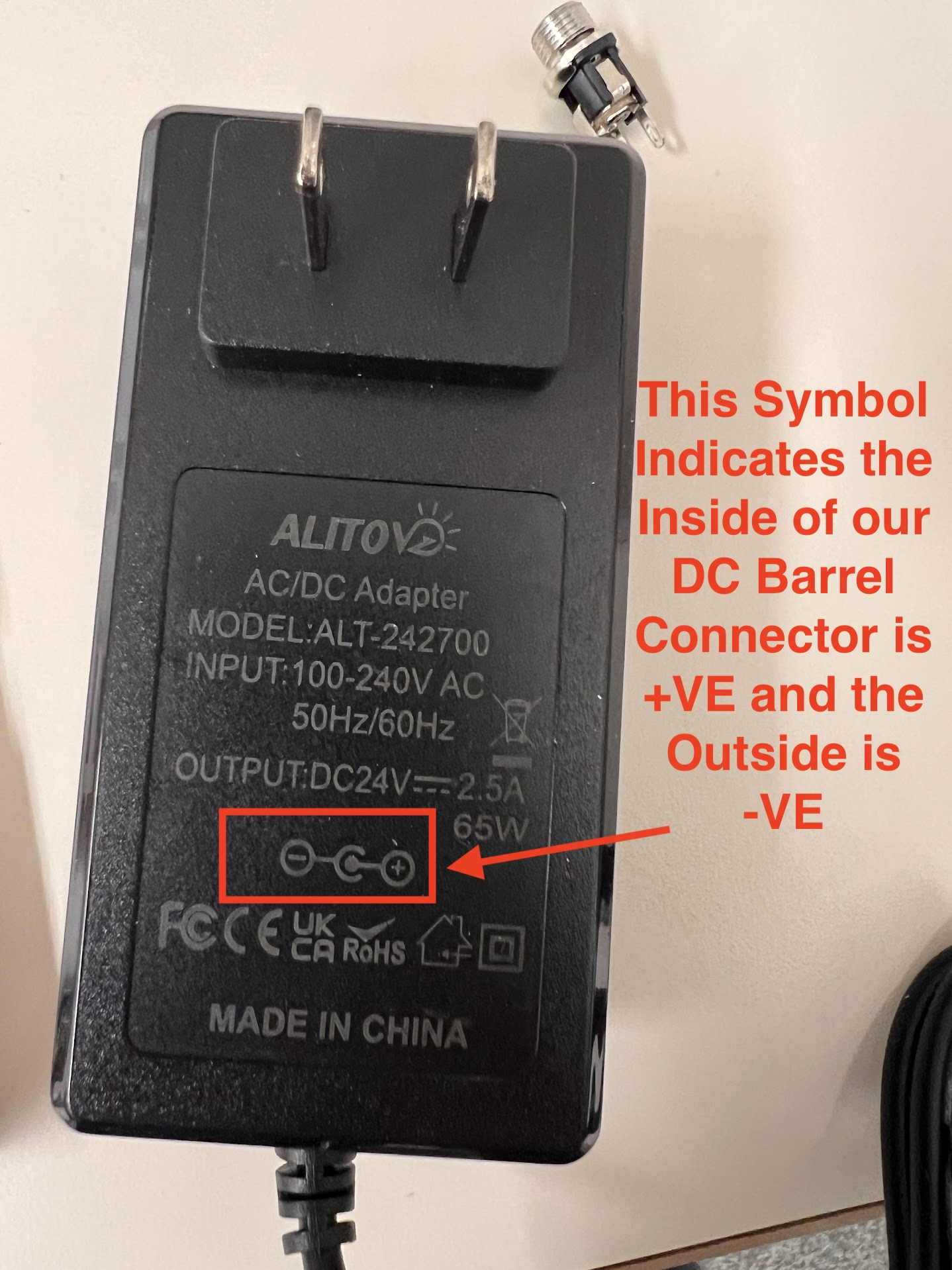

- Both Valves require 24V DC Current to Turn ON and Consume about 1.5W of Power or 60mA of Current.

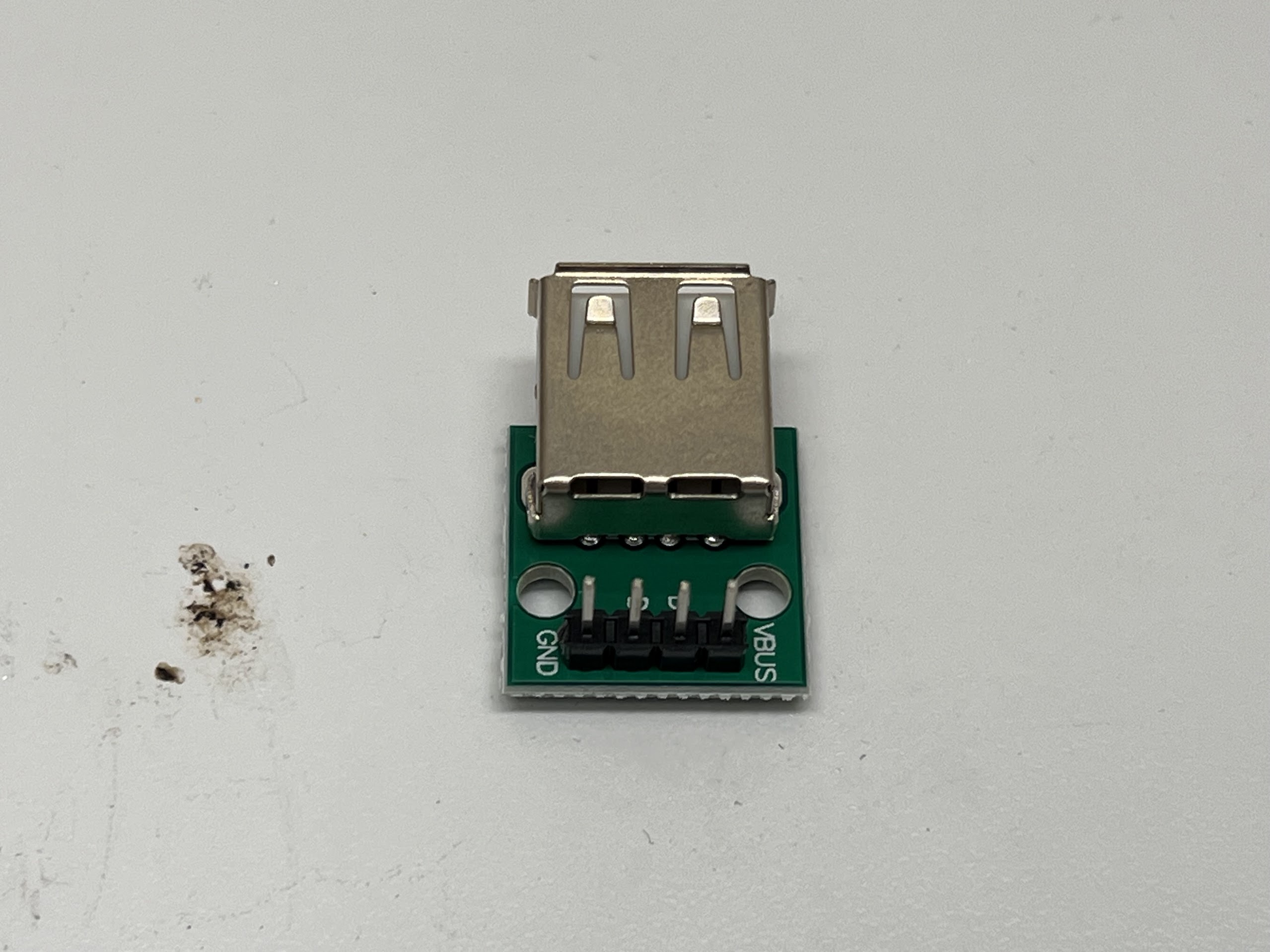

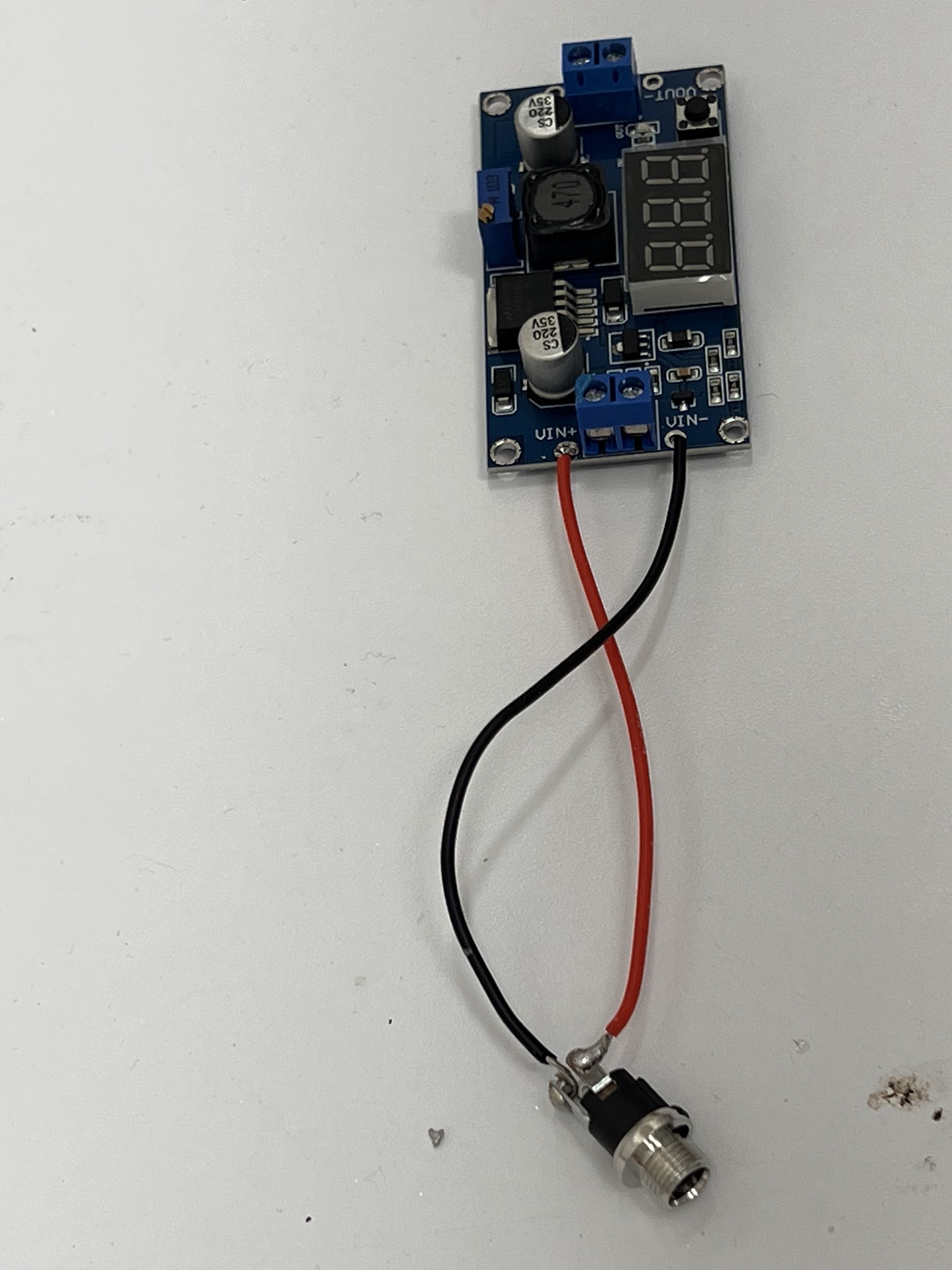

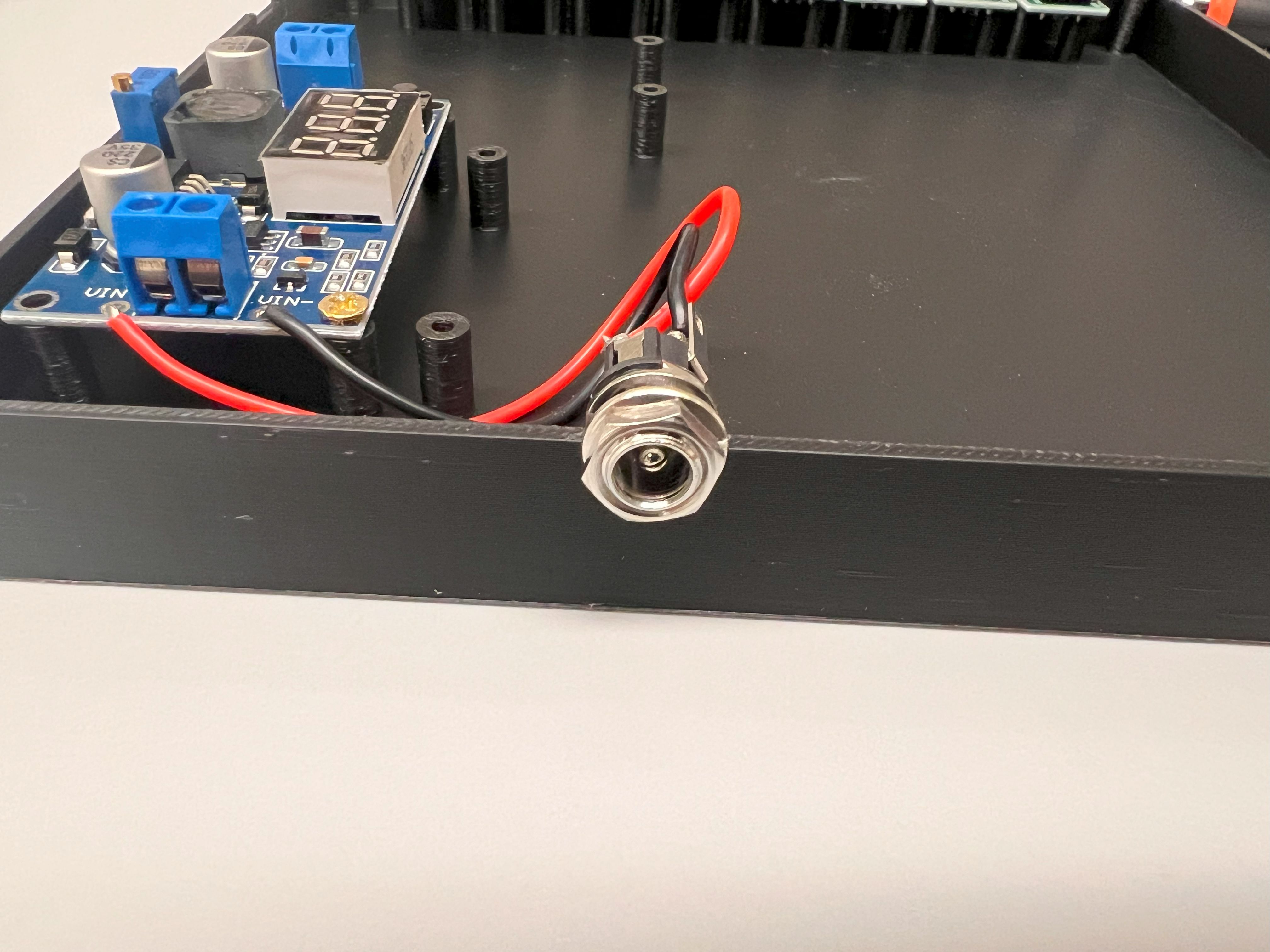

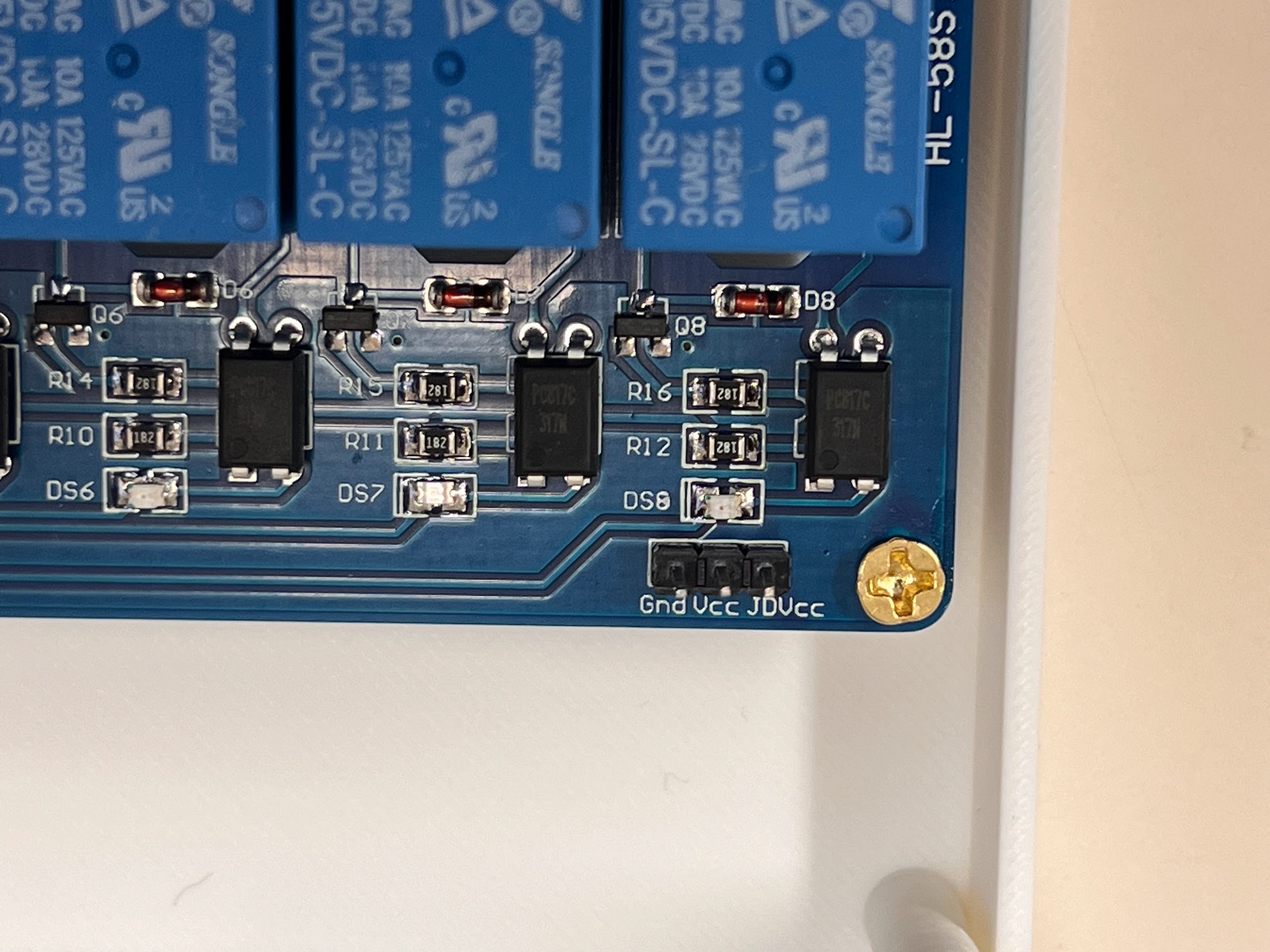

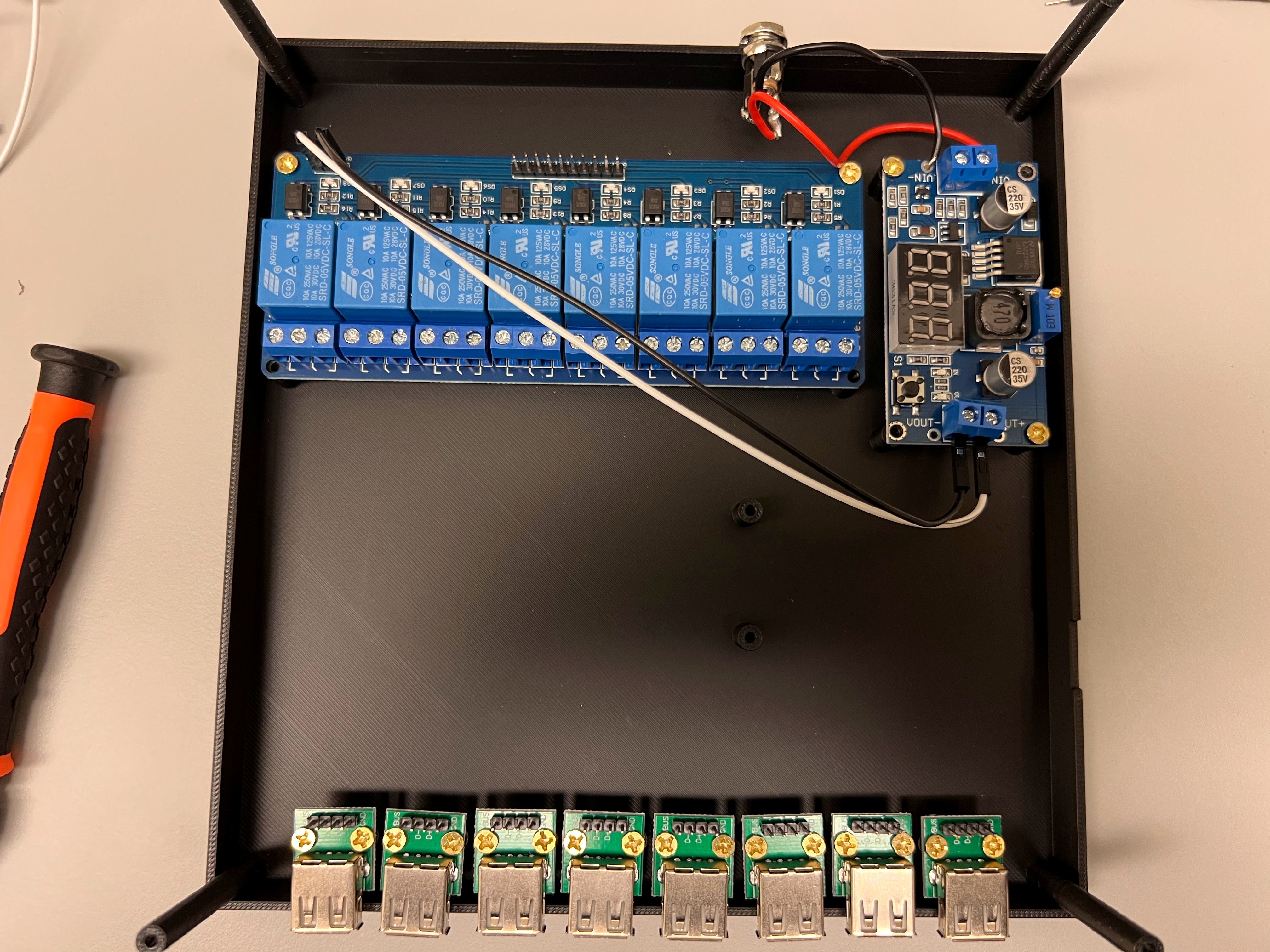

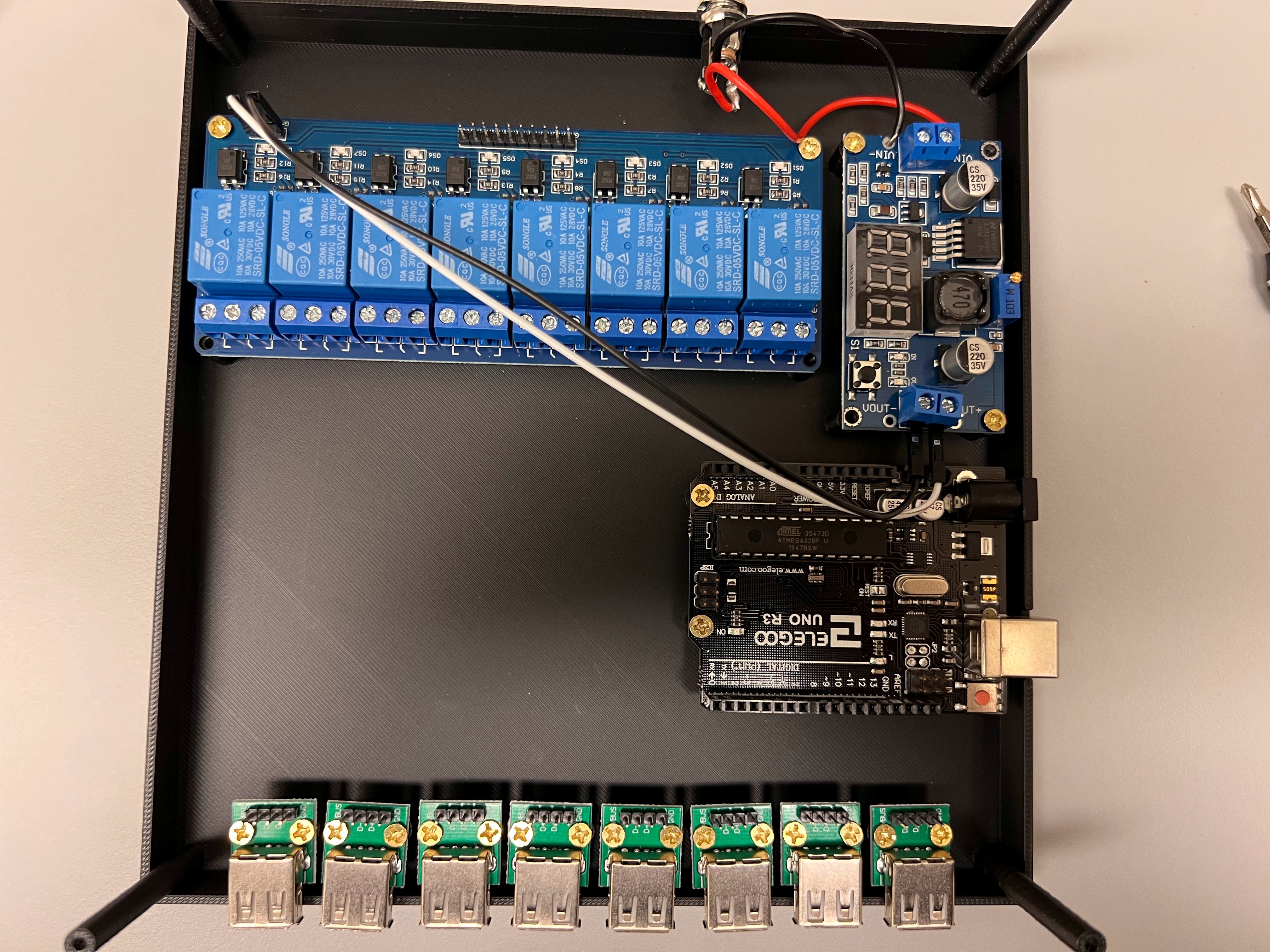

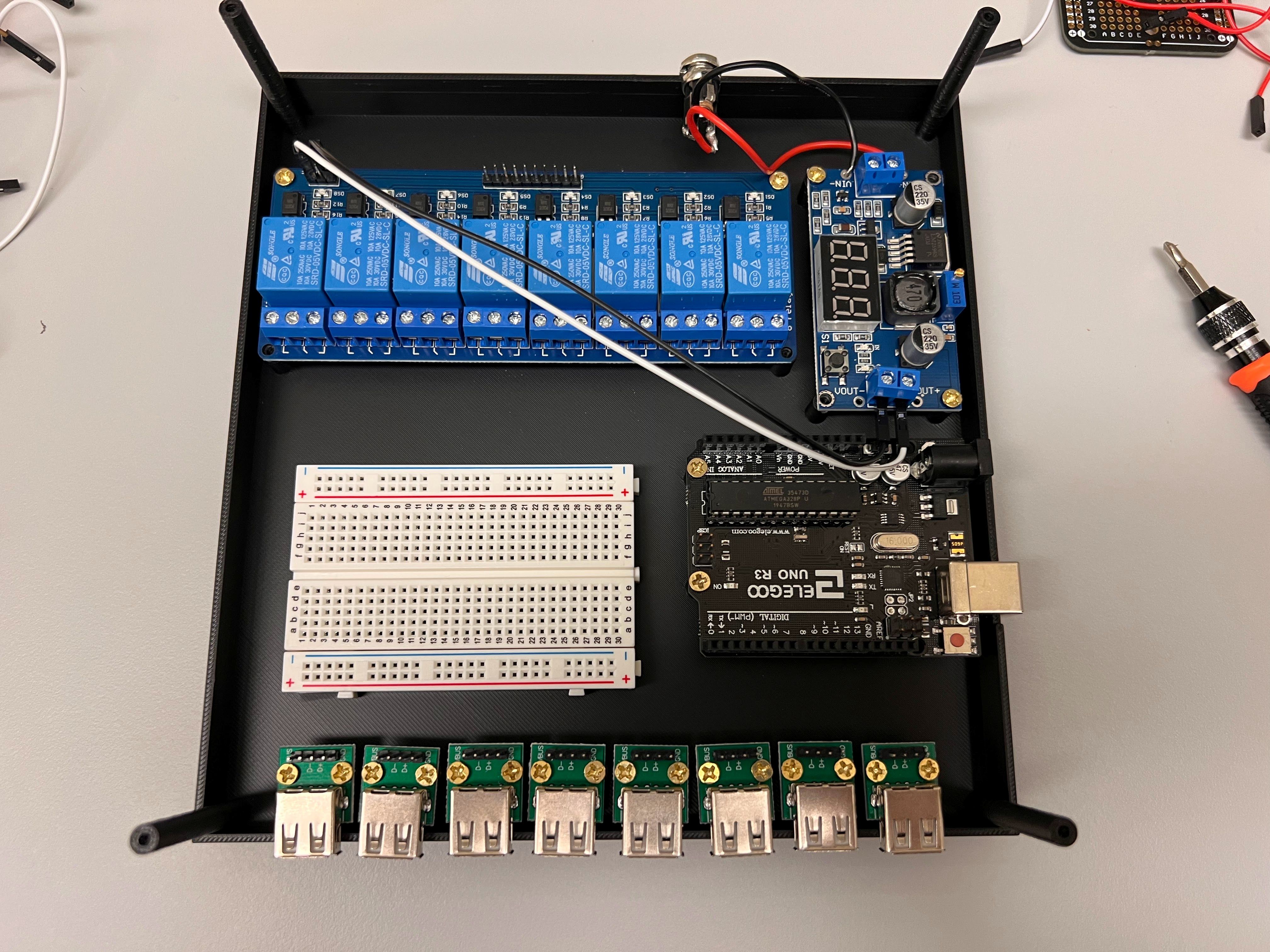

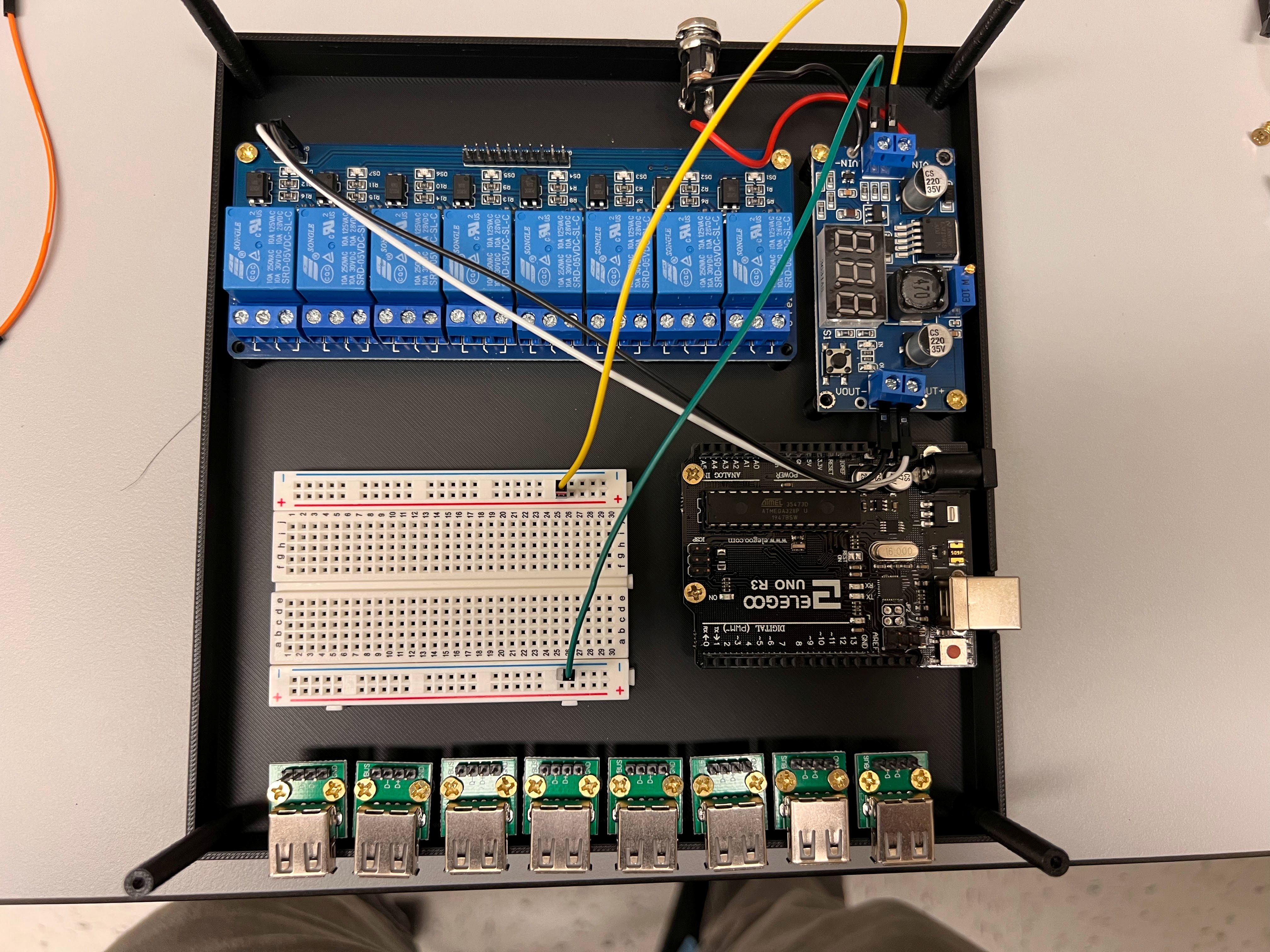

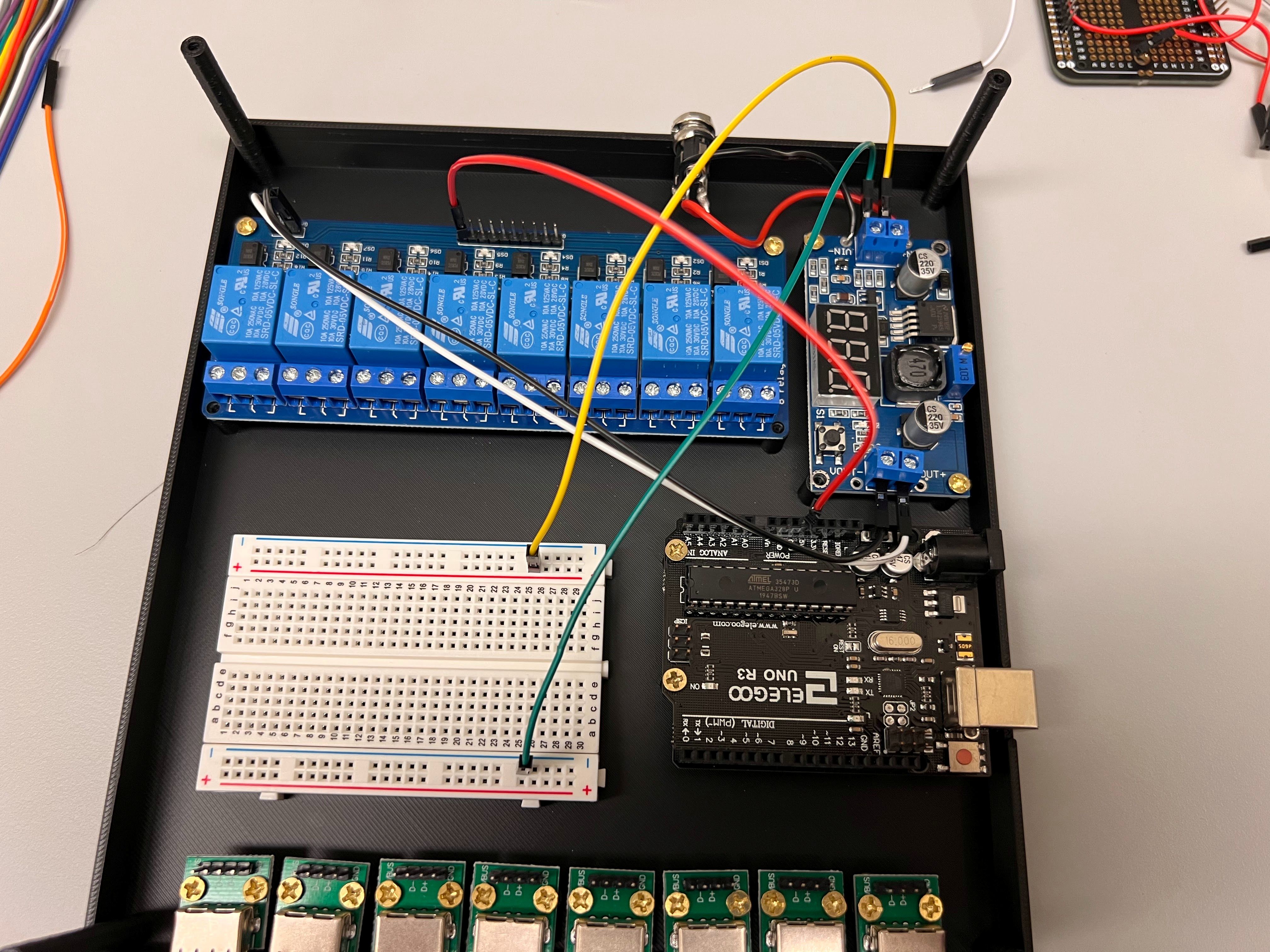

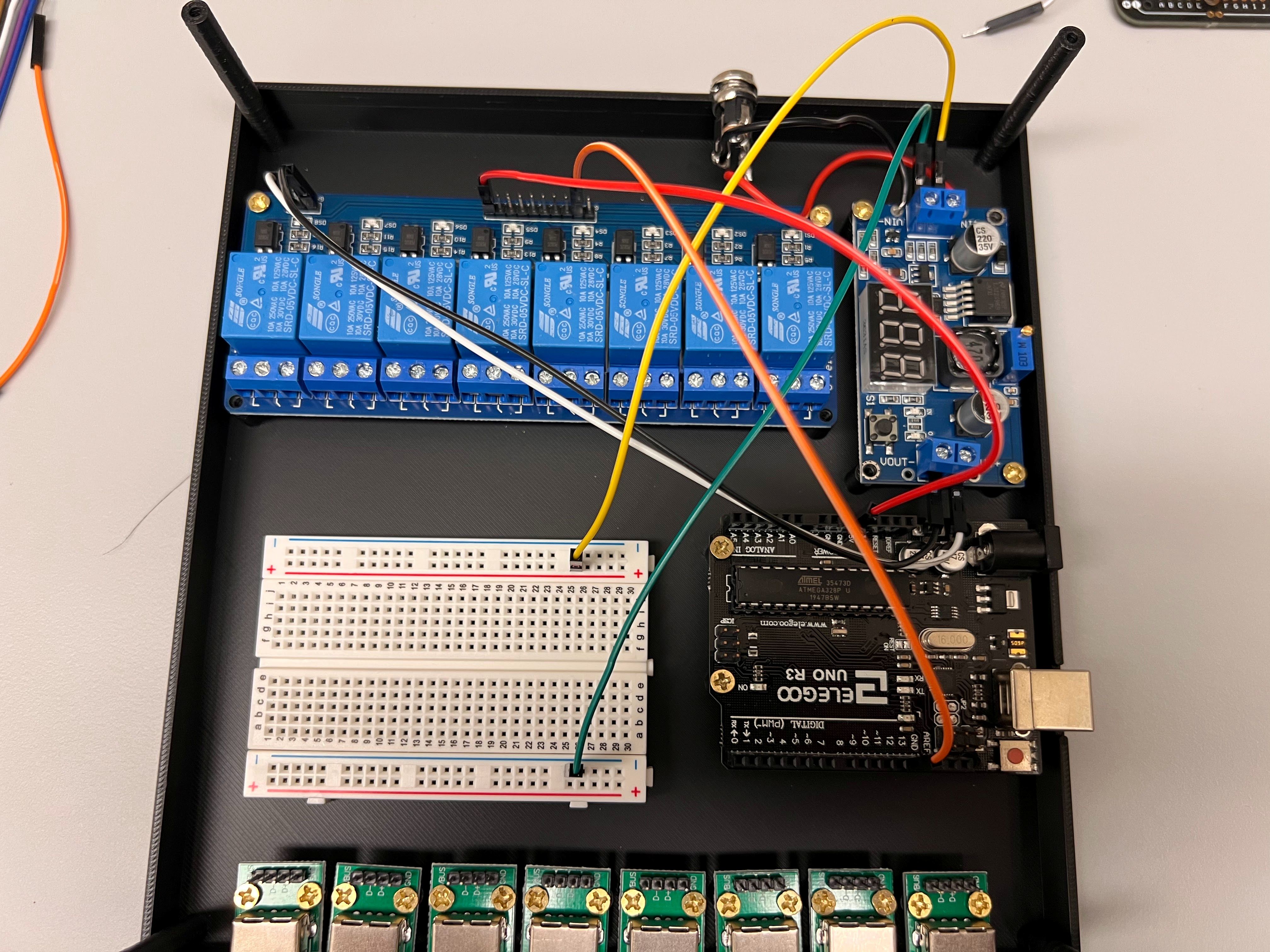

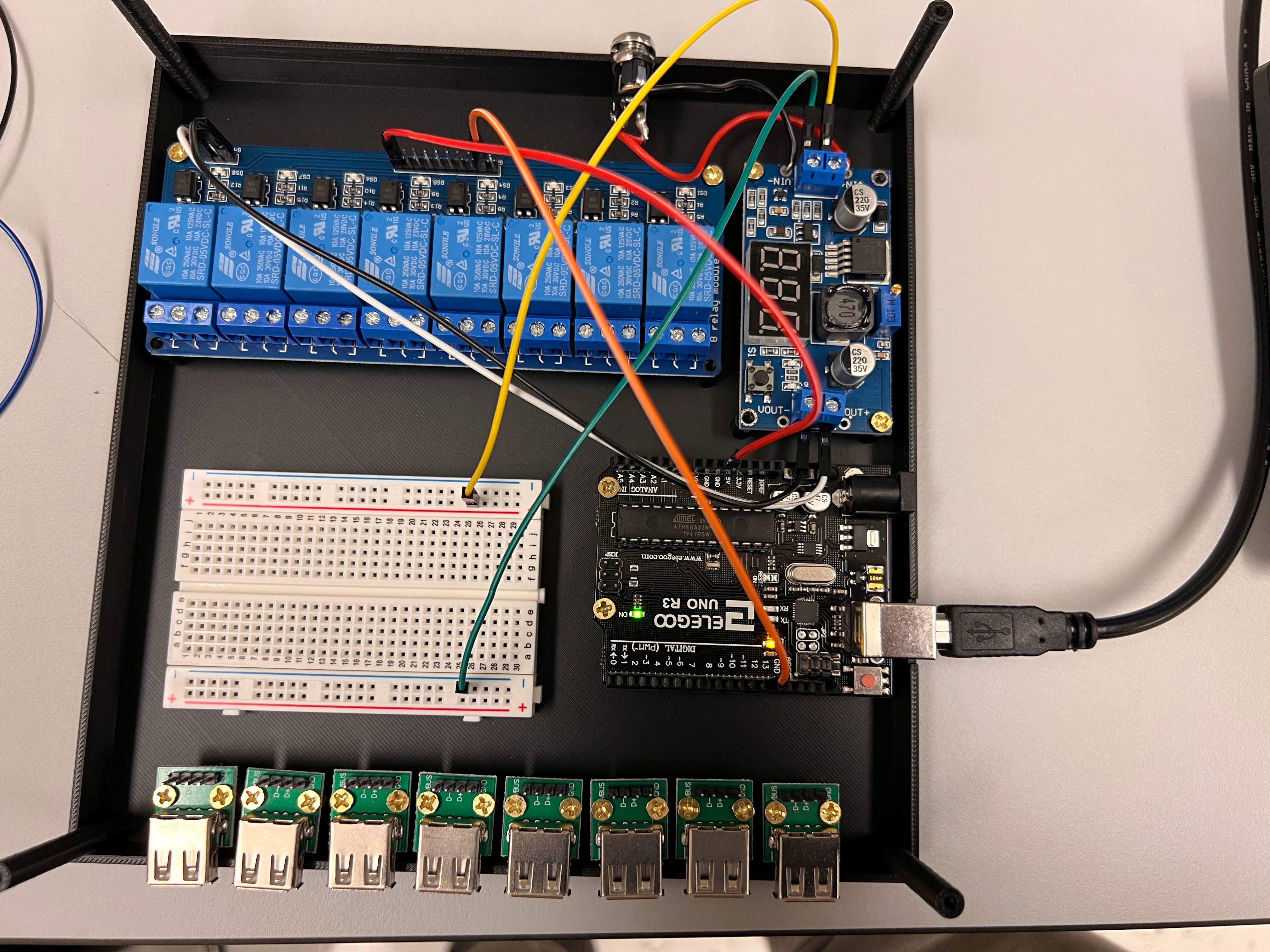

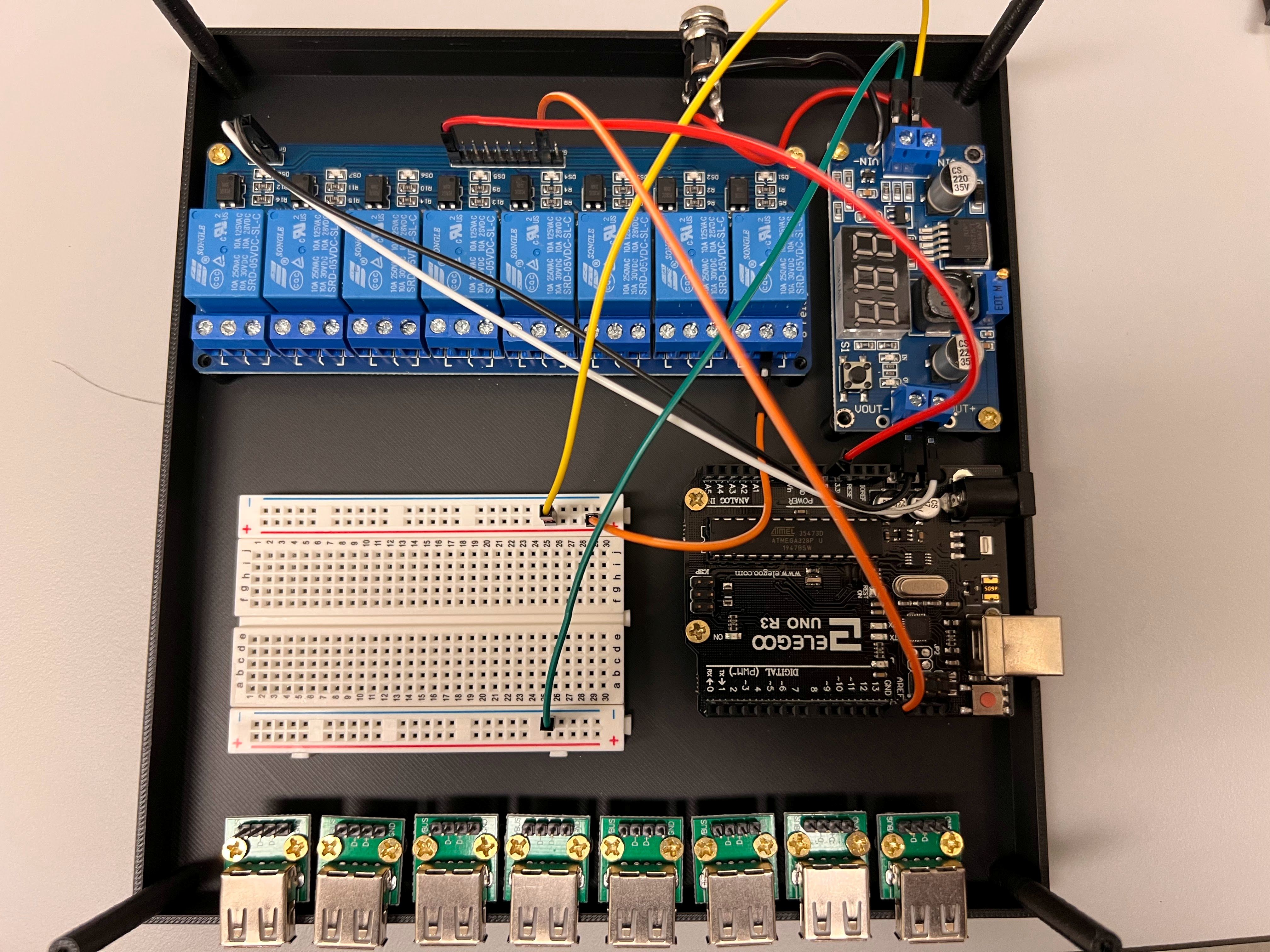

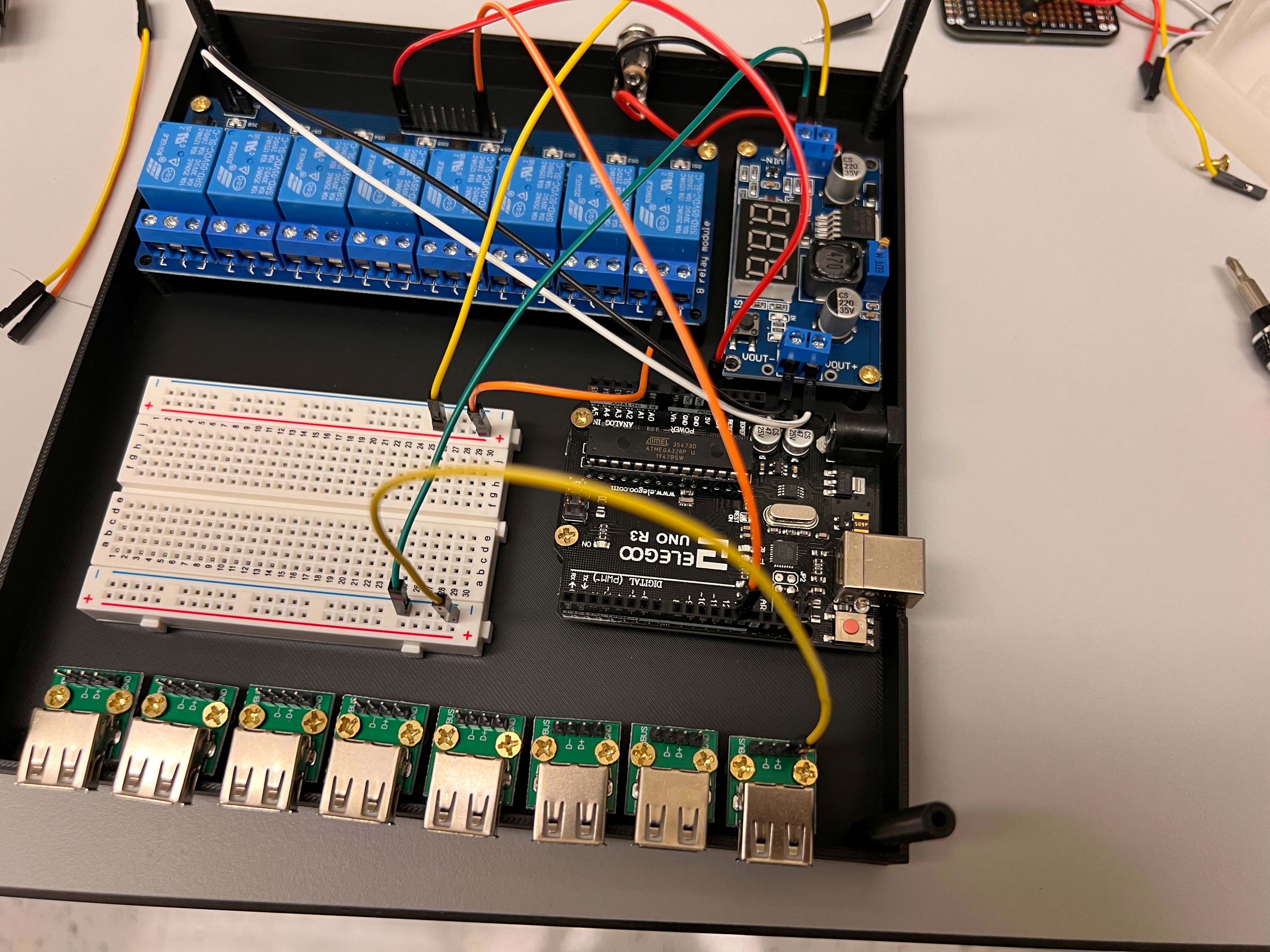

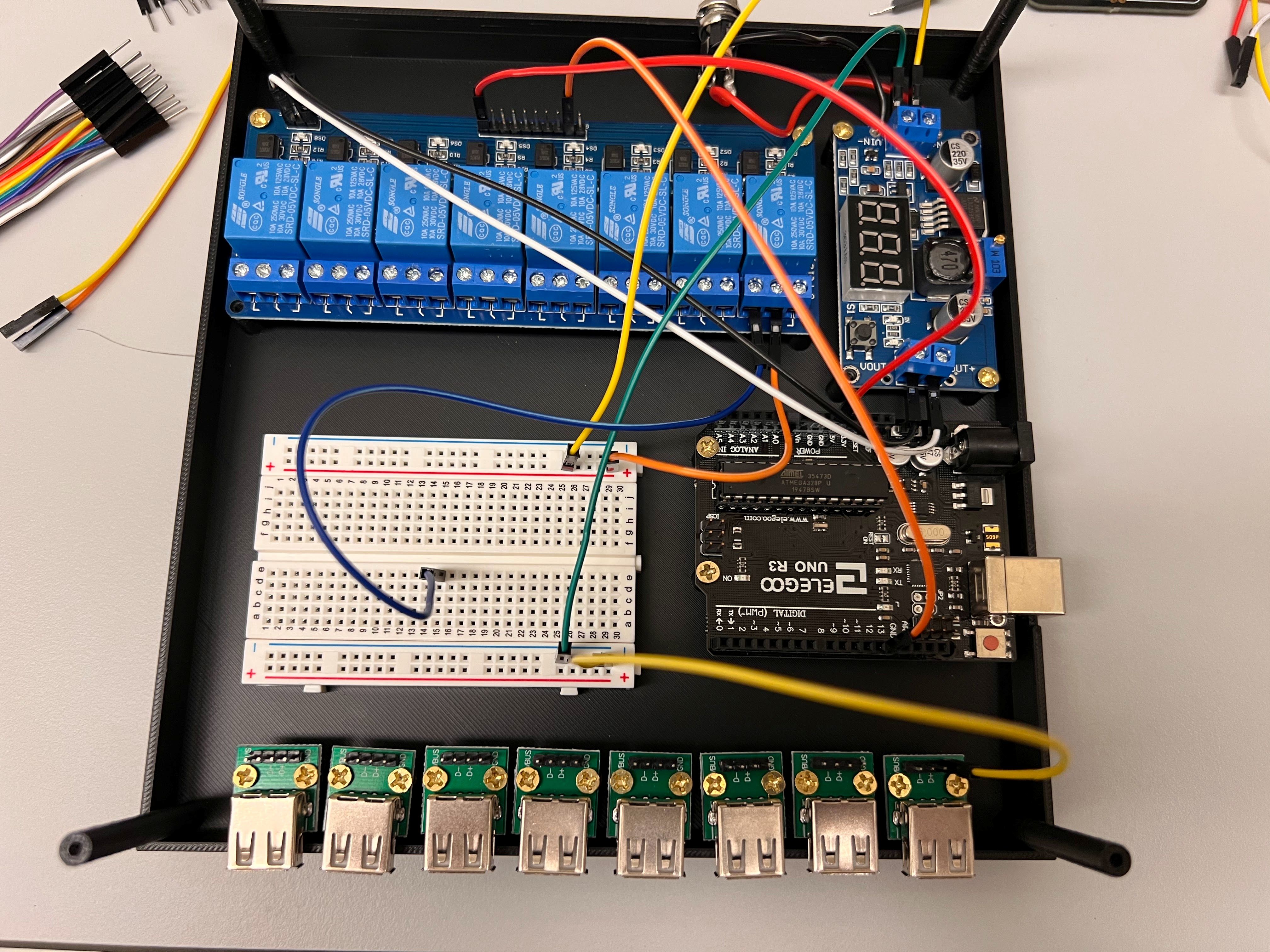

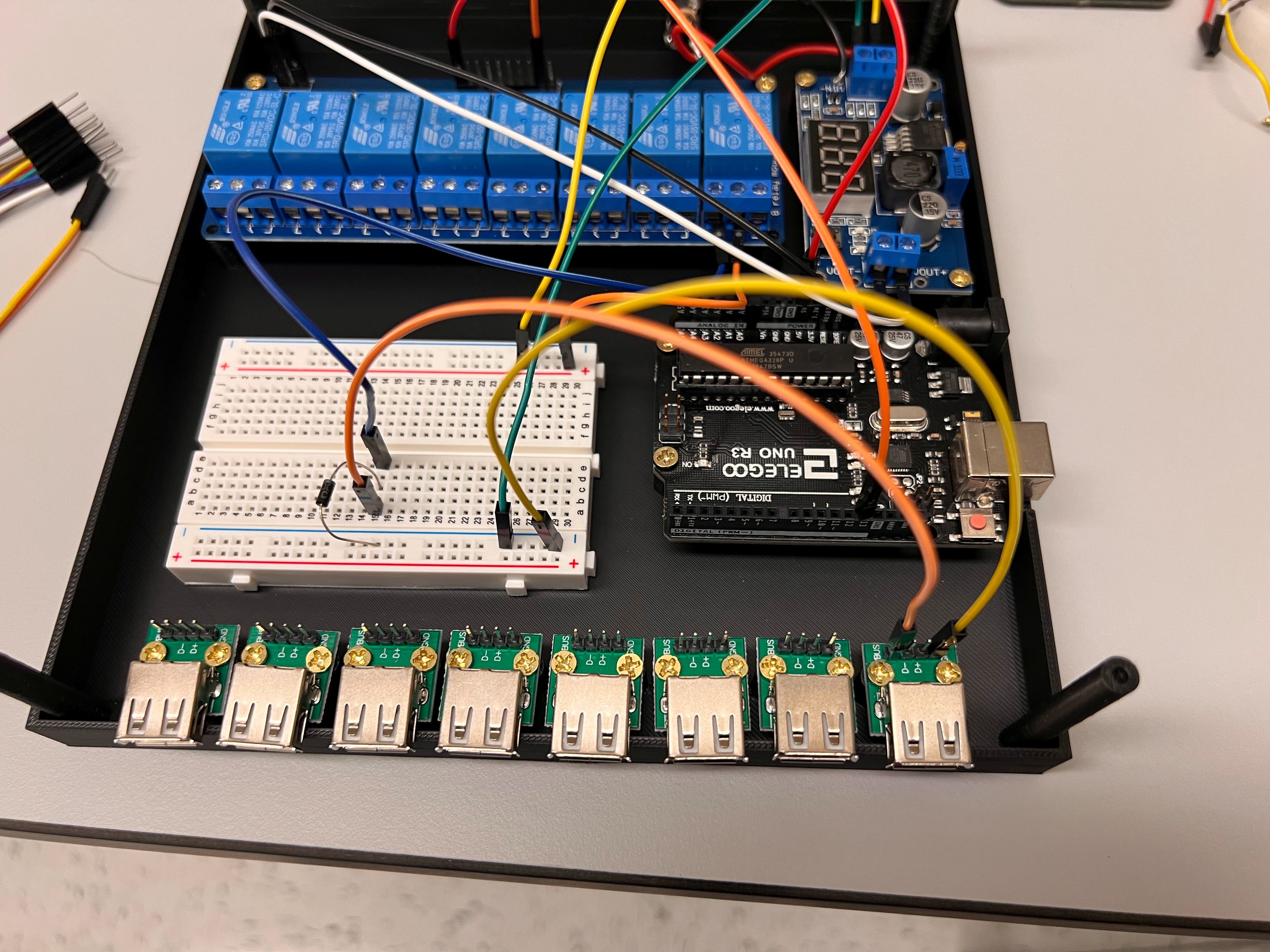

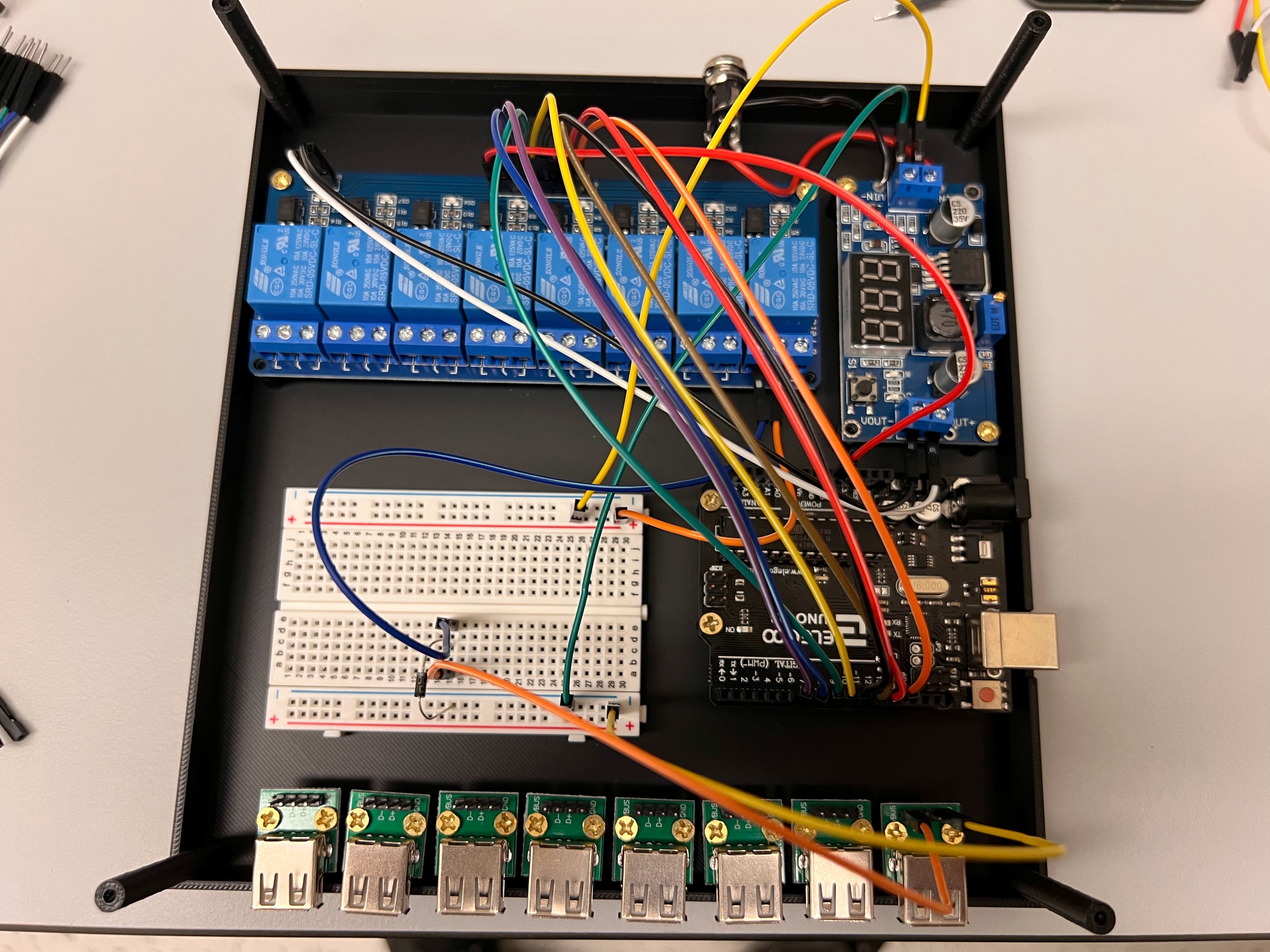

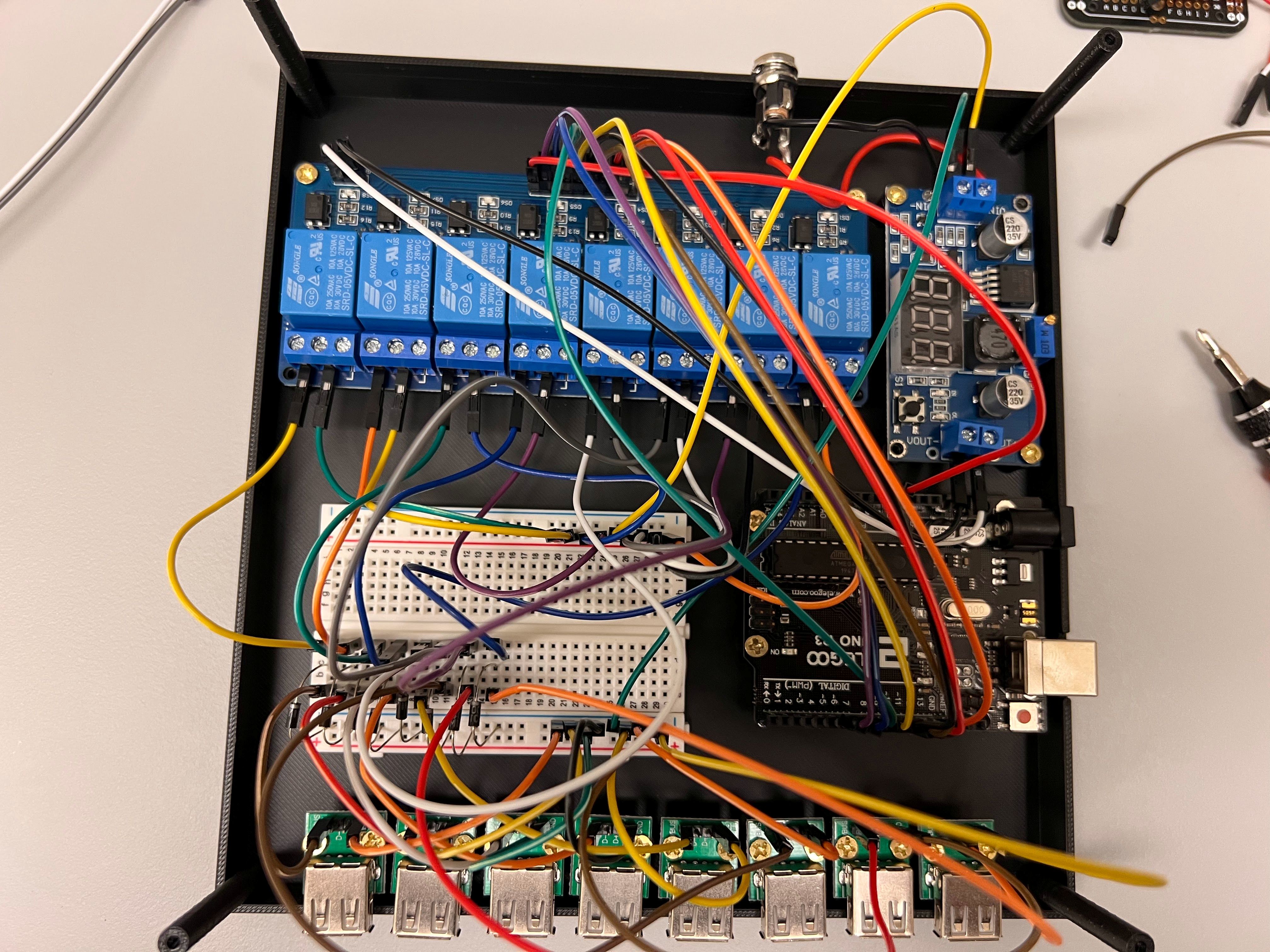

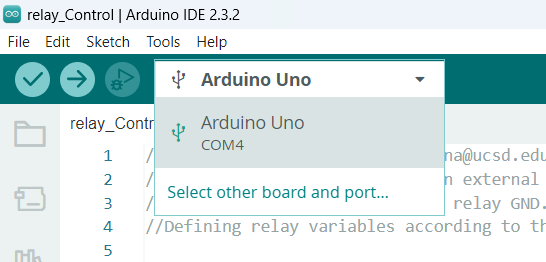

- We will be using a 8-Channel Relay Board Connected to an Arduino UNO R3 Clone to Control the Flow of Current to the Valves.

- Here is a great Youtube video that explains how this works.

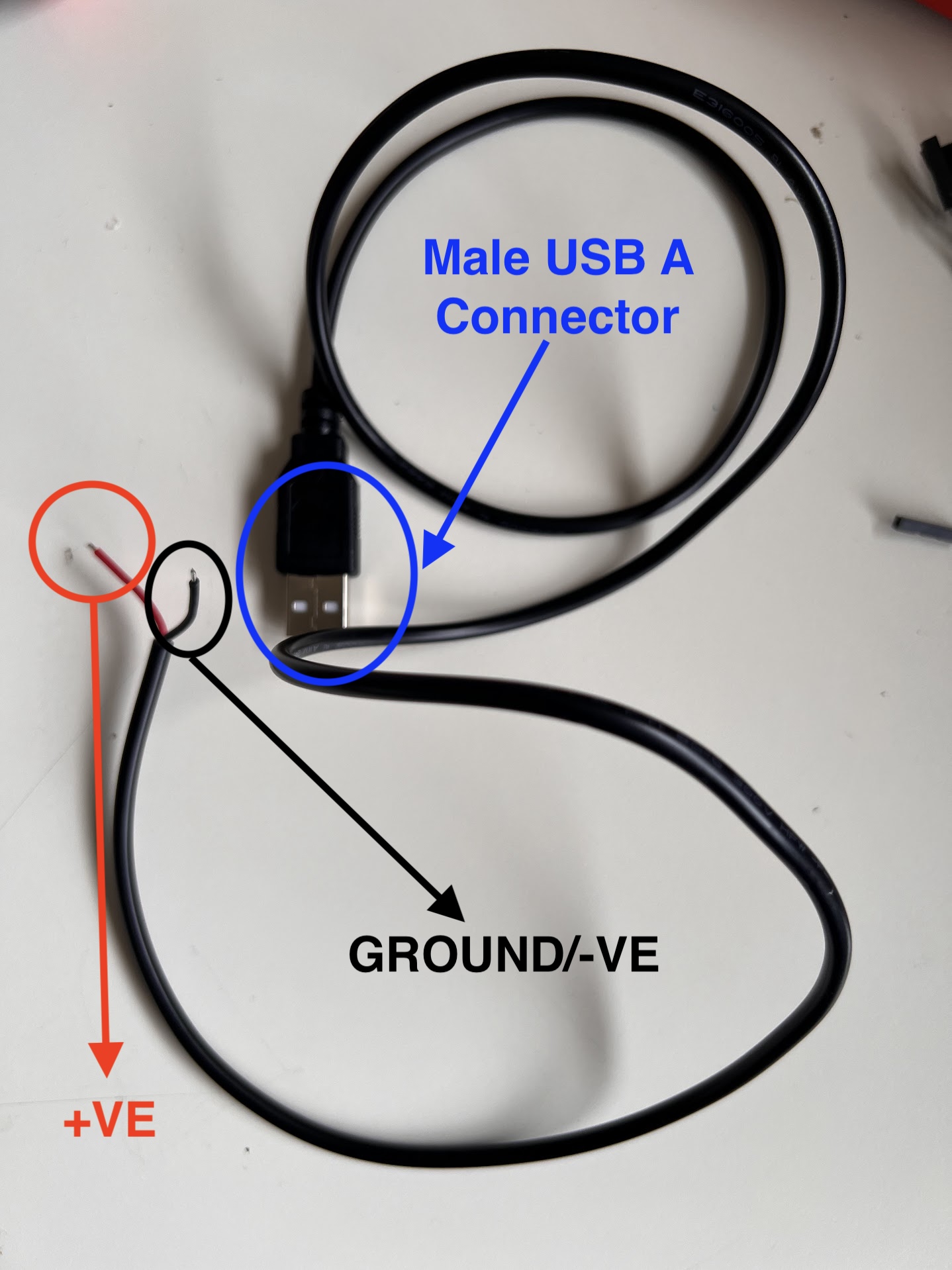

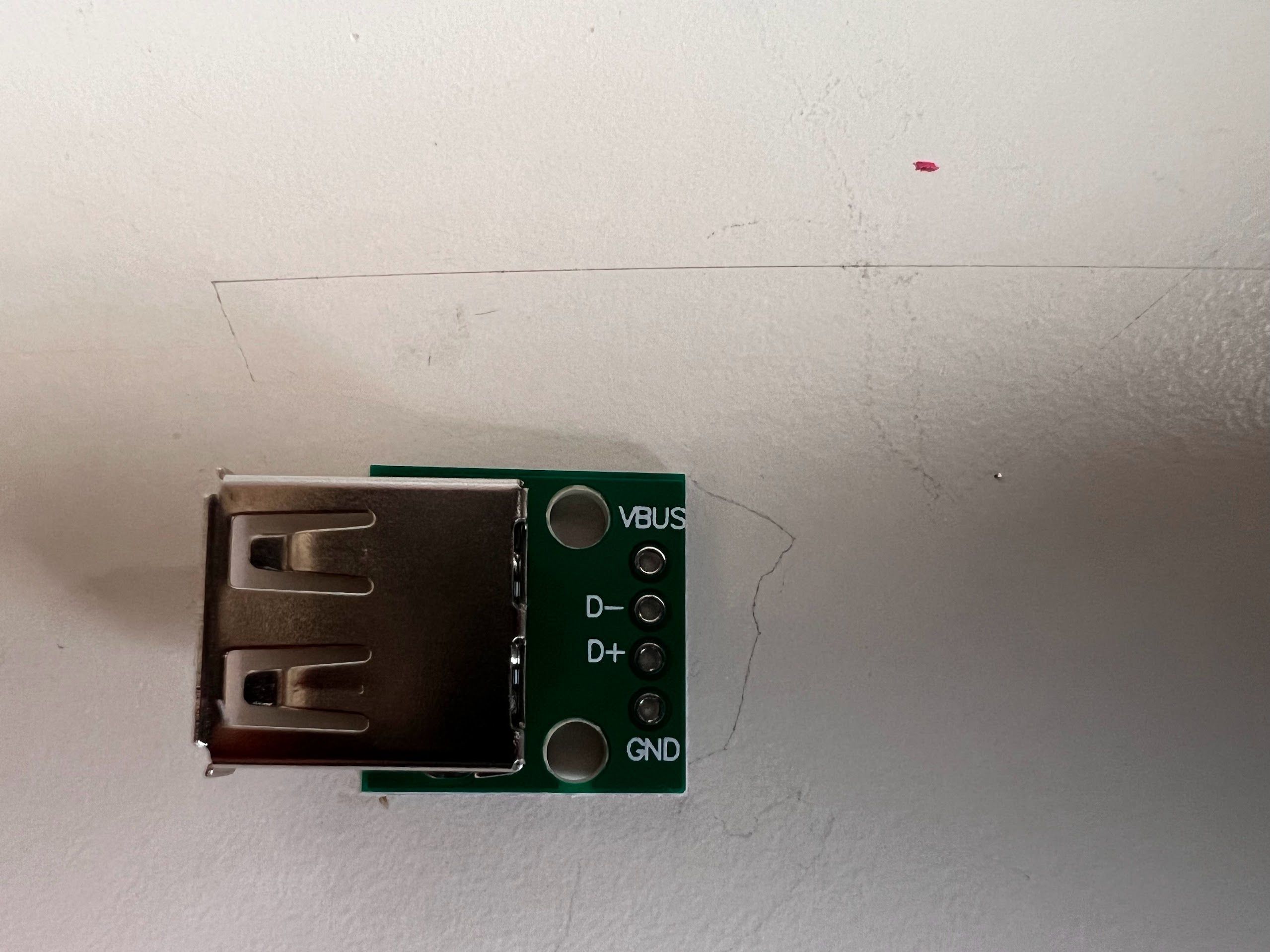

- The 8-Channel Relay requires an Optically Isolated 5V DC Power Supply.

- The Arduino UNO R3 Clone can be operated using the Power from the USB Port Alone.

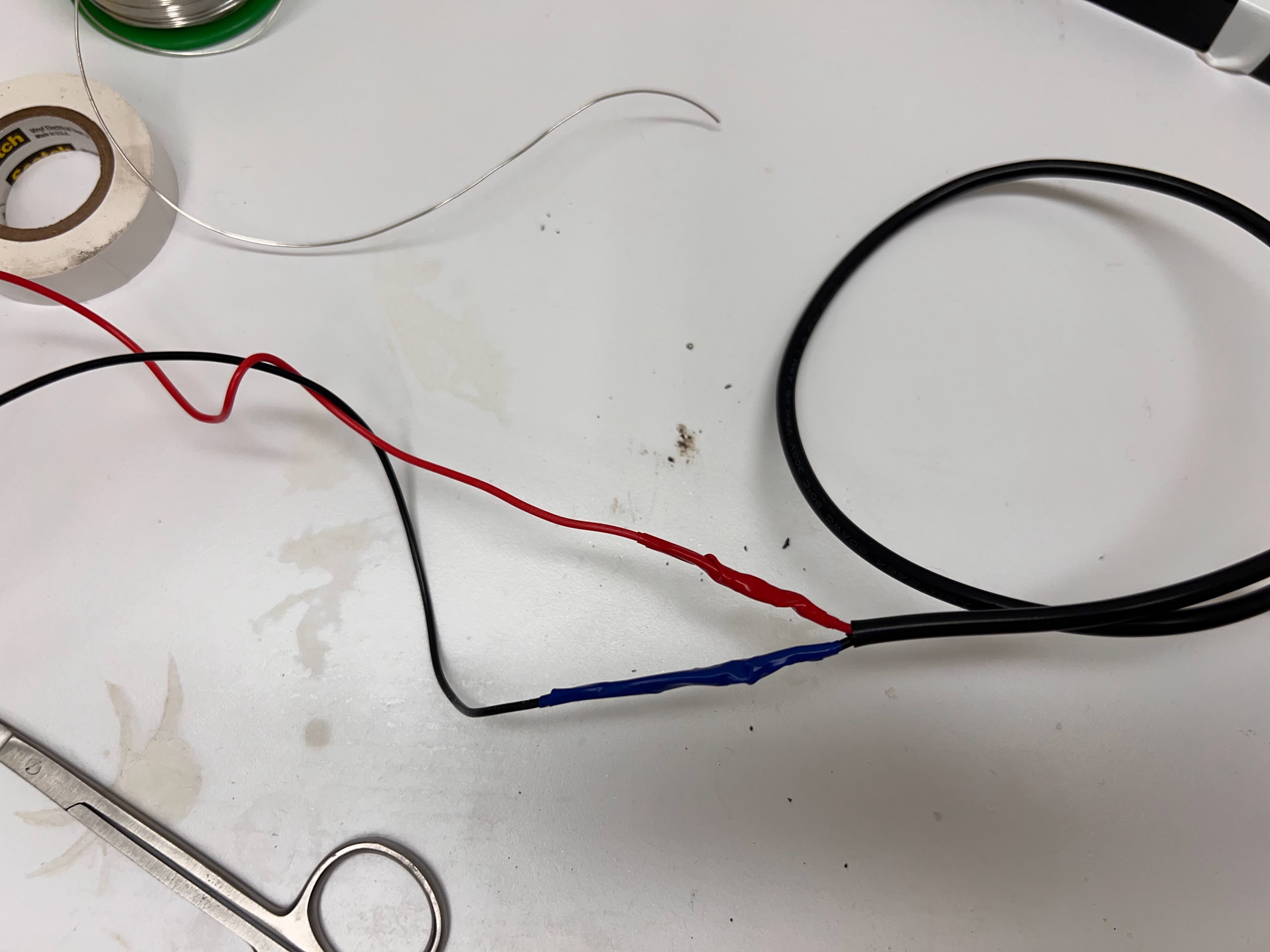

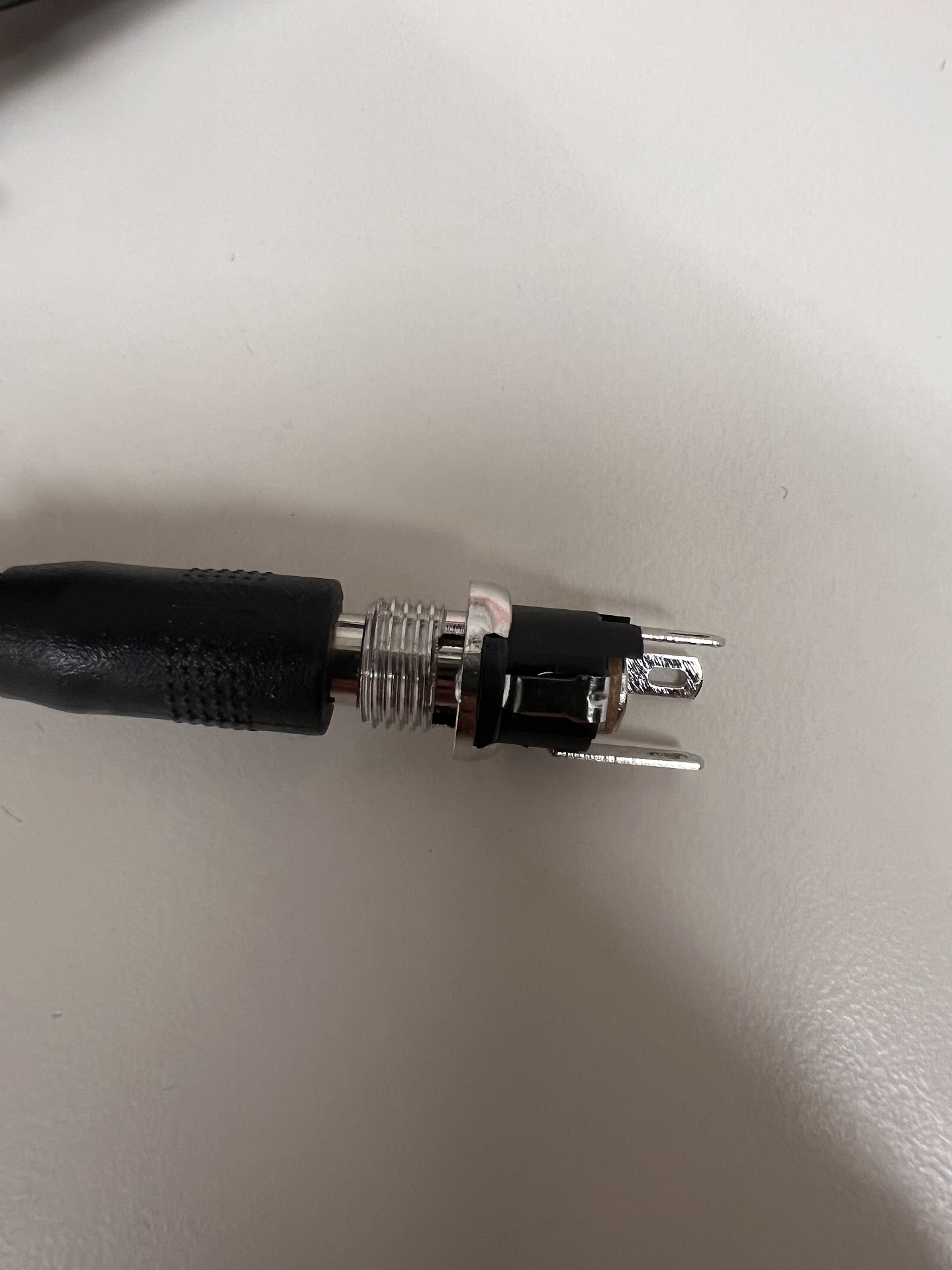

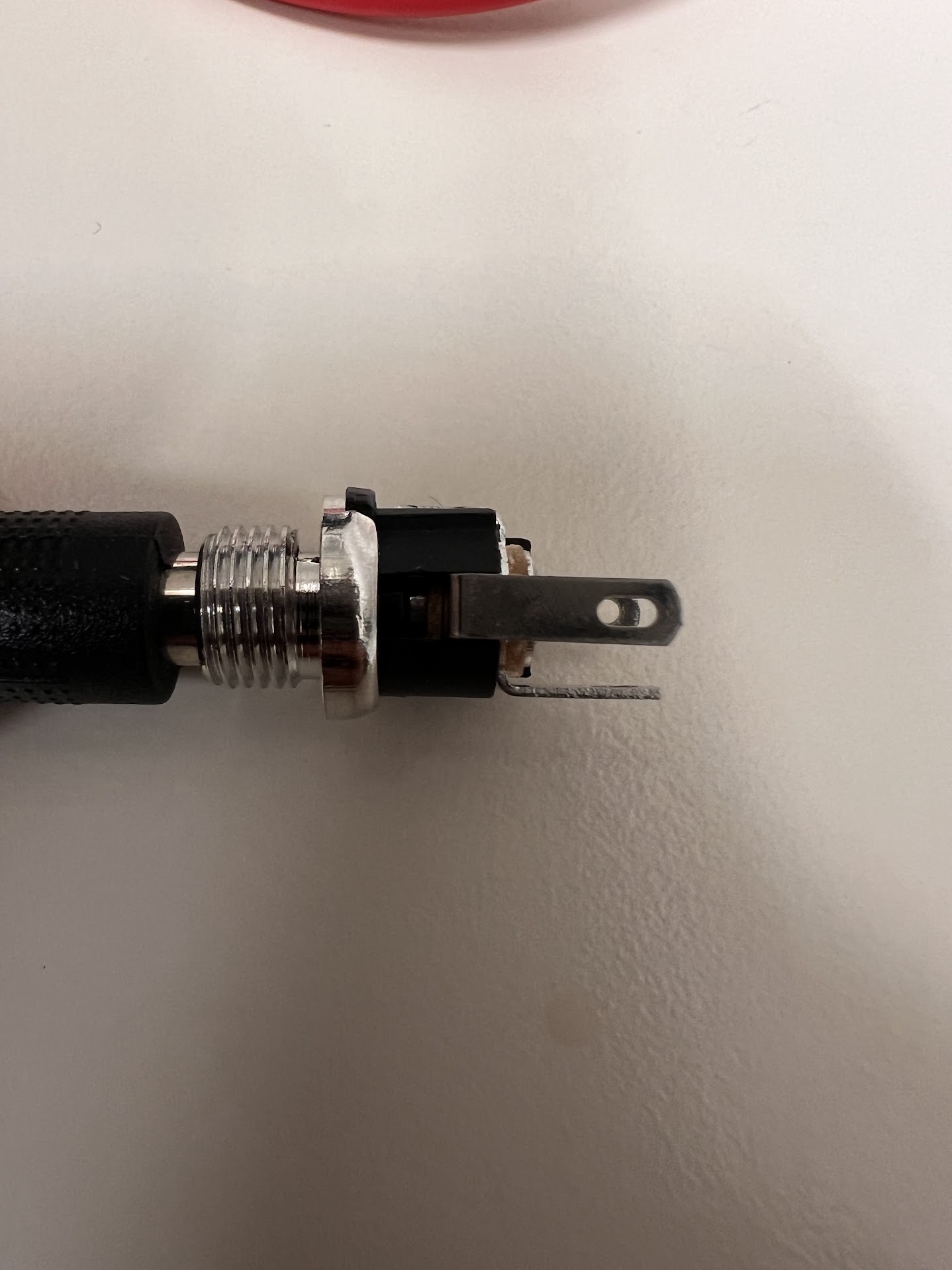

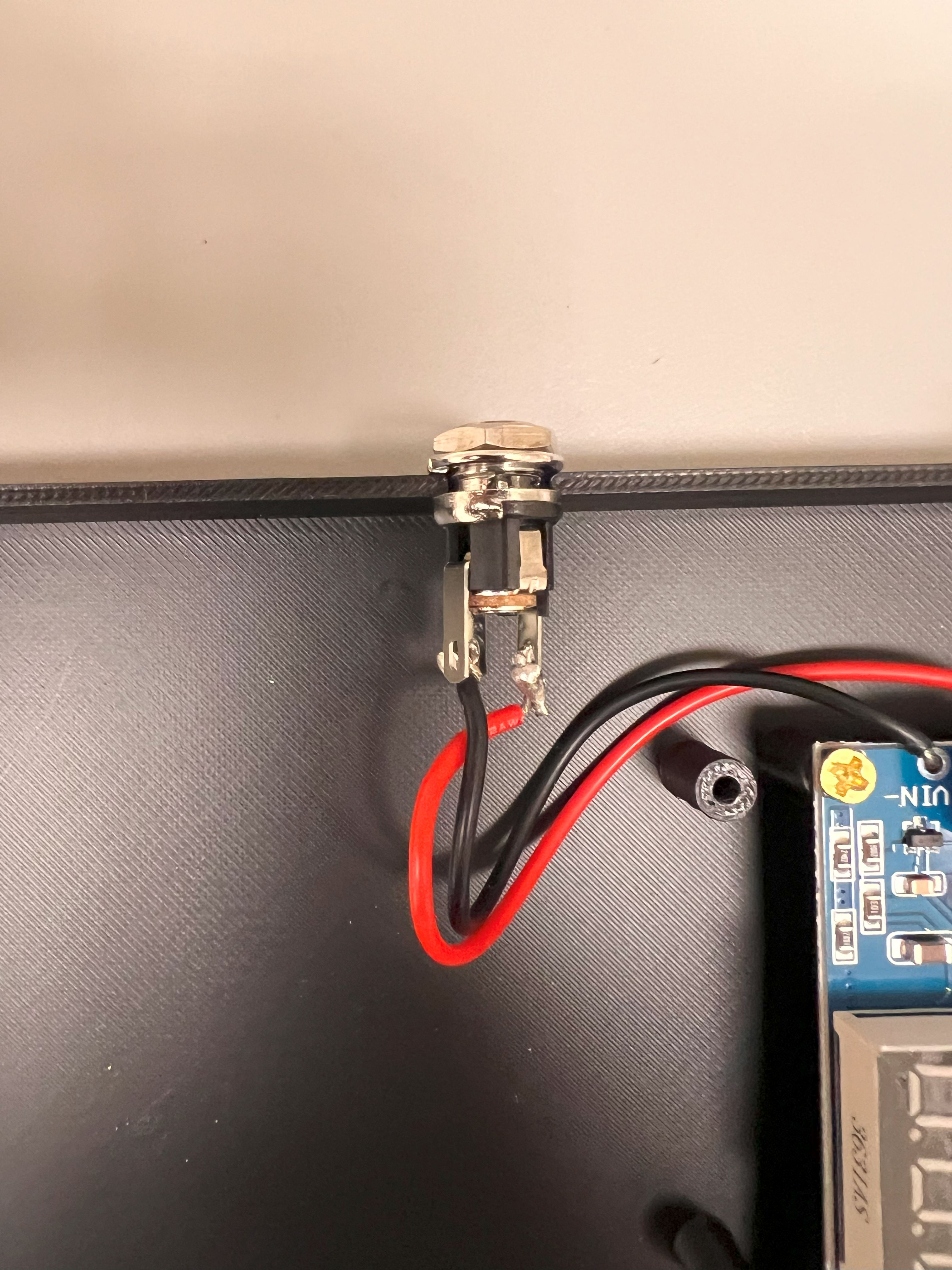

- We could have used a separate 5V Power supply to power the 8-Channel Relay. But we will be using a DC-DC Buck Converter to Step Down the 24V DC to 5V DC for the 8-Channel Relay instead. This way we can use a Single Power Source for all the Components.

- You can watch this Youtube Video to learn how it works.

3D Printing Valve Controller Housing¶

- We used a Bambu Lab X1 Carbon to print the Housing.

- 0.4mm Nozzle

- Textured PEI Plate

- We generated a 3MF File with all the Settings we used for the Print. You can open this file on the Orca Slicer.

- The Original STEP Files and F3D Files can be found in this directory.

- We recommend getting a 3D Printing Accessories Kit if you haven't purchased one already.

- Its extremely helpful in removing supports and cleaning up the print.