Purpose of Protocol¶

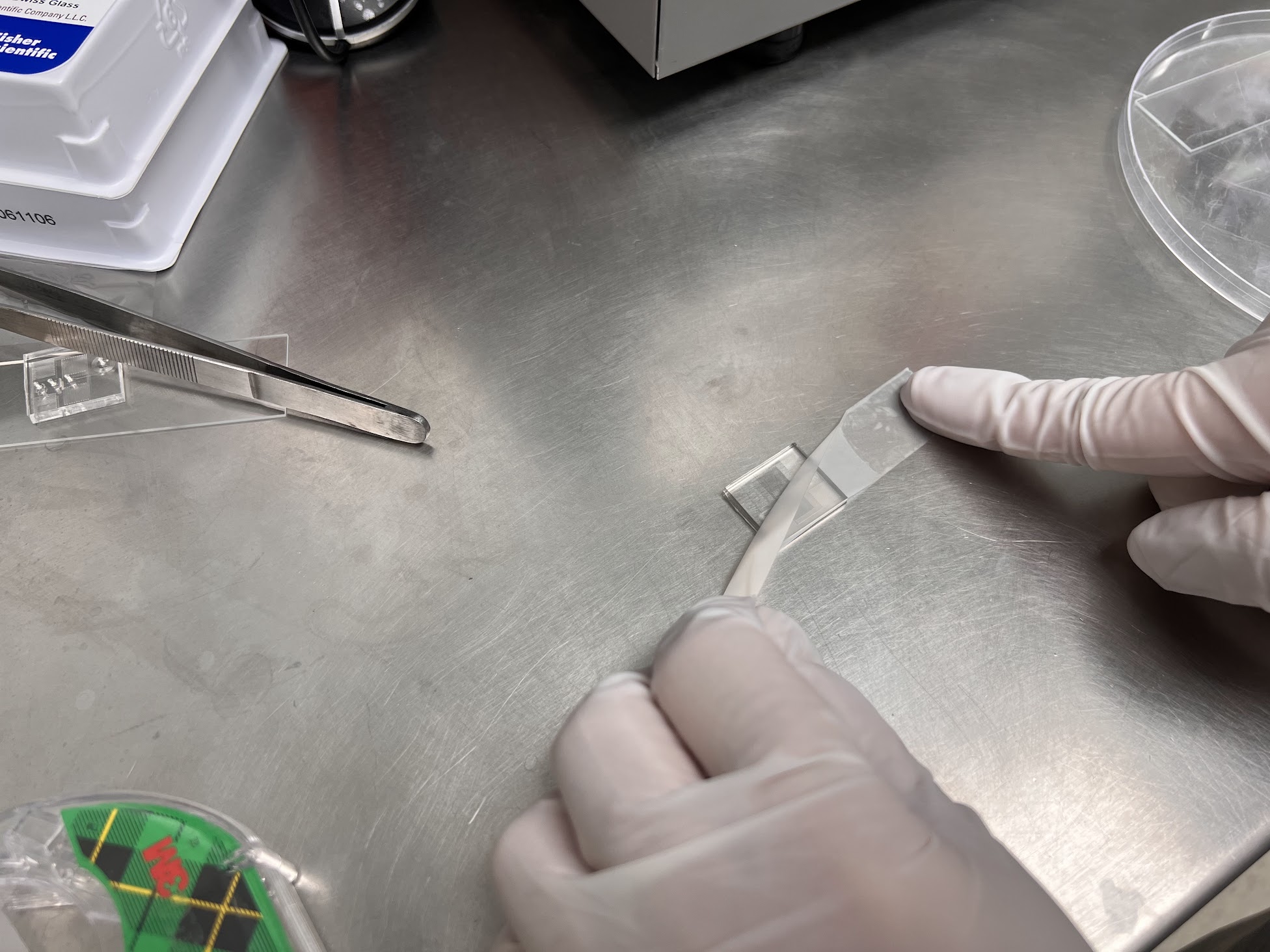

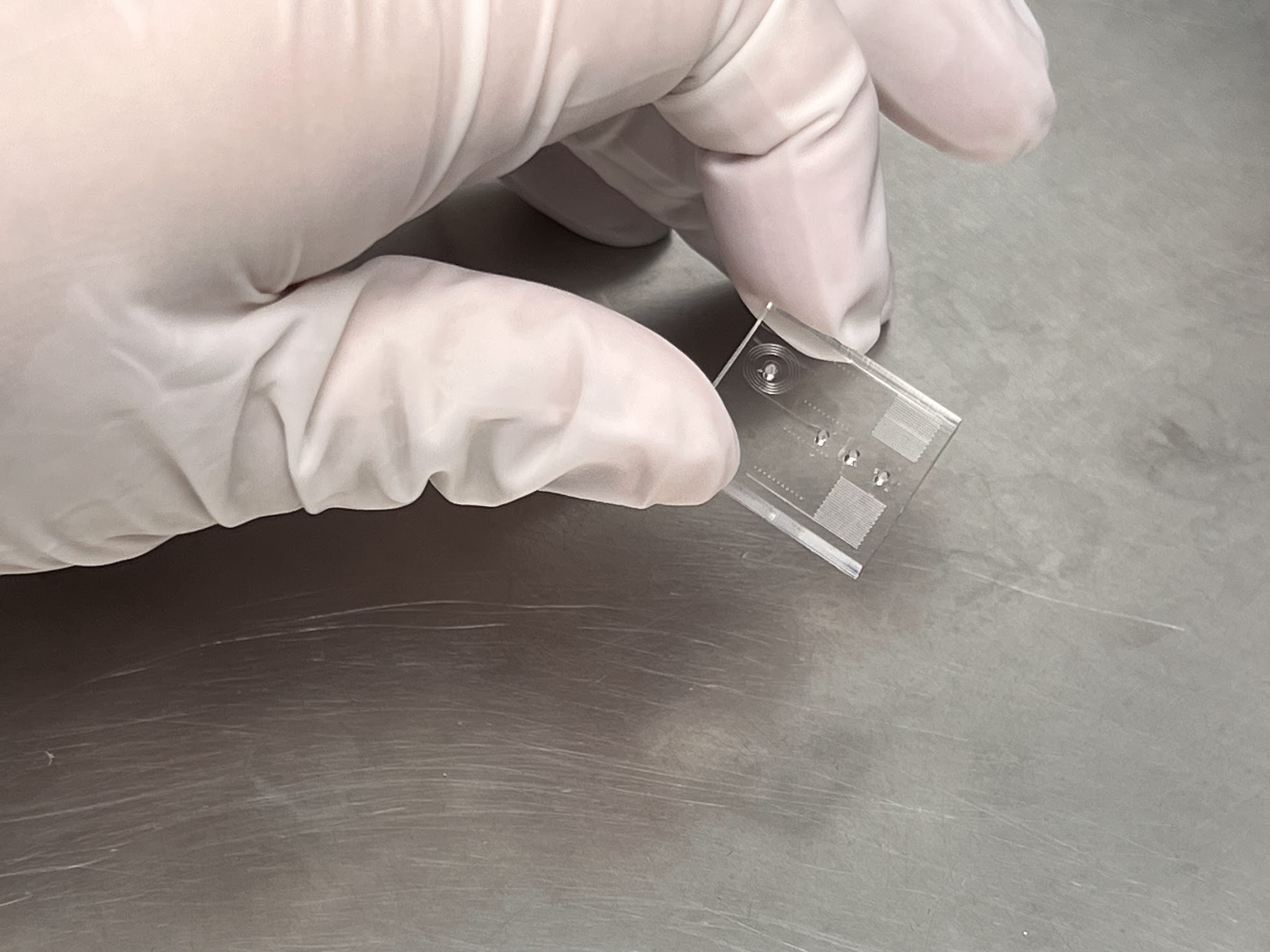

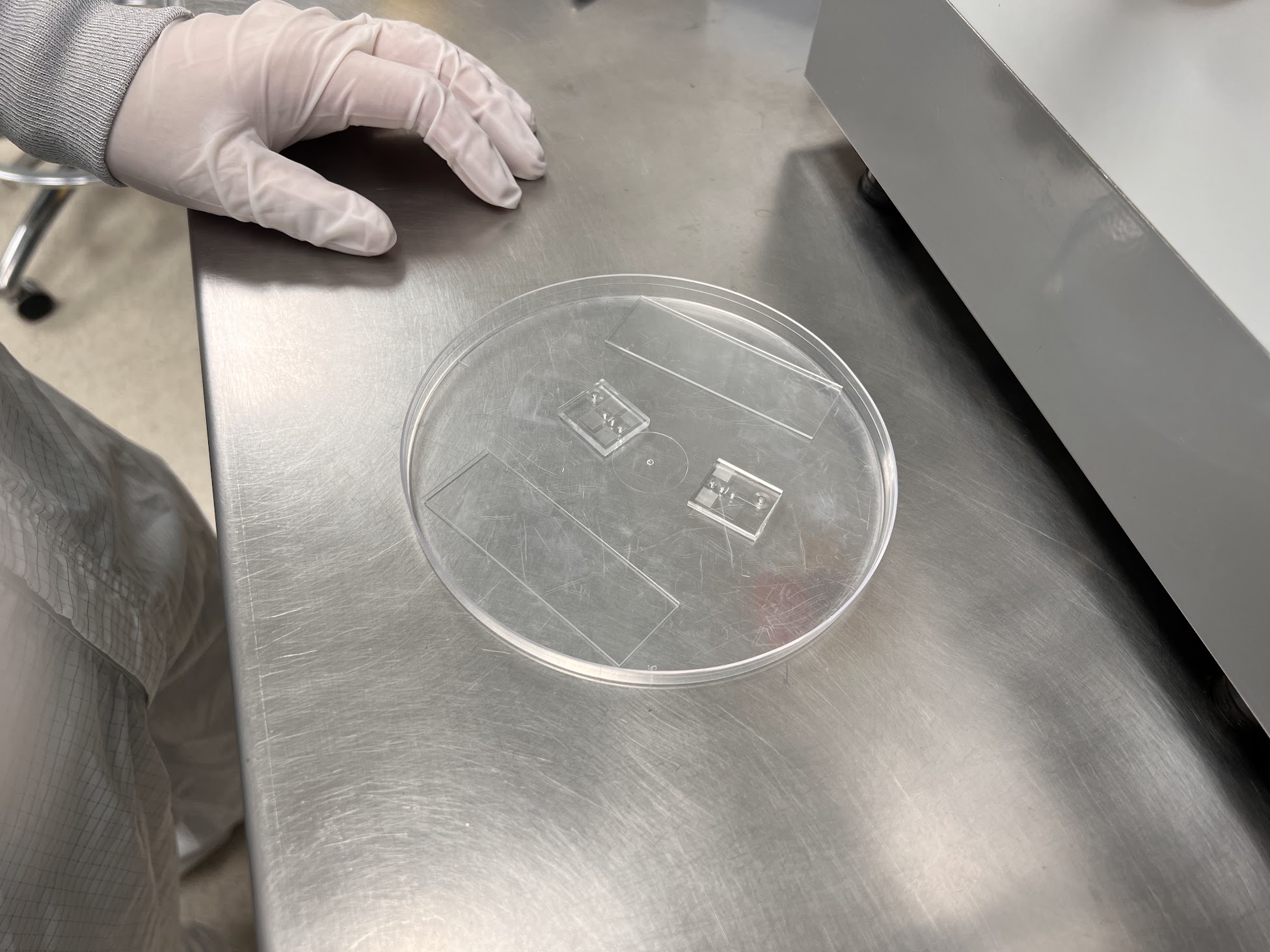

- We need to seal the PDMS on the side of the Microfluidic pattern so we can run liquids through the Chip.

Preheat the Tepla Asher in Prepration for Bonding¶

Make a reservation of the Tepla Asher for 3 hours using the FOM Reservation System.

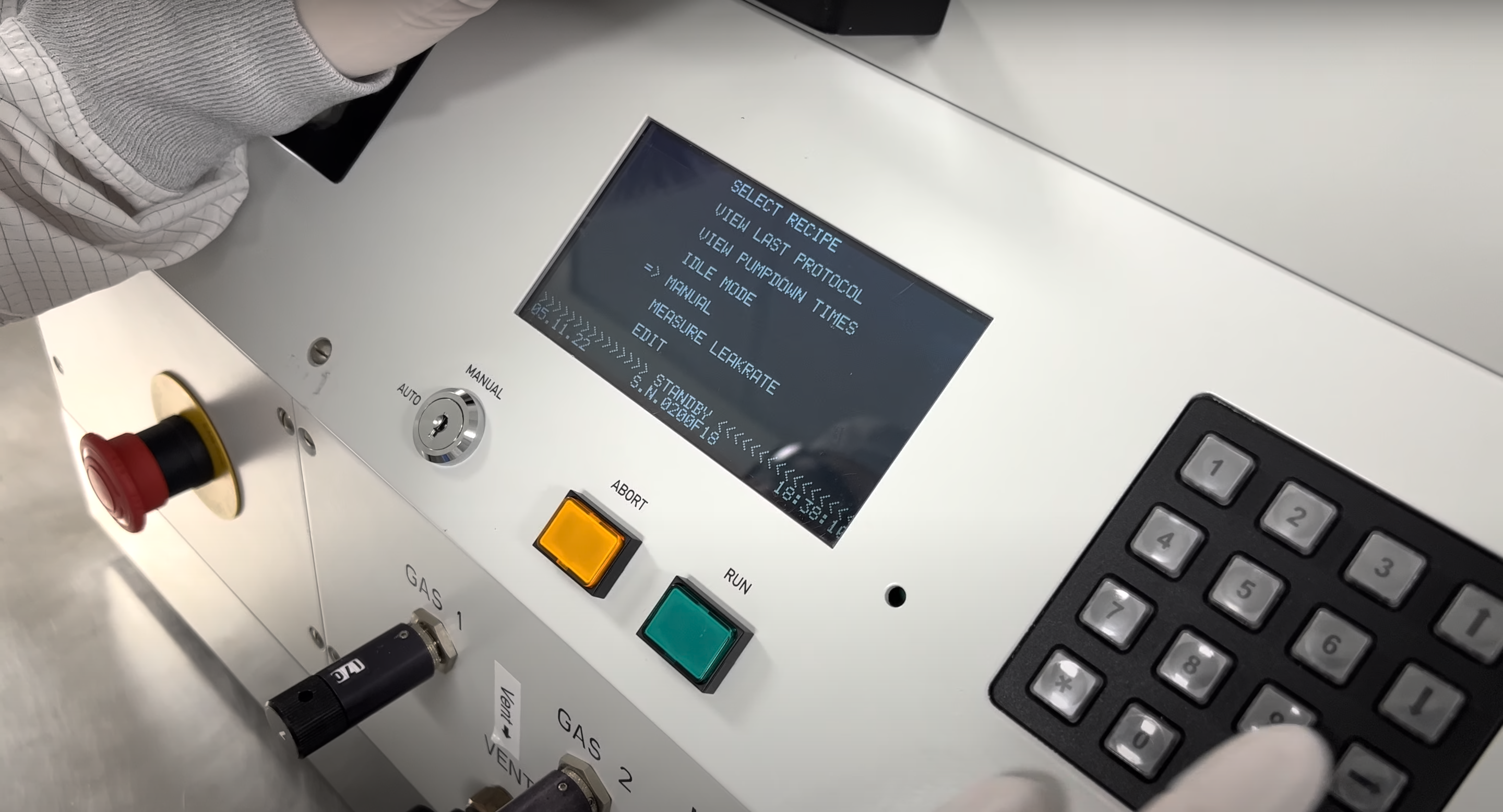

Log on to the Tepla Asher. You should find the machine in Idle. Press Abort to Exit

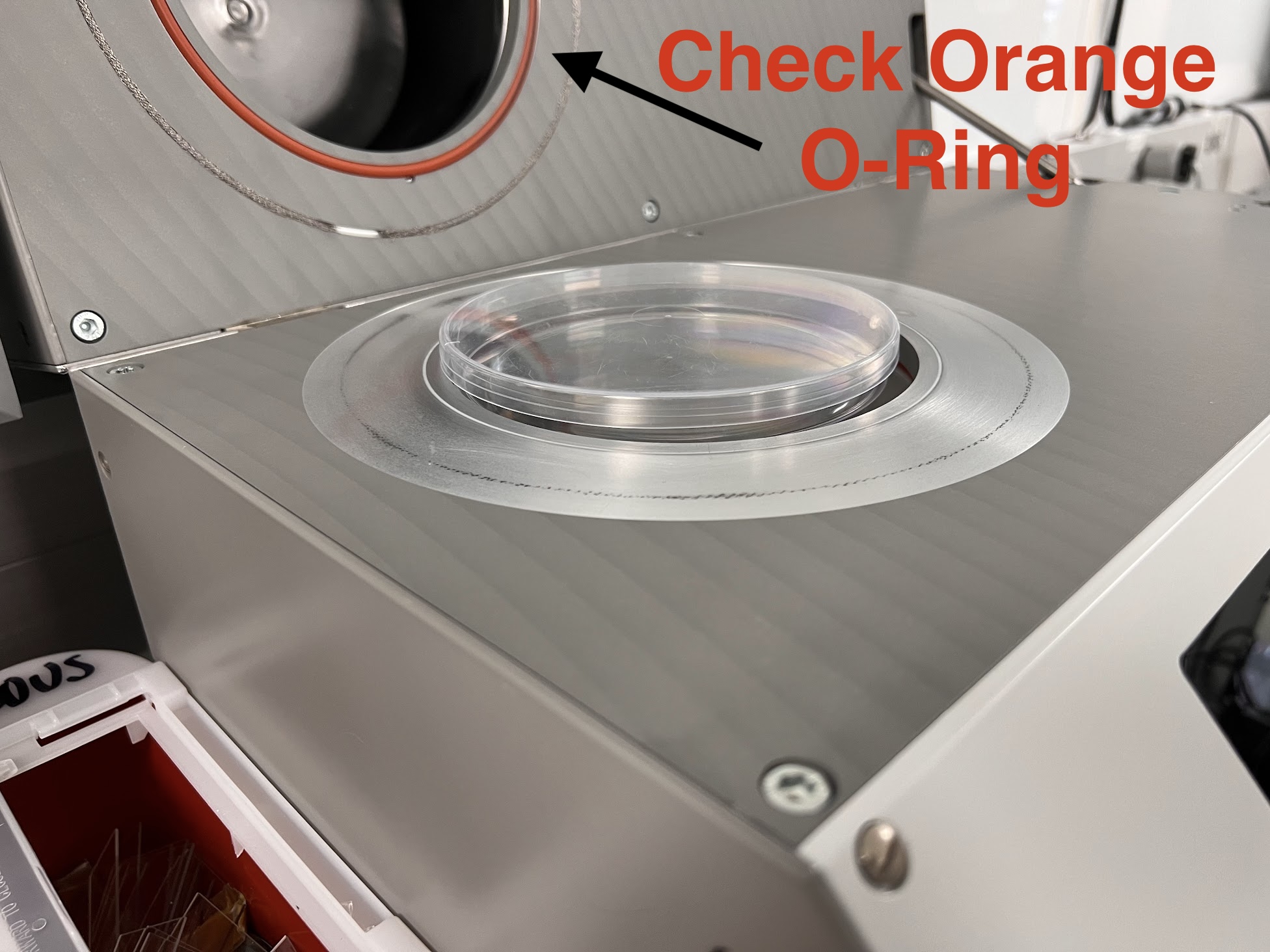

Slowly Rotate the Vent Knob 90 Degrees counter-clockwise to the Open Position Labelled on the Machine with the Arrow.

Final Position:

Open the Top Portion to reset the device. Then close the Vent valve by Rotating Clockwise.

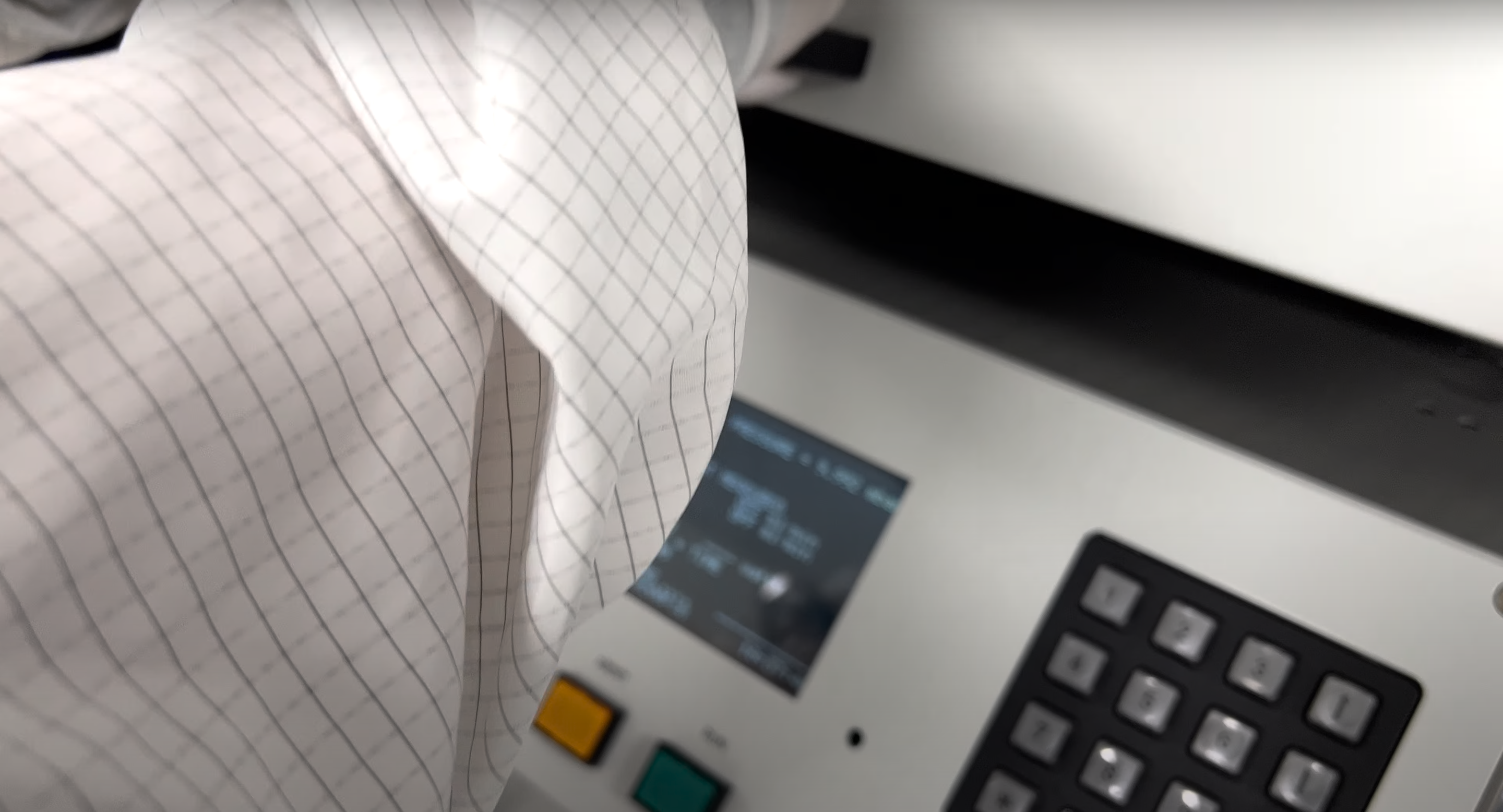

Press ENT on the Keypad to reach the Menu.

Select the MANUAL Mode using the Keypad and Press ENT.

Set GAS 1 Flow Rate to the maximum flow rate of 110.

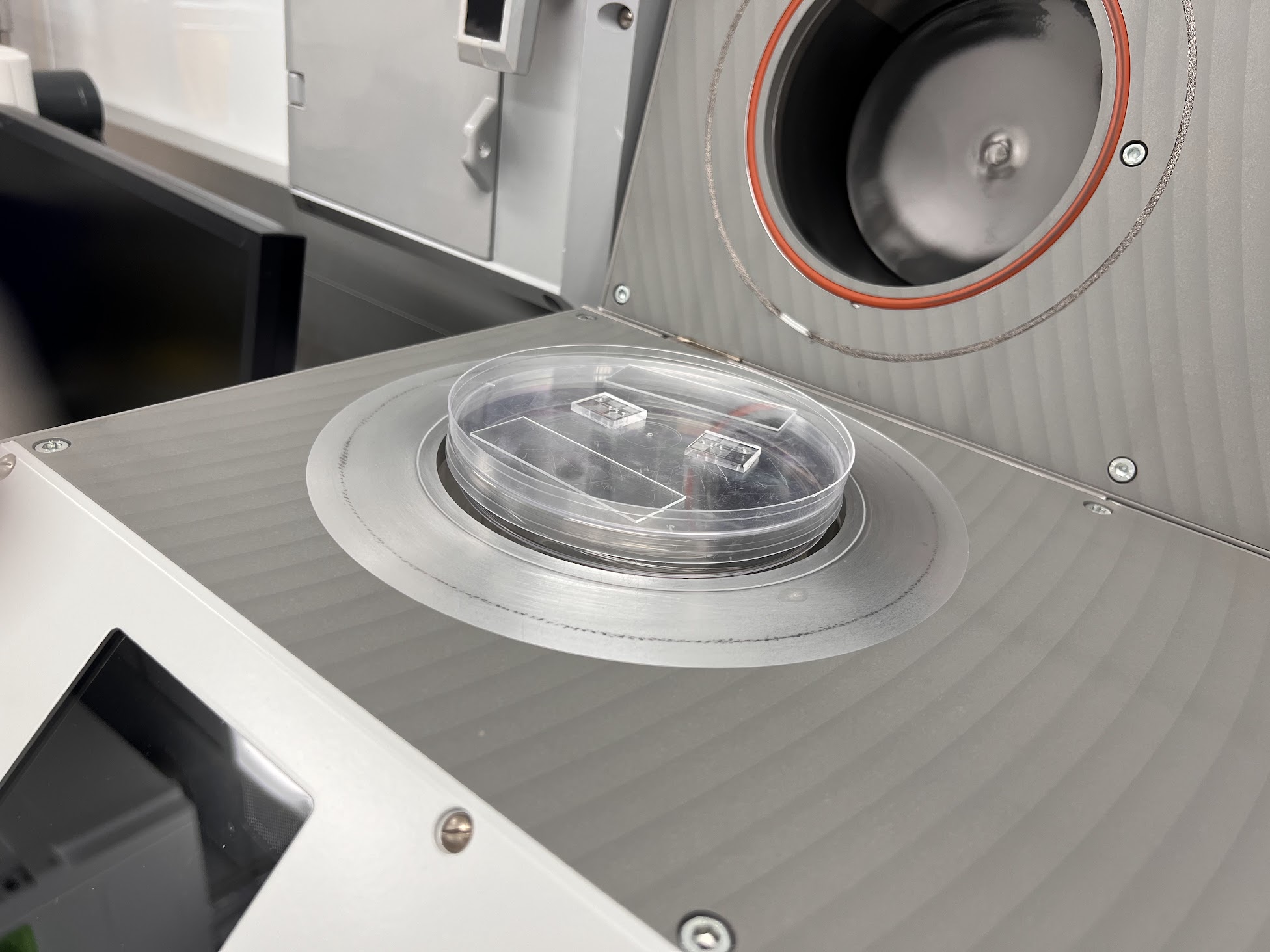

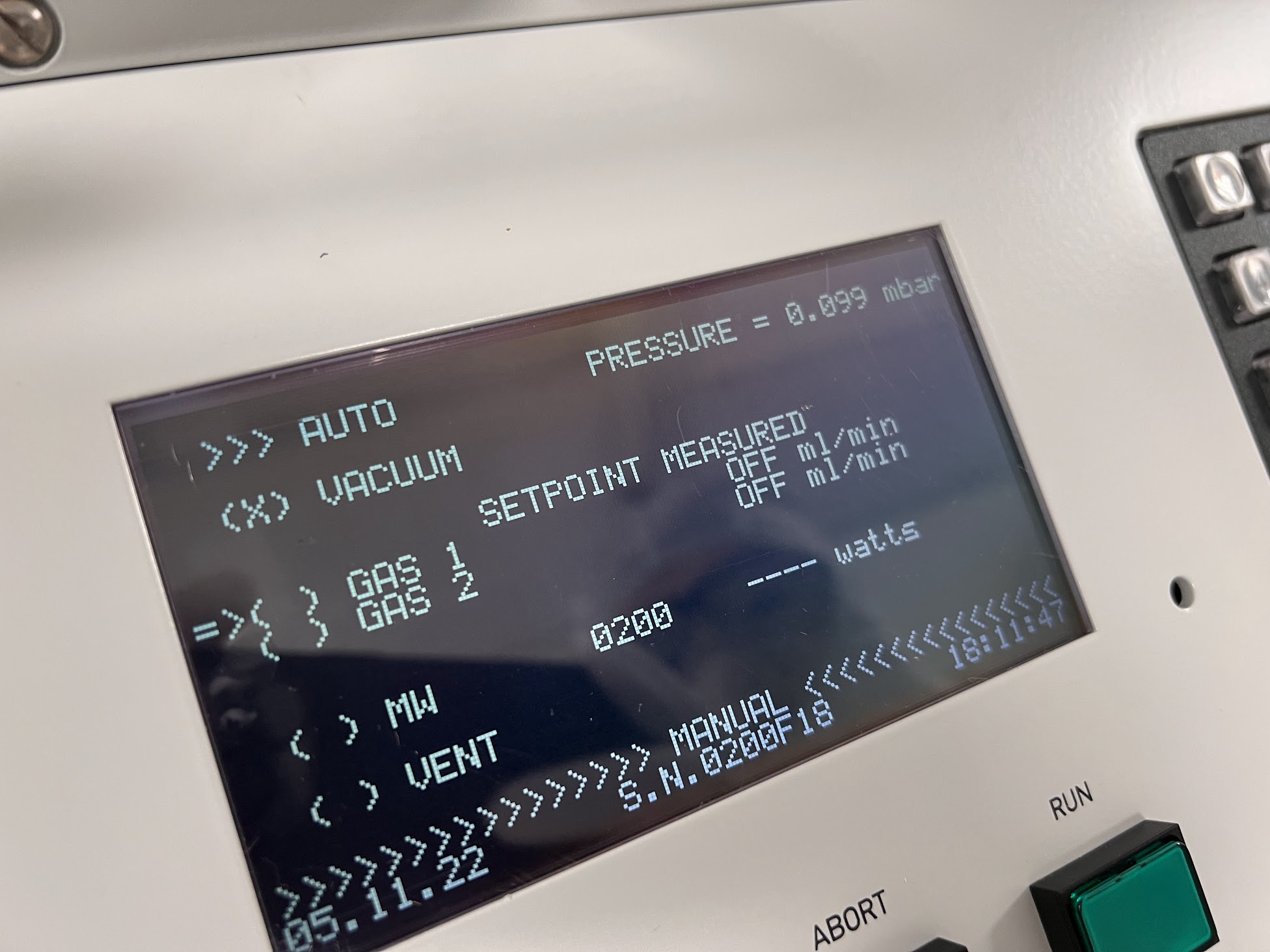

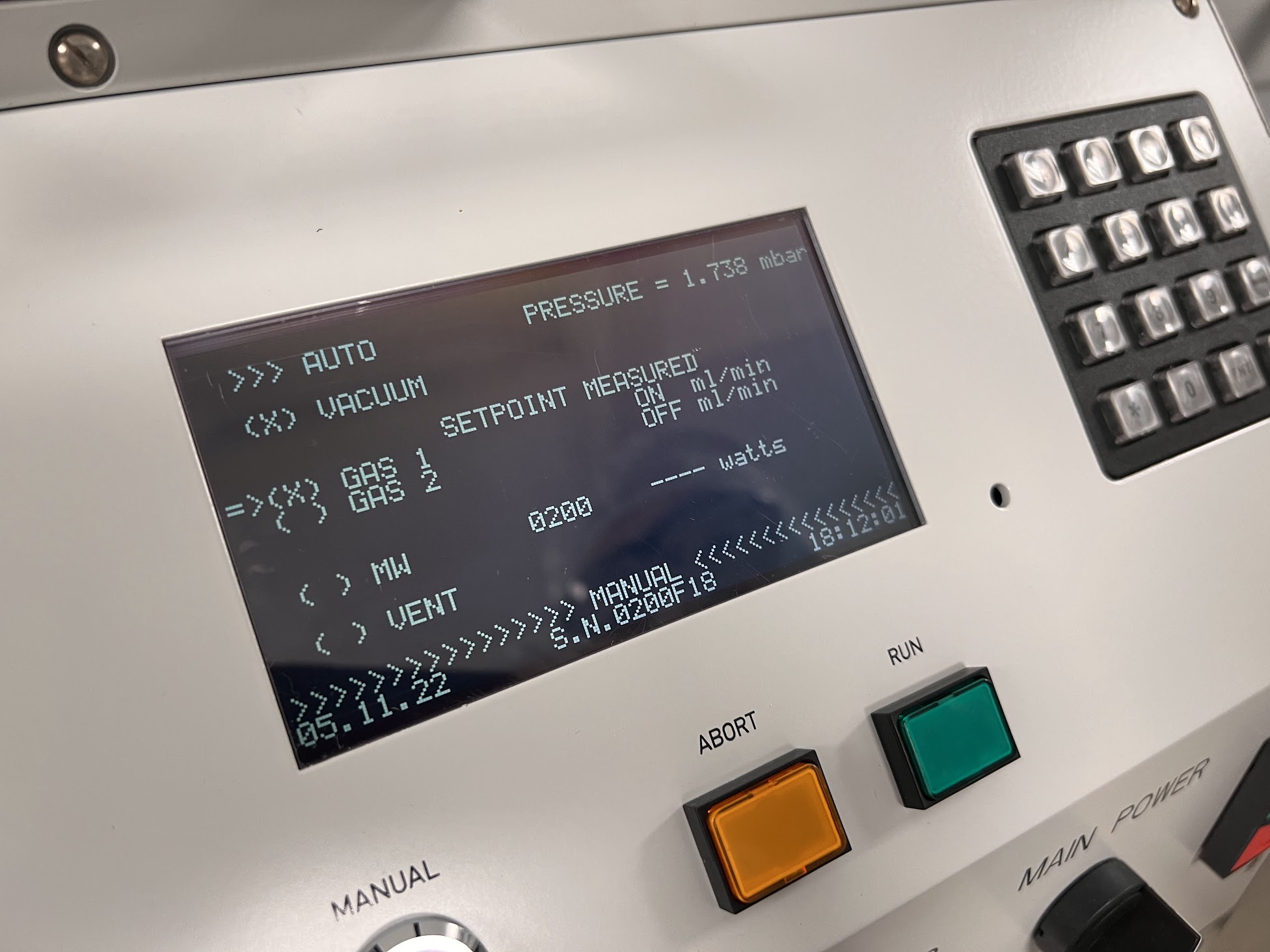

Pump Down the System by Selecting VACUUM and then press ENT.

Wait till the PRESSURE reaches less than 0.100 mbar.

Select GAS 1 and press ENT.

Wait for the PRESSURE to stabilize

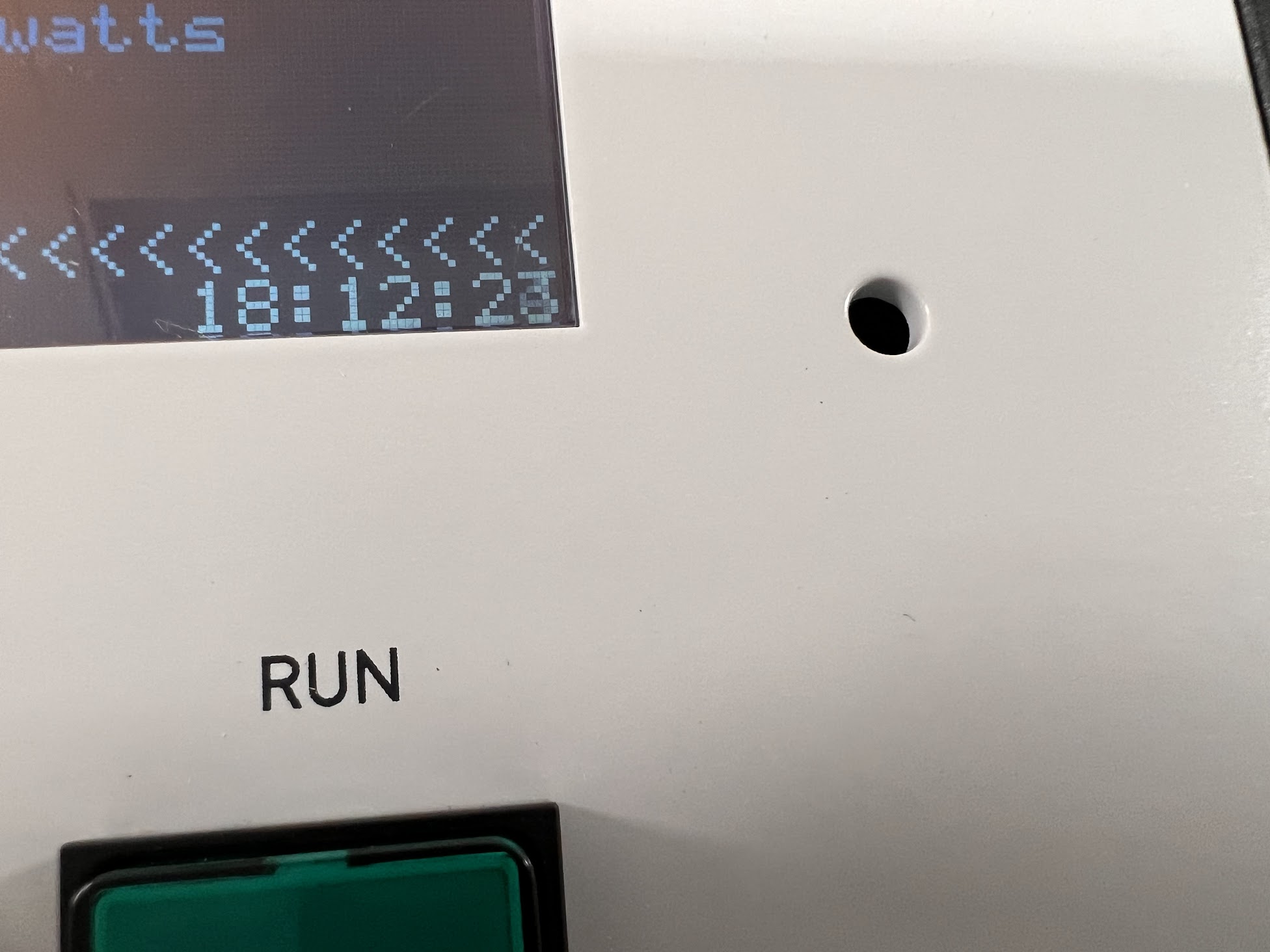

Select MW to set the Power Level and set it to 200.

Now go back to MW and Press ENT to turn to power on

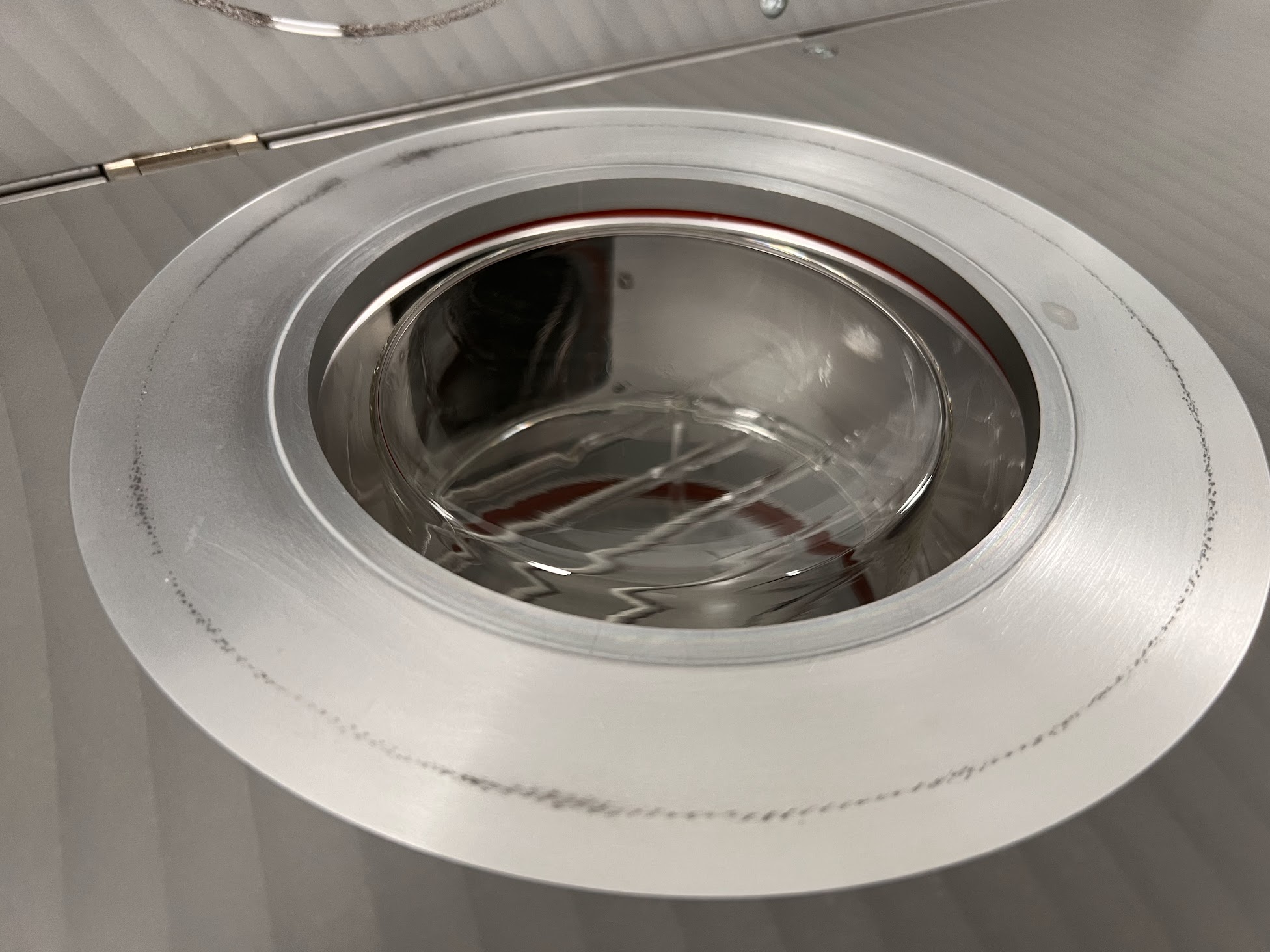

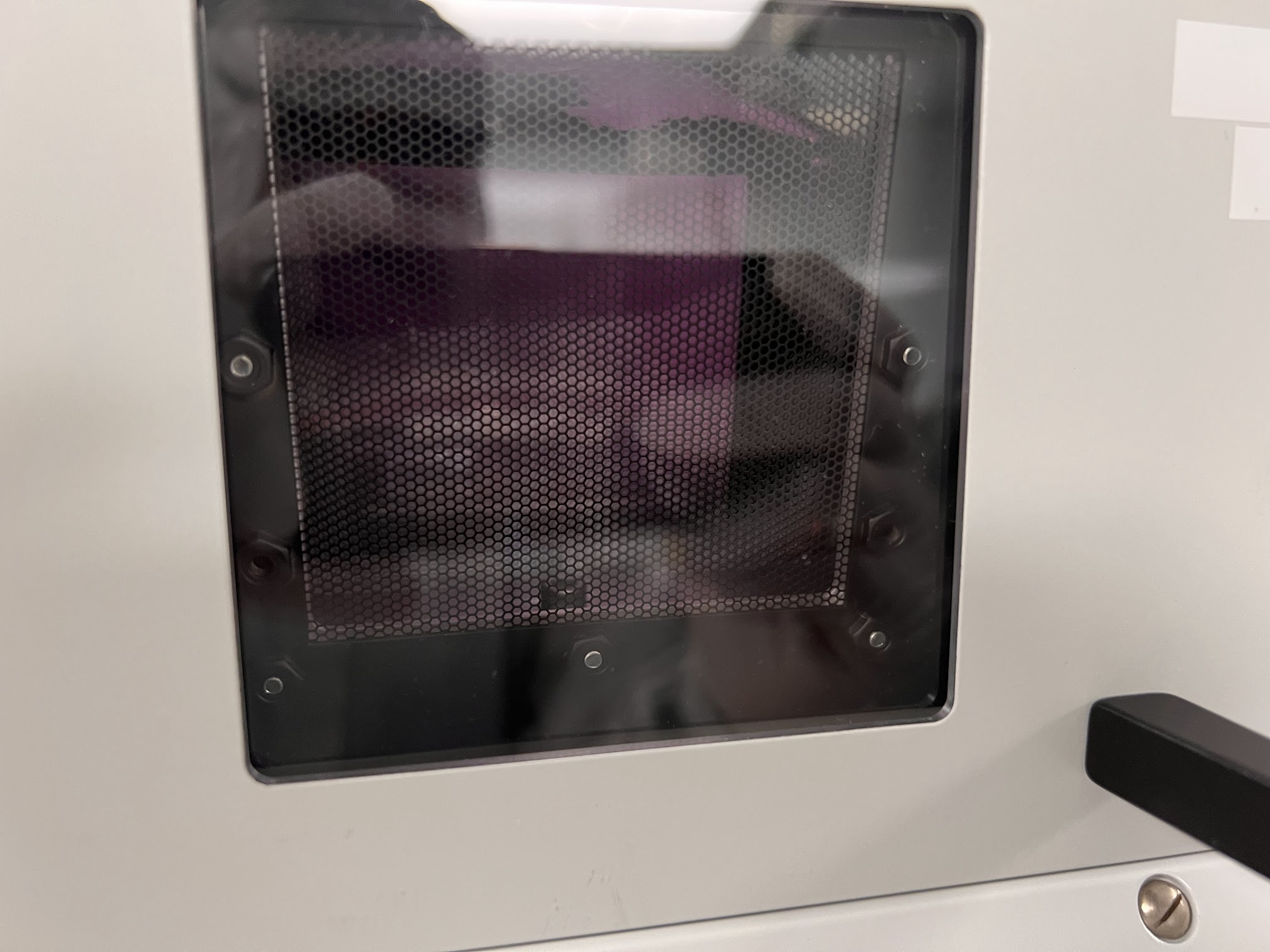

After a few minutes you should see a purple glow inside the Main Chamber indicating the Plasma is now on.

- Keep the Power on for 10 Minutes. This much time is needed to Heat up the machine coils for producing the Plasma consistently.

- Turn the ceiling light above the Tepla Asher off to see the plasma more clearly.

- I suggest keeping the light above the Tepla off till all the chips have been bonded.

Select VENT and press ENT. Now slowly Open the Vent Valve and Rotate it to the Open position as mentioned previously. See Video Below.