Preparation¶

- You need Prior Authorization to use the EVG620 and the Dektak XT. Make sure you have the prior authorizations and training well in advance.

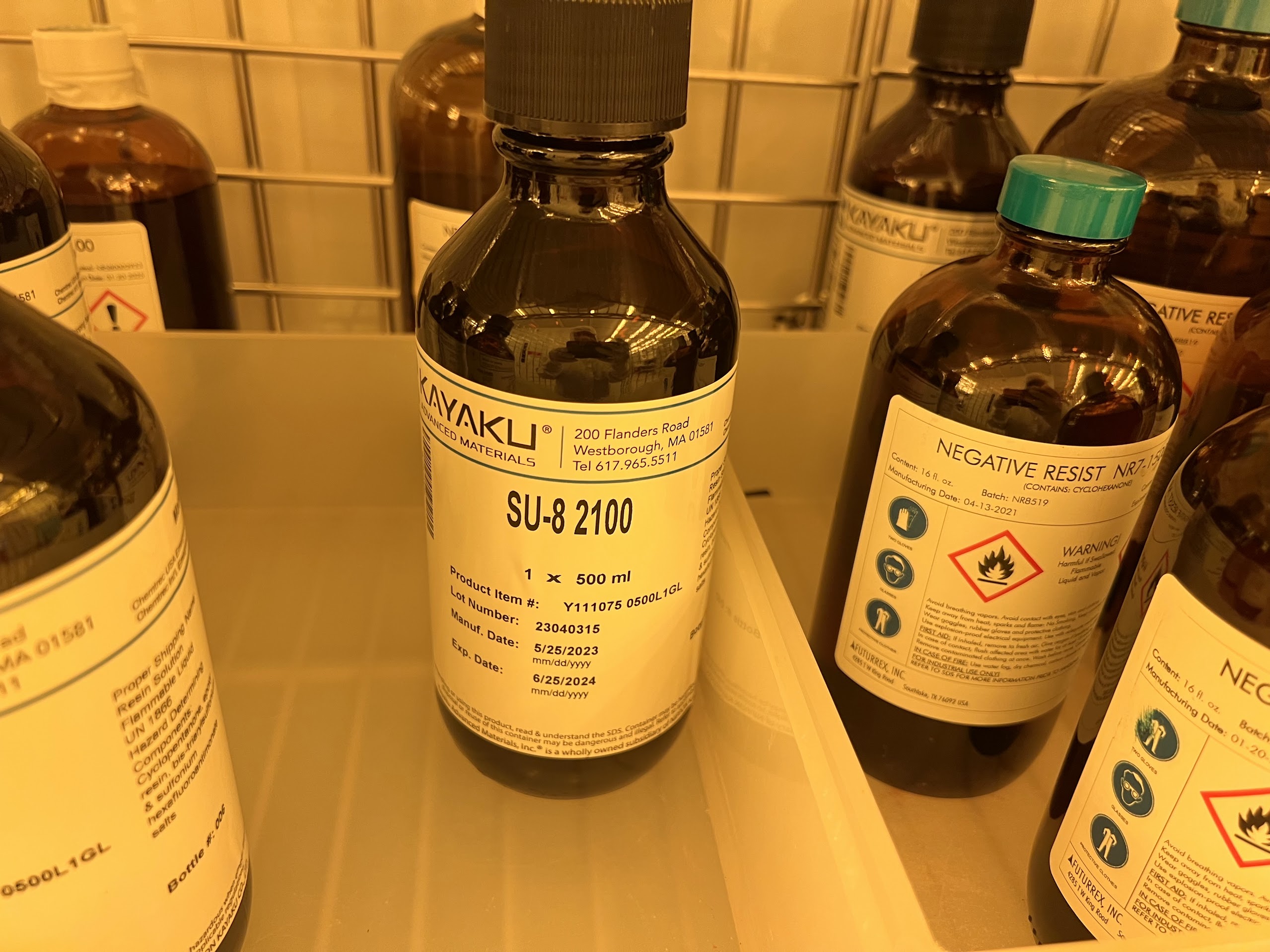

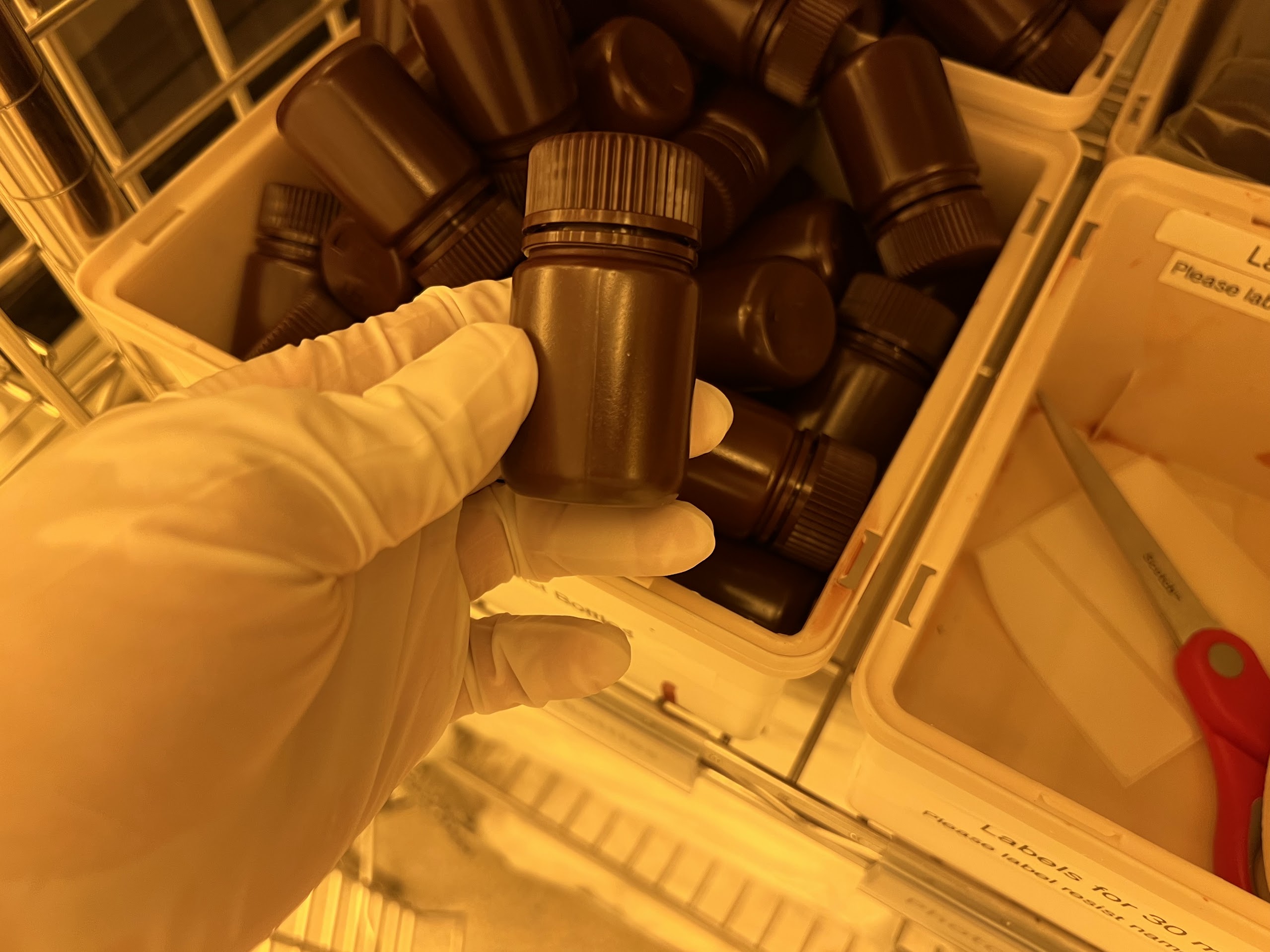

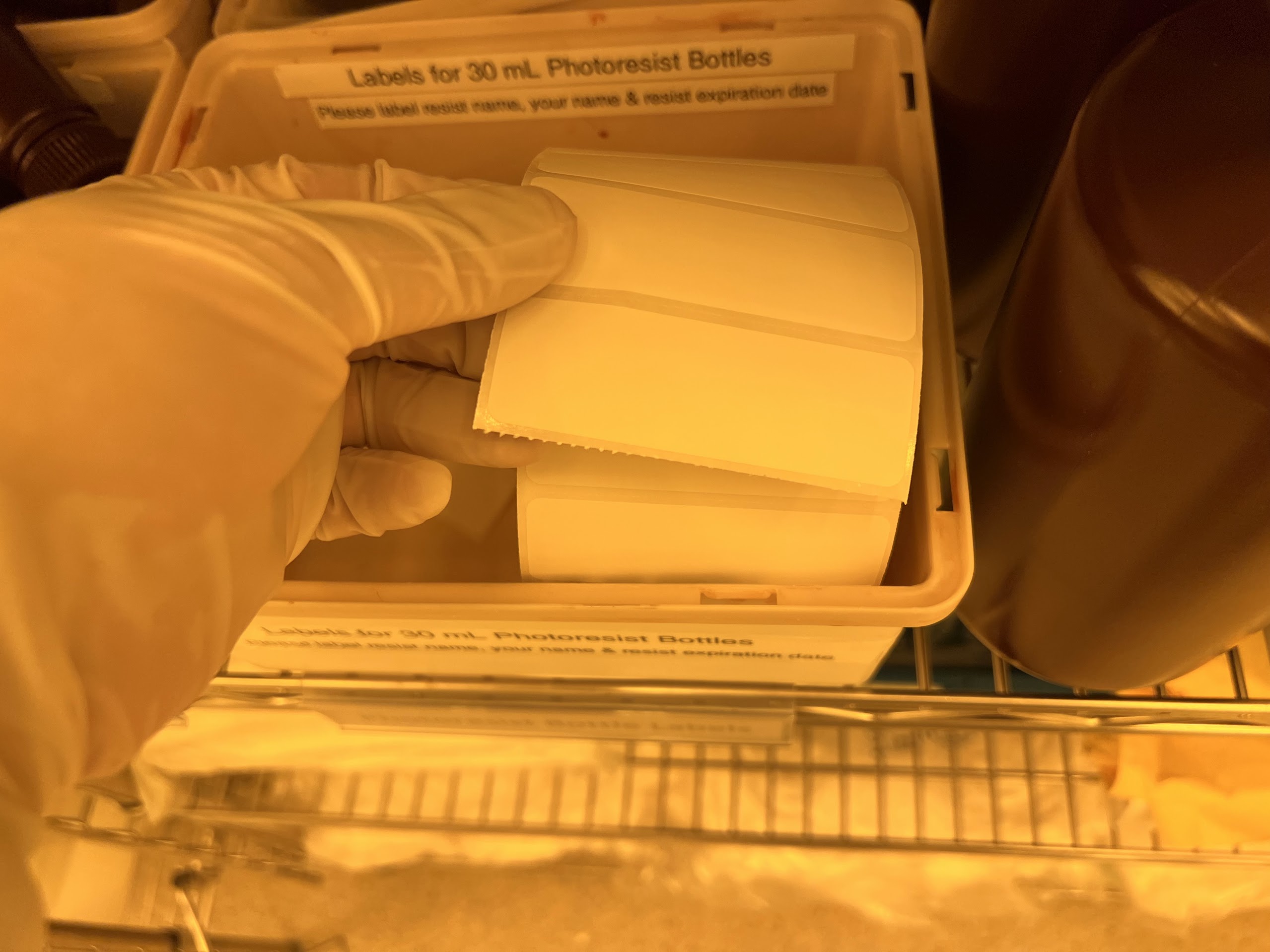

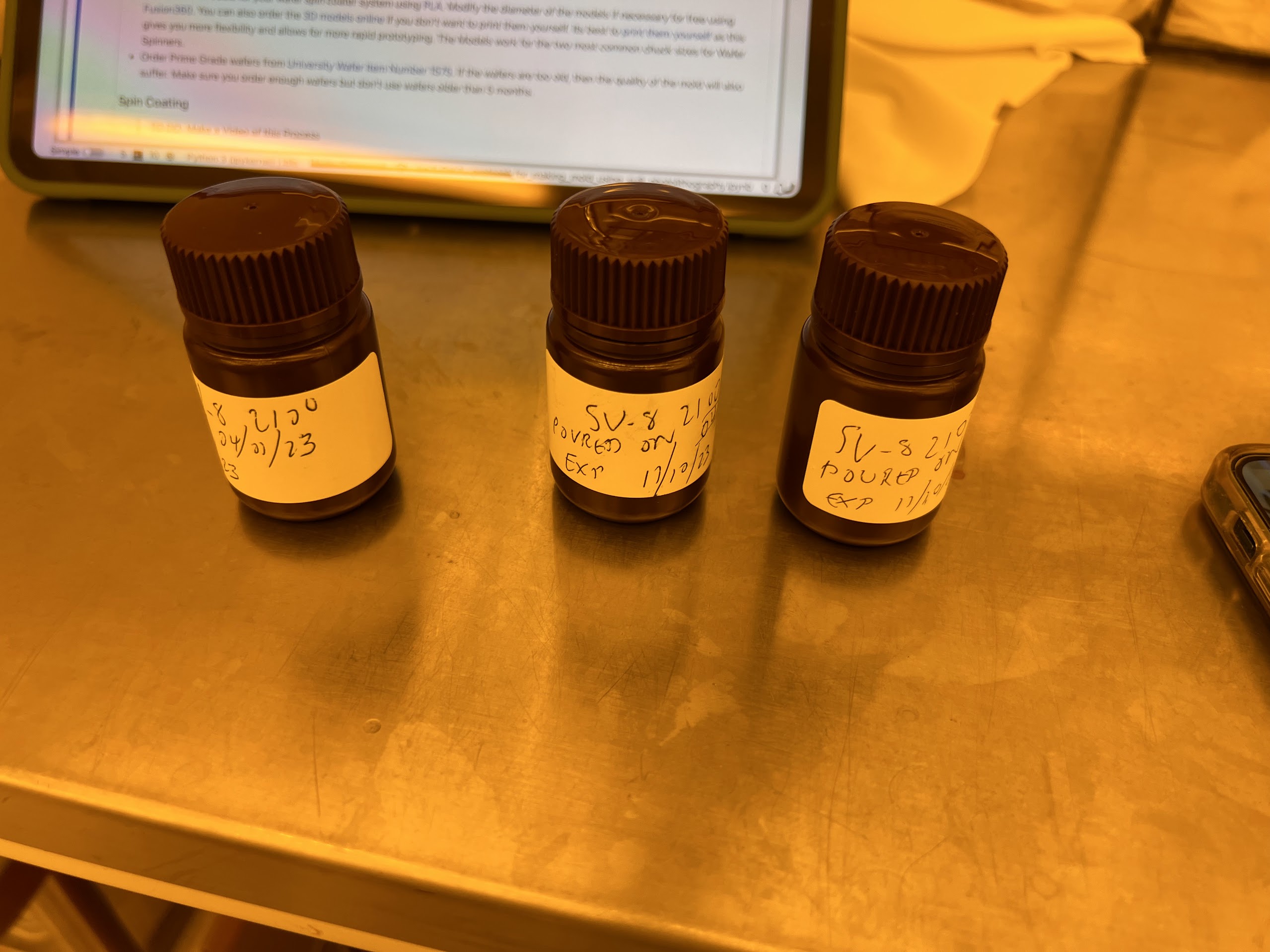

- At least three weeks before you begin the mold making process you should pour SU-8 2100 into Dark Nalgene bottles.

- Label the Nalgene bottles with the date you poured the resist and the expiry date.

- It’s important to do this early because SU-8 2100 is a very thick resist and can easily trap air bubbles which will make the Photoresist spin coat very uneven after pouring it onto the silicon wafer.

- Air bubbles in the resist will lead to significant variation in the depth of the microfluidic channels downstream. Three weeks is generally enough time for these bubbles to disappear. You will get much higher quality molds if you do this in advance.

- Fill about 2/3 of each Nalgene Bottle with SU-8 2100.

- Try not to spill any resist on the lip of the bottle or into the cap. This resist can dry and form flakes that can ruin your photoresit coating.

- Clean any resist on the lip or cap with a Cloth Cleanroom wipe soaked in Acetone.

- Don't let any Acetone into the main SU-8 Bottle or Nalgene Bottle by accident.

- Clean any resist spilled on the main SU-8 Bottle or Nalgene bottle on the sides with a Cloth Cleanroom wipe Soaked in Acetone.

- Execute the Cell Below to Watch a video of the Process.

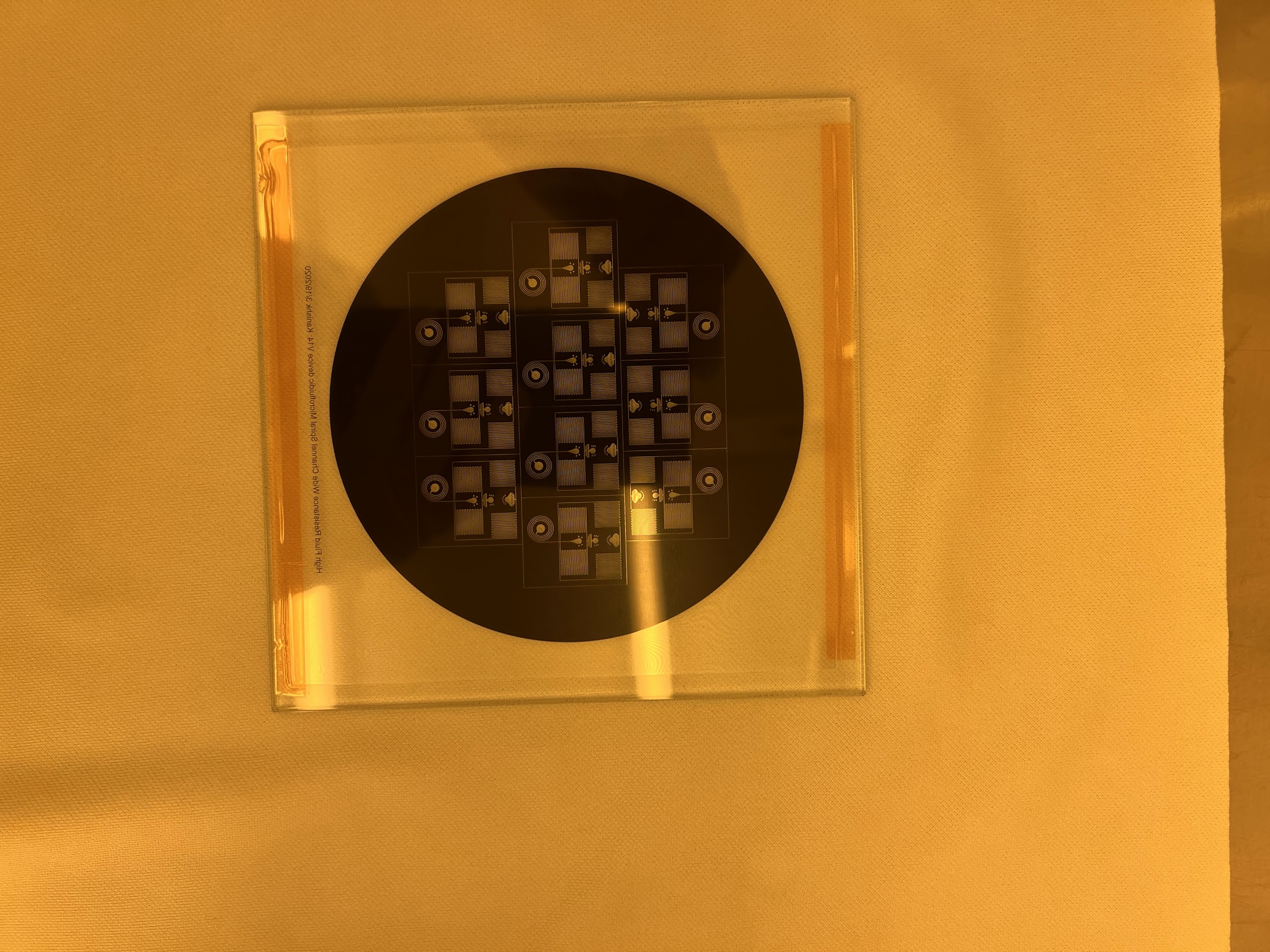

|

|

|

|