Protocol for creating the PDMS Microfluidic Chips from the Mold at Nano3 Facility at UC San Diego:¶

- Protocol adapted from Nano3 PDMS Molding Course.

- Make a reservation of the PDMS Clean Space for 6 hours using the FOM Reservation System.

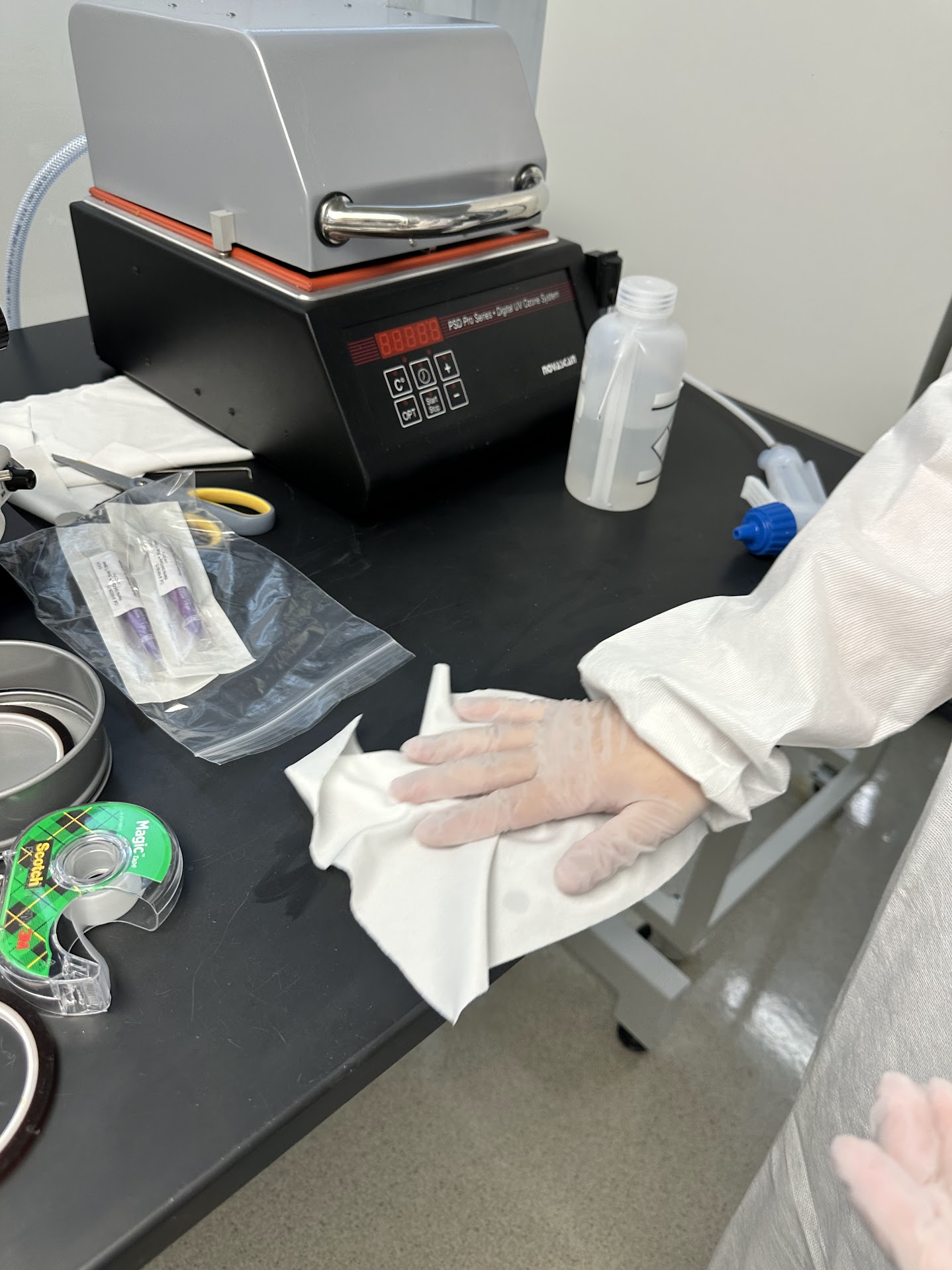

- Clean the work area with Isopropanol(IPA) and cloth cleanroom wipes.

- Clean the containers/wafer carriers brought into the cleanspace as much as possible.

- I generally store the items I want to keep dust/particle free in a sealed container which I only open inside the Cleanroom/Cleanspace.

- Wafers should also only be stored inside the Wafer Carrier. The Wafer Carrier should only be opened inside the Cleanspace/Cleanroom.

- Both the PDMS Cleanspace and Cleanroom have filtered air which keeps the air dust and particle free.

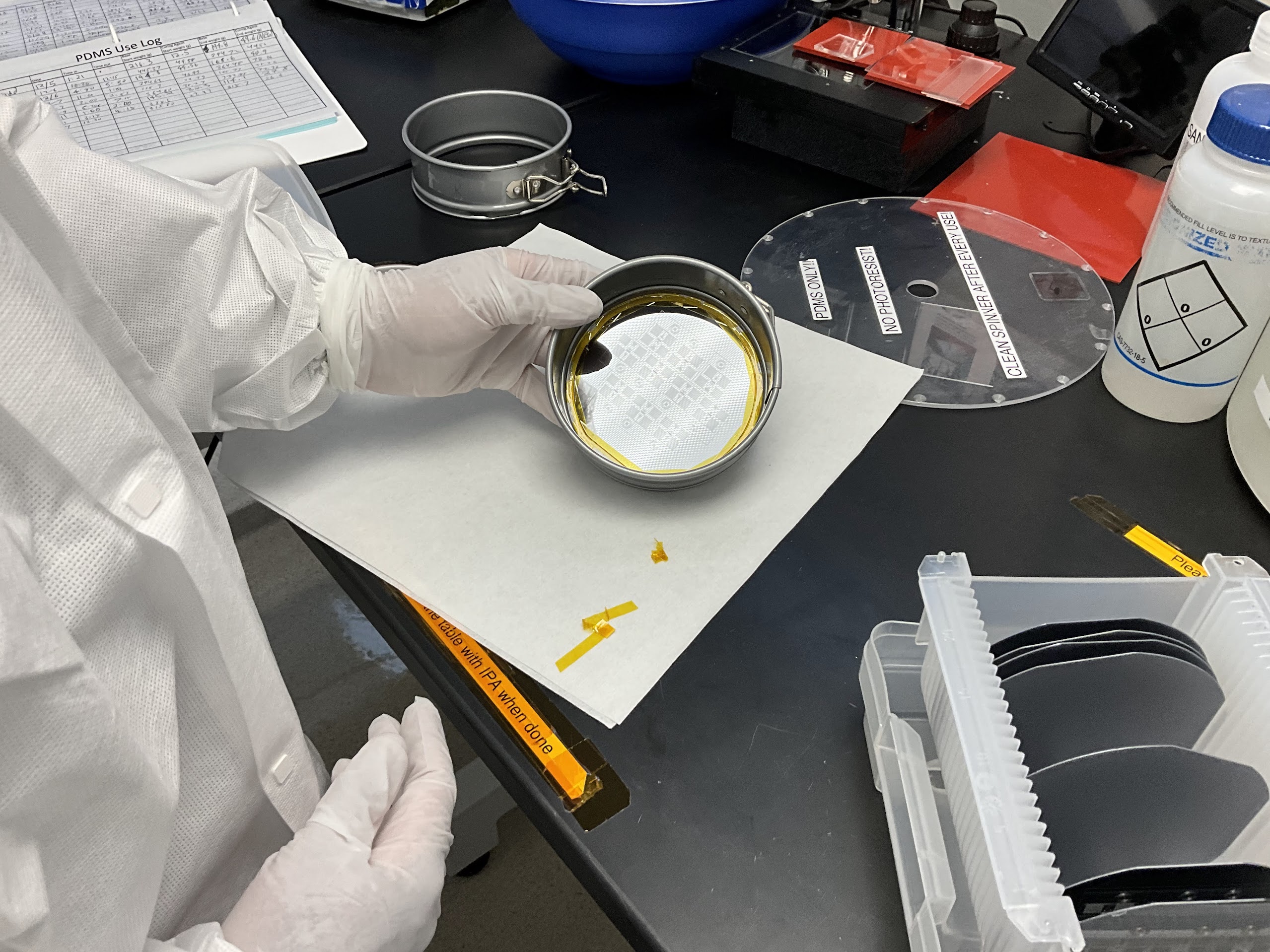

- Clean the Springform Pan Thoroughly:

- Remove the base from the top part of the 4.5 inch Springform pan by releasing the latch on the side of the pan.

- Clean the springform pan top and its base as much as possible. There should be no particles on the pan base.

- Any Remaining particles on the base can create large air gaps under the wafer which can make the wafer hard to remove and possibly even destroy the wafer when you try to remove it.

- Please clean the pans throughly with IPA and Cloth Cleanroom wipes.

- Execute the cell below to watch a video on how to clean.