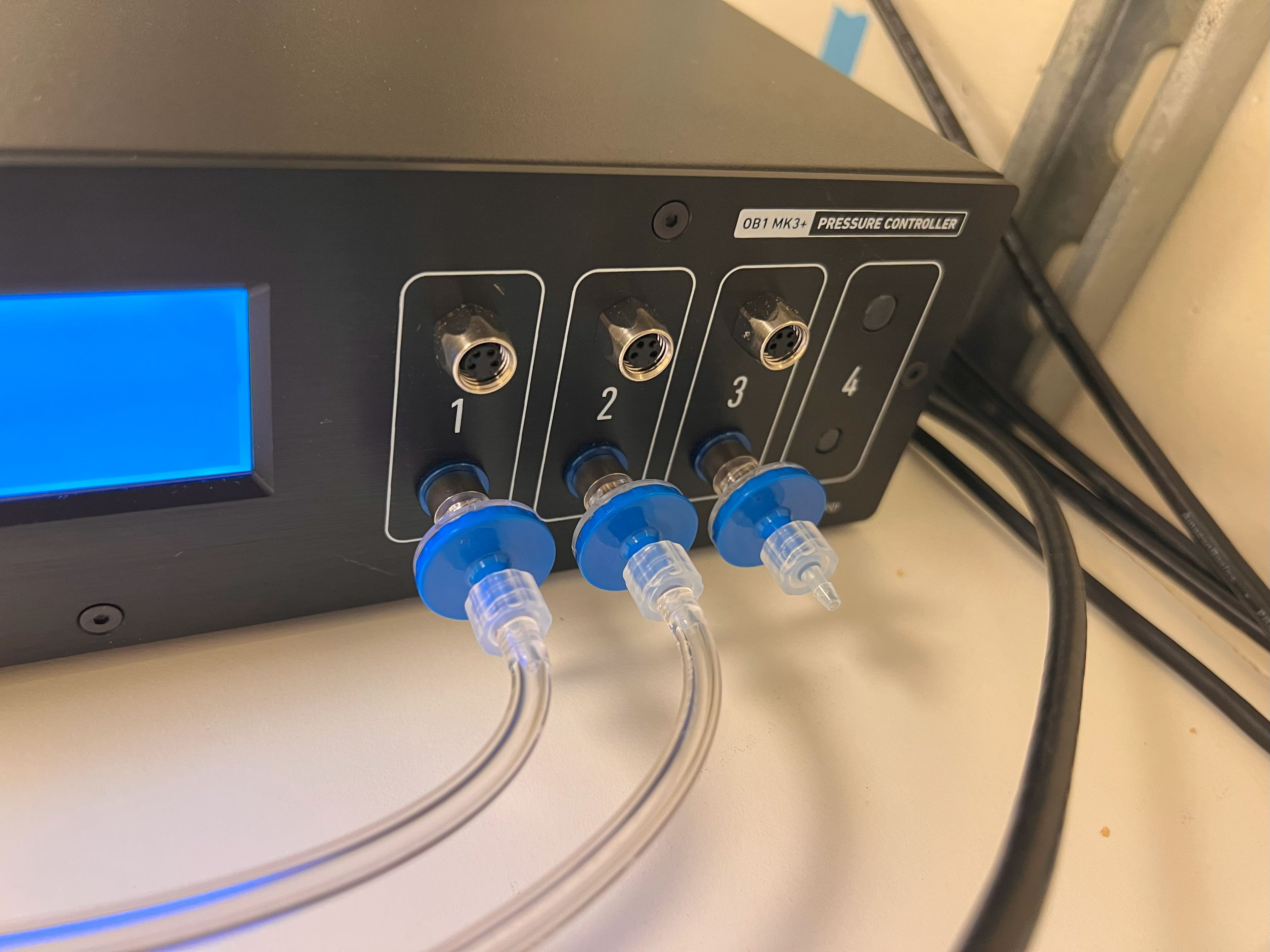

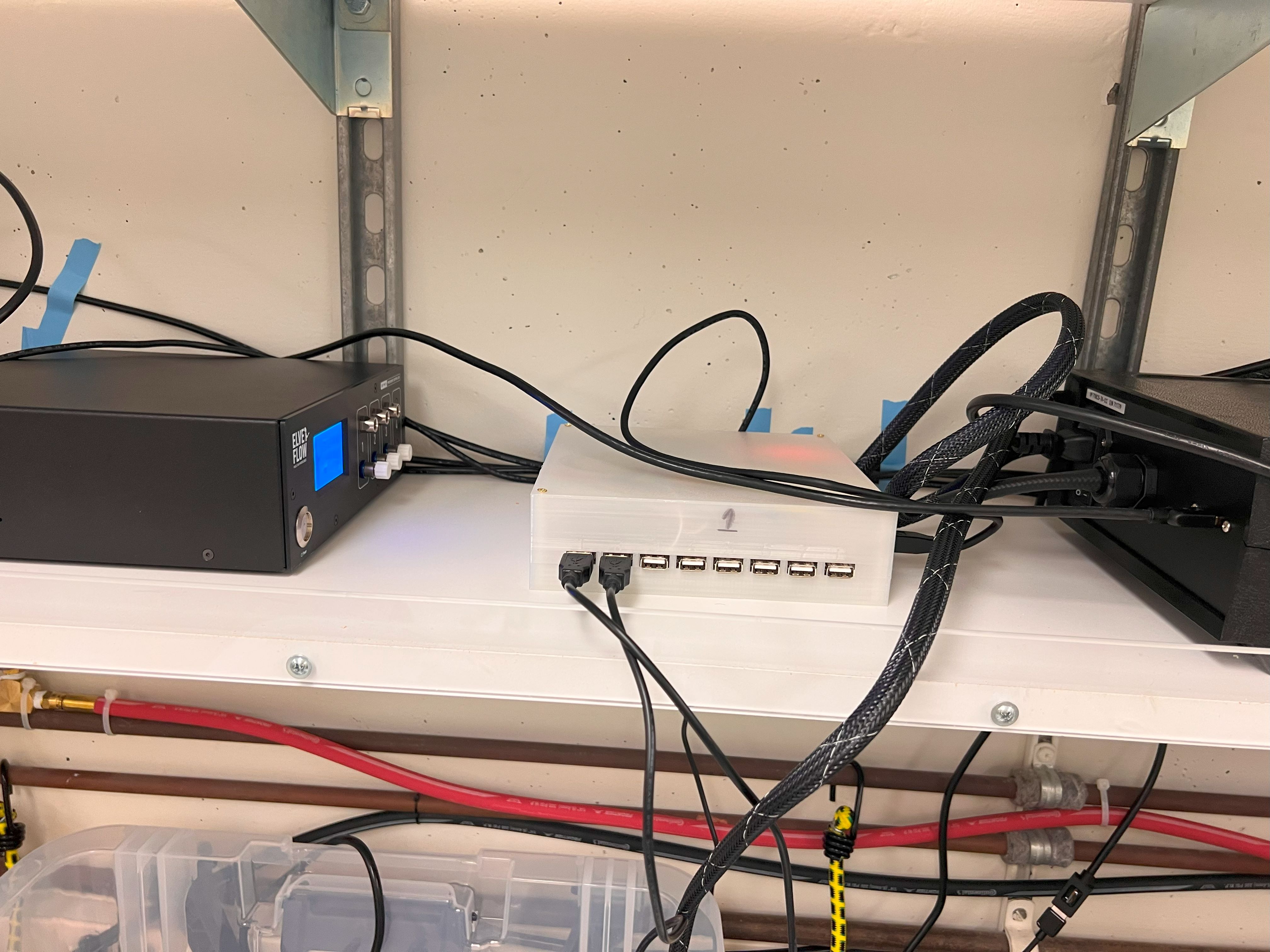

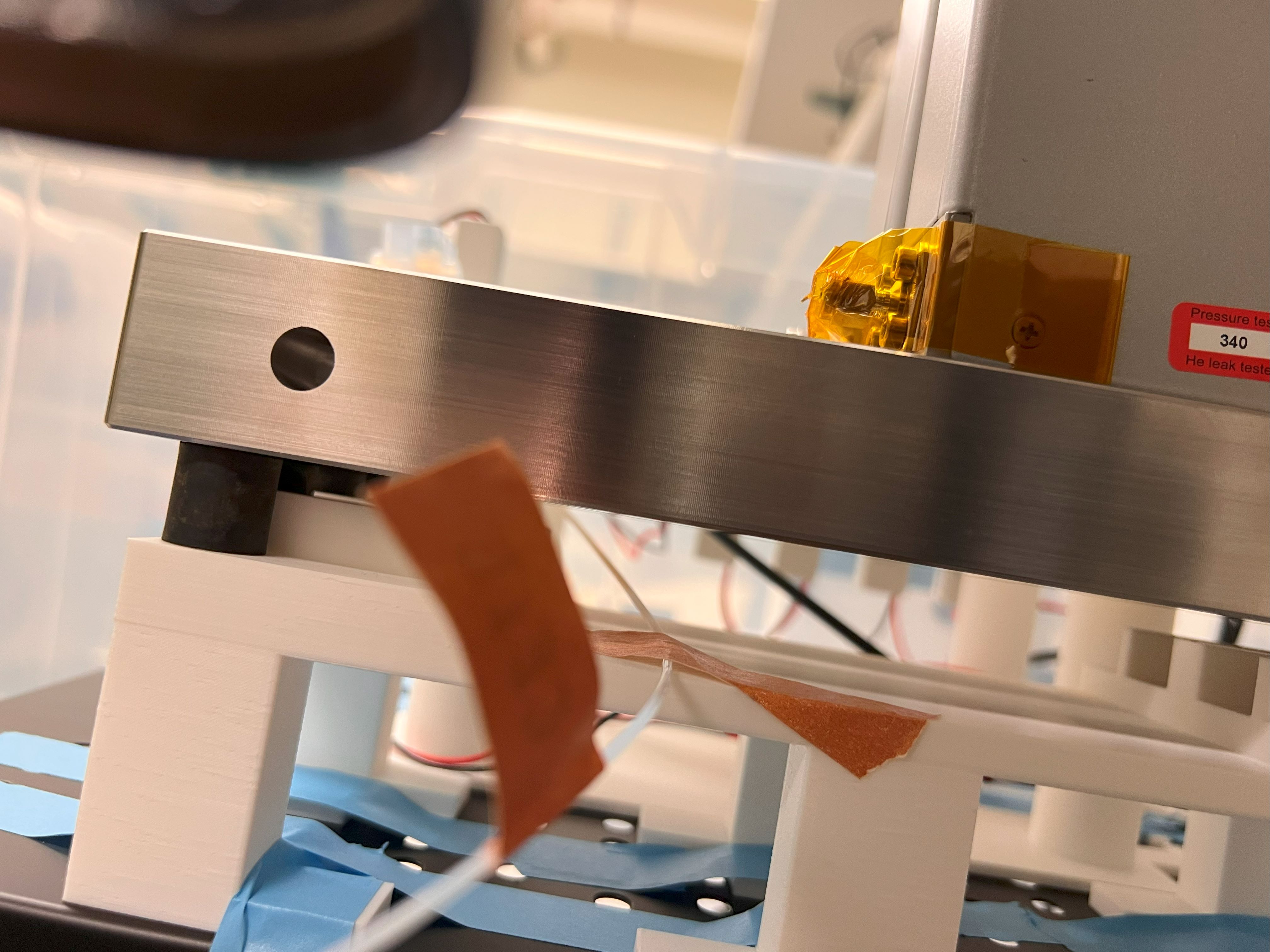

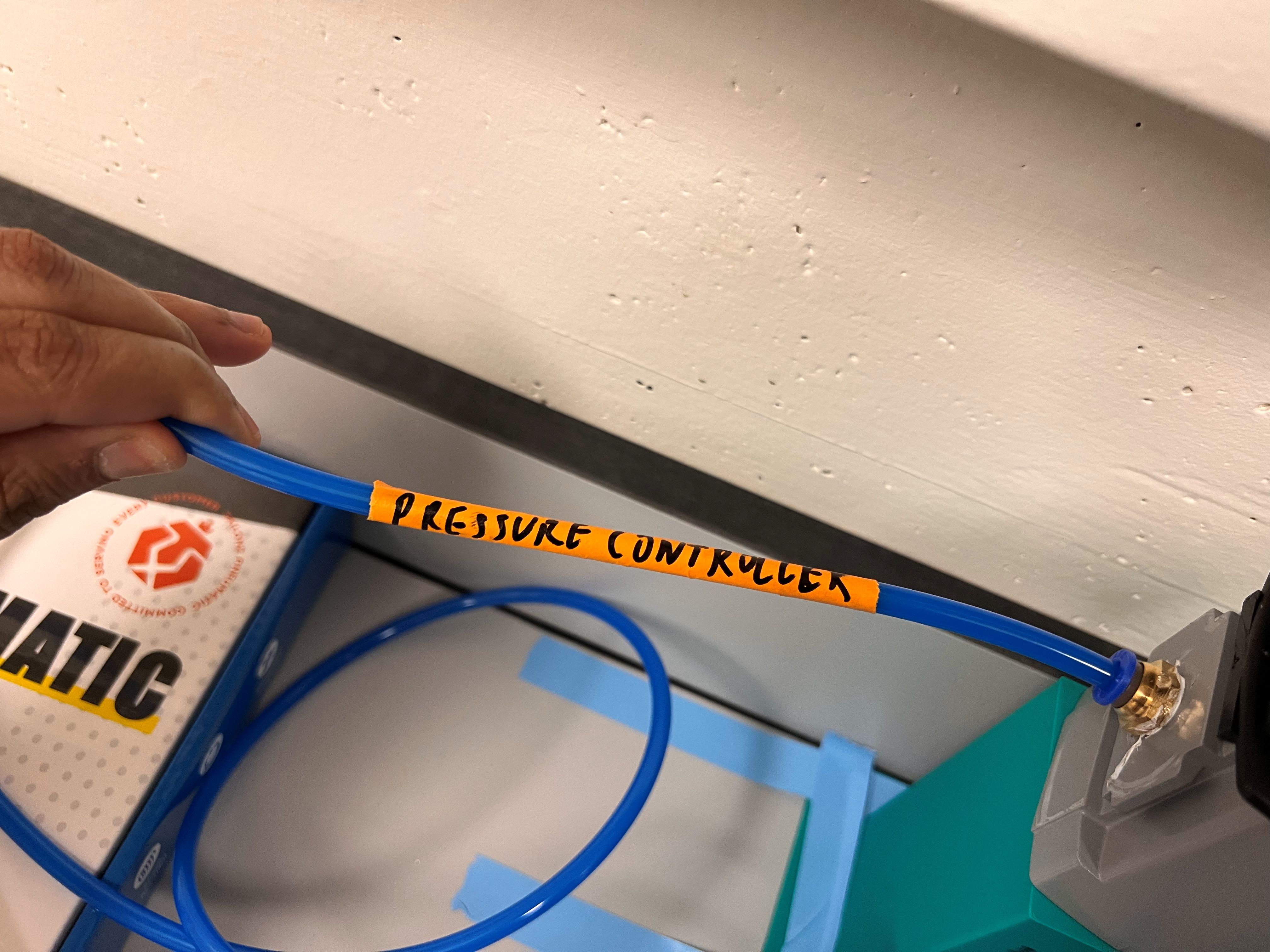

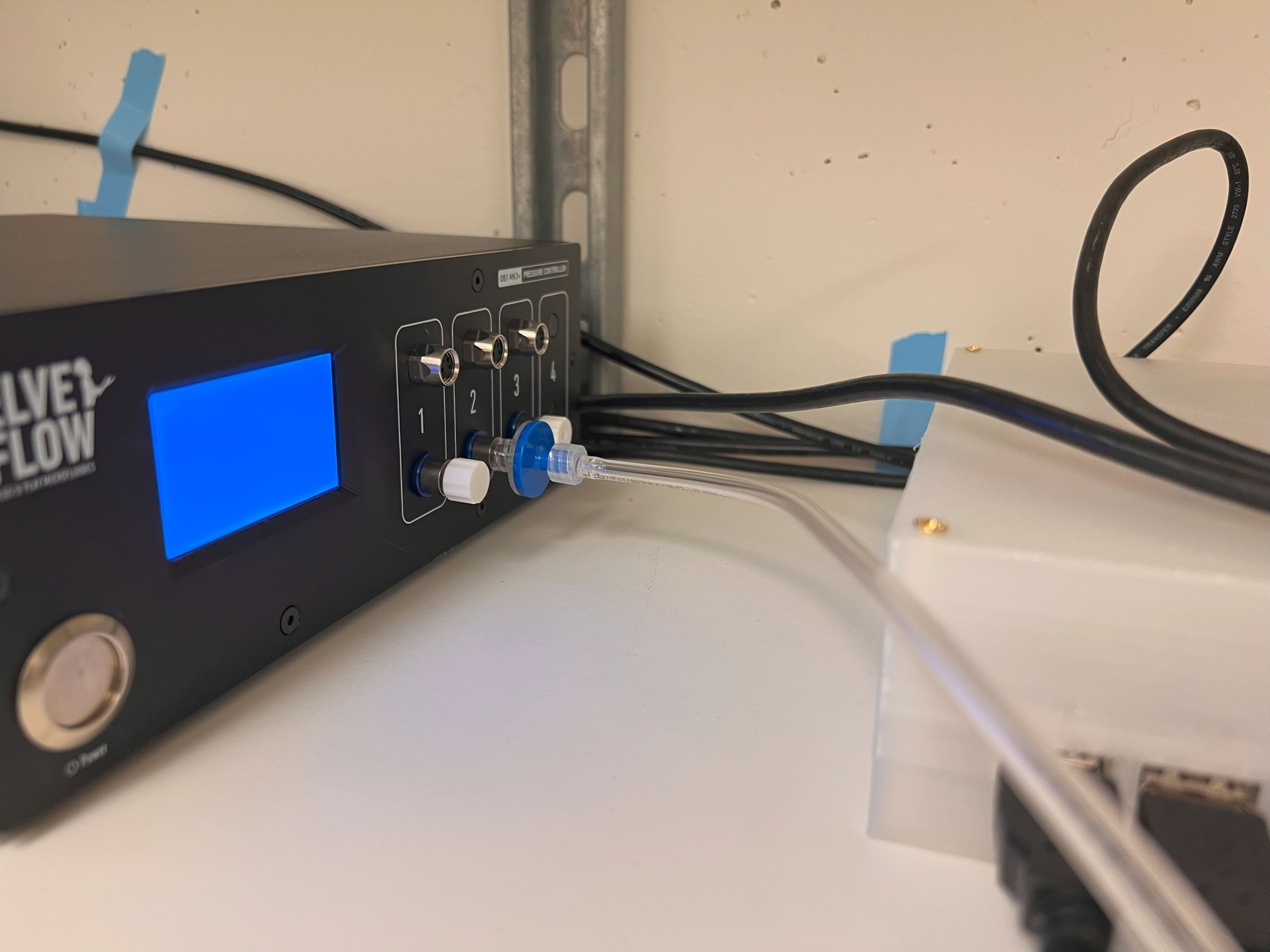

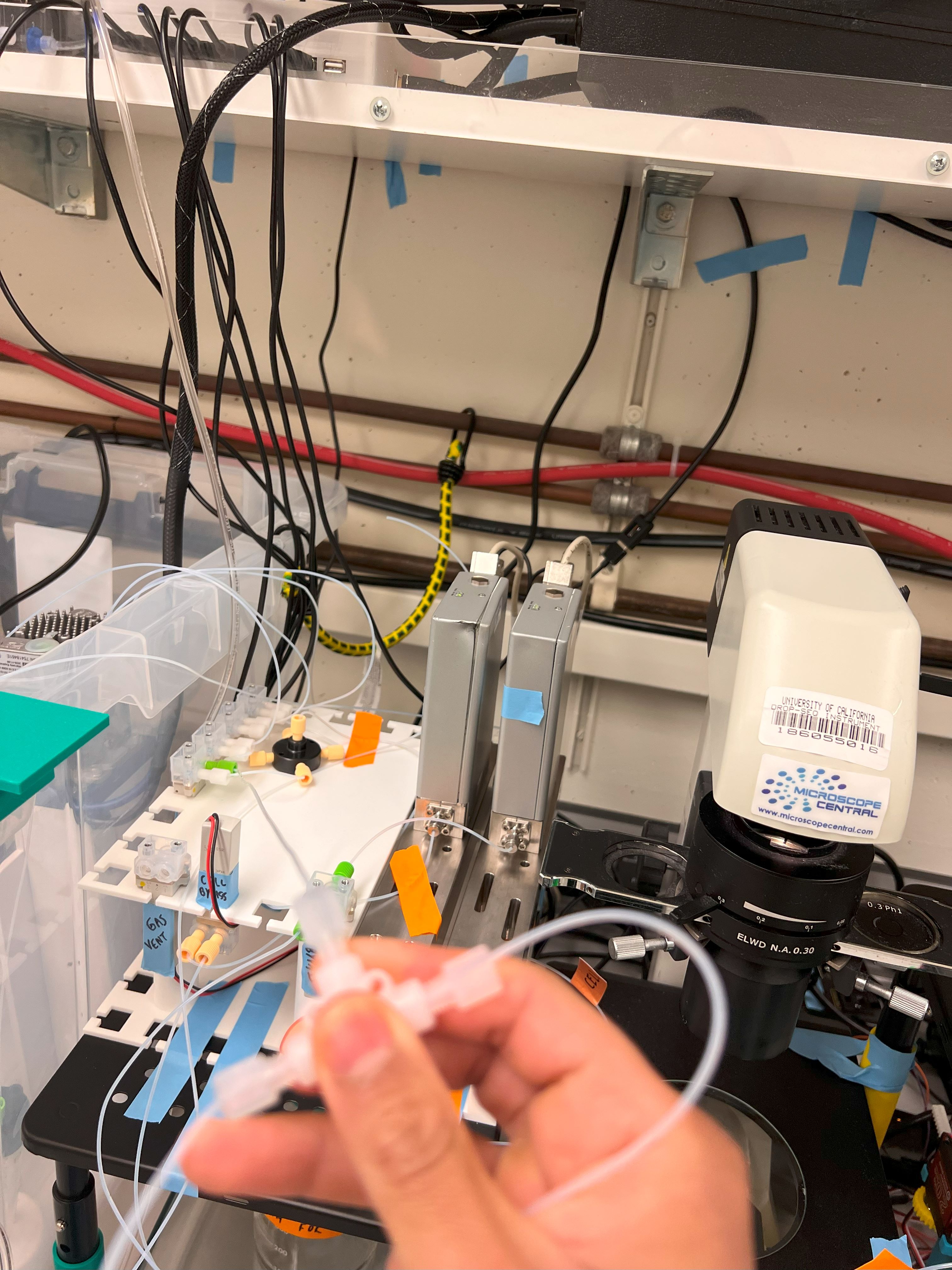

Pressure Controller Connection Started

Pressure Controller ID: 0

True

{'baudrate': 9600, 'bytesize': 8, 'parity': 'N', 'stopbits': 1, 'xonxoff': False, 'dsrdtr': False, 'rtscts': False, 'timeout': 1, 'write_timeout': 0, 'inter_byte_timeout': None}

True

{'baudrate': 9600, 'bytesize': 8, 'parity': 'N', 'stopbits': 1, 'xonxoff': False, 'dsrdtr': False, 'rtscts': False, 'timeout': 1, 'write_timeout': 0, 'inter_byte_timeout': None}

True

{'baudrate': 9600, 'bytesize': 8, 'parity': 'N', 'stopbits': 1, 'xonxoff': False, 'dsrdtr': False, 'rtscts': False, 'timeout': 1, 'write_timeout': 0, 'inter_byte_timeout': None}

COM12

{'baudrate': 9600, 'bytesize': 8, 'parity': 'N', 'stopbits': 1, 'xonxoff': False, 'dsrdtr': False, 'rtscts': False, 'timeout': 1, 'write_timeout': 0, 'inter_byte_timeout': None}

True

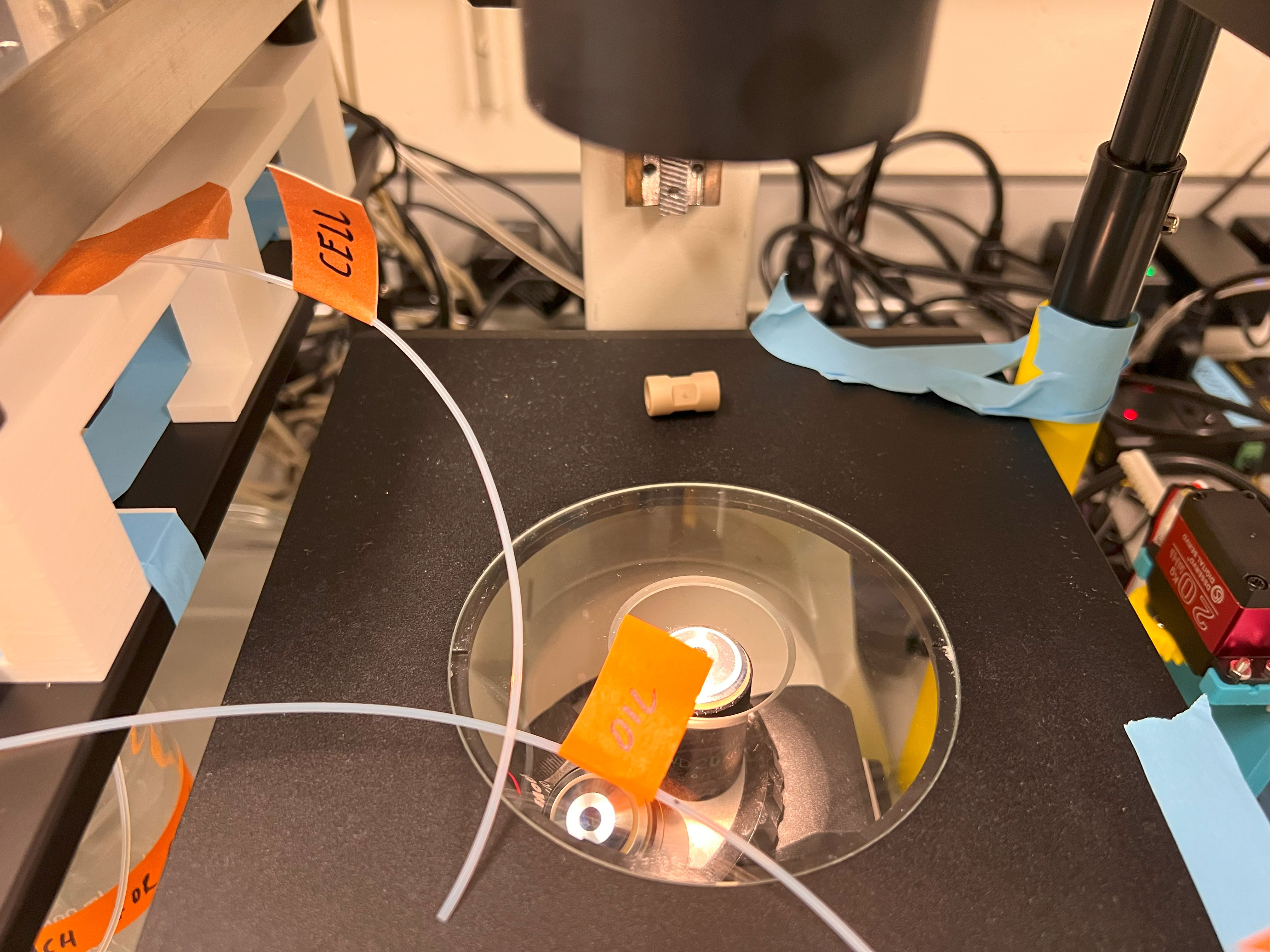

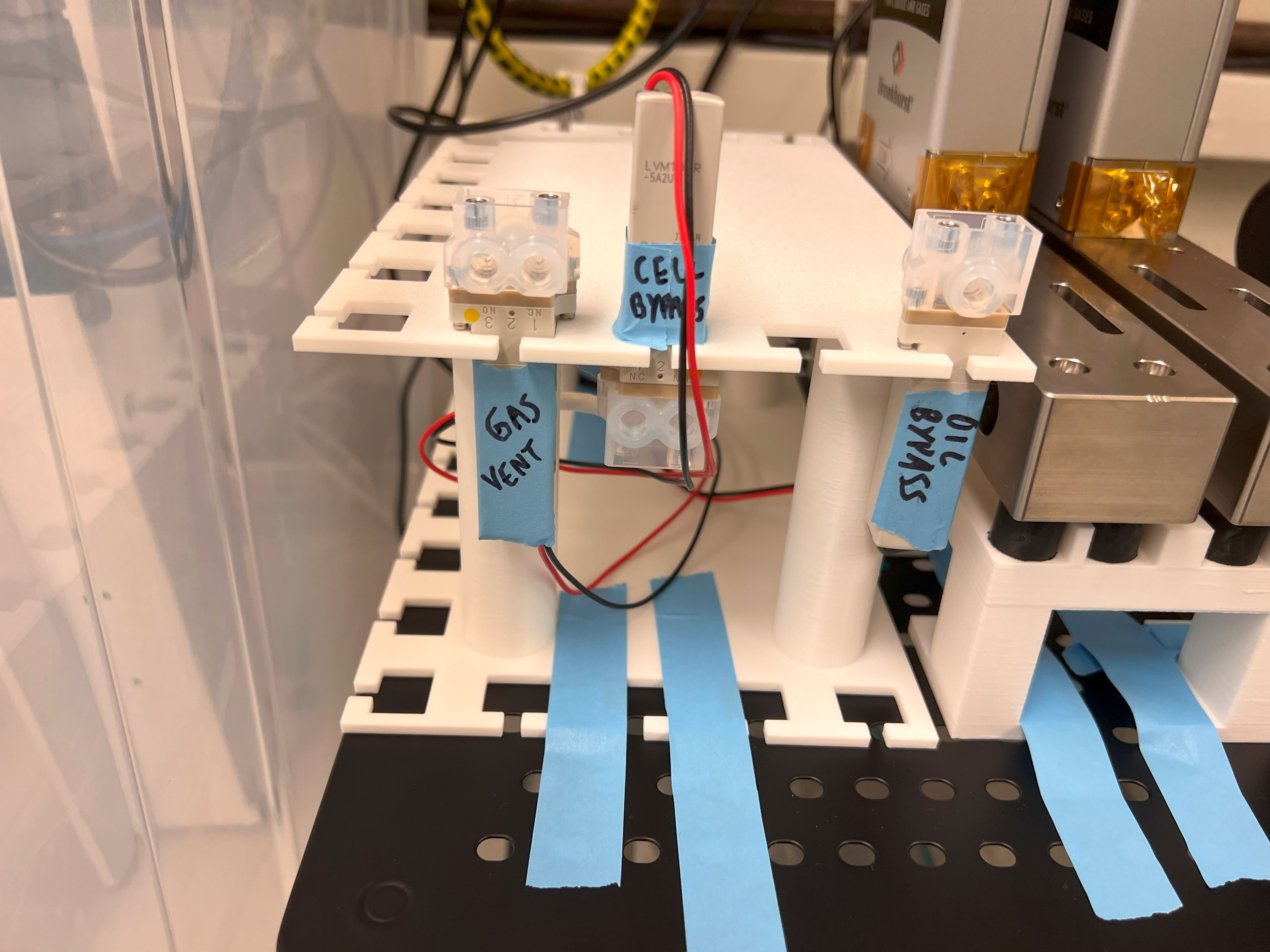

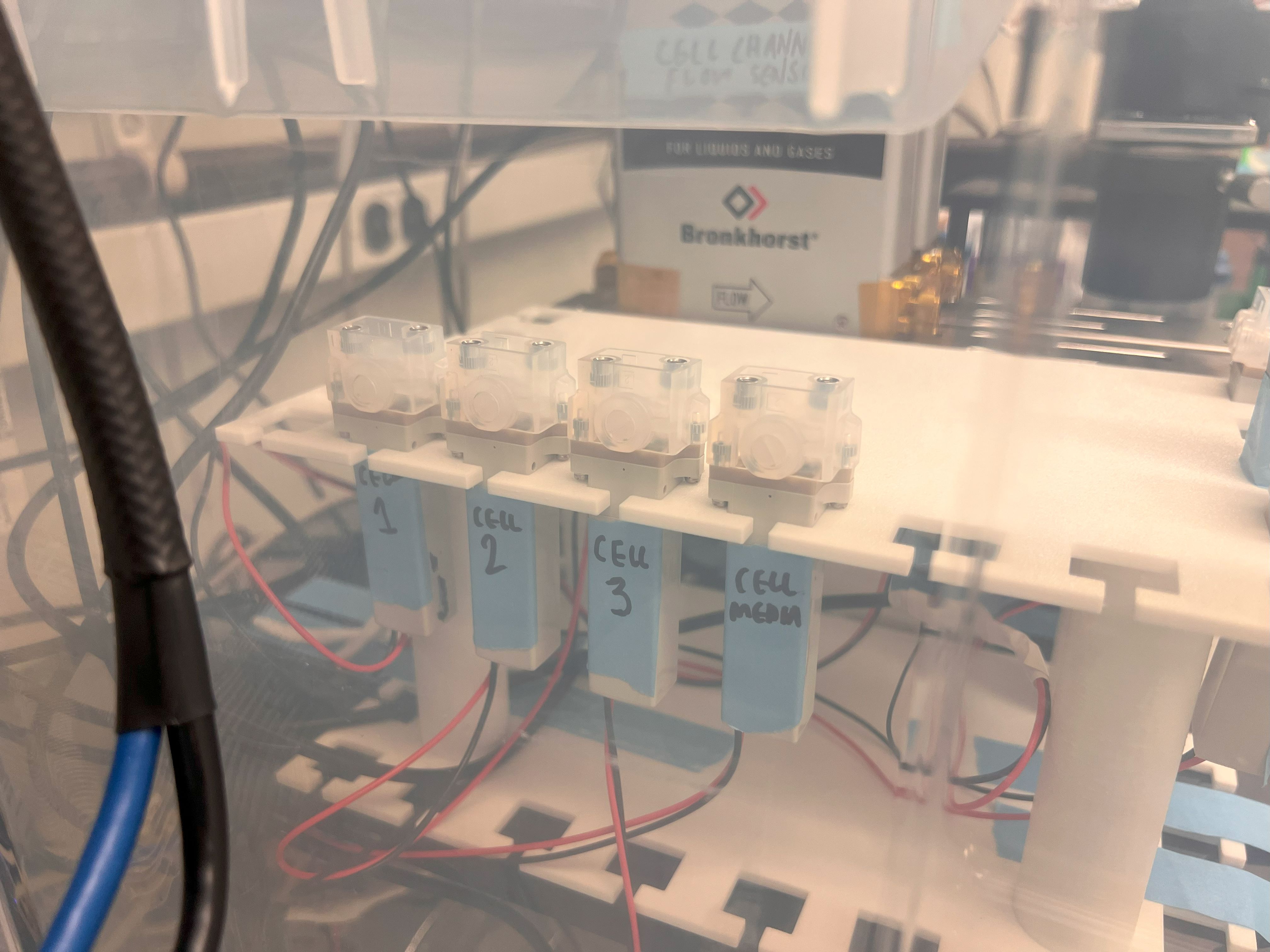

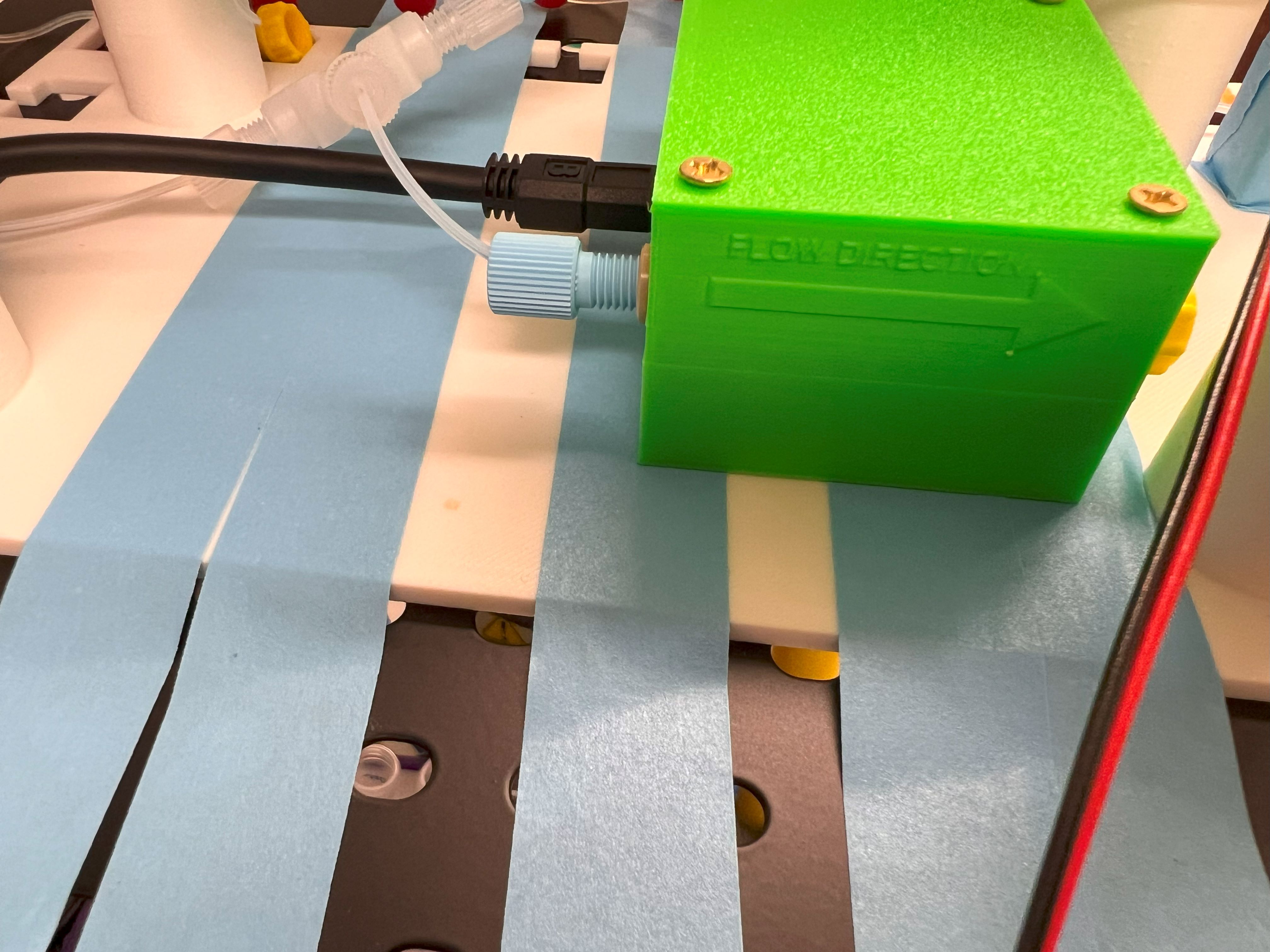

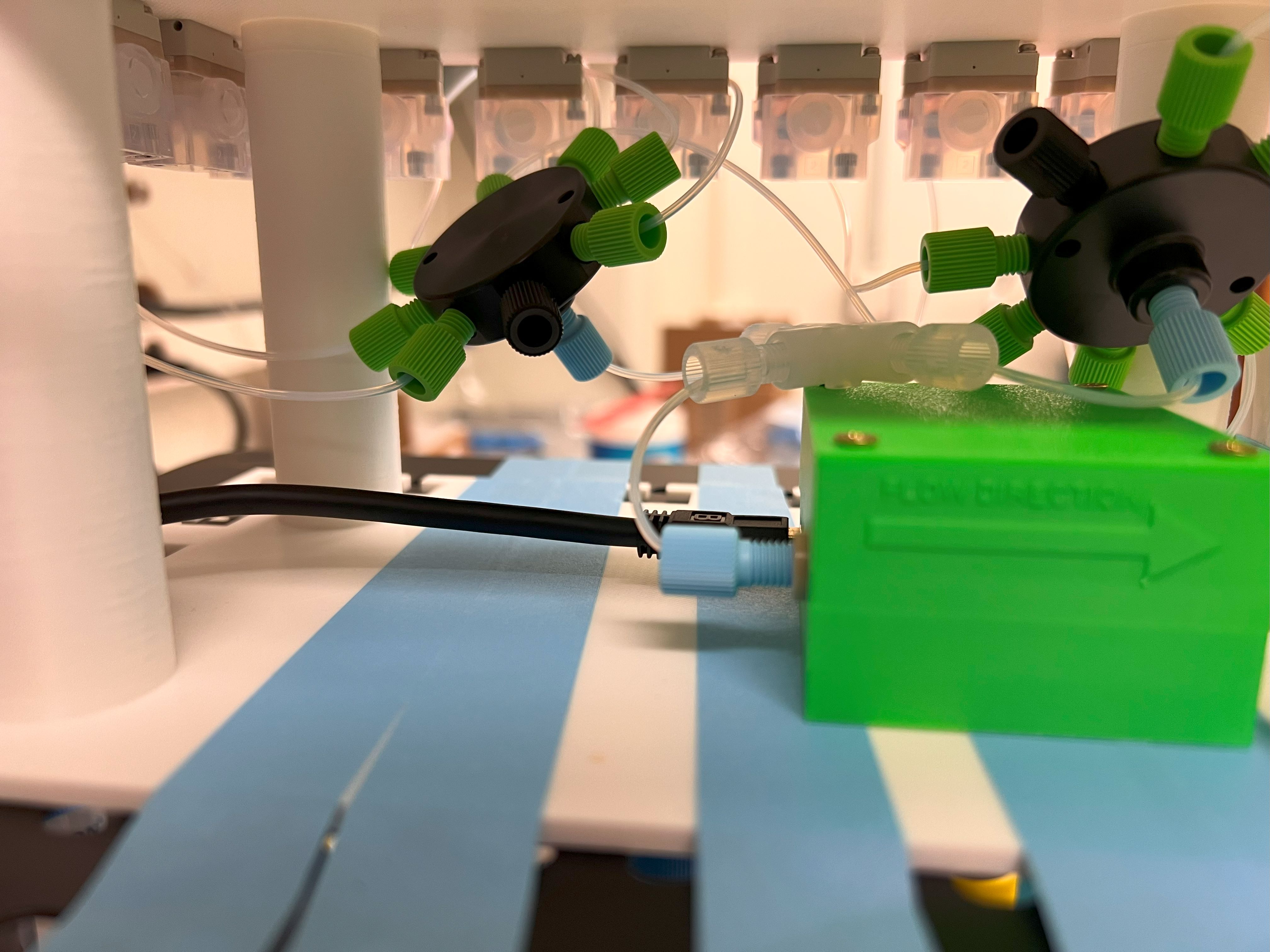

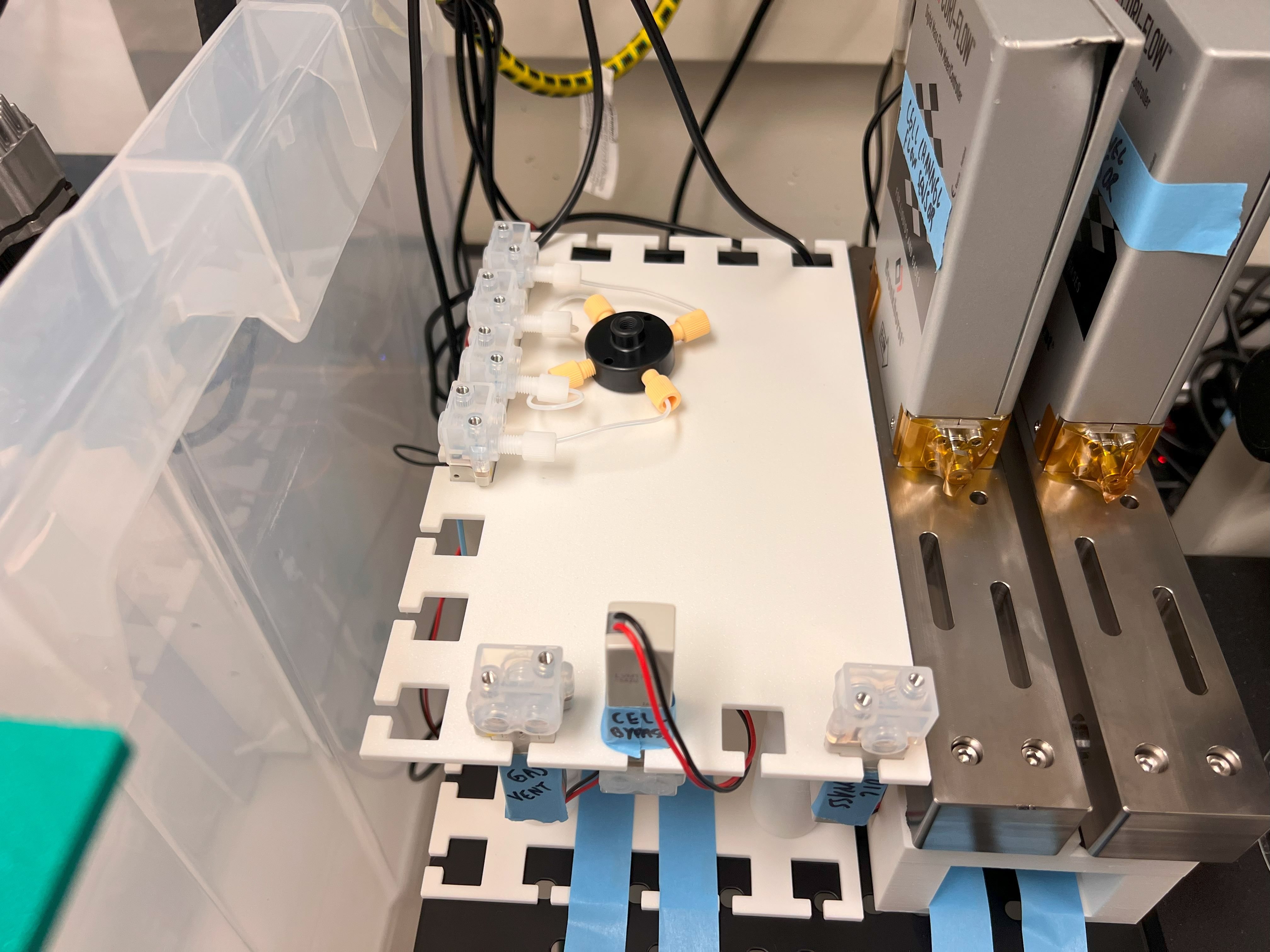

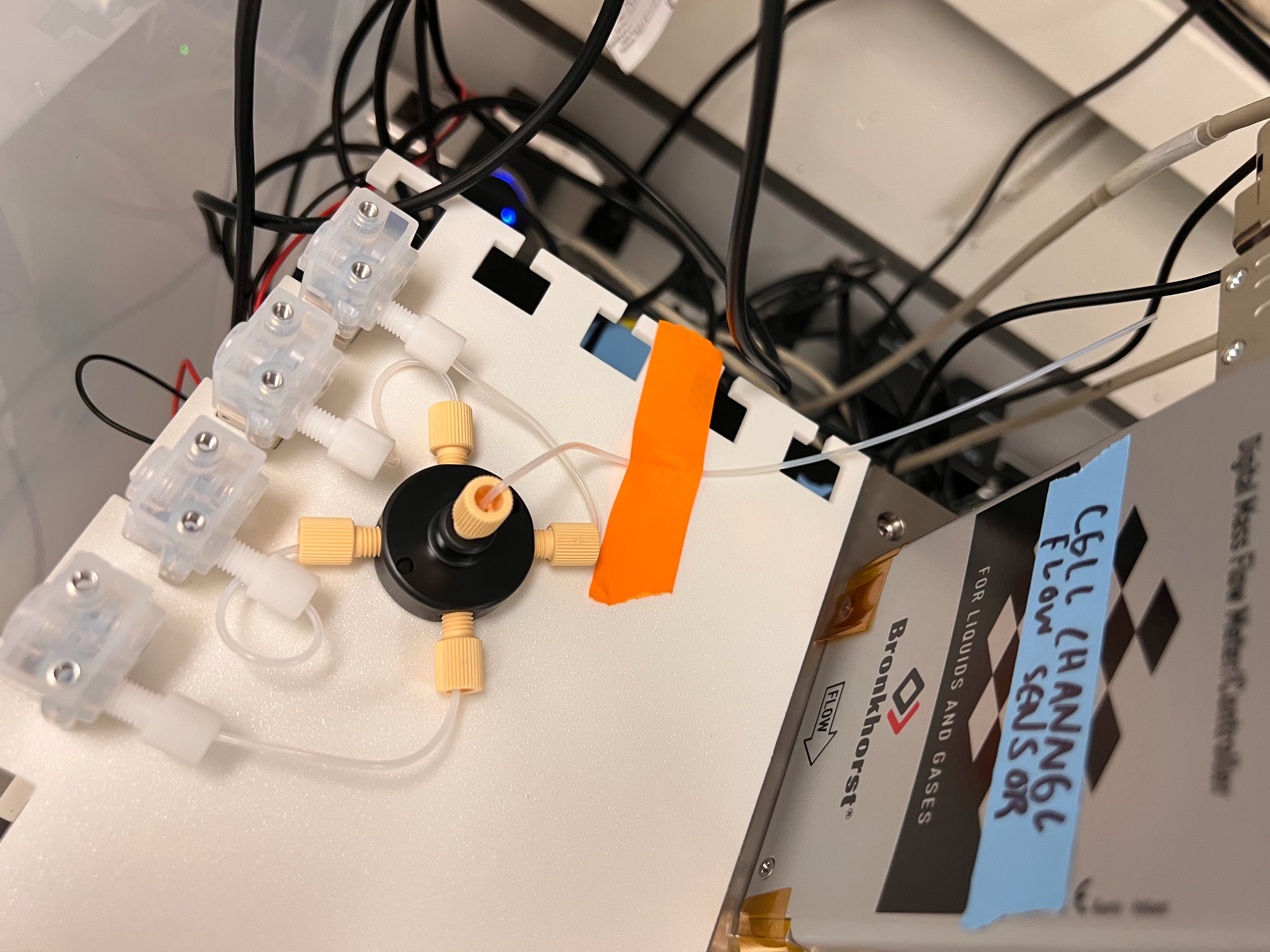

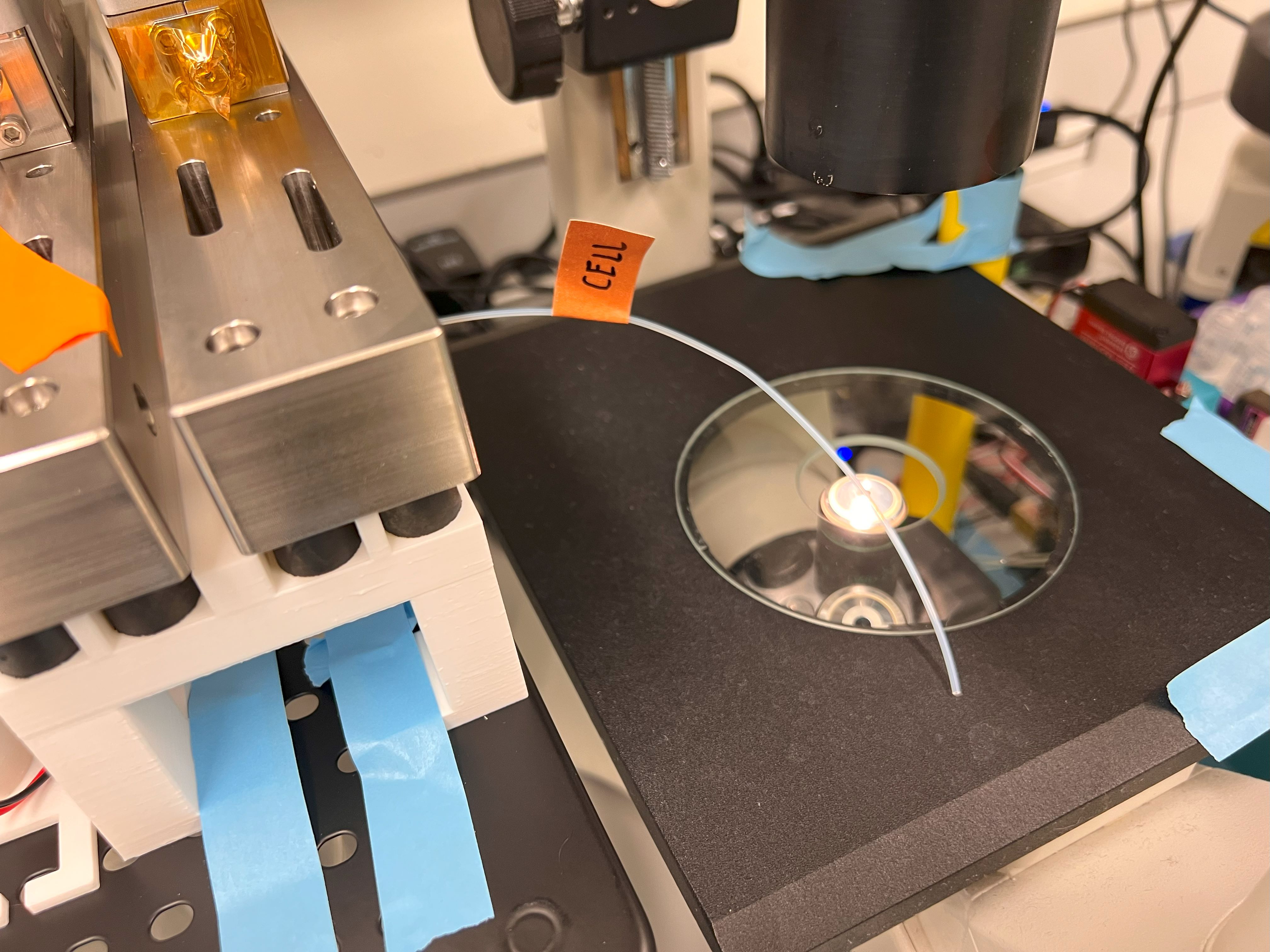

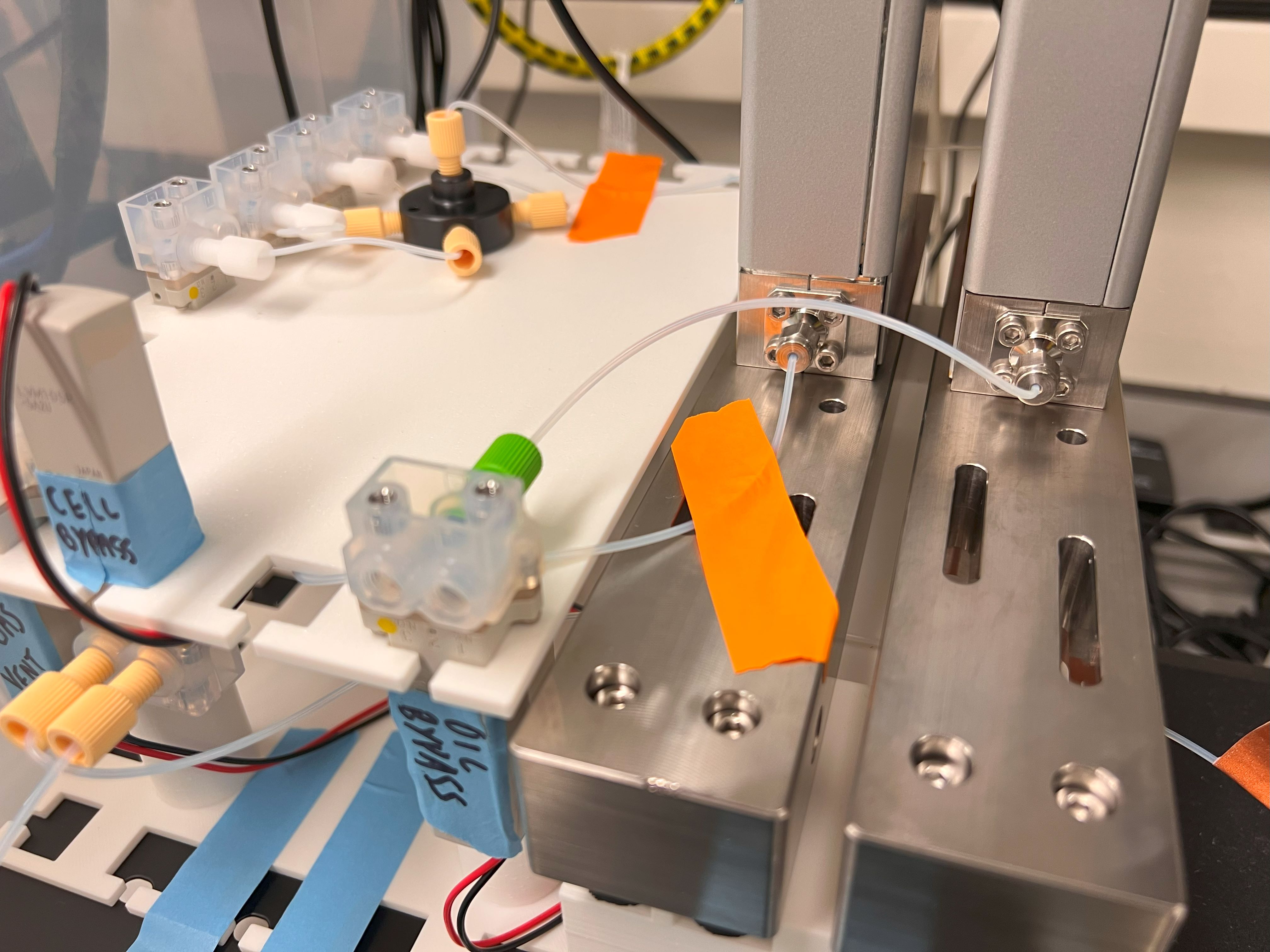

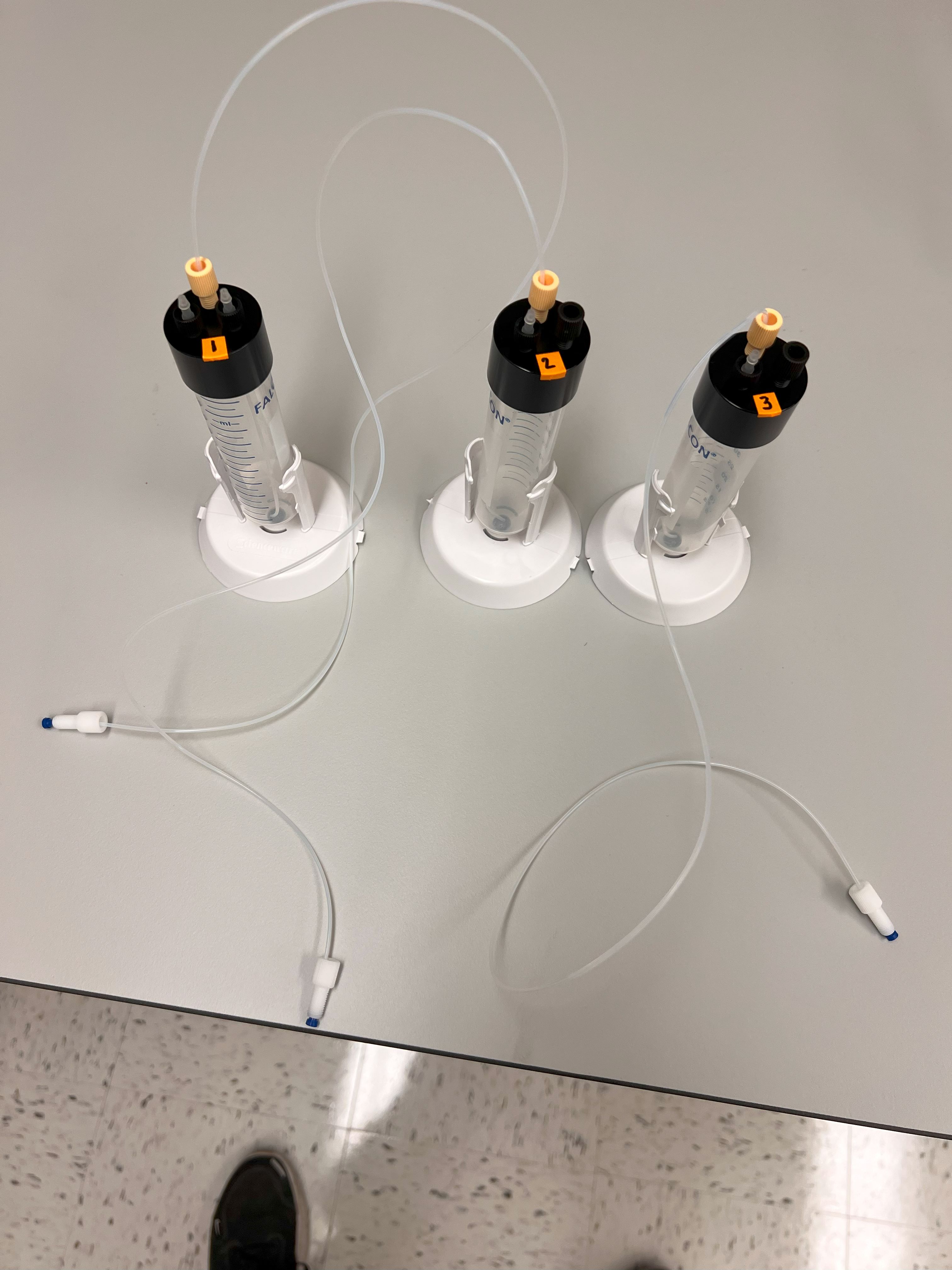

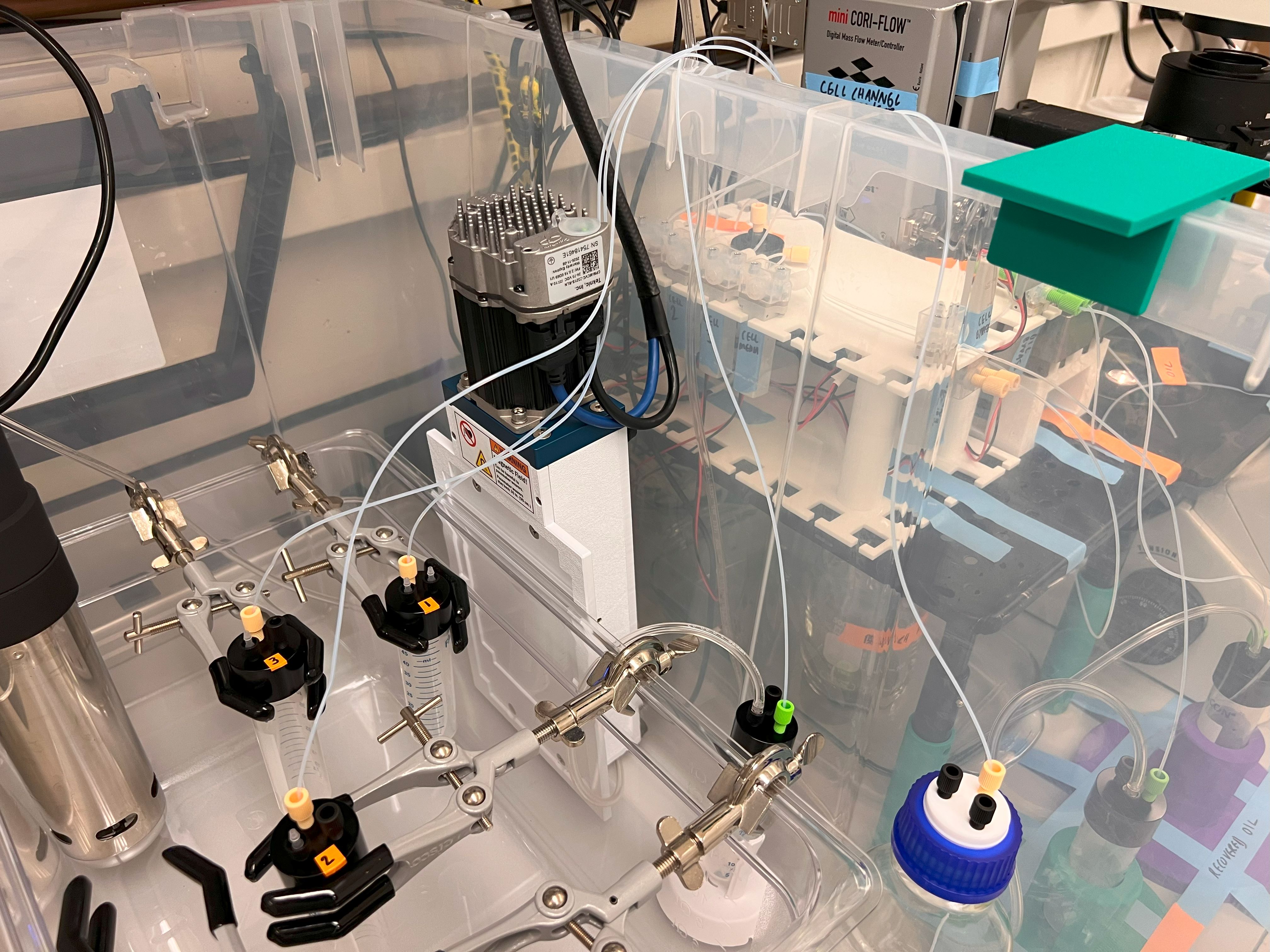

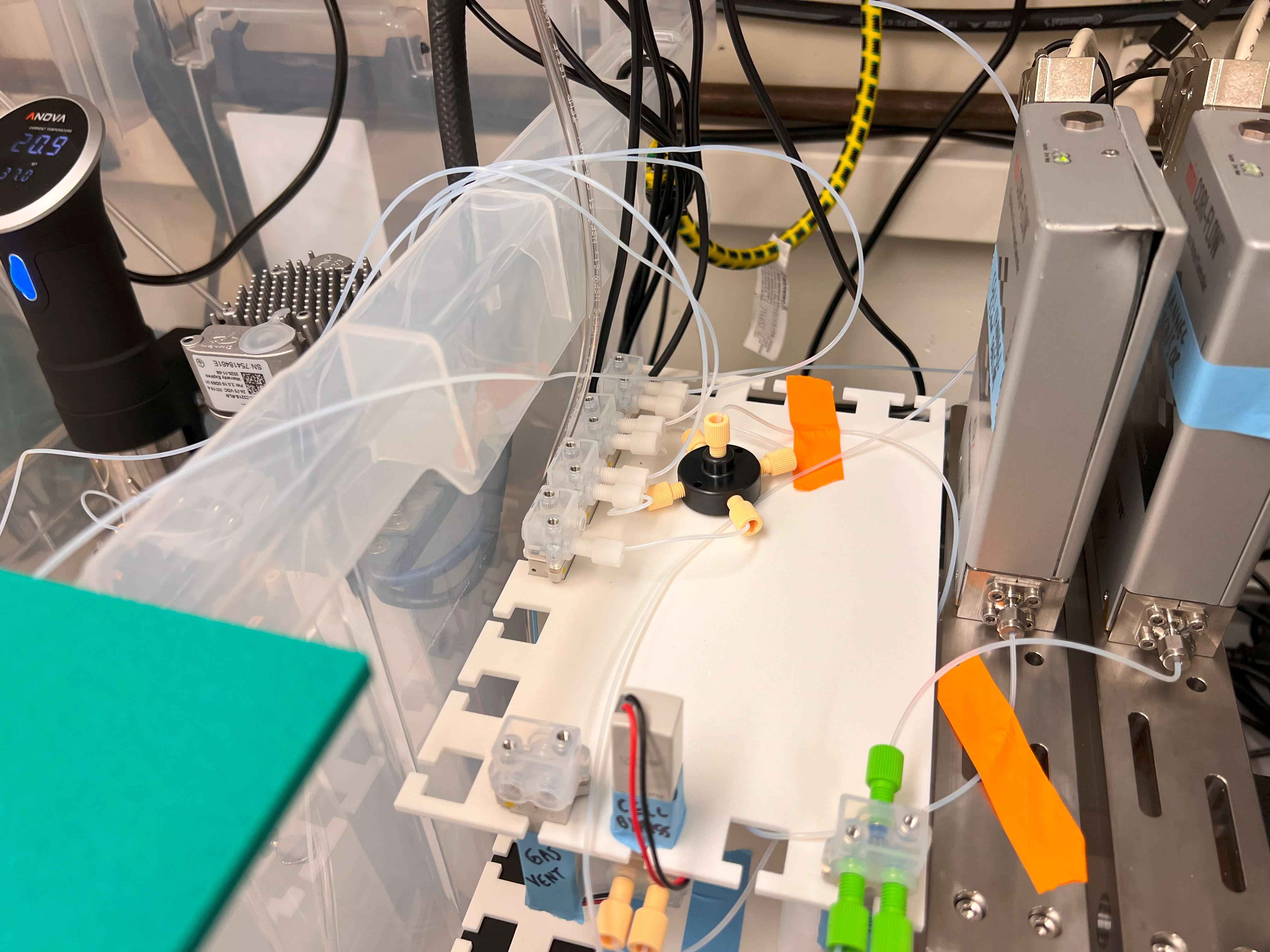

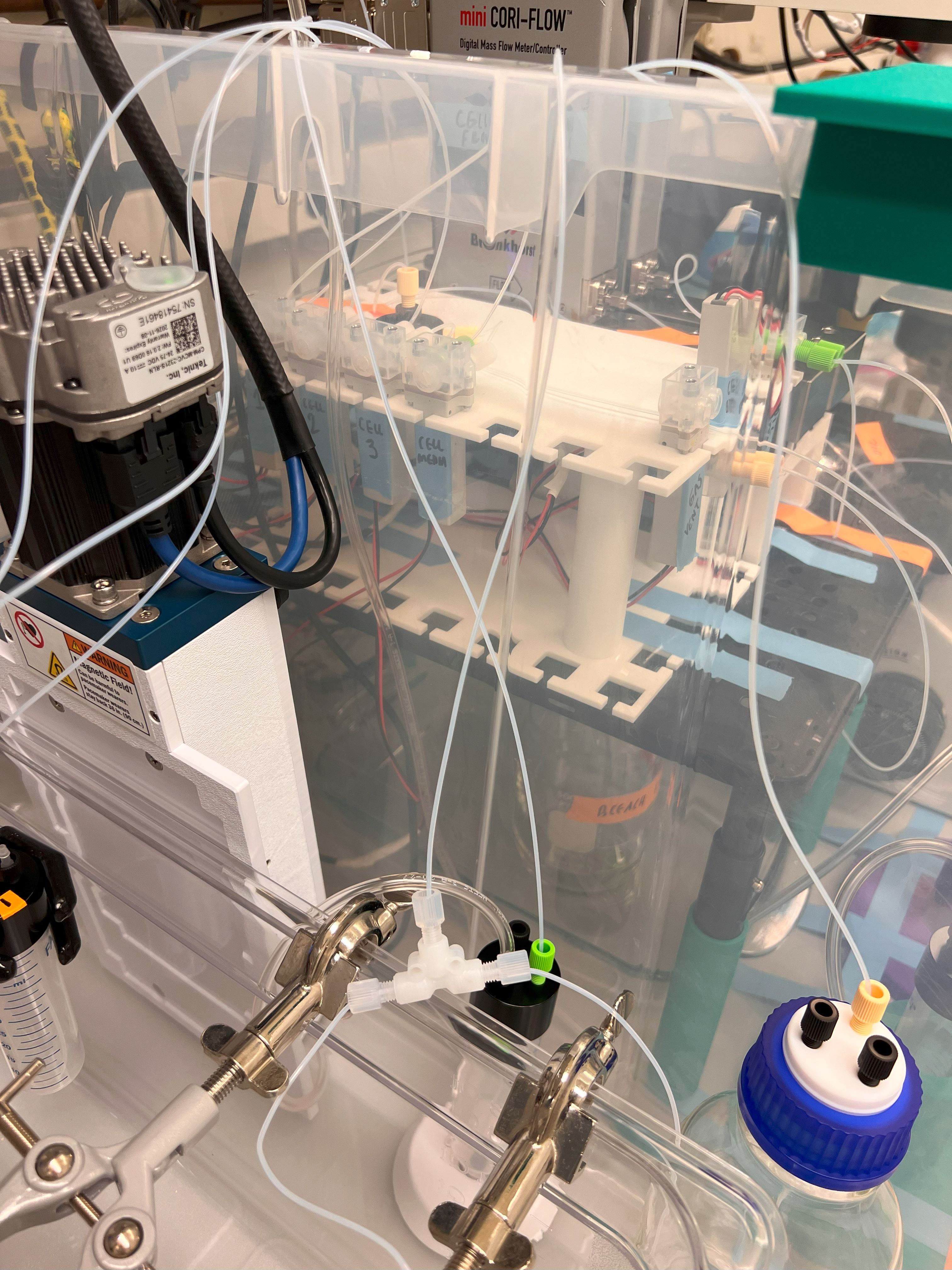

Cell Channel Flow Meter ID: 3000

error 0 :

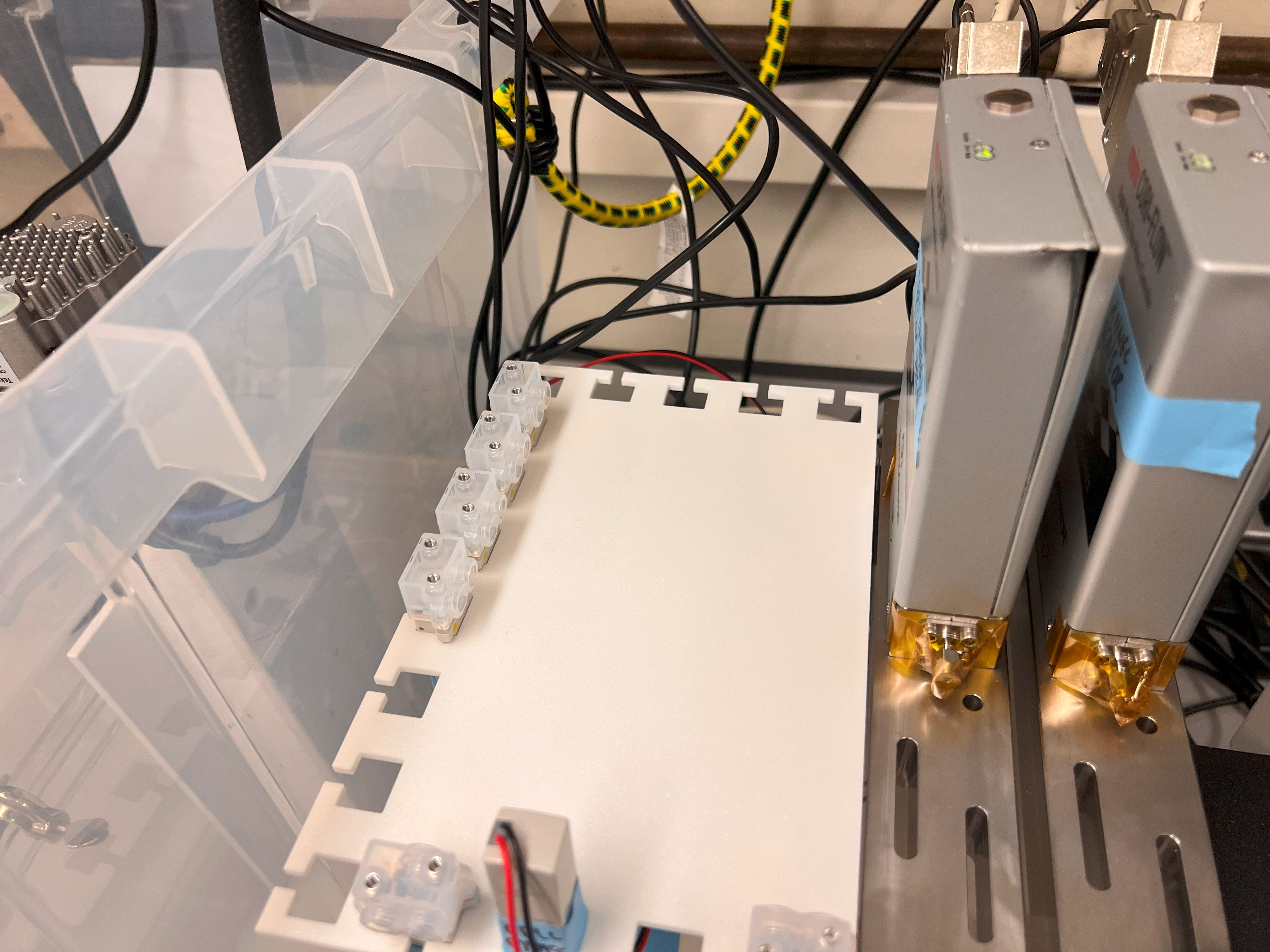

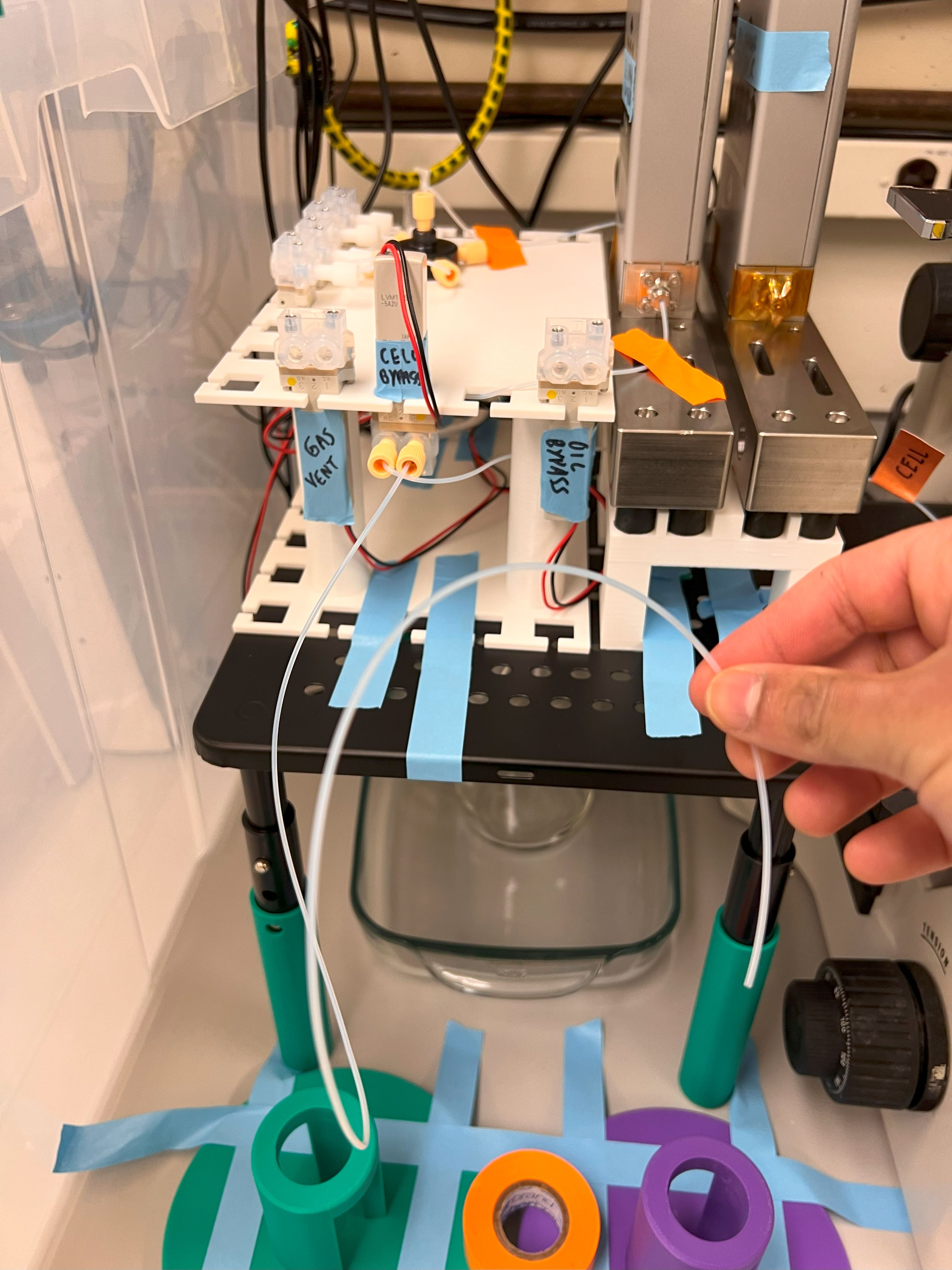

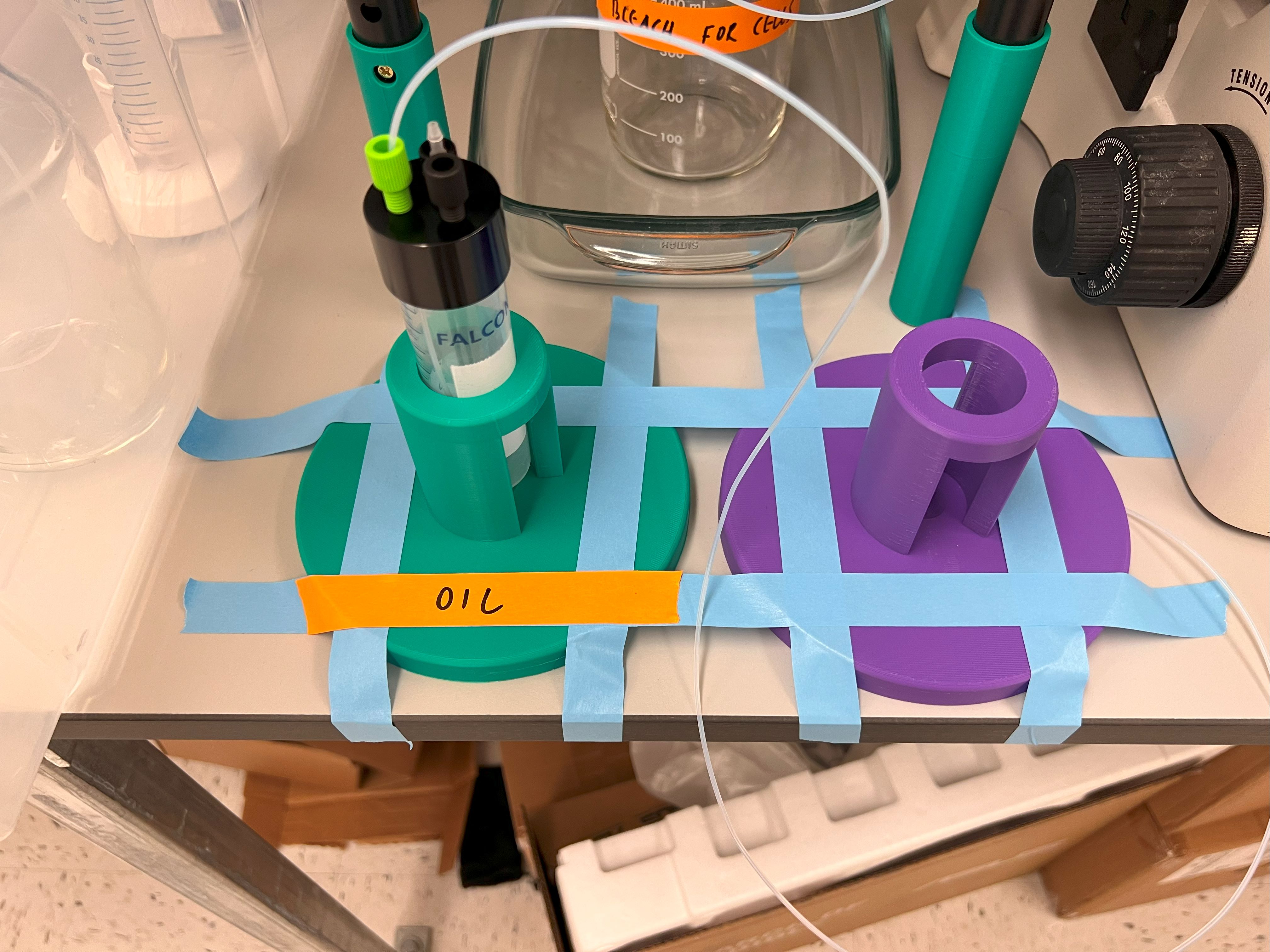

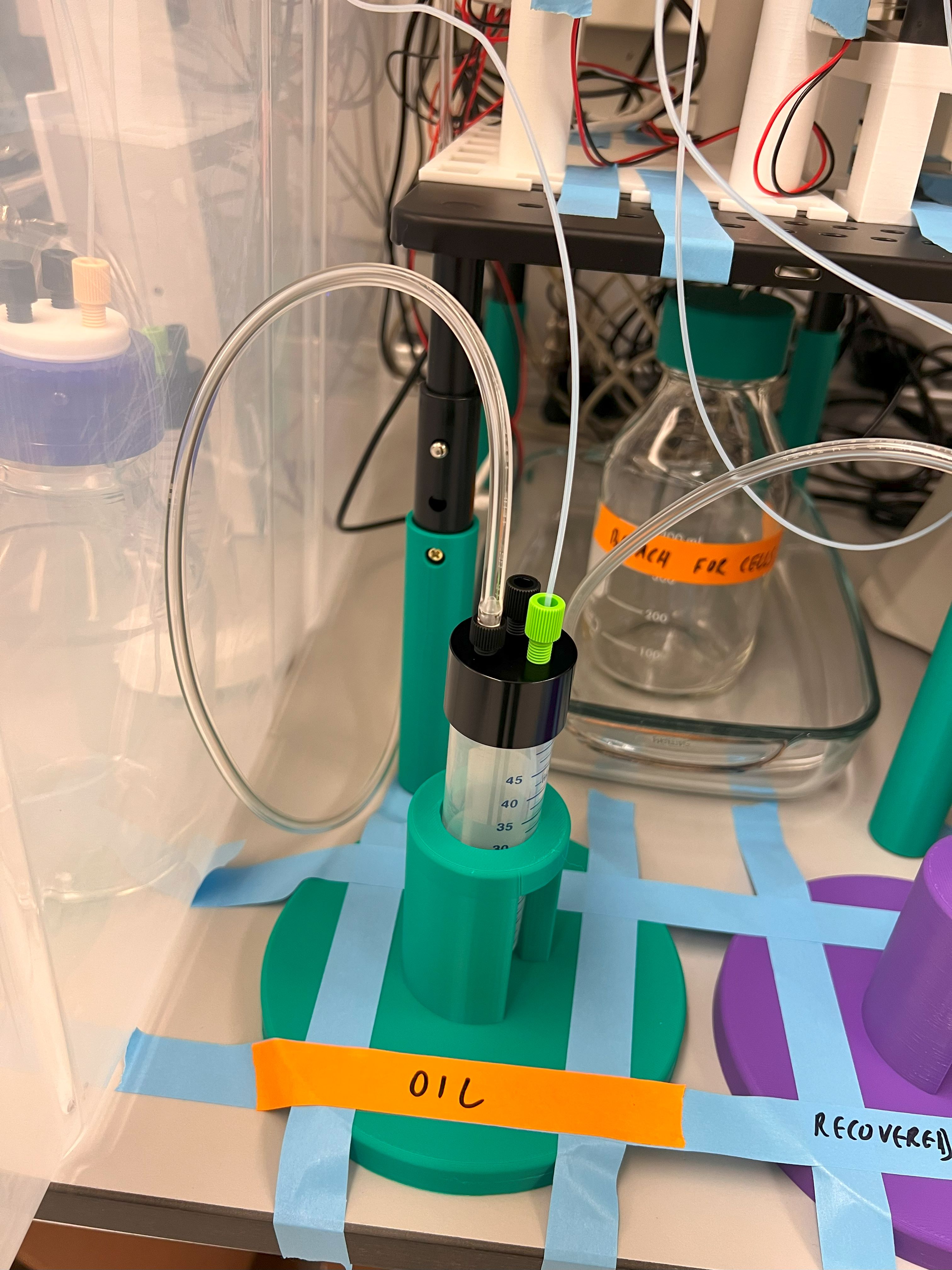

Oil Channel Flow Meter ID: 3001

error 0 :

Cell Channel Density:

1.2680259943008423

Cell Channel Flow rate:

-1103.77129063566

Oil Channel Density:

2.1396427154541016

Oil Channel Flow rate:

-1381.2710424672853

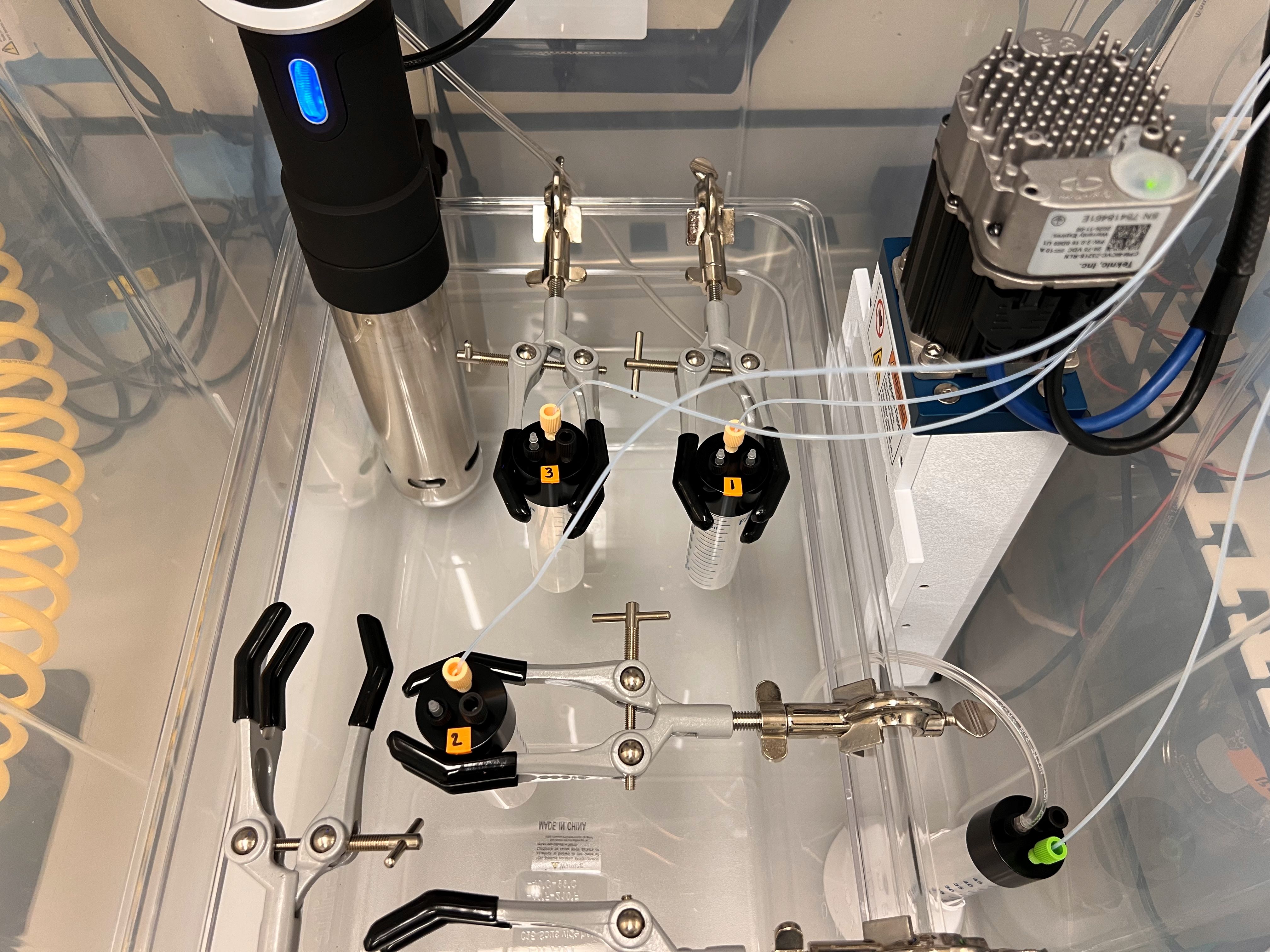

COM15

{'baudrate': 9600, 'bytesize': 8, 'parity': 'N', 'stopbits': 1, 'xonxoff': False, 'dsrdtr': False, 'rtscts': False, 'timeout': 1, 'write_timeout': 1, 'inter_byte_timeout': None}

True

COM9

{'baudrate': 9600, 'bytesize': 8, 'parity': 'N', 'stopbits': 1, 'xonxoff': False, 'dsrdtr': False, 'rtscts': False, 'timeout': 1, 'write_timeout': 1, 'inter_byte_timeout': None}

True

COM7

{'baudrate': 9600, 'bytesize': 8, 'parity': 'N', 'stopbits': 1, 'xonxoff': False, 'dsrdtr': False, 'rtscts': False, 'timeout': 1, 'write_timeout': 1, 'inter_byte_timeout': None}

True

COM10

{'baudrate': 9600, 'bytesize': 8, 'parity': 'N', 'stopbits': 1, 'xonxoff': False, 'dsrdtr': False, 'rtscts': False, 'timeout': 1, 'write_timeout': 0, 'inter_byte_timeout': None}

True

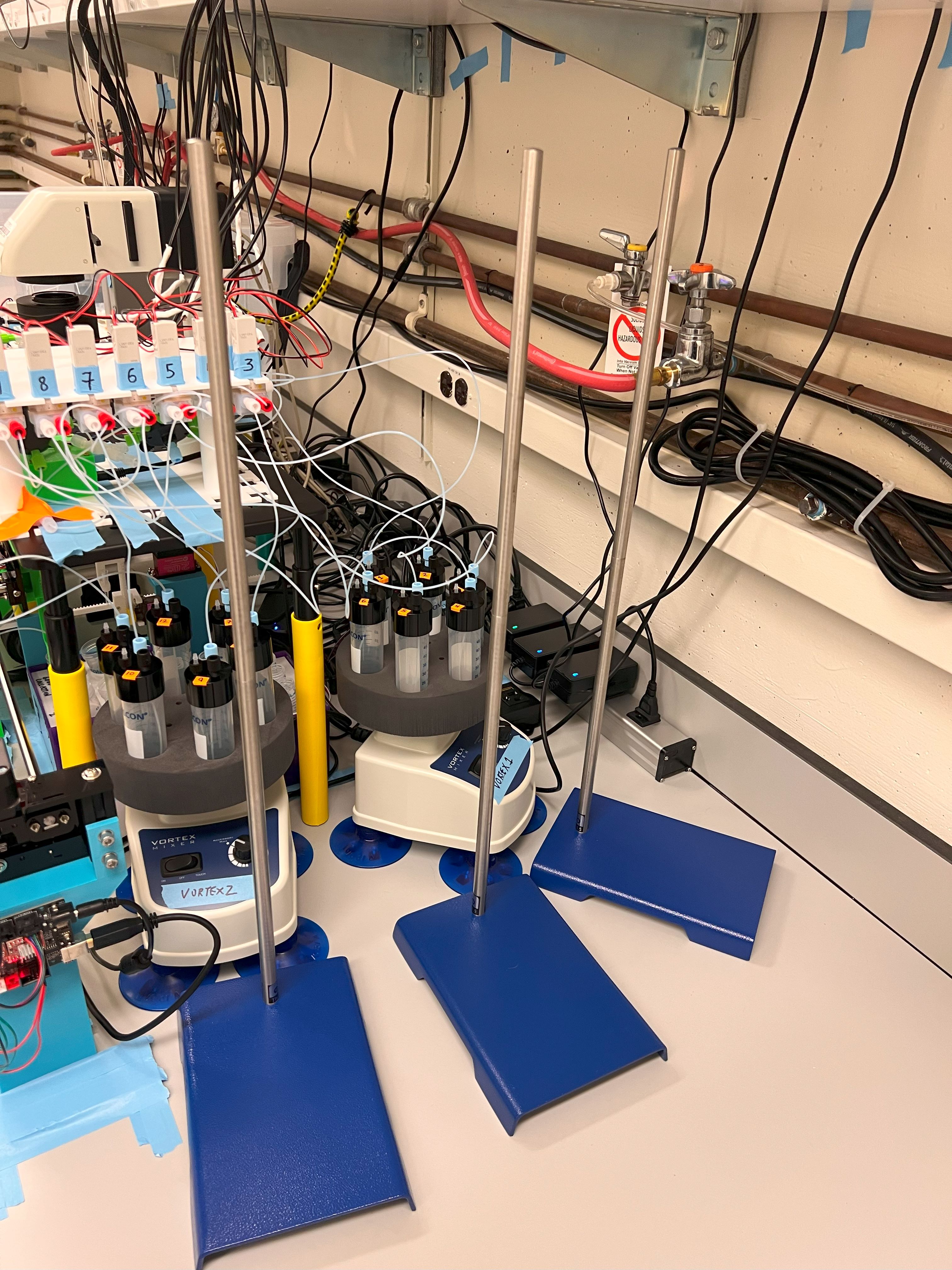

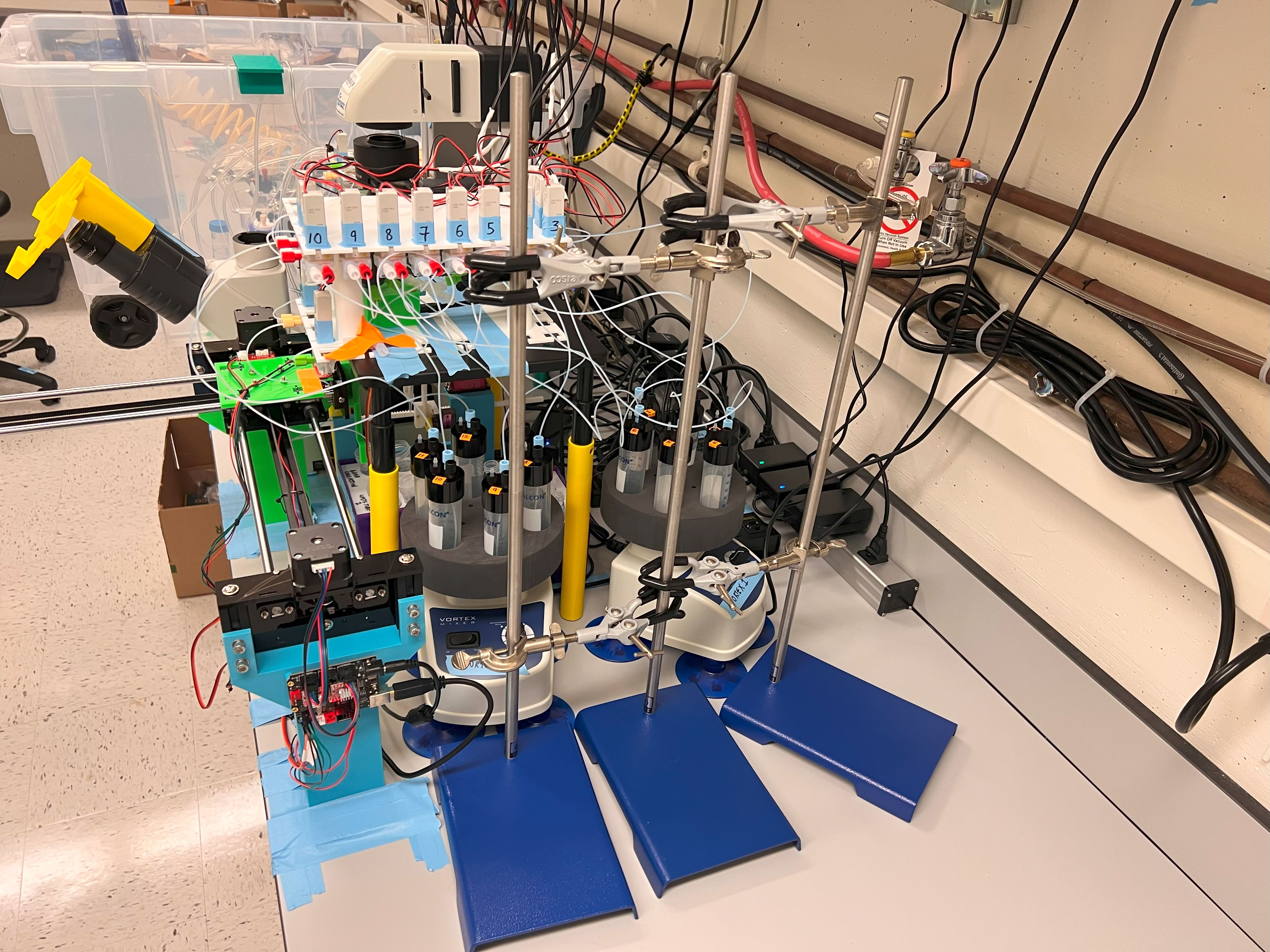

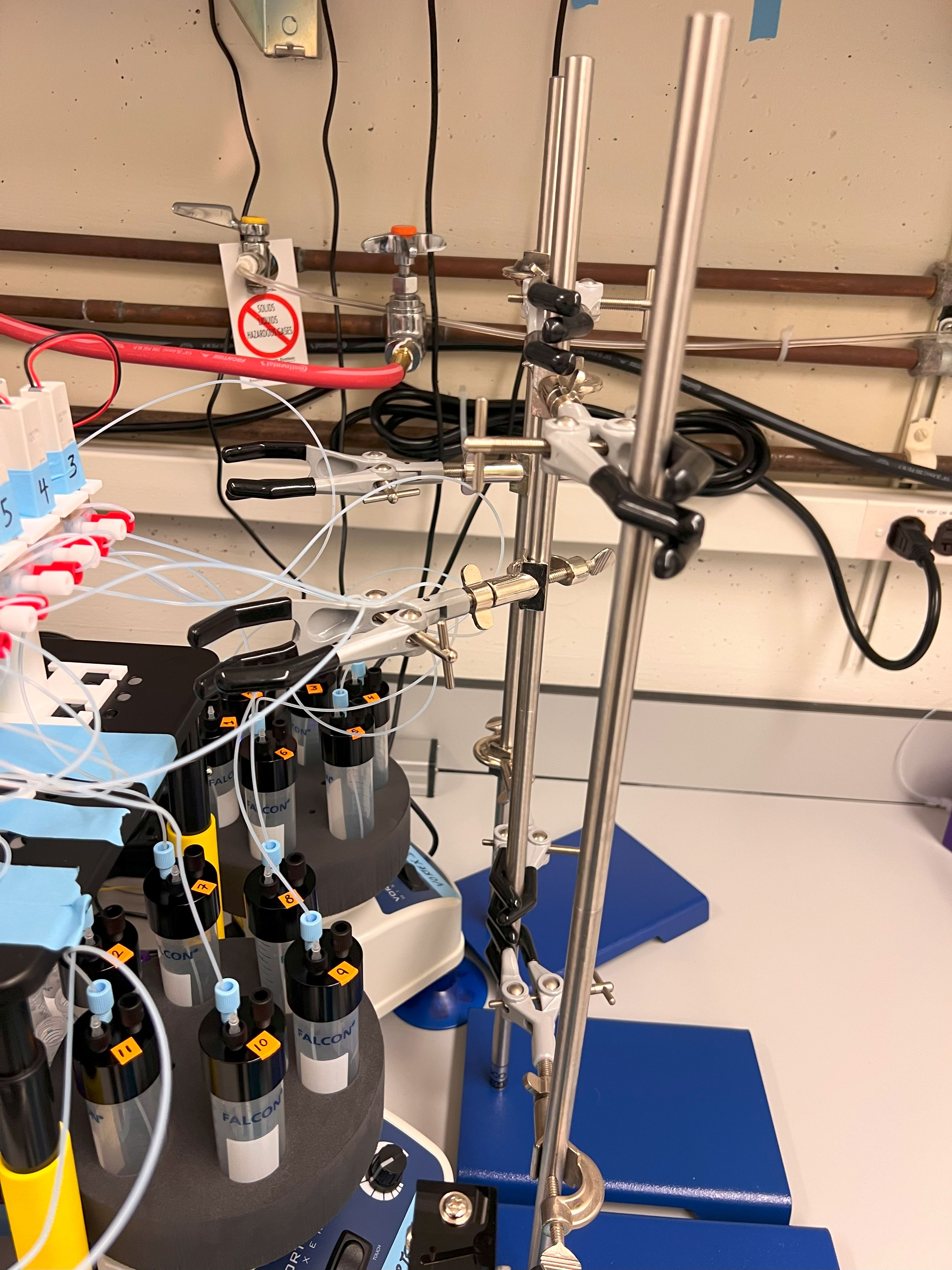

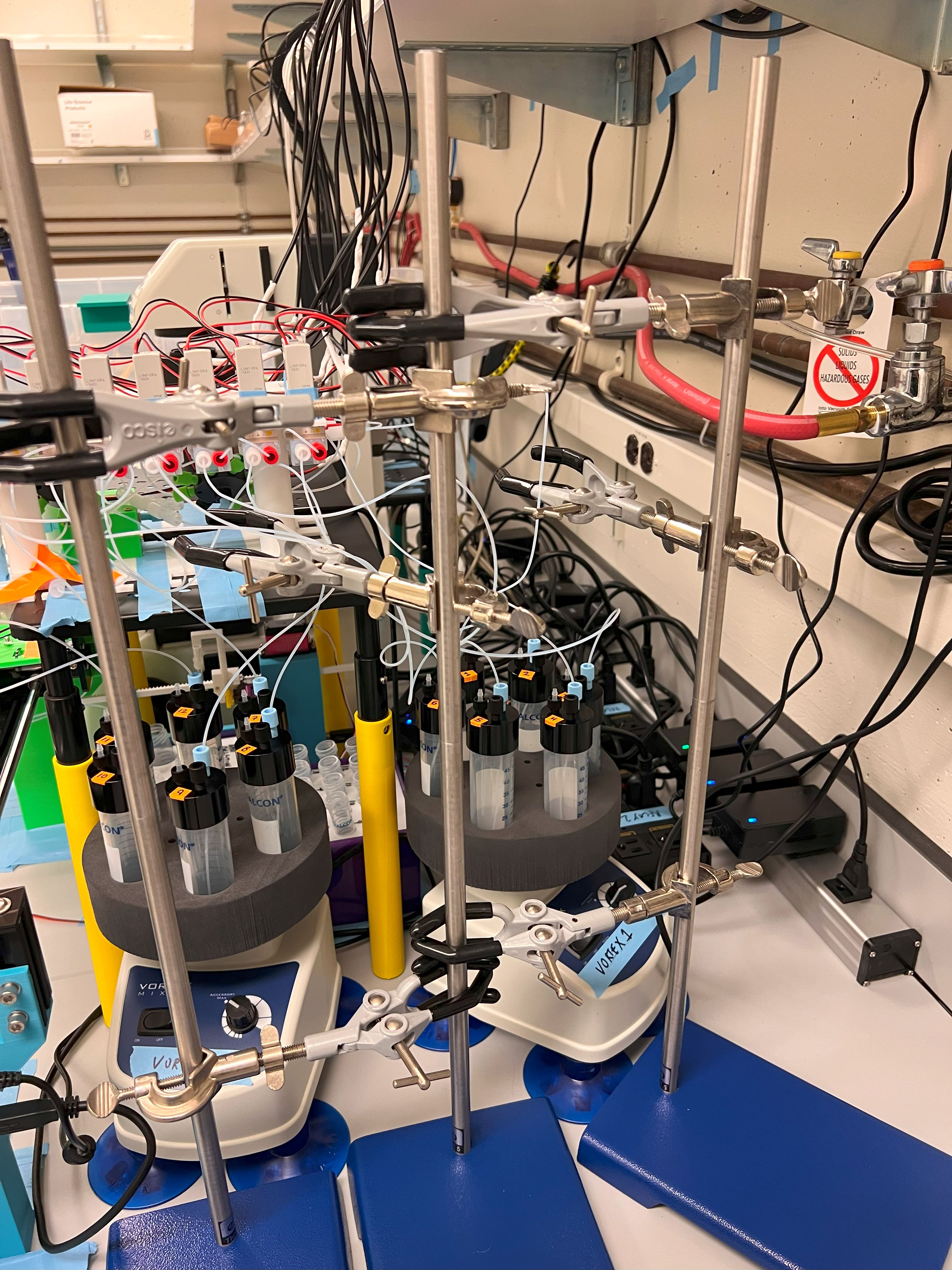

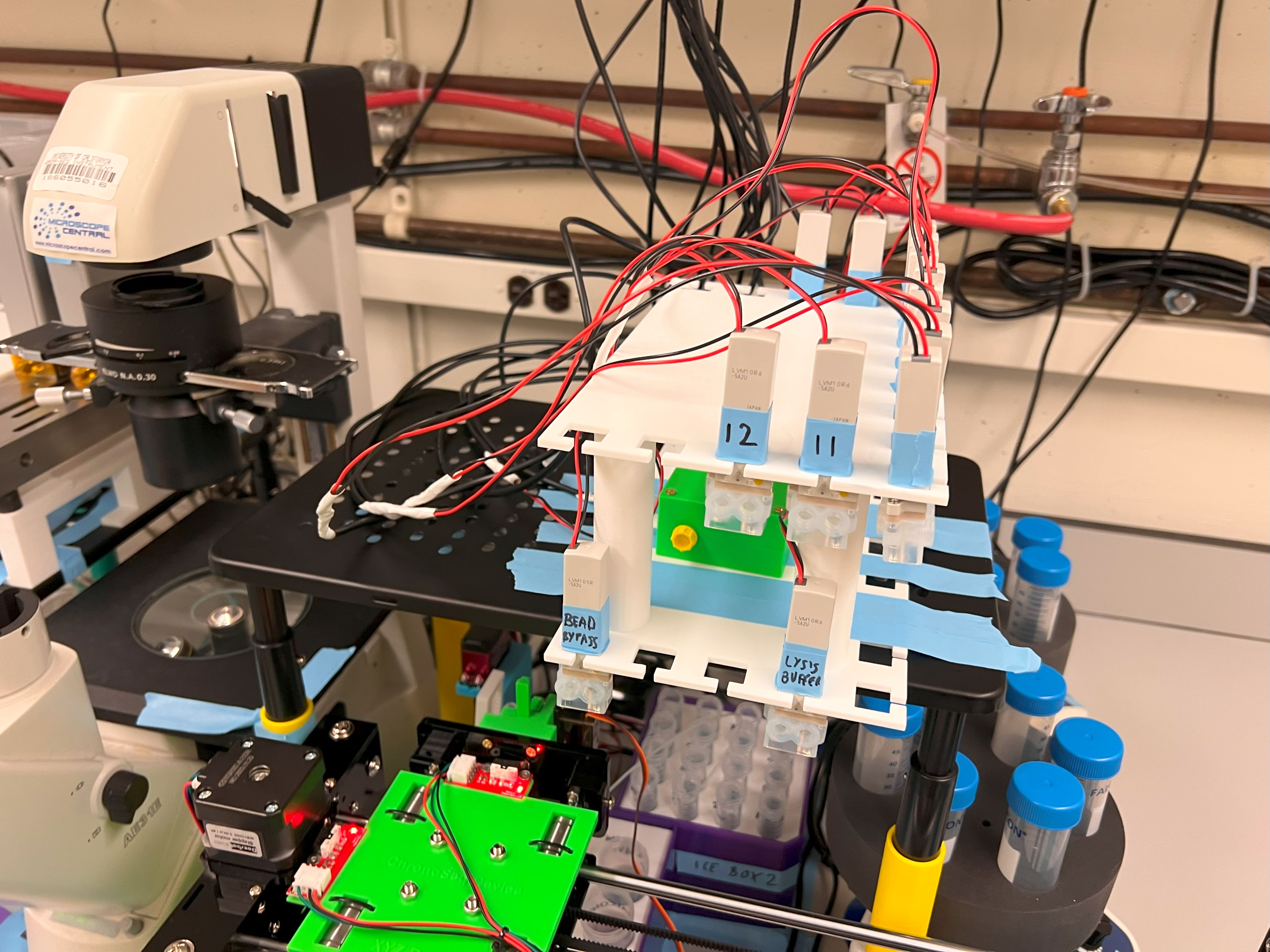

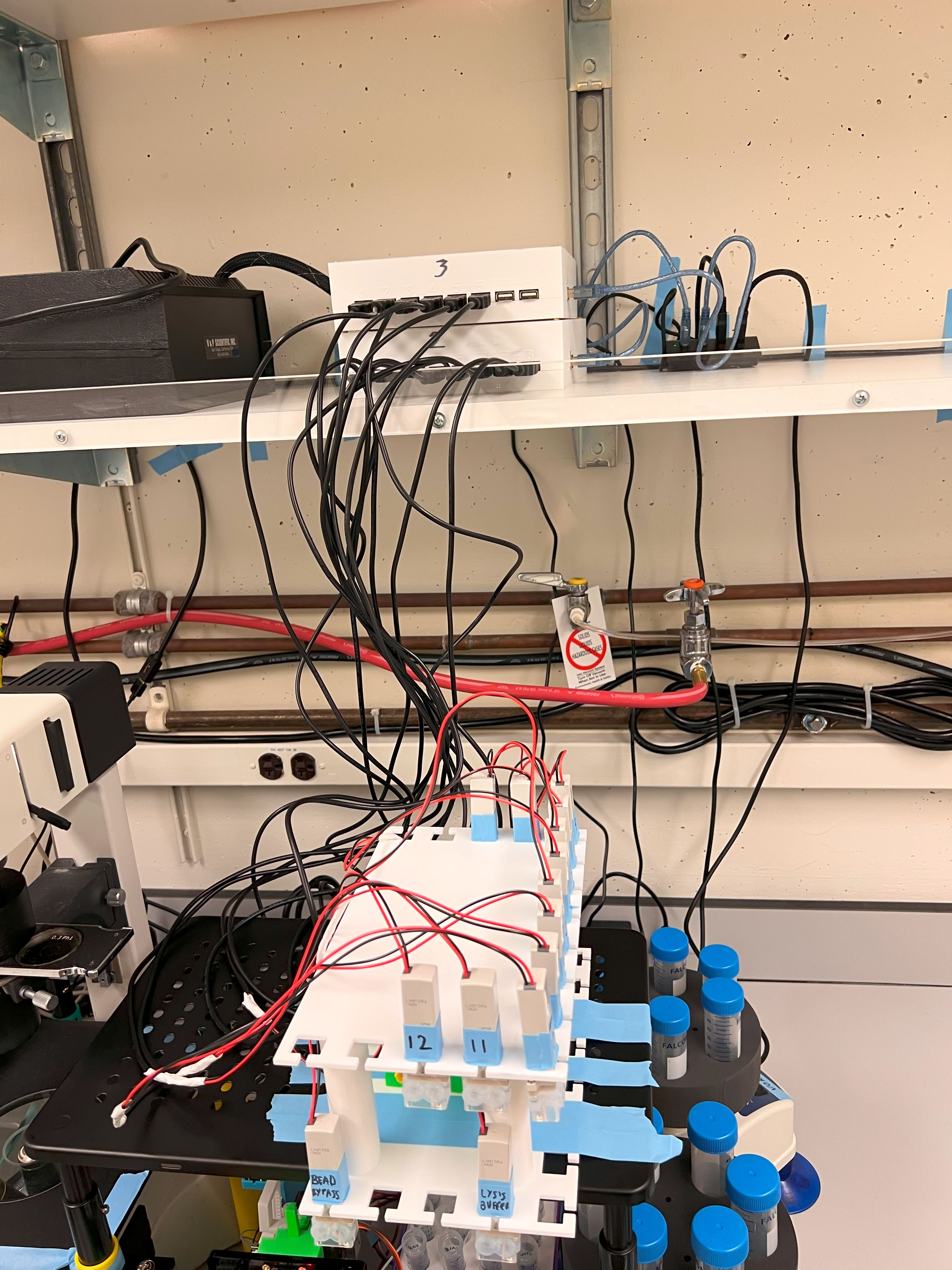

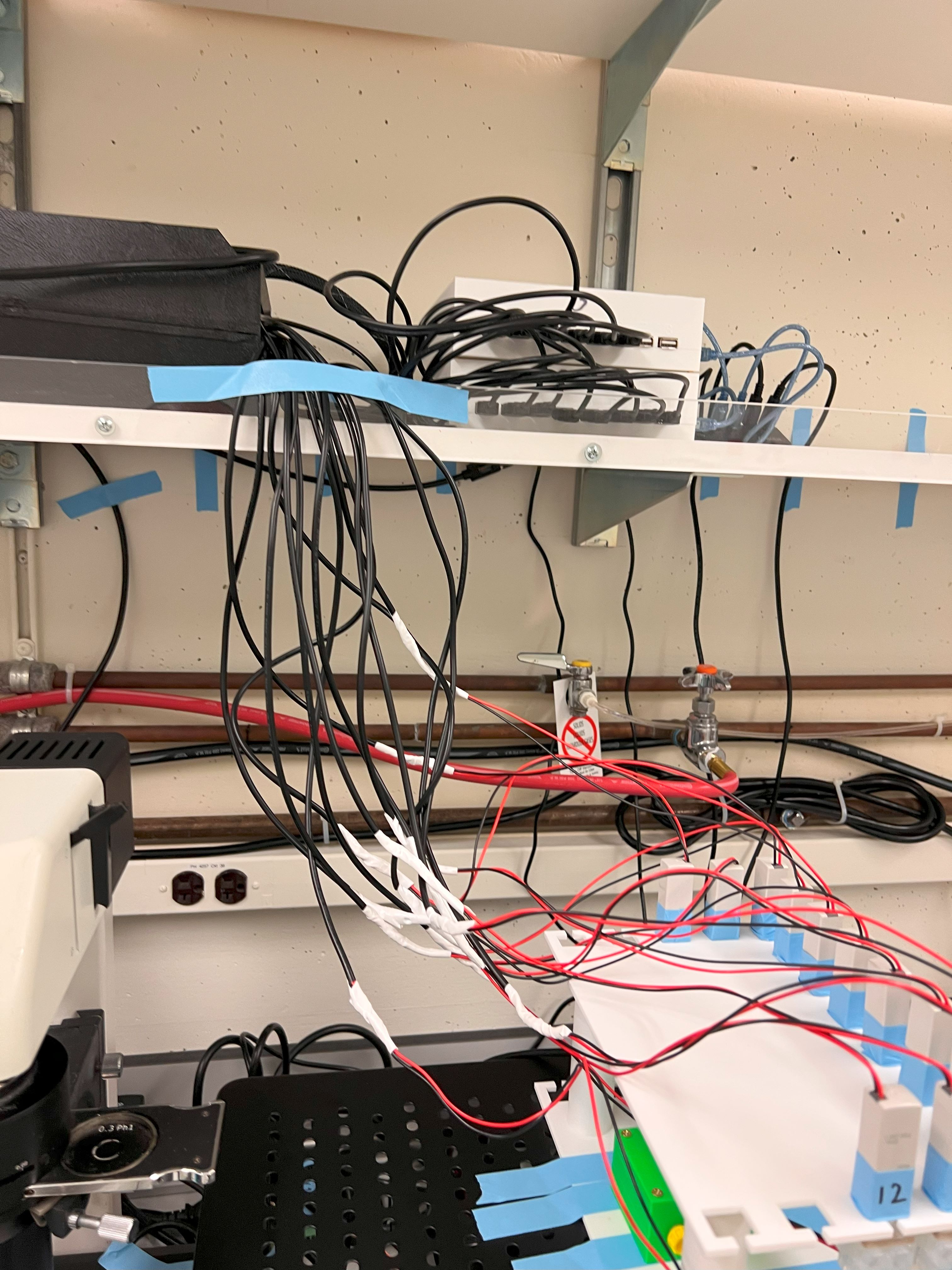

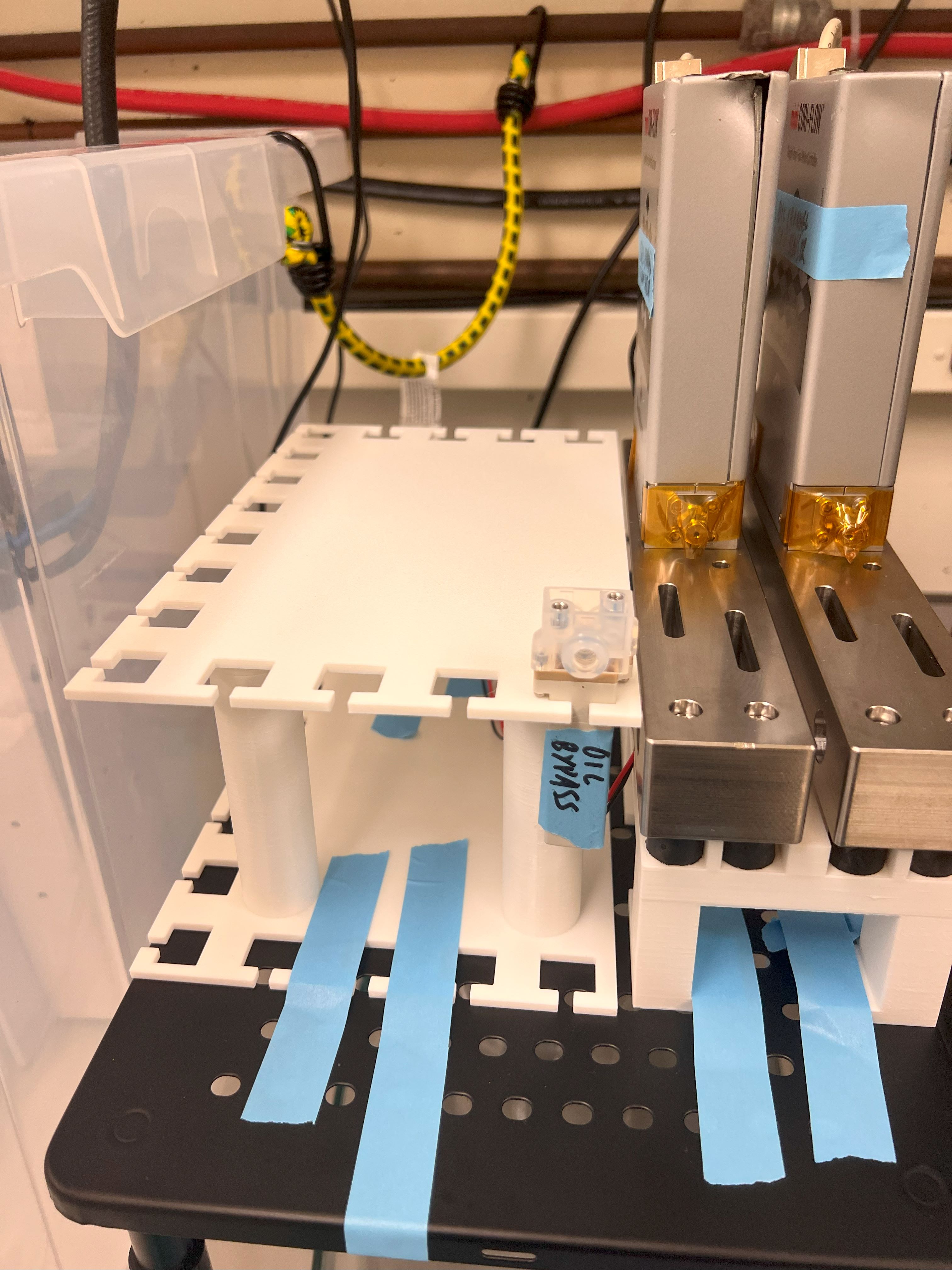

.jpg)

.jpg)