Instructions for the ChronoSeq Device assembly from Individual Components¶

Design of equipment.¶

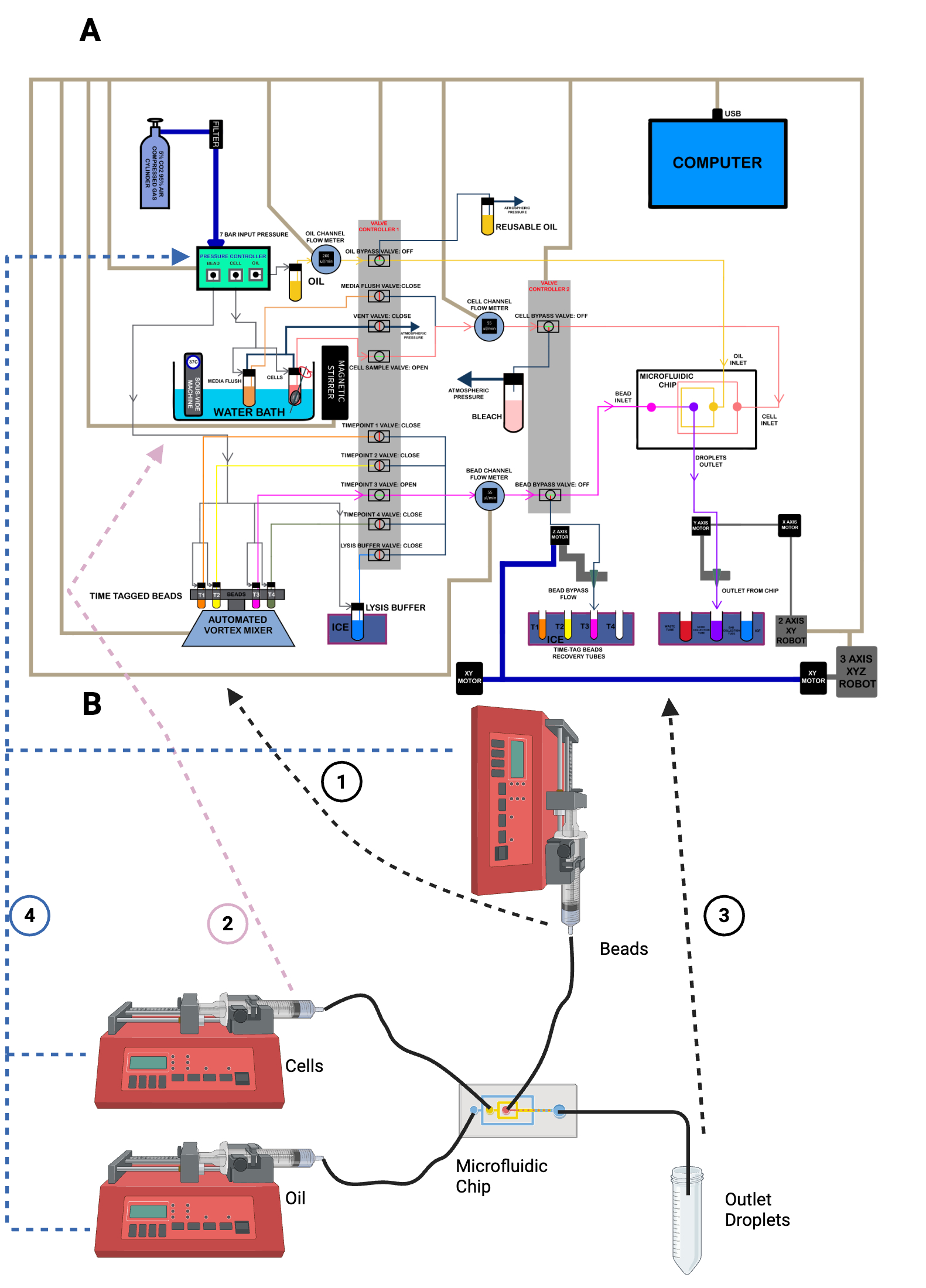

Our device design addresses several challenges not present in the original Dropseq system (See Figure Below). First, extended cell viability. We maintain cell suspension viability for experiments lasting 2 hours or longer, compared to typical 30-minute Dropseq runs. Second, cross-contamination prevention. We implemented a washing system to remove unused cells or beads between samples. Third, sample isolation. We designed a system to prevent mixing wash fluid with droplets. To address these challenges, our device operates in two main phases during each injection cycle. 1. Flushing phase that clears fluid lines of residual beads or cells from previous injections. 2. Injection phase that precisely introduces cells and time-tagged beads into the microfluidic chip. This integrated system enables controlled, sequential introduction of cells and time-tagged beads, capturing gene expression dynamics across multiple time points in a single experiment.

ChronoSeq vs Dropseq comparison |

|---|

|

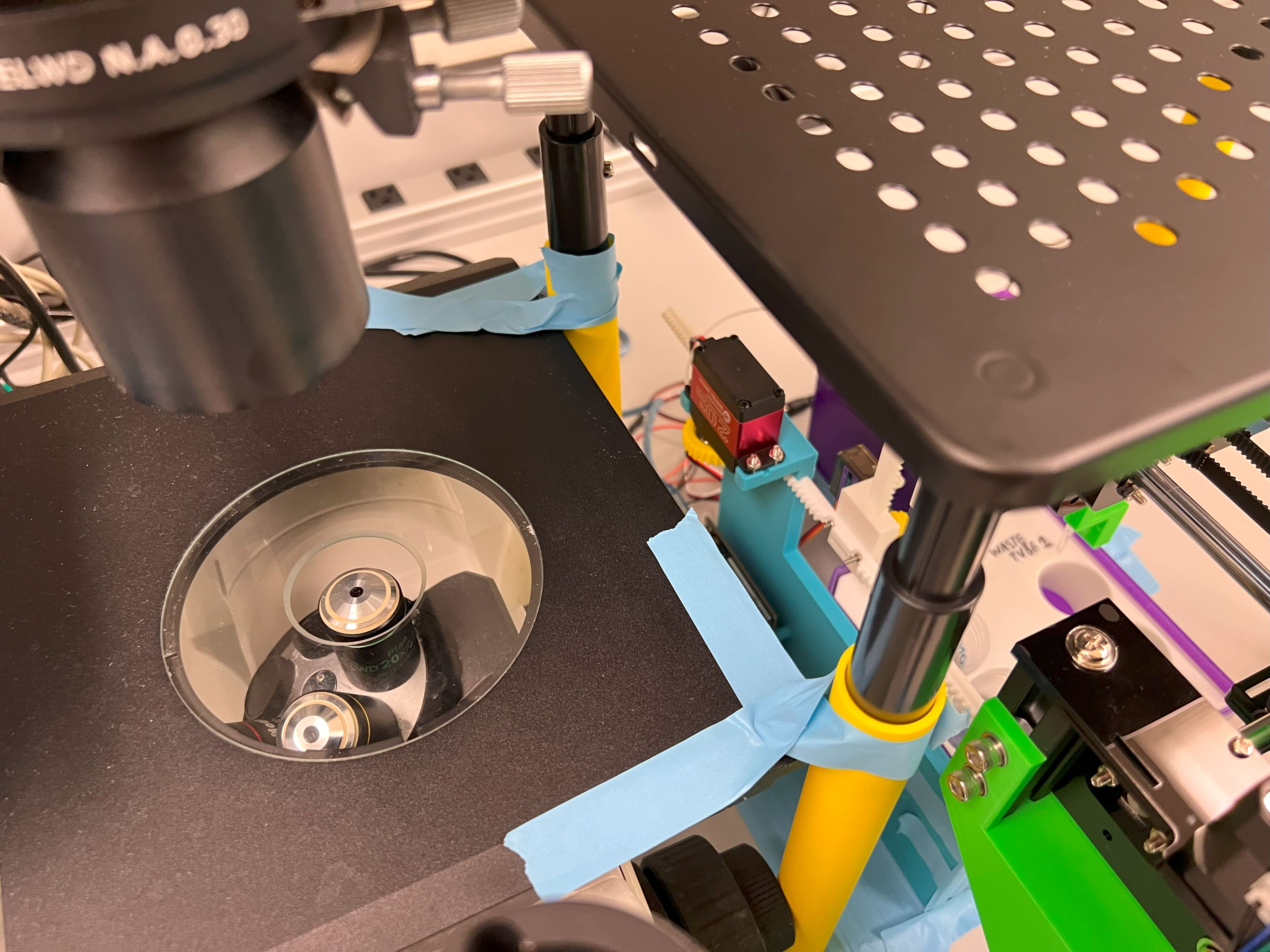

The Figure above compares the ChronoSeq device (A) with Dropseq device (B).¶

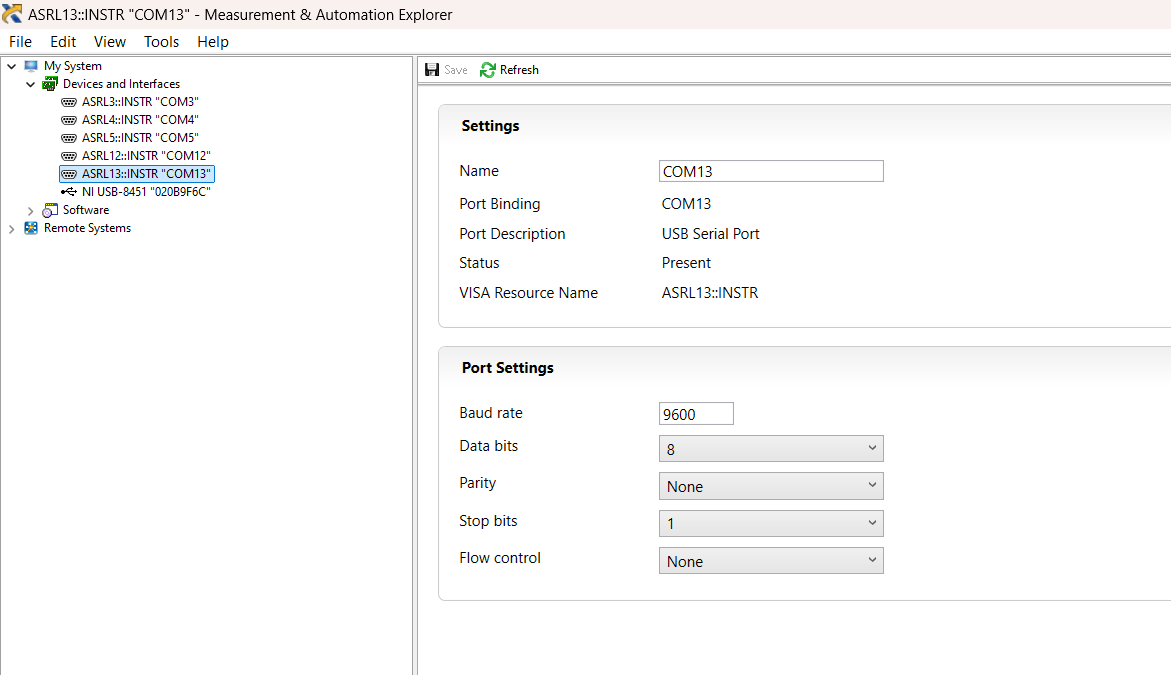

The ChronoSeq device is controlled via serial connections to a computer, which coordinates the actions of its various components, while the Dropseq device works by setting flow rates manually on syringe pumps. Some key features distinguish the ChronoSeq device:

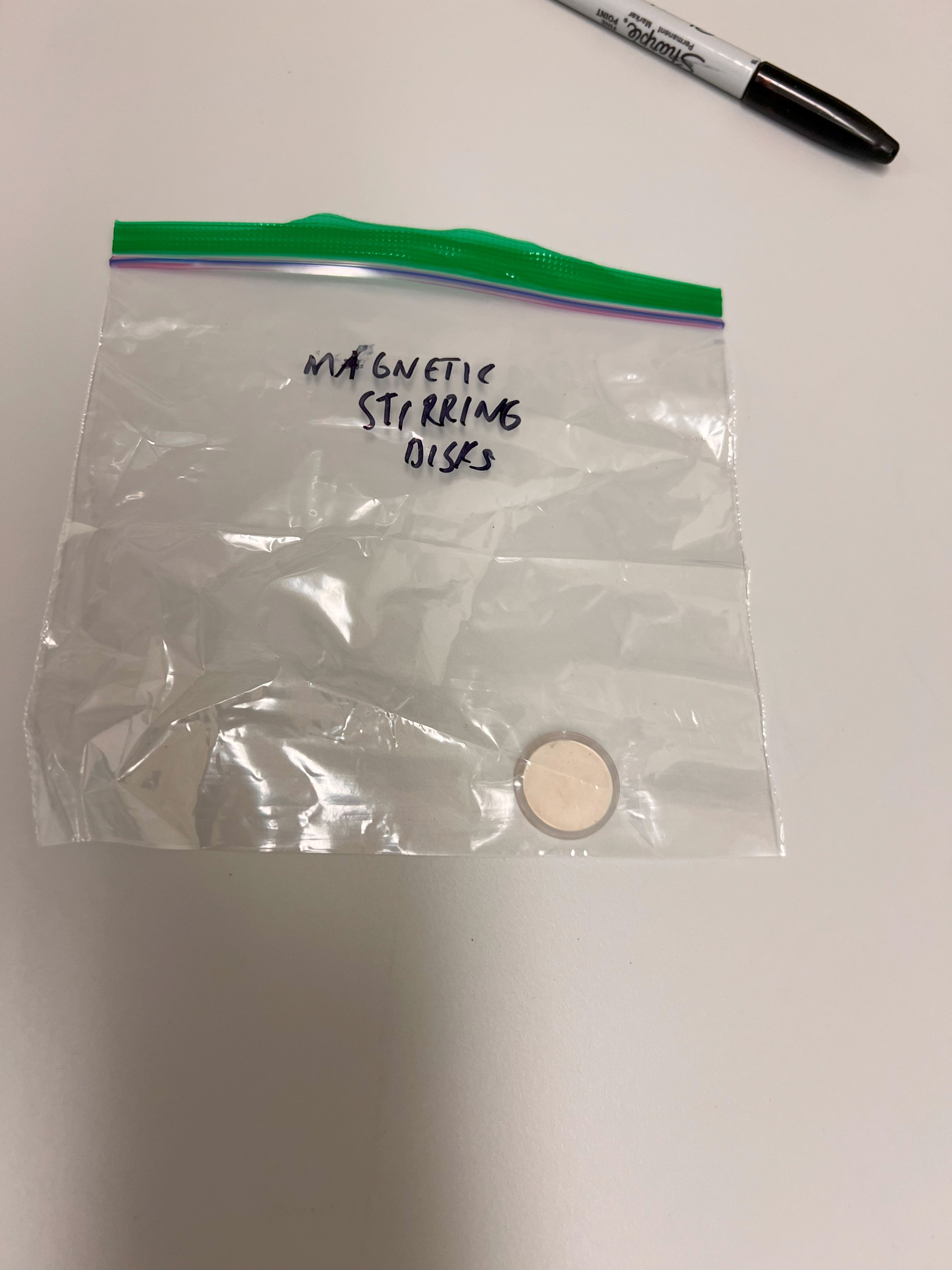

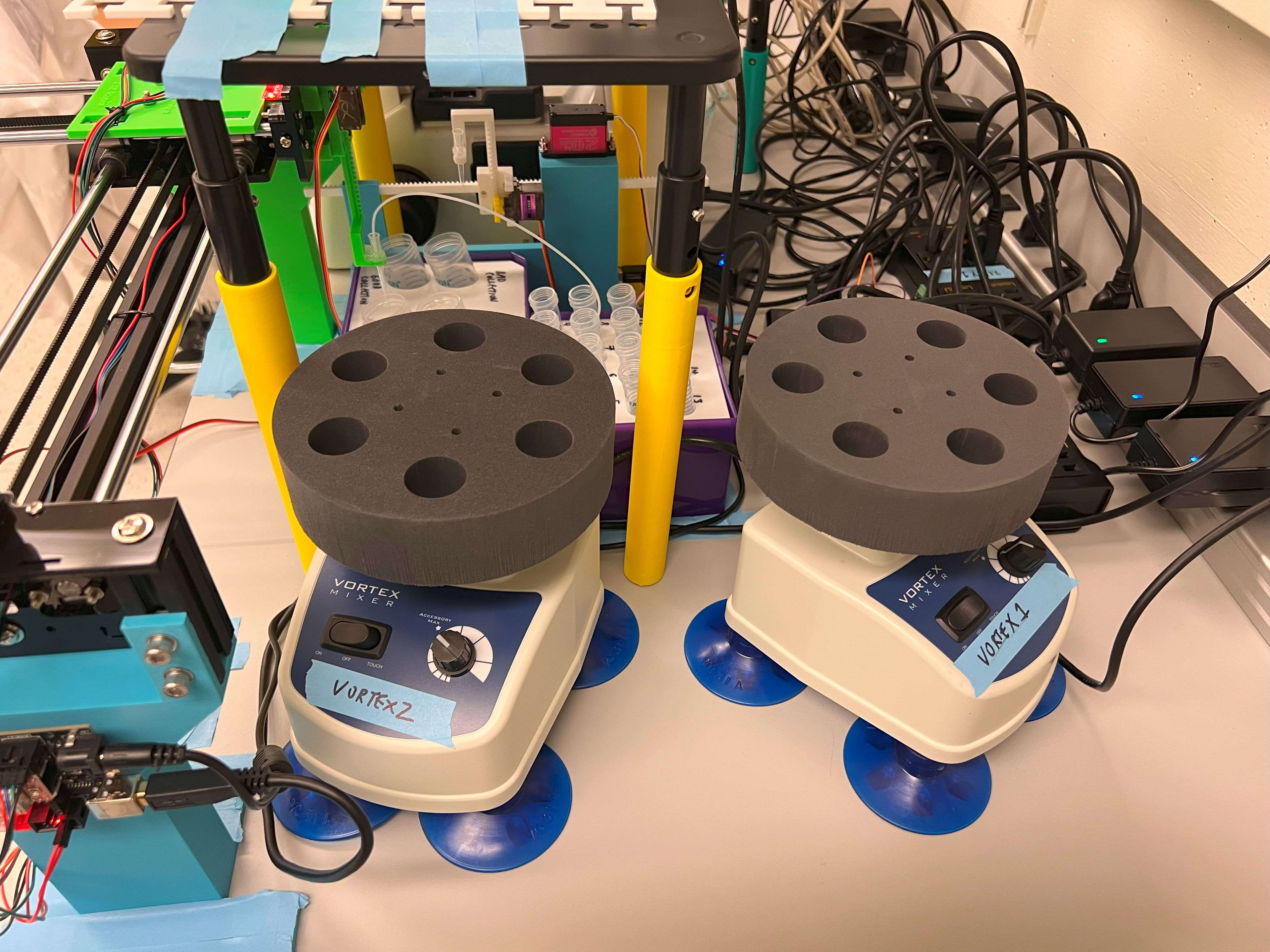

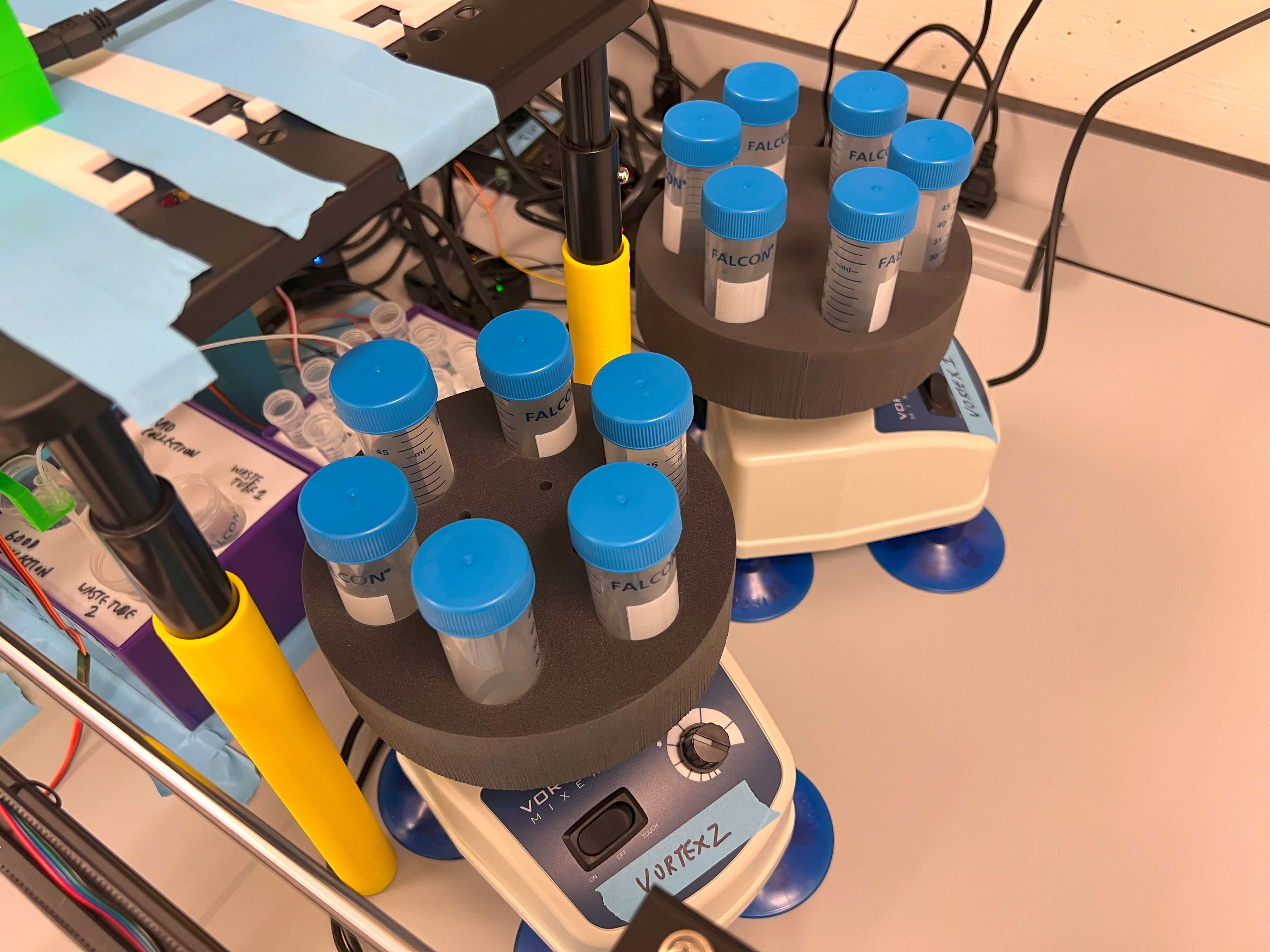

- Bead handling: ChronoSeq incorporates an automated vortex mixer to keep the beads evenly suspended before injection. Dropseq uses a magnetic stirrer for bead suspension, which leads to high dead volumes and complicates automation for multiple time-tags. ChronoSeq allows for the easy addition of more time-tags in the future if necessary. Additionally, loading and unloading the beads is simplified; we can directly screw a new 50 mL tube containing beads into the reservoir. The time-tagged bead reservoirs are connected to timepoint valves, which facilitate the selection of the appropriate time-tagged beads for injection into the microfluidic chip.

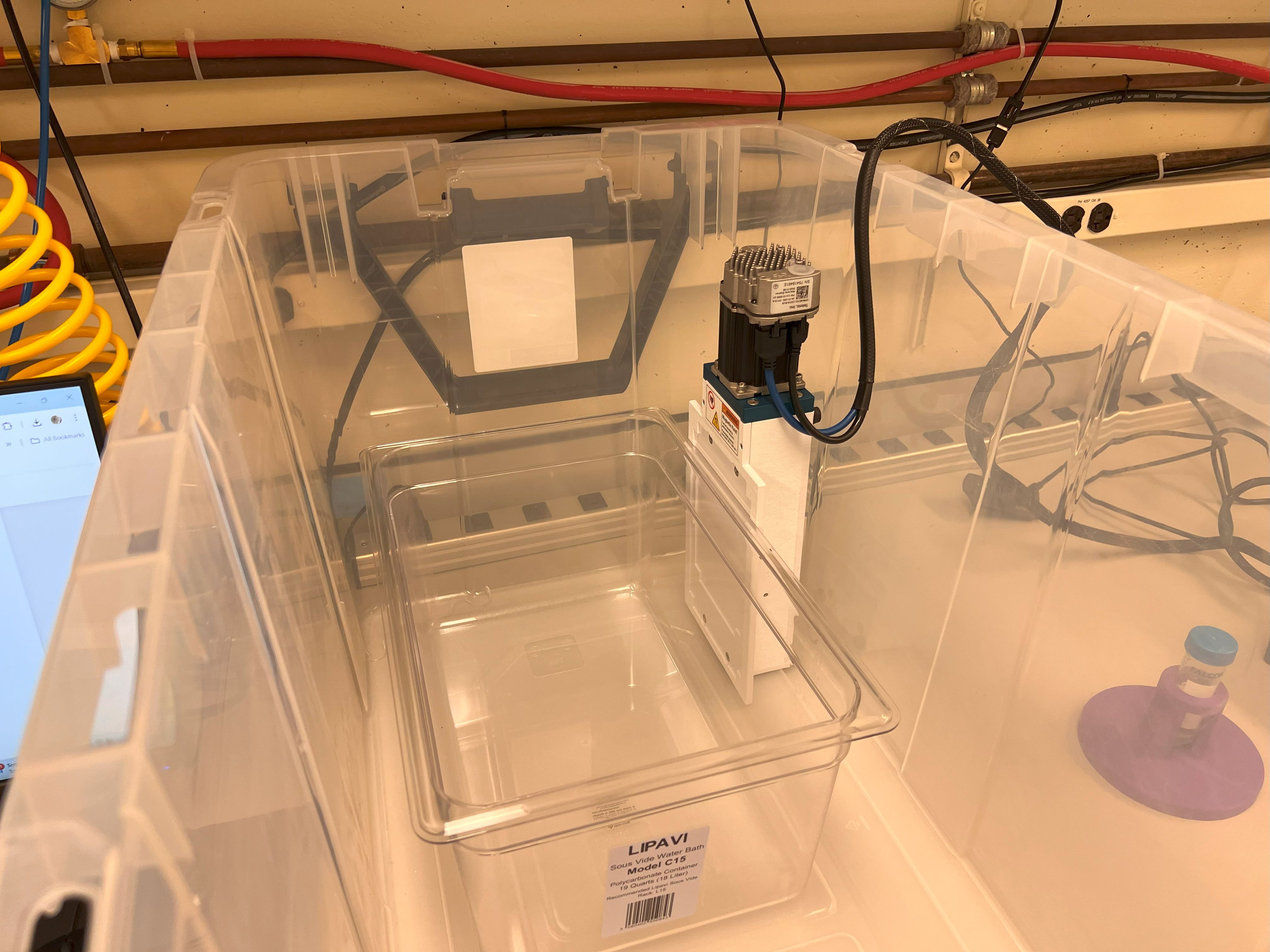

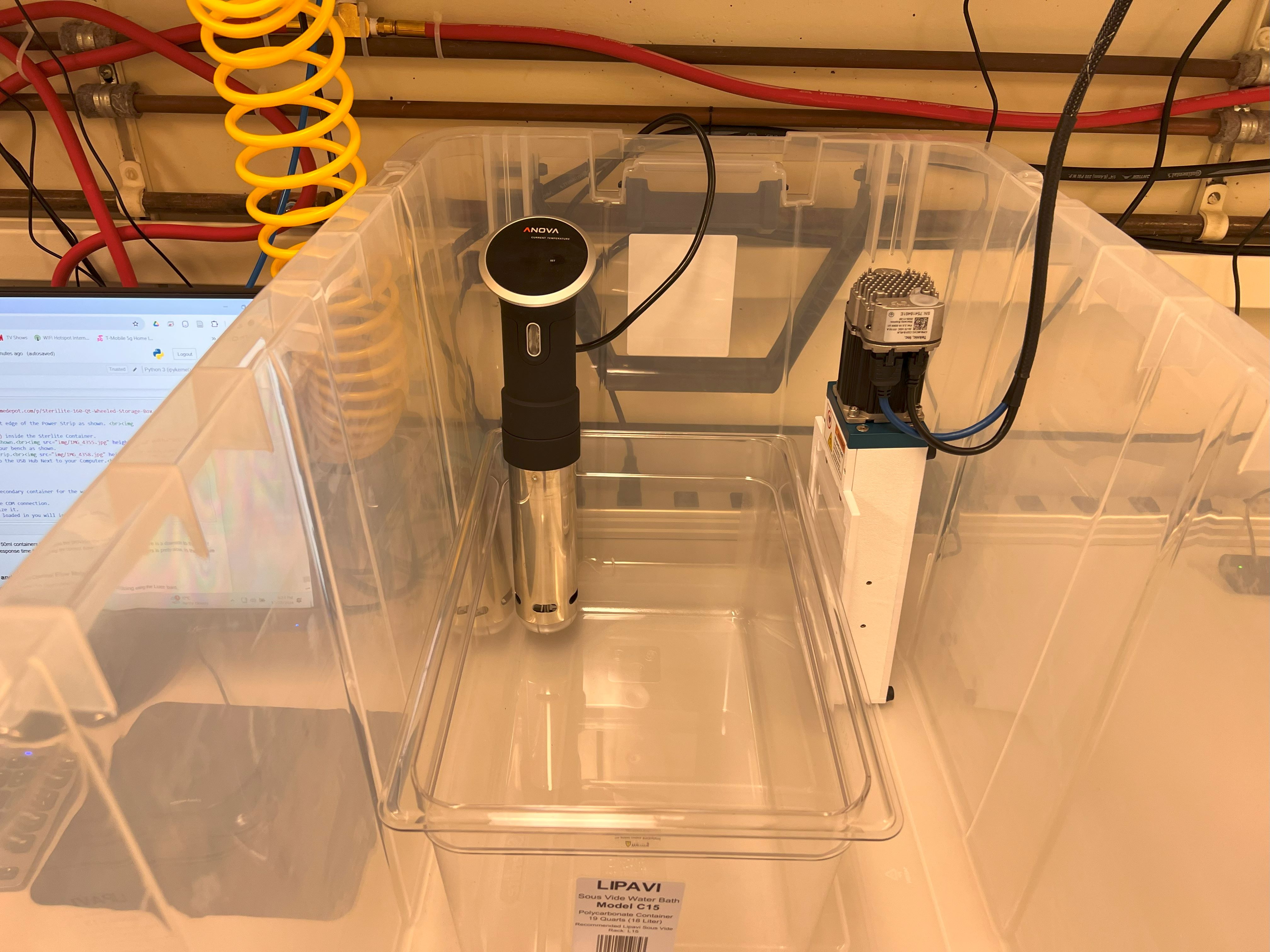

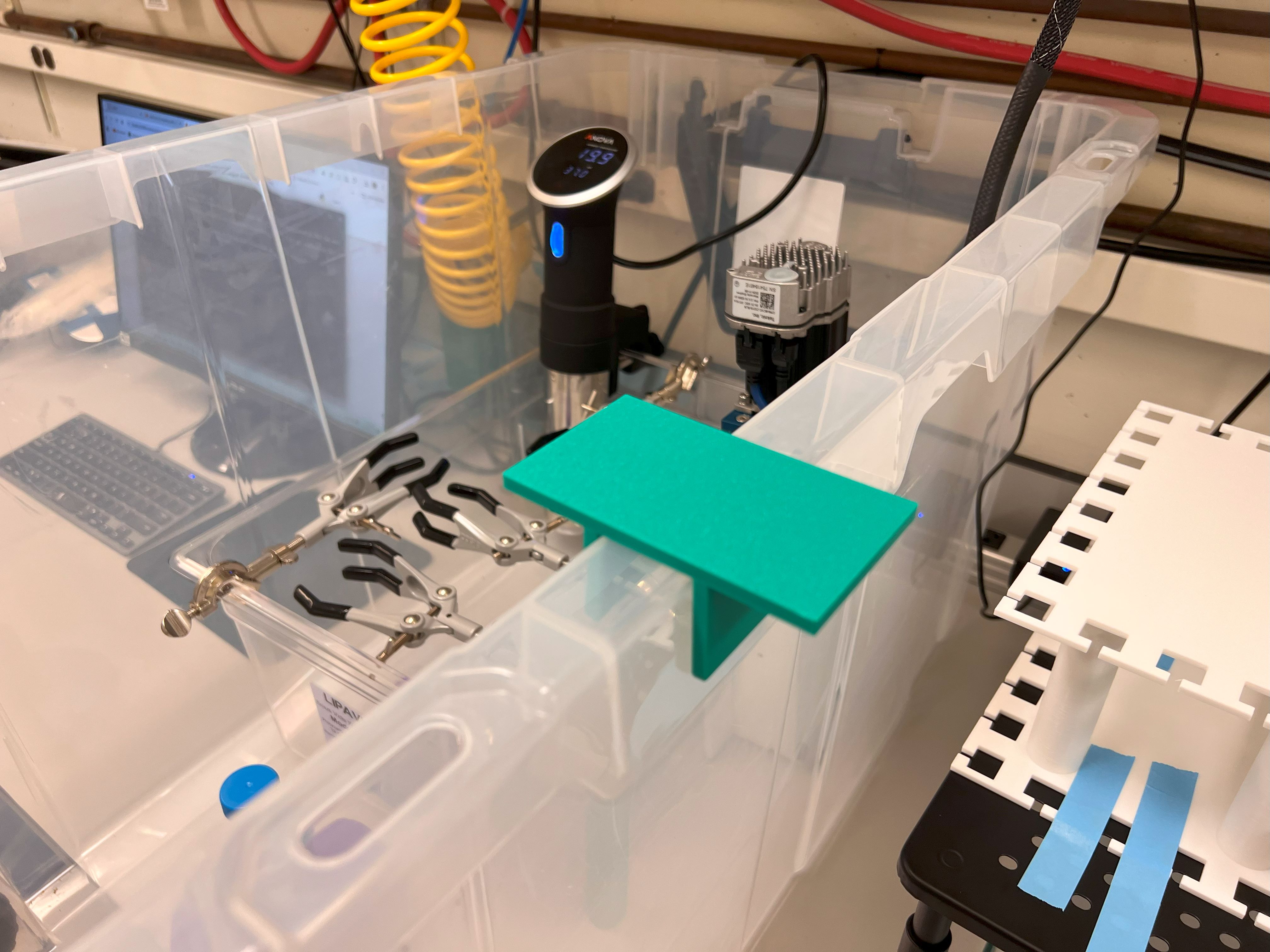

- Cell culture system: In the Dropseq device, cells are directly loaded into a syringe for injection, typically running for 15 to 30 minutes. However, our goal is to maintain cell viability for at least 2 hours. Leaving cells at room temperature without growth media and in the absence of 5% CO2 can lead to excessive cell death and unwanted perturbations. To address this, we have integrated a cell culture system directly into the ChronoSeq device, featuring a water bath to maintain cells at 37°C, along with a 5% CO2 gas cylinder that serves as a pressure source and aids in cell culture. Furthermore, we can add additional tubes to culture multiple cell suspensions separately and use valves to select which cell suspension is injected into the microfluidic chip.

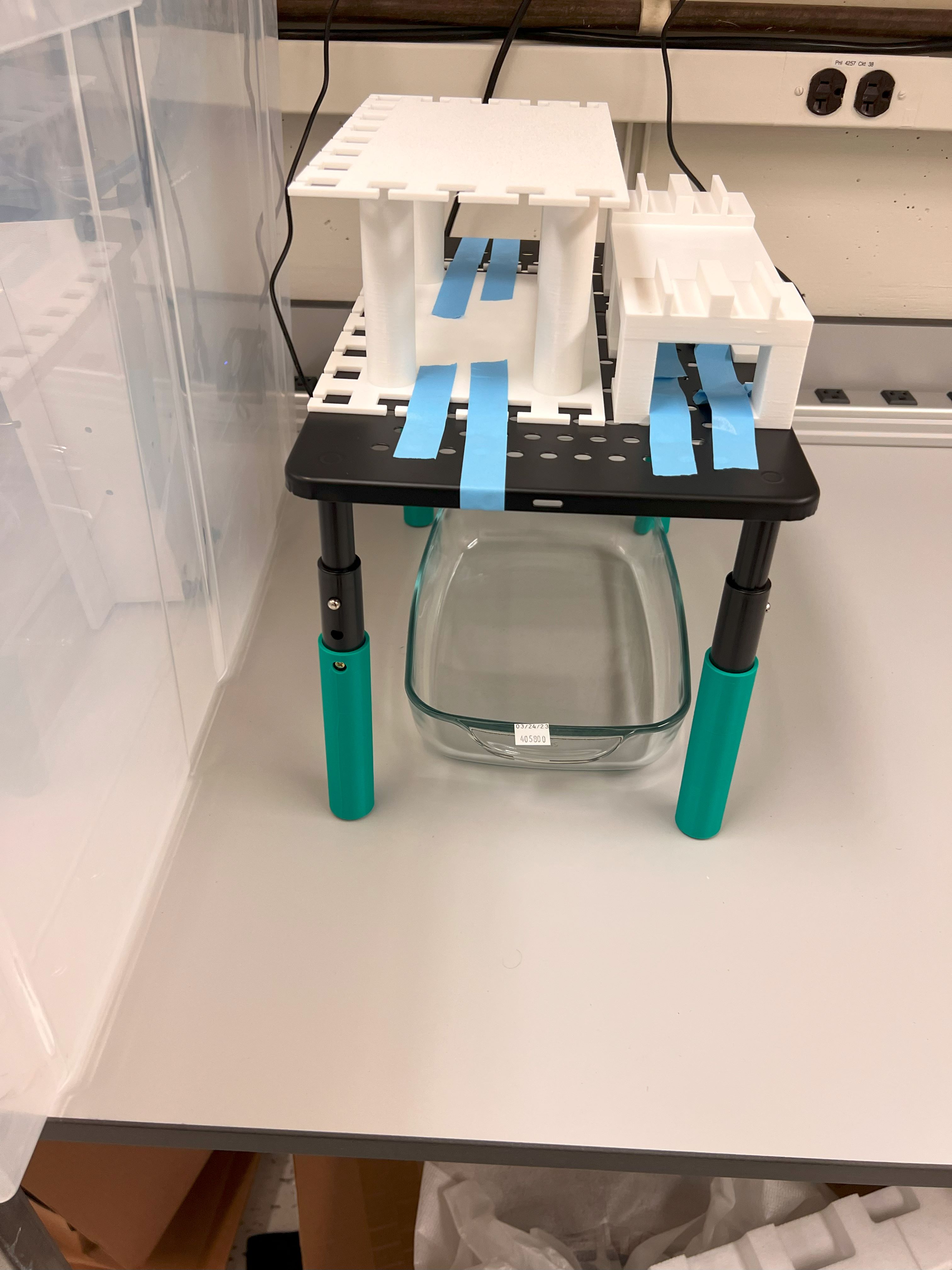

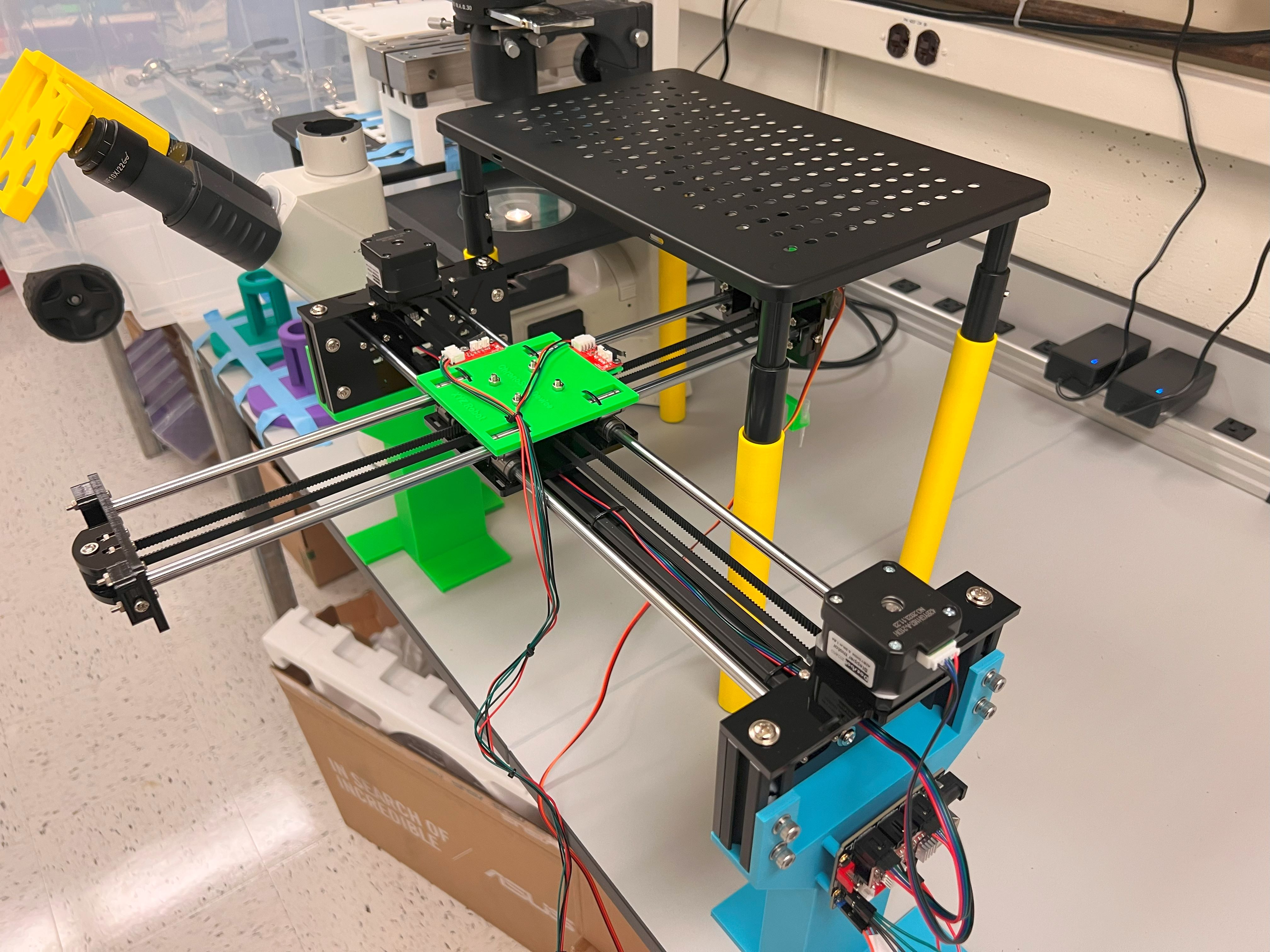

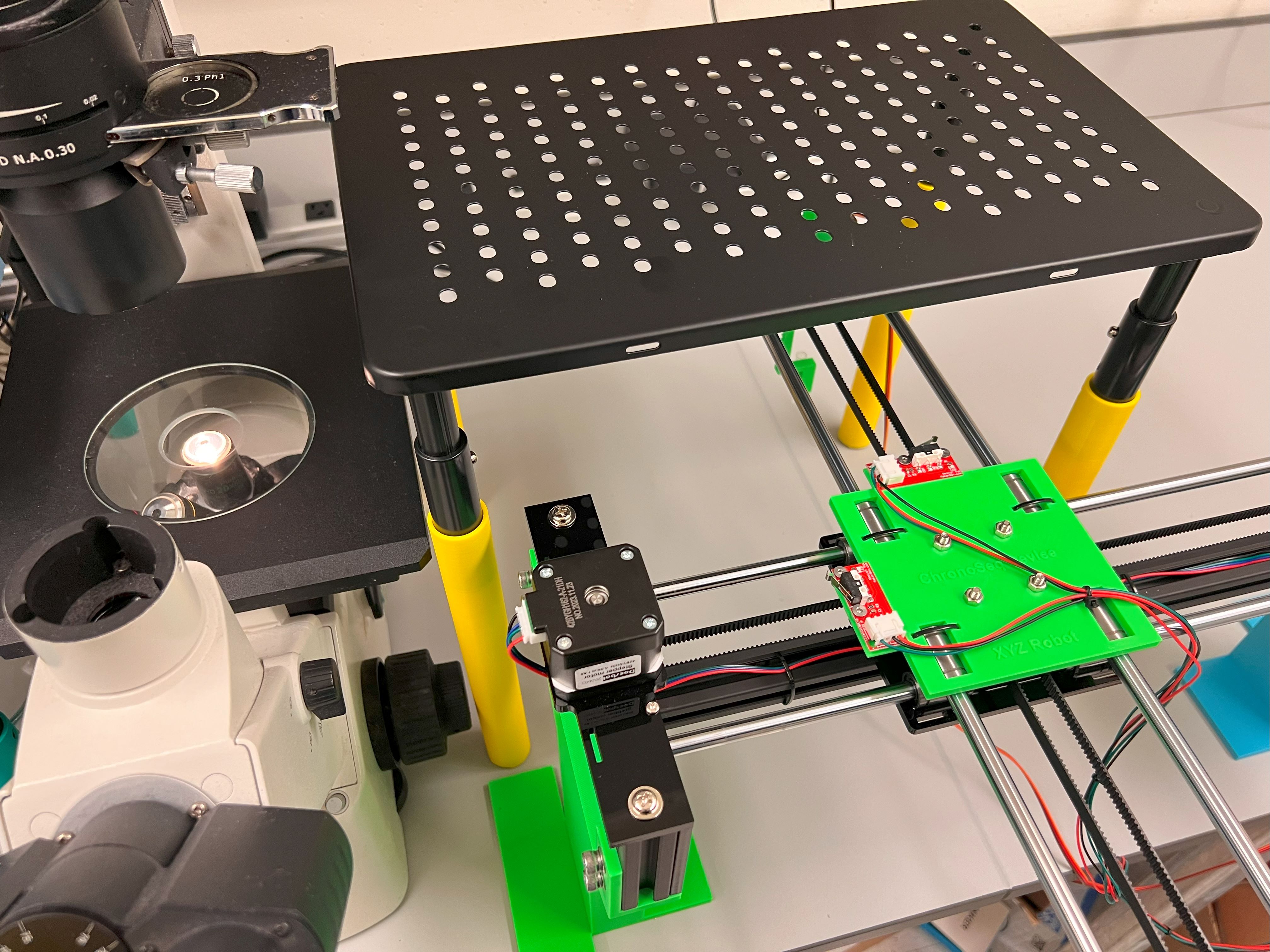

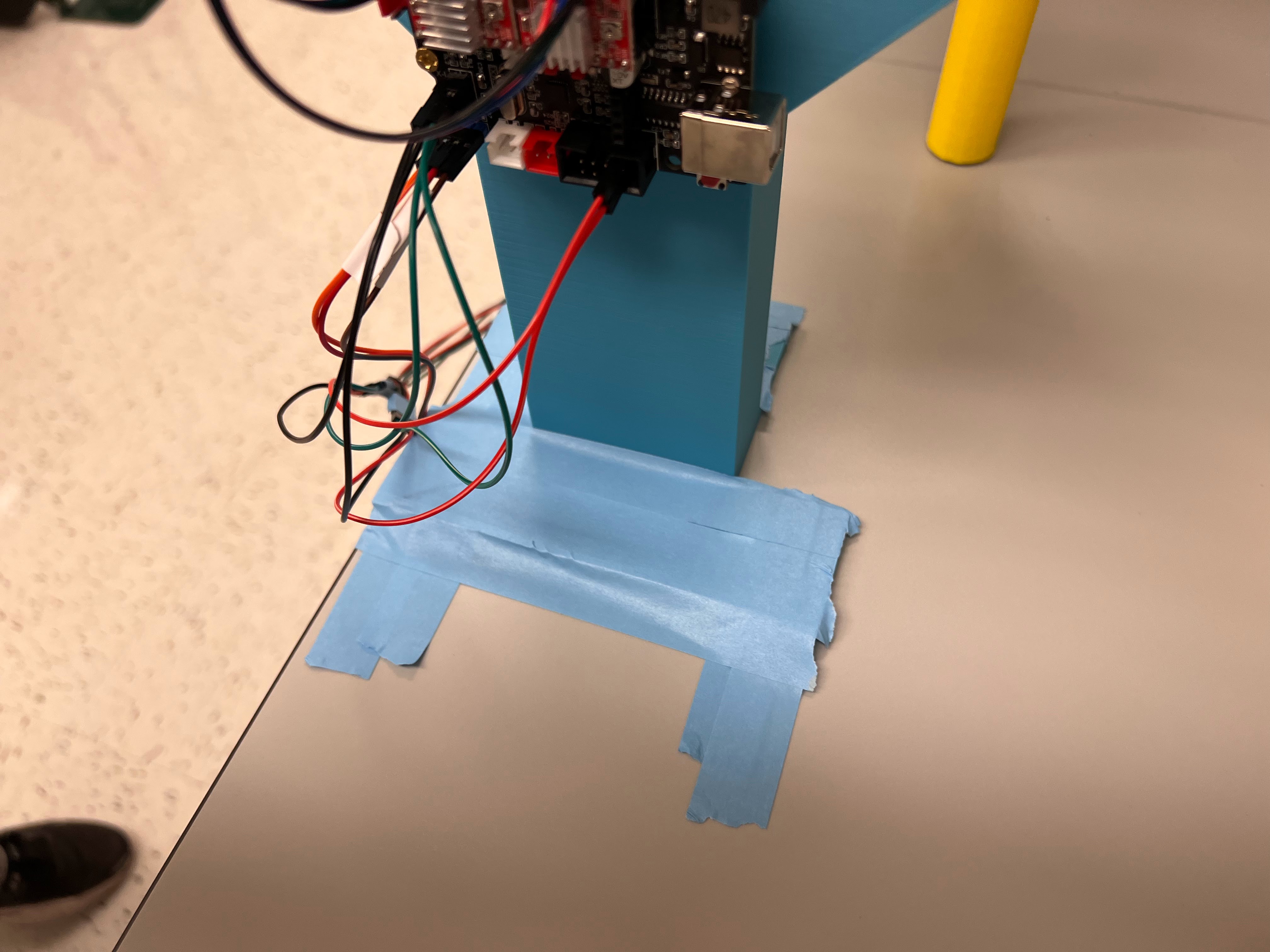

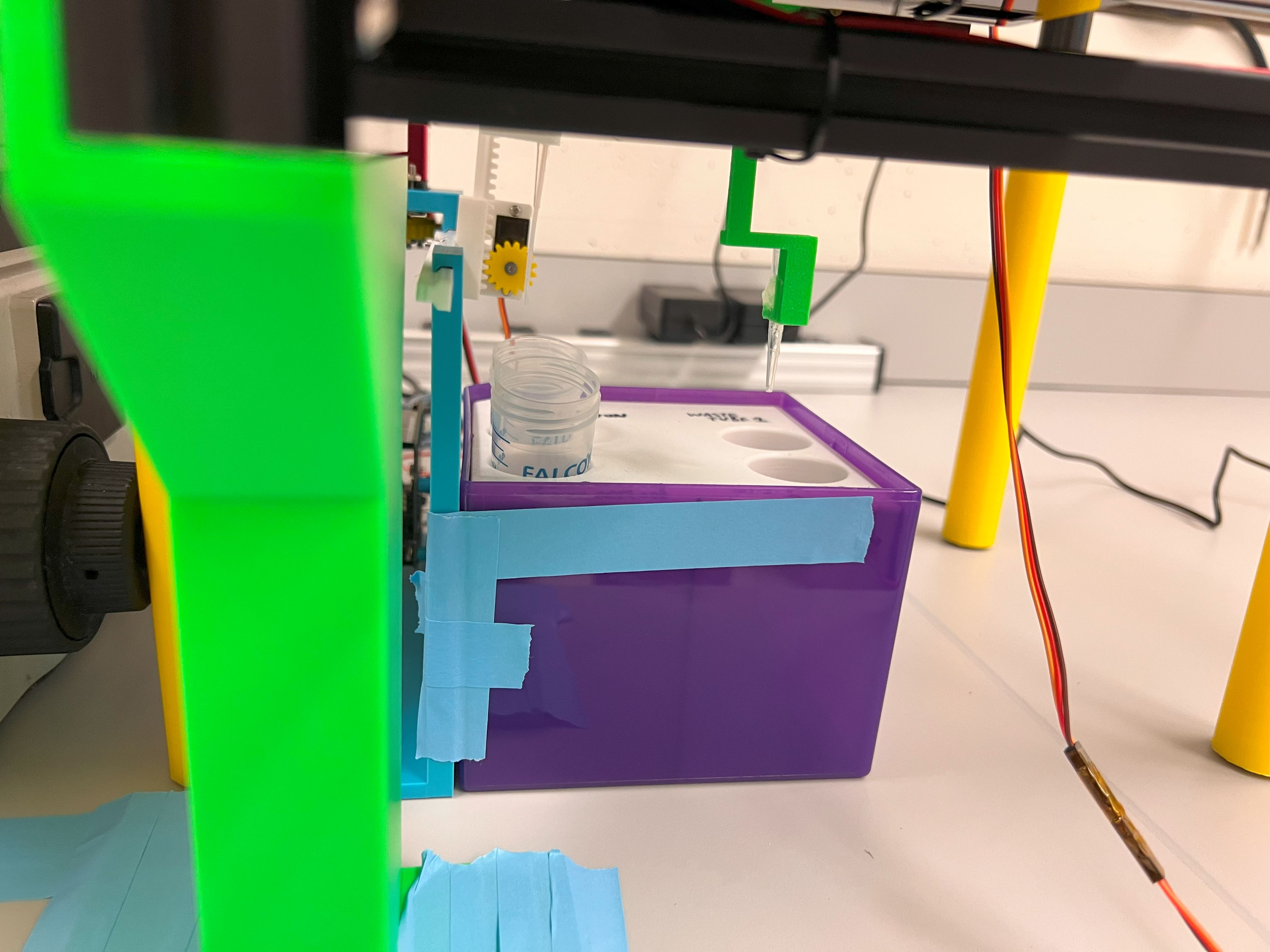

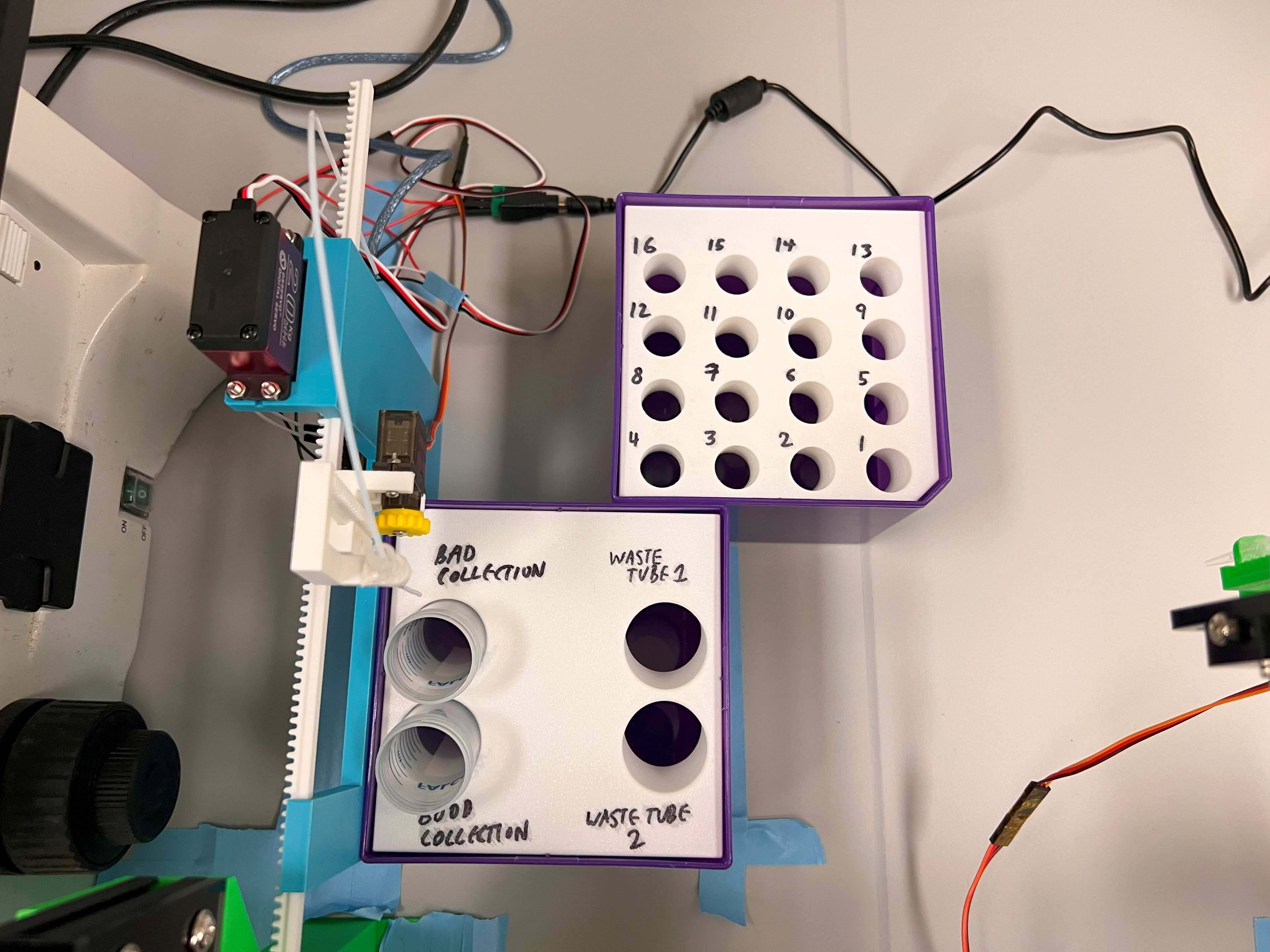

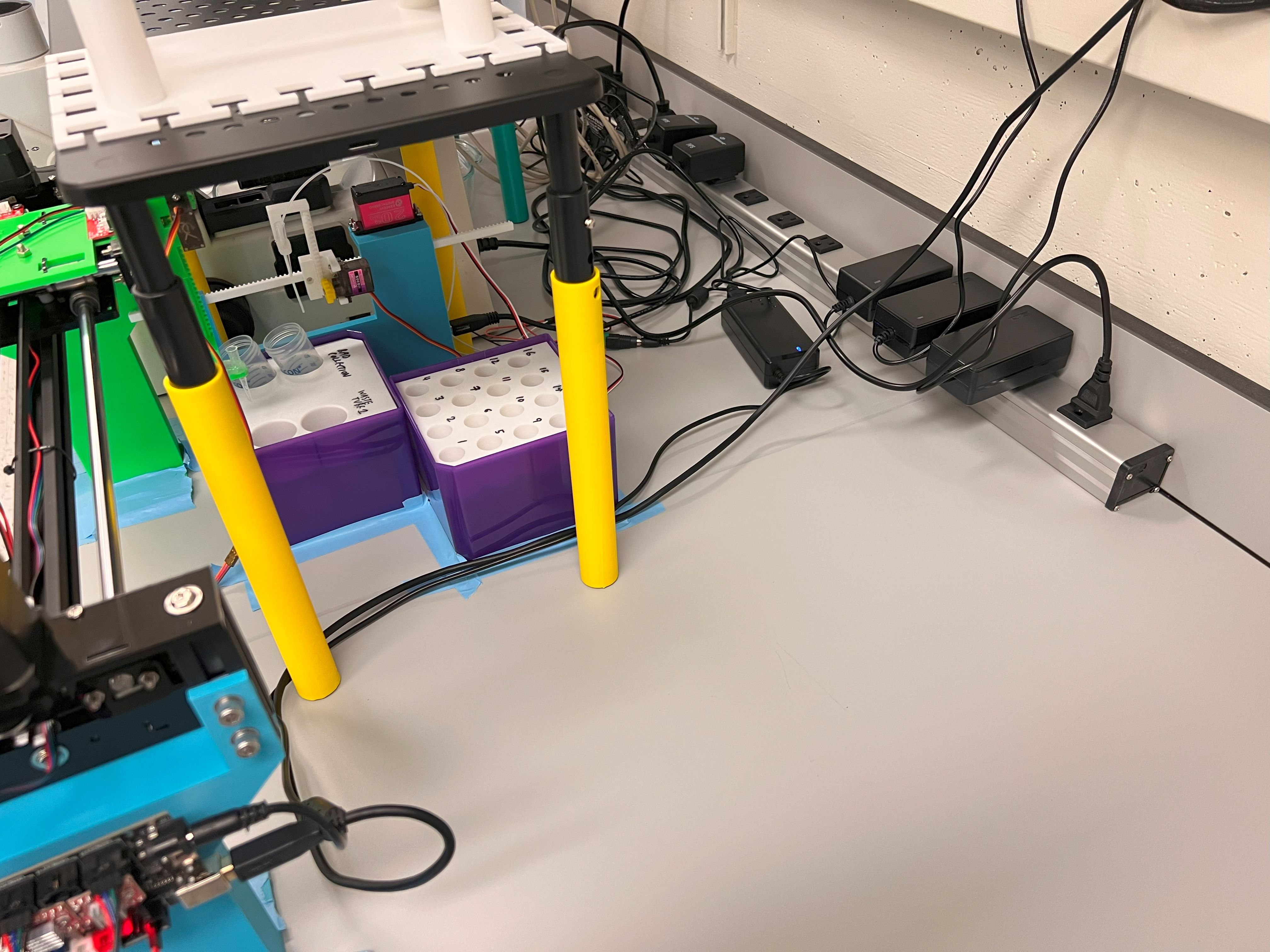

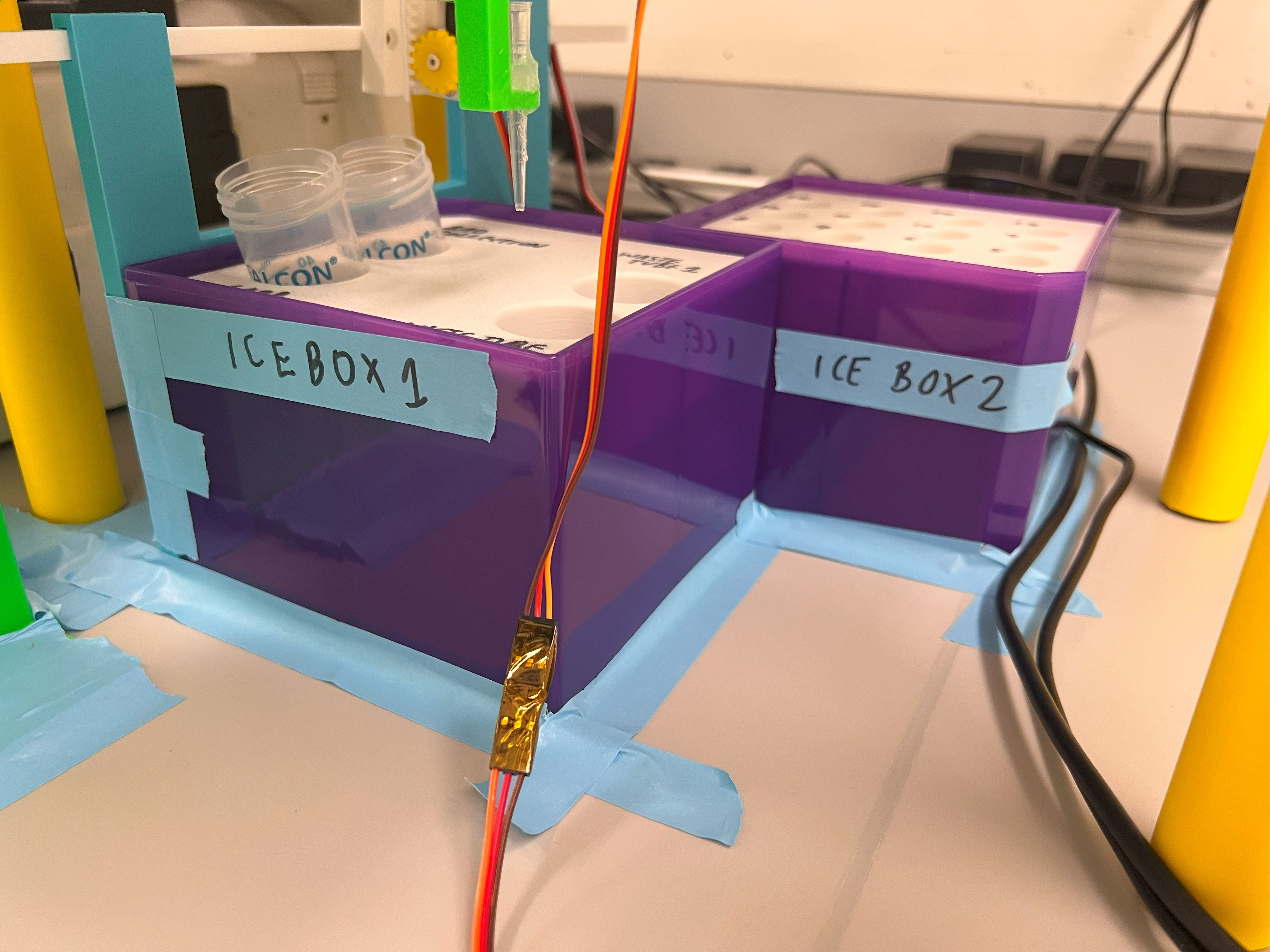

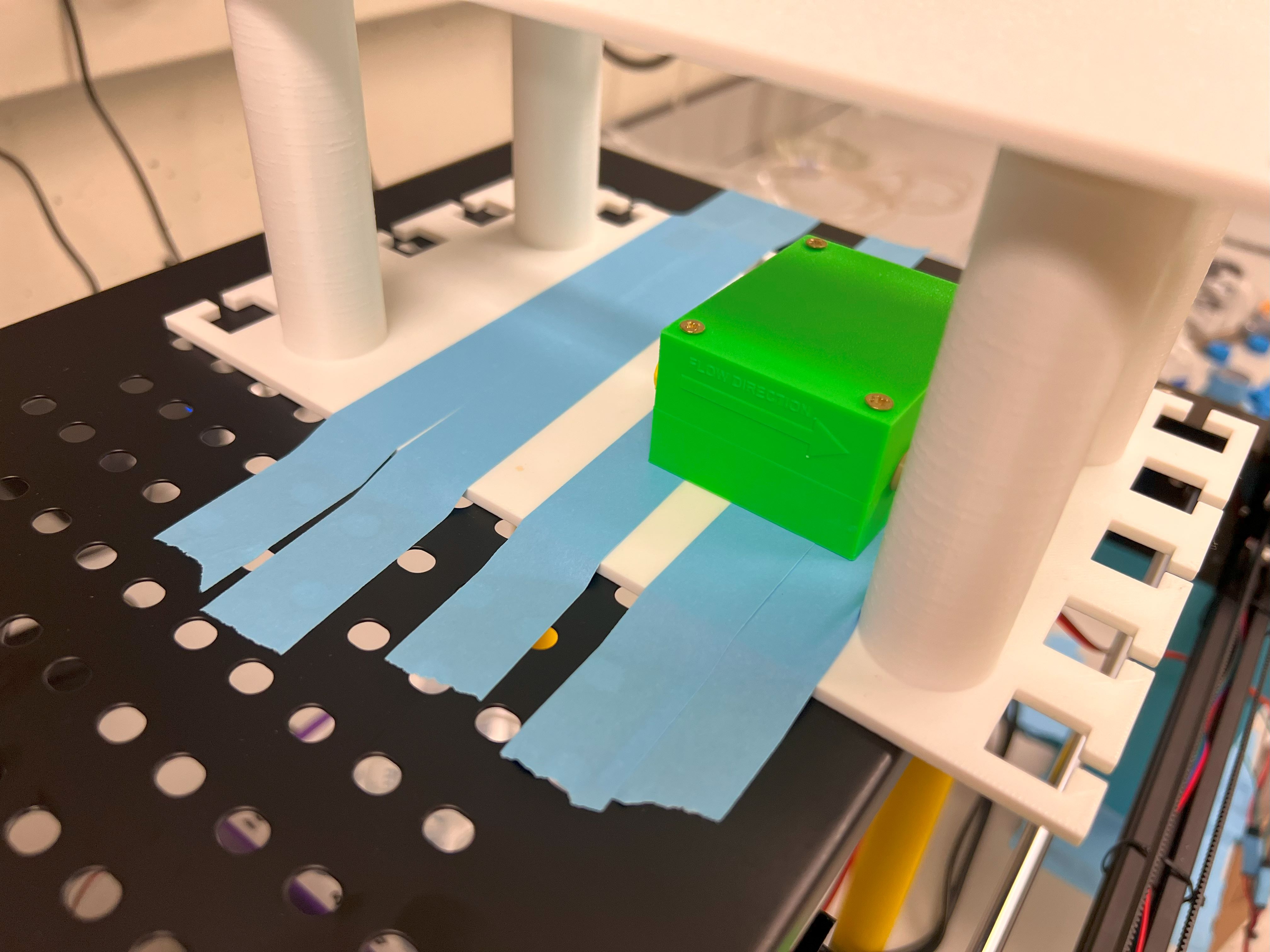

- Droplet collection: In the Dropseq device, droplets are collected directly in a 50 mL tube kept on ice. However, in our system, it is crucial to prevent the beads and cells from previous injections from mixing with those from new injections. To achieve this, we developed a washing system to clear the fluid lines of residual beads and cells. We also need to ensure that washing liquids and unused cell suspensions do not mix with the collected droplets. To solve this issue, we designed a robotic system that facilitates droplet collection and bead recovery. This robot automatically moves the outlet tubing to the correct tube, preventing the mixing of droplets with washing fluids. Additionally, it can recover unused beads from the fluid lines, minimizing waste and reducing experimental costs. Like the Dropseq device, the droplets in our system are also kept on ice using ice boxes.

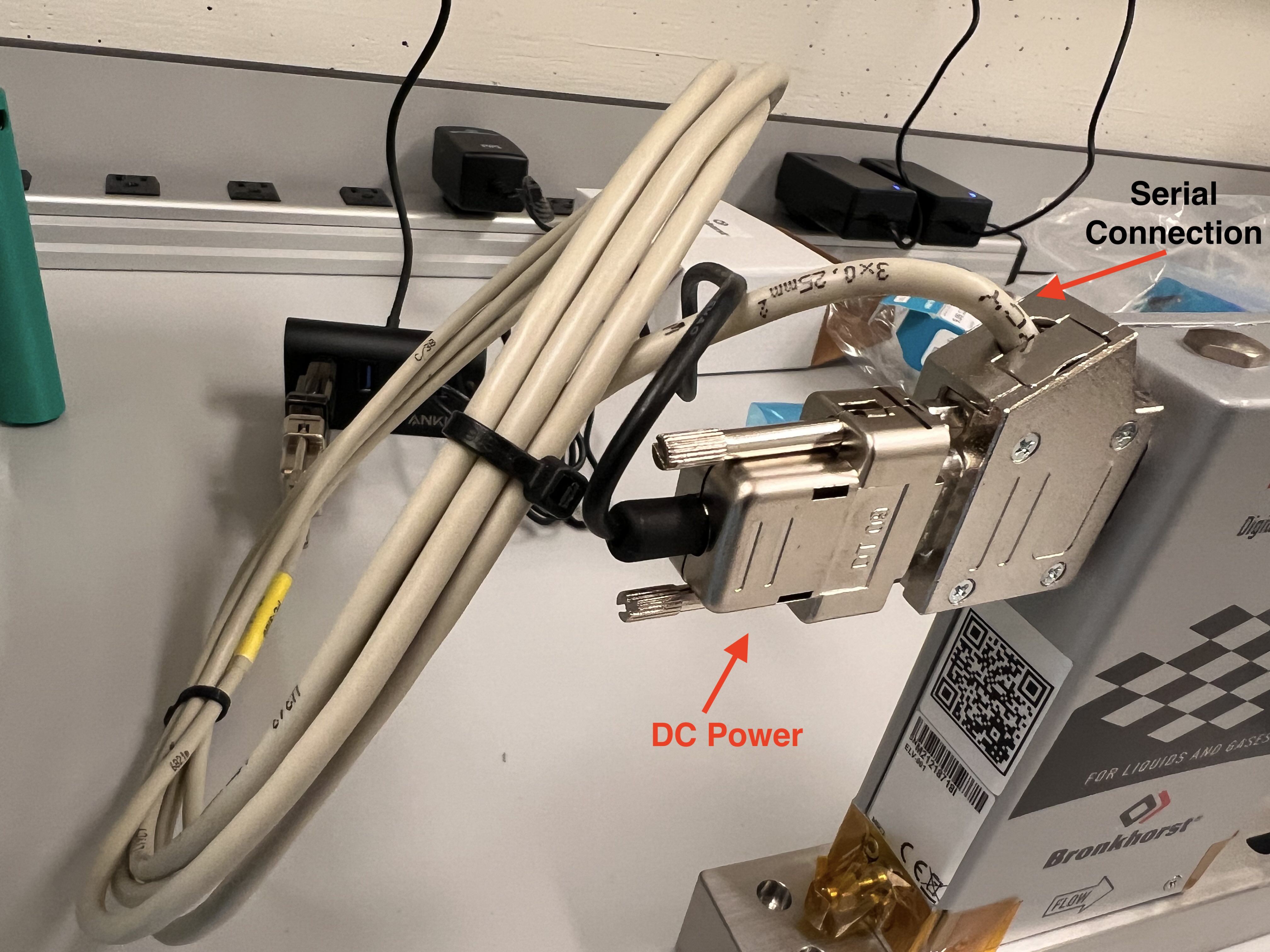

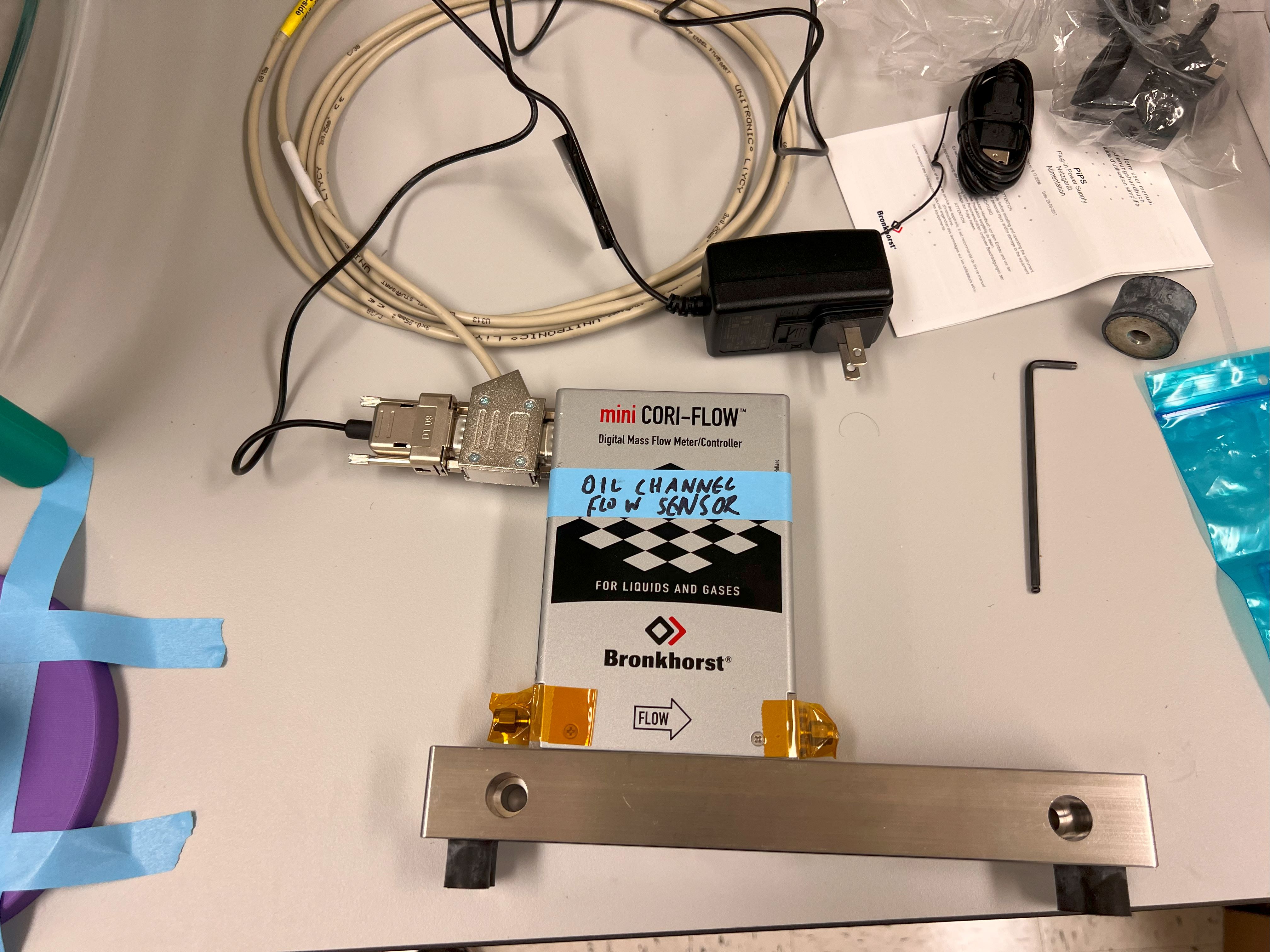

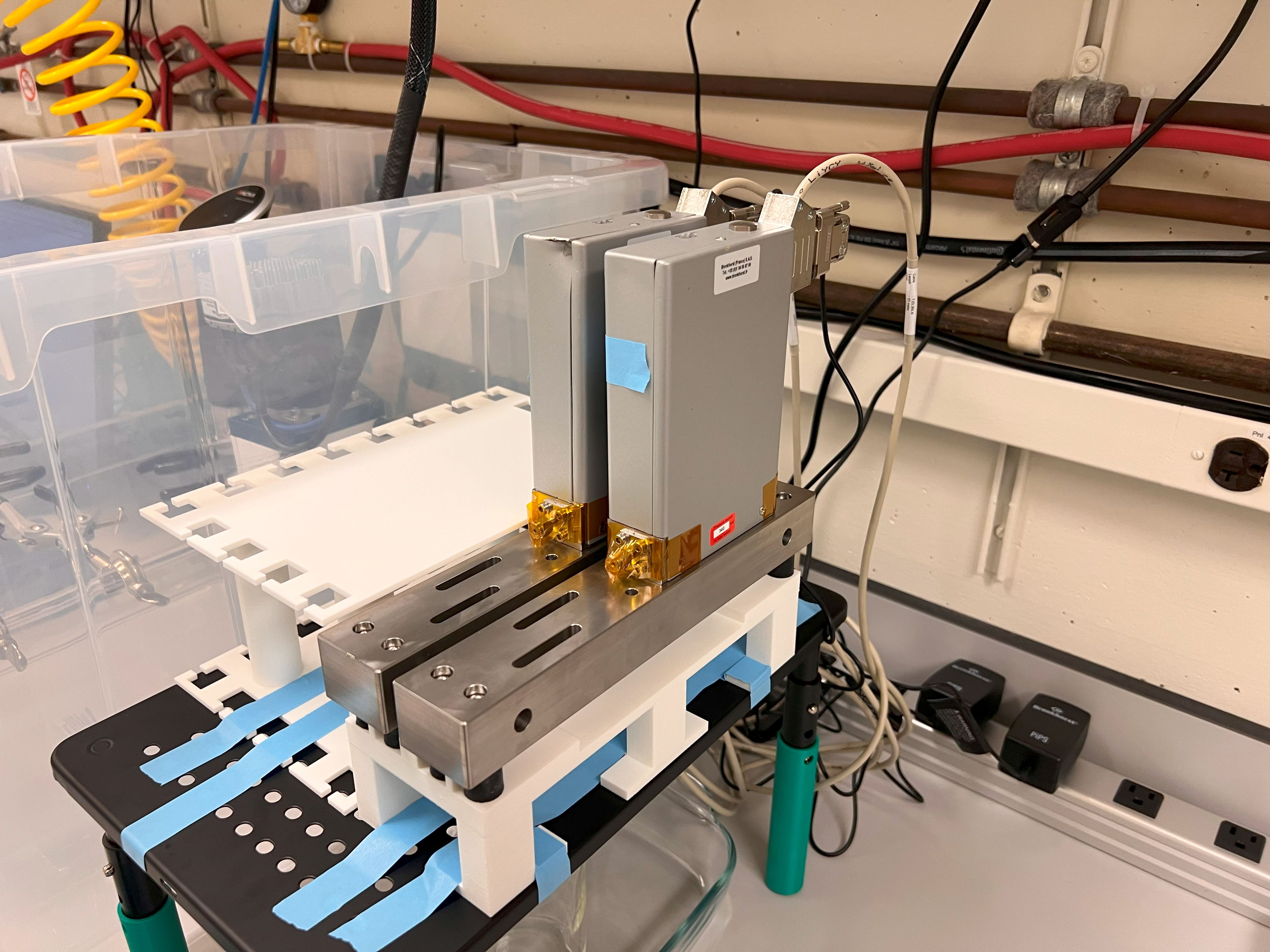

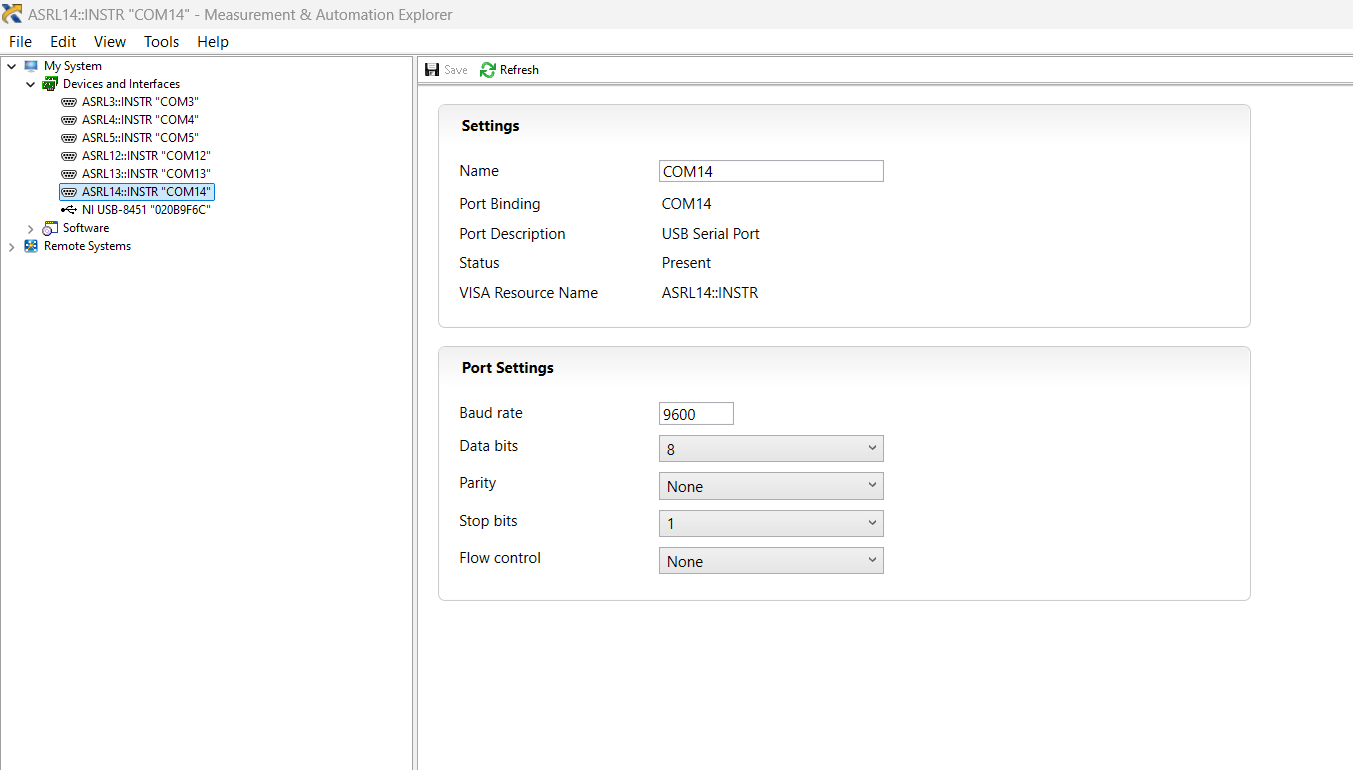

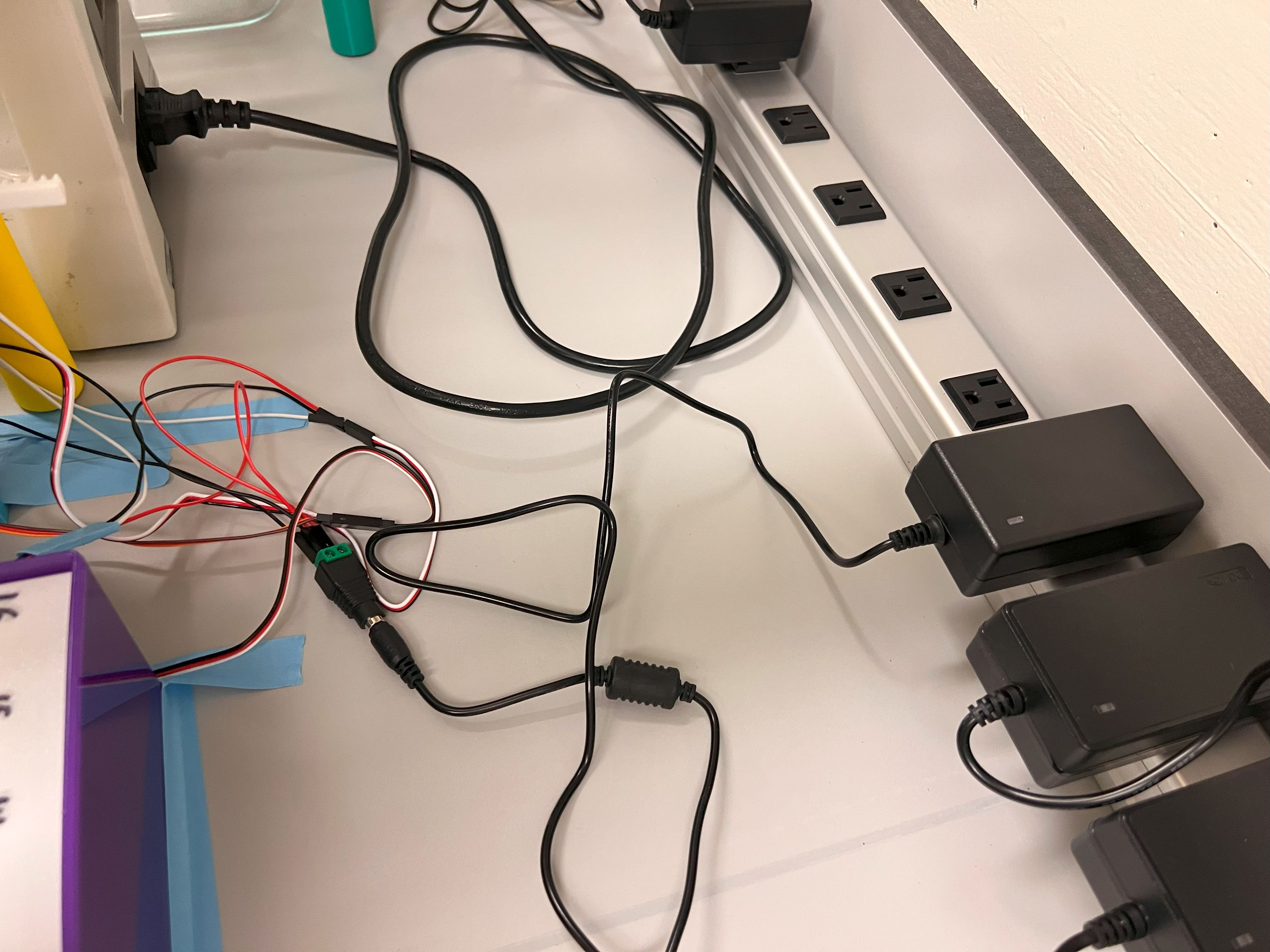

- Flow control: In the Dropseq device, precise speed control is essential for droplet formation. Speeds that are too high can inhibit droplet formation, while low speeds can negatively impact throughput. To achieve this precise control, Dropseq employs syringe pumps, which allow direct manipulation of the syringe's squeezing rate. In our case, we require high flow rates for flushing and low flow rates for droplet formation. Low flow rates like Dropseq flow rates, are insufficient for quickly washing unused beads and cells from the device. Therefore, we implemented a compressed air pressure controller and flow sensors for each of the bead, cell, and oil channels. The compressed air controller enables rapid changes in flow rate, while the flow sensors provide the precise control needed for high-quality droplet formation during low flow rate operation.

3D Printing Parts¶

- We used a Bambu Lab X1 Carbon to print the Parts.

- 0.4mm Nozzle

- Textured PEI Plate

- We used PLA filament for our 3D Prints. Most Generic brands work quite well.

- We found ELEGOO PLA to be reasonably priced.

- Their spools were also neatly wound, reducing the chance of Print Failure.

- You can choose from many different colors.

- We don't recommend getting Translucent or Transparent PLA filaments.

- The Filament runout sensor doesn't work well with these types of Filaments.

- We generated several 3MF Files with all the Settings we used for the Print. You can open these files on the Orca Slicer.

- The Original STEP Files and F3D Files can be found in the same directory.

- Some of the prints included in this directory:

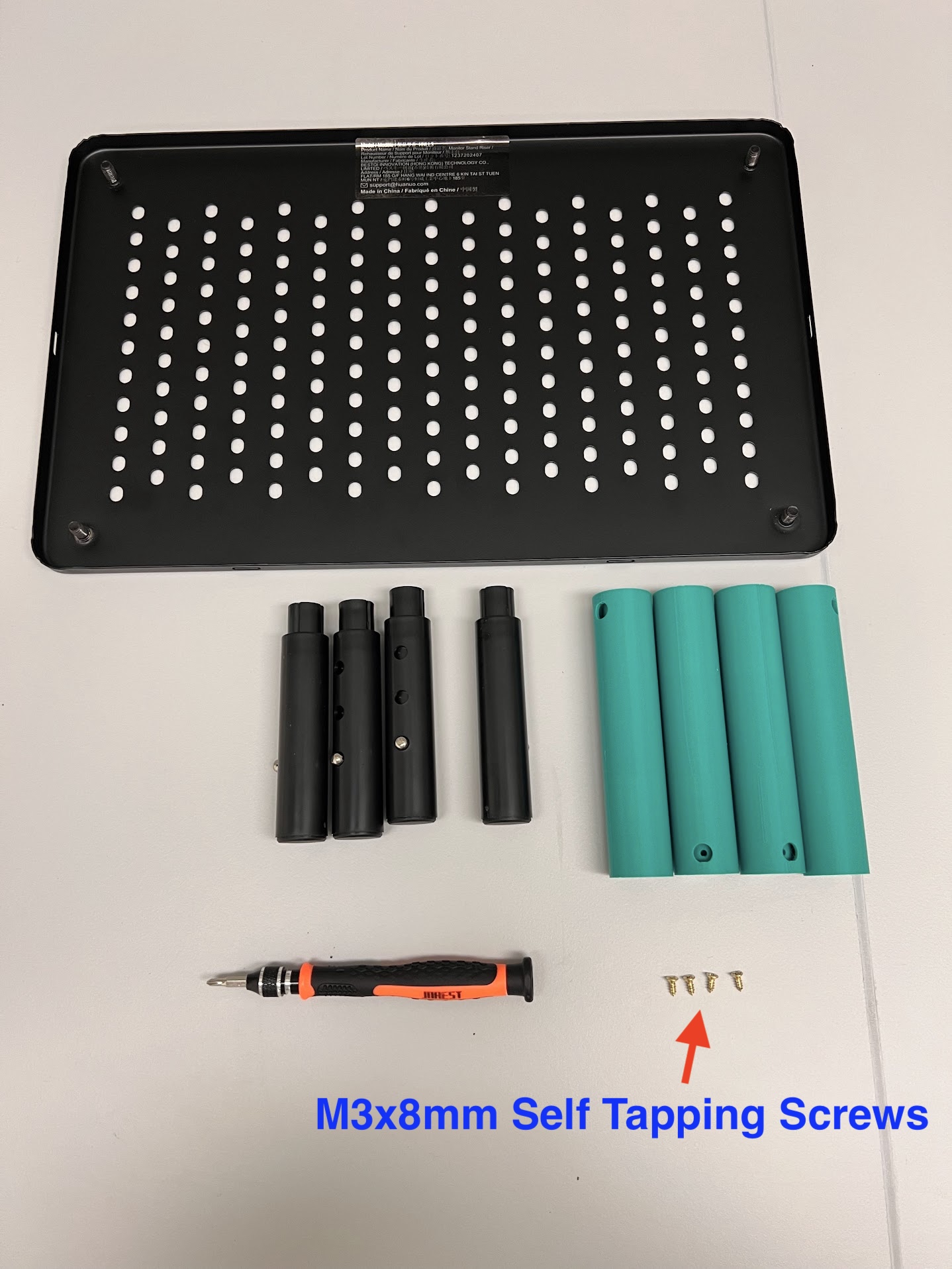

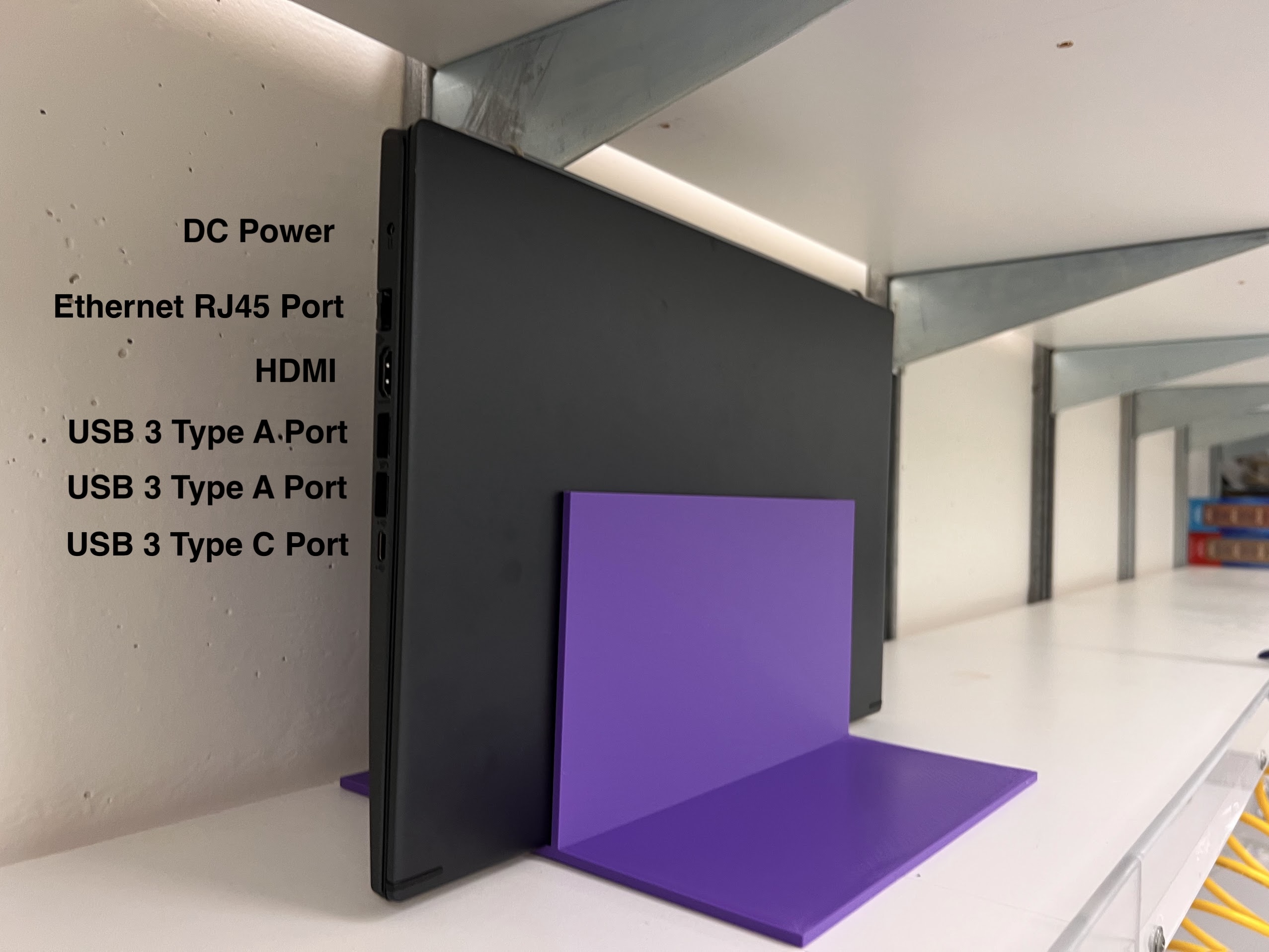

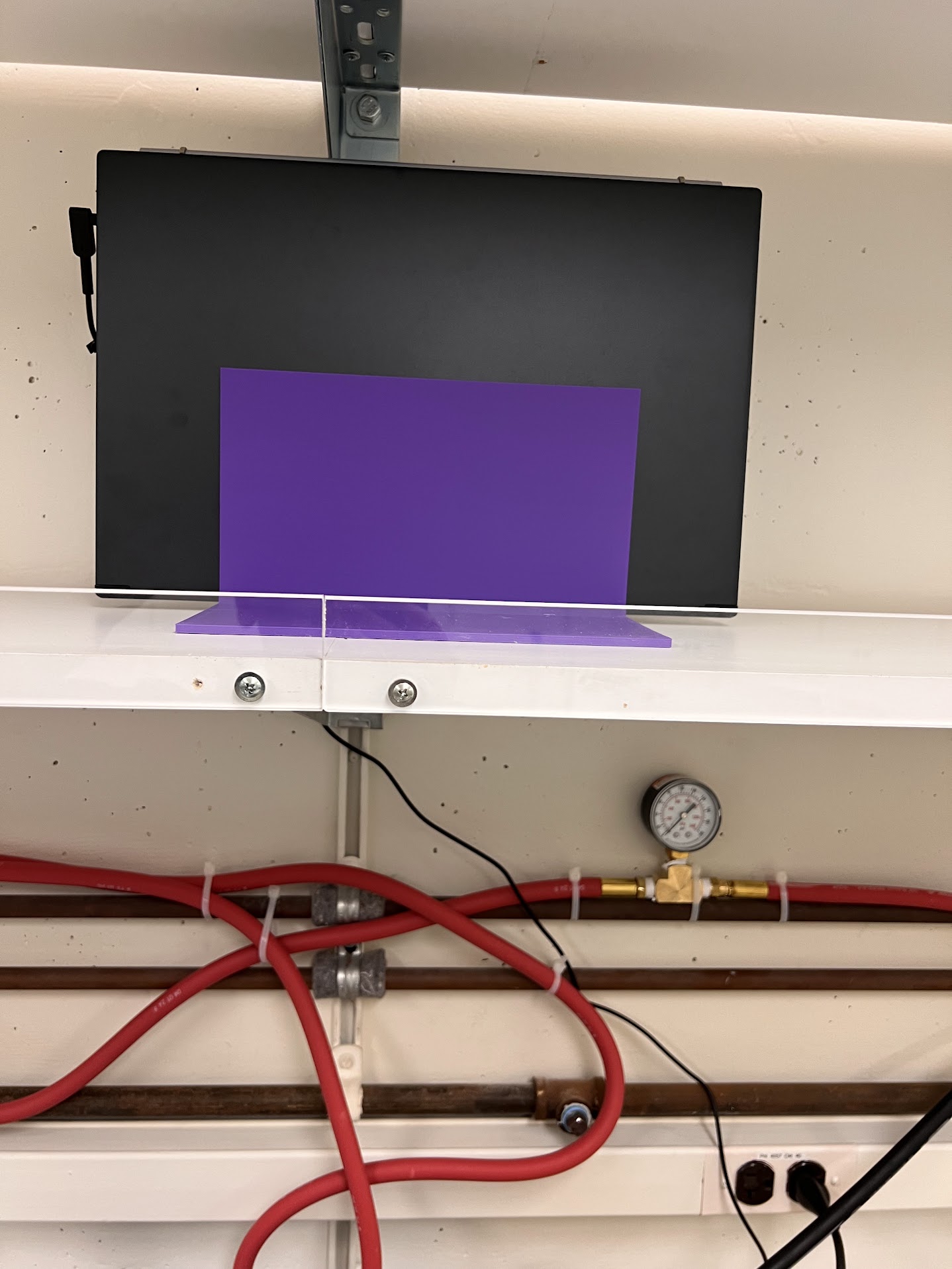

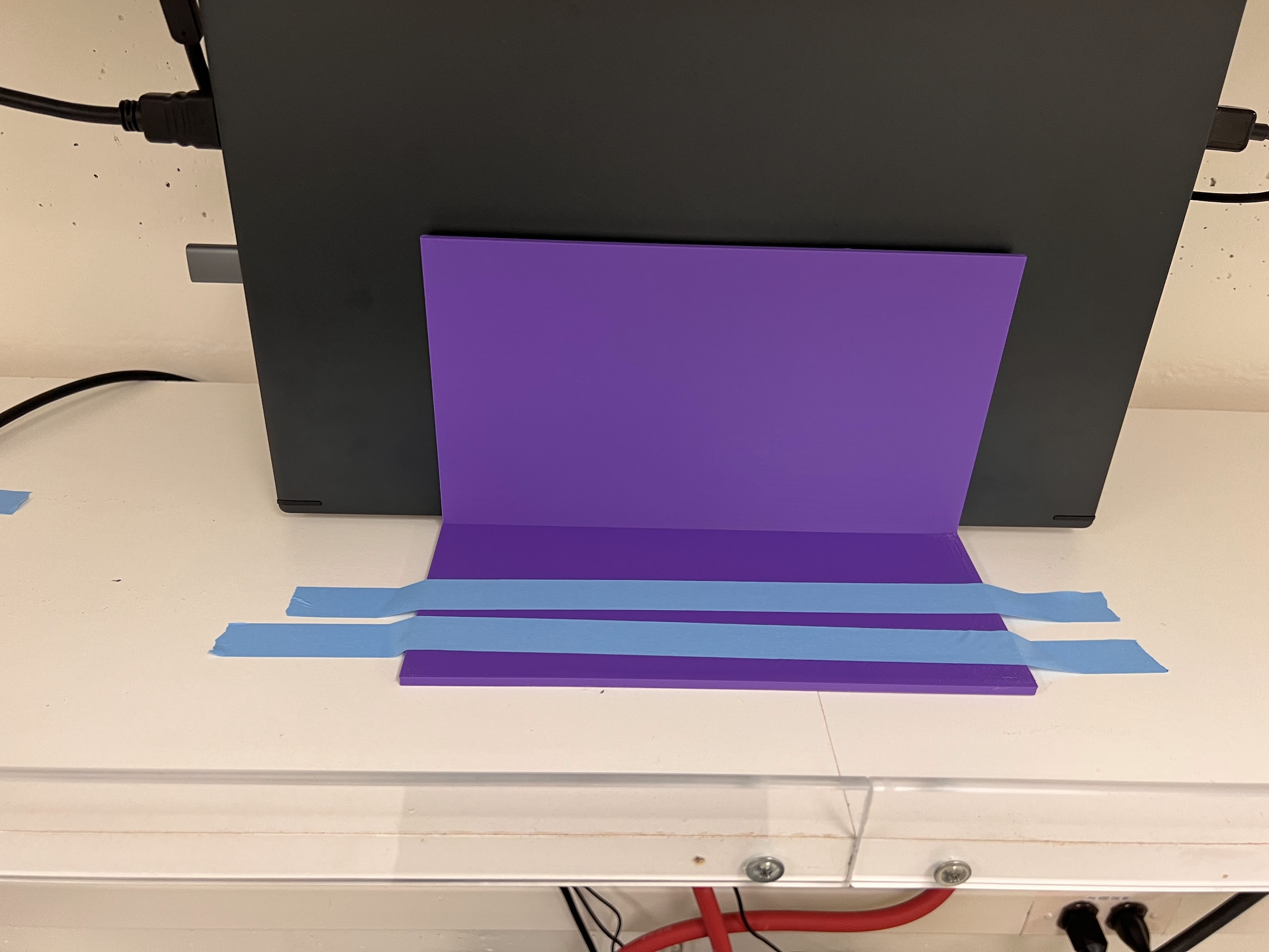

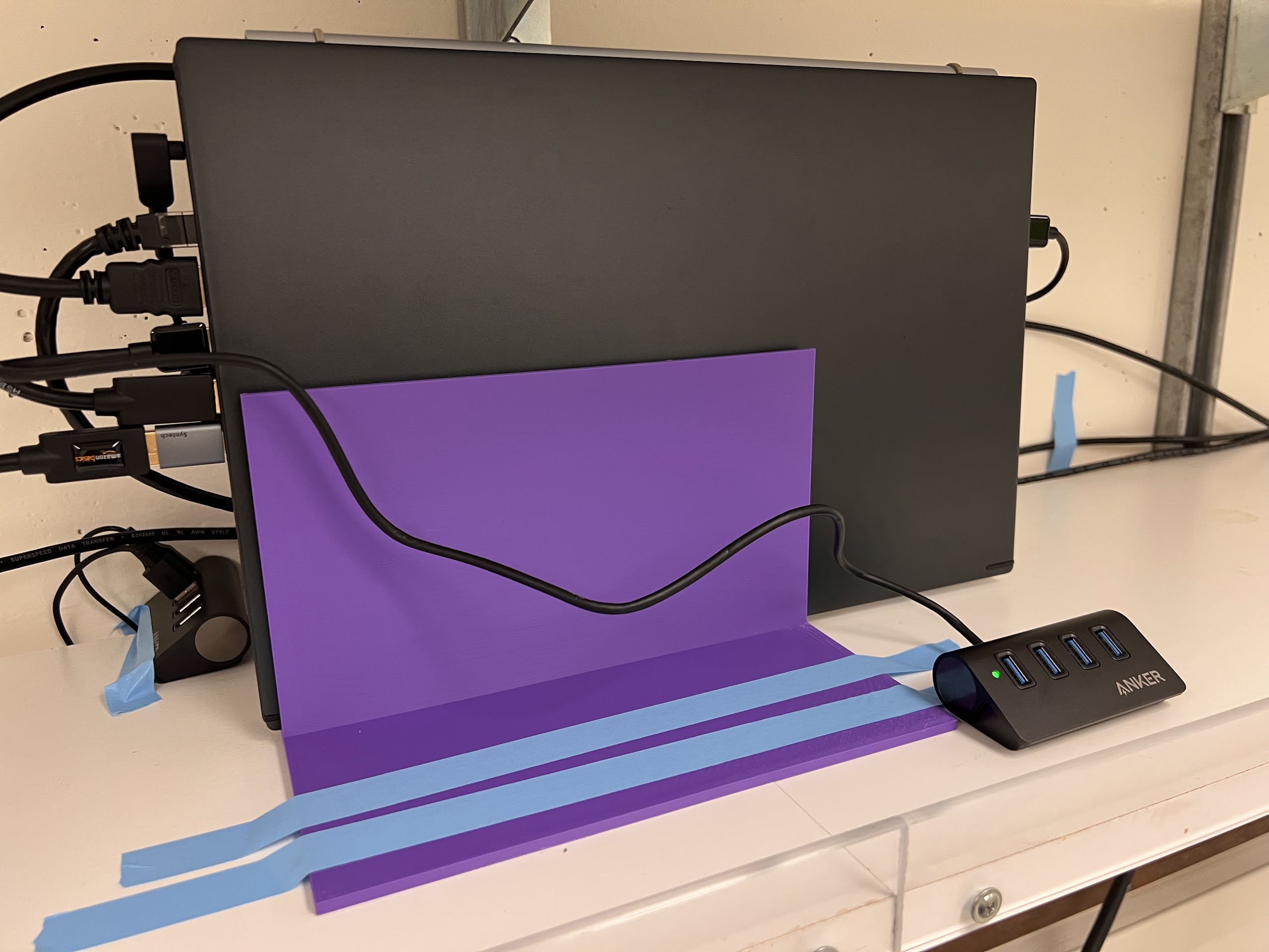

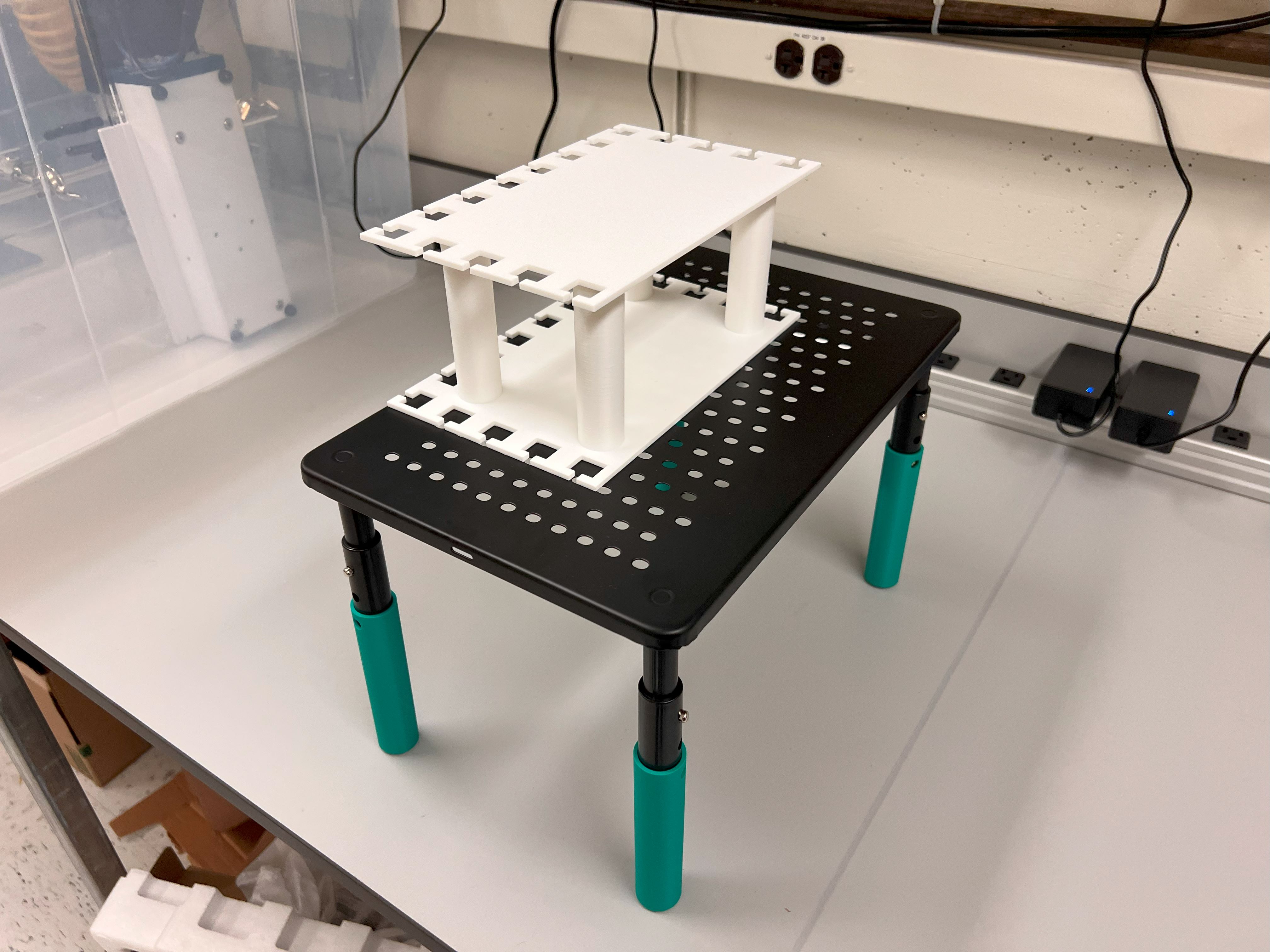

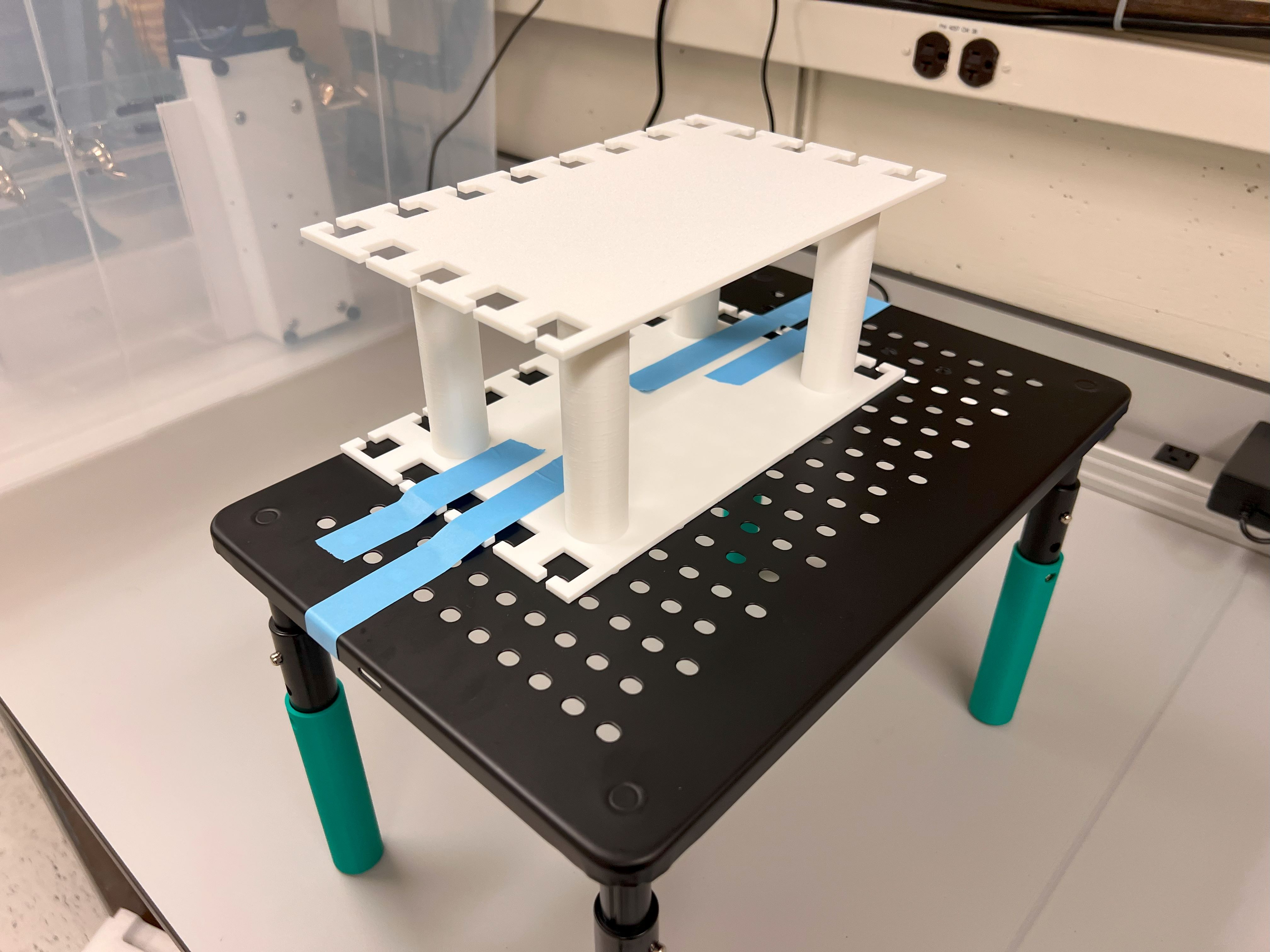

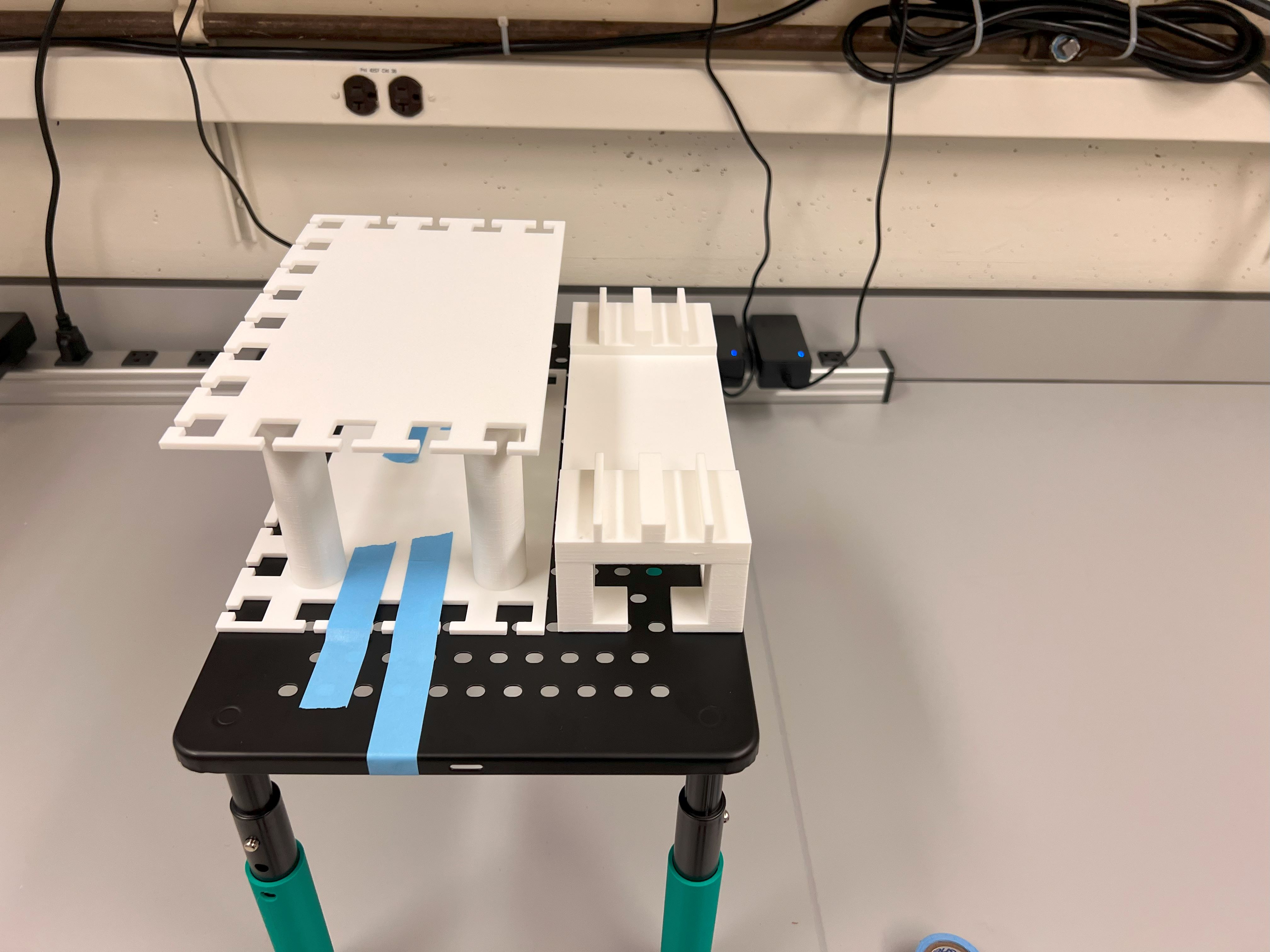

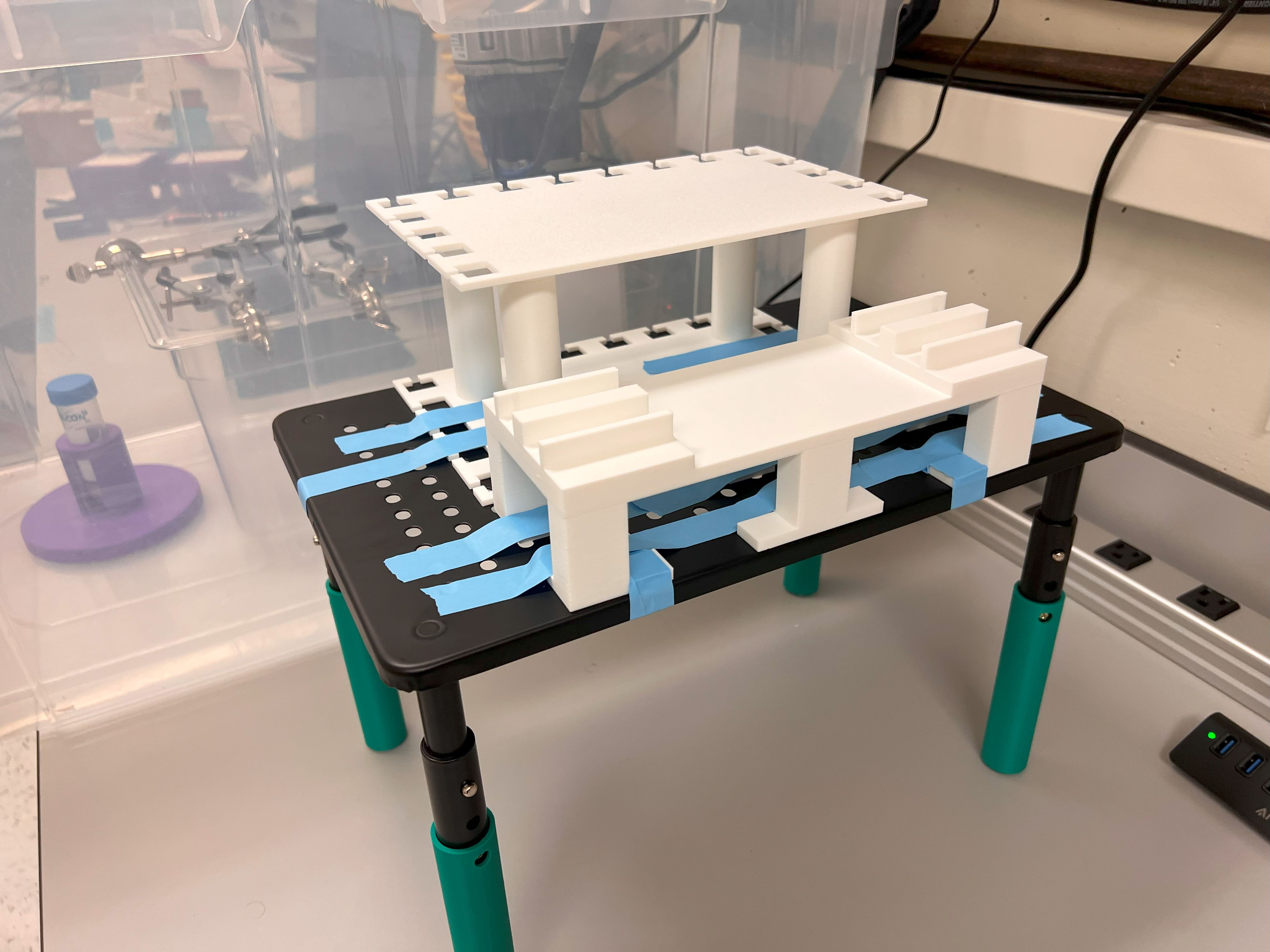

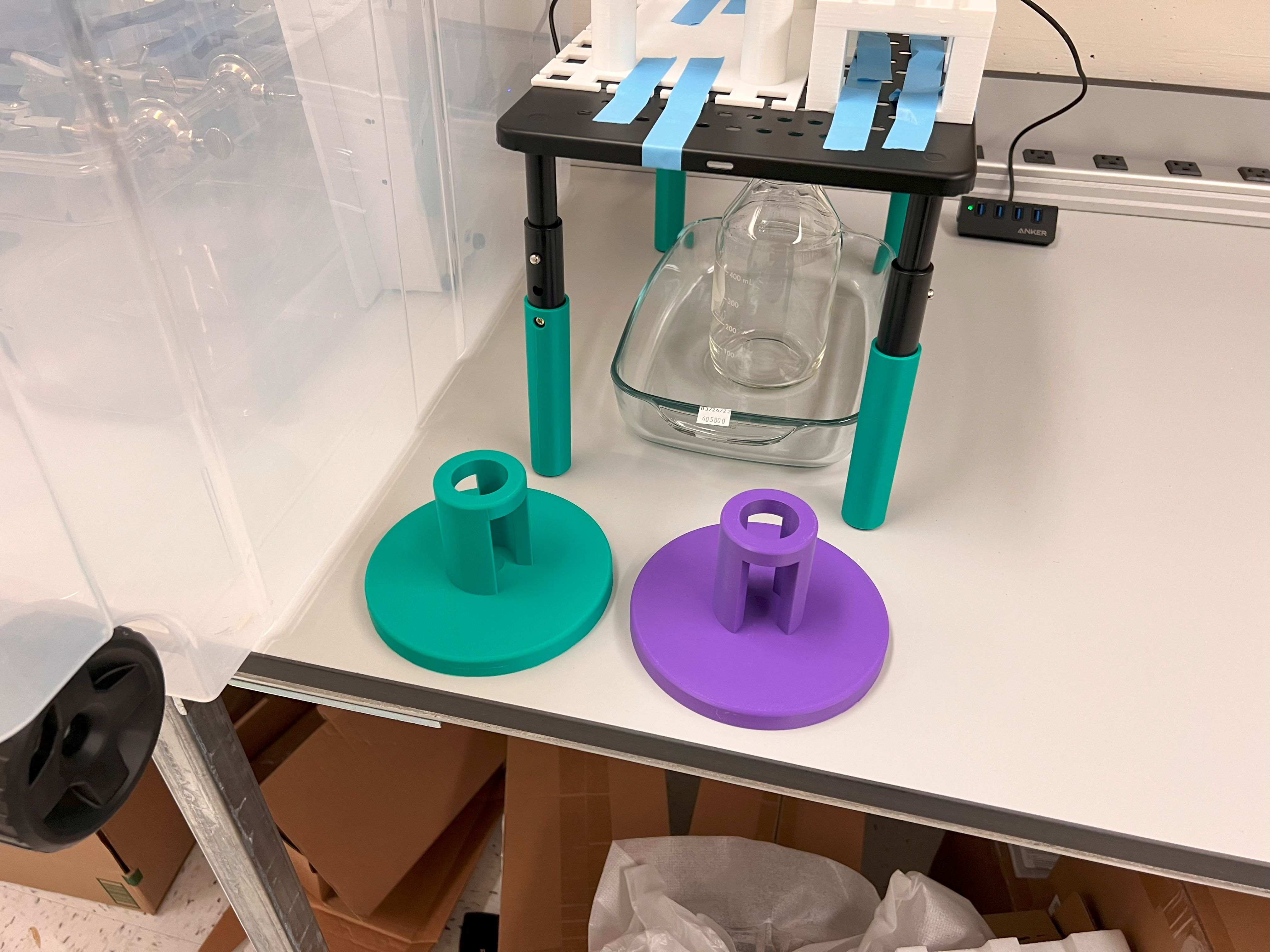

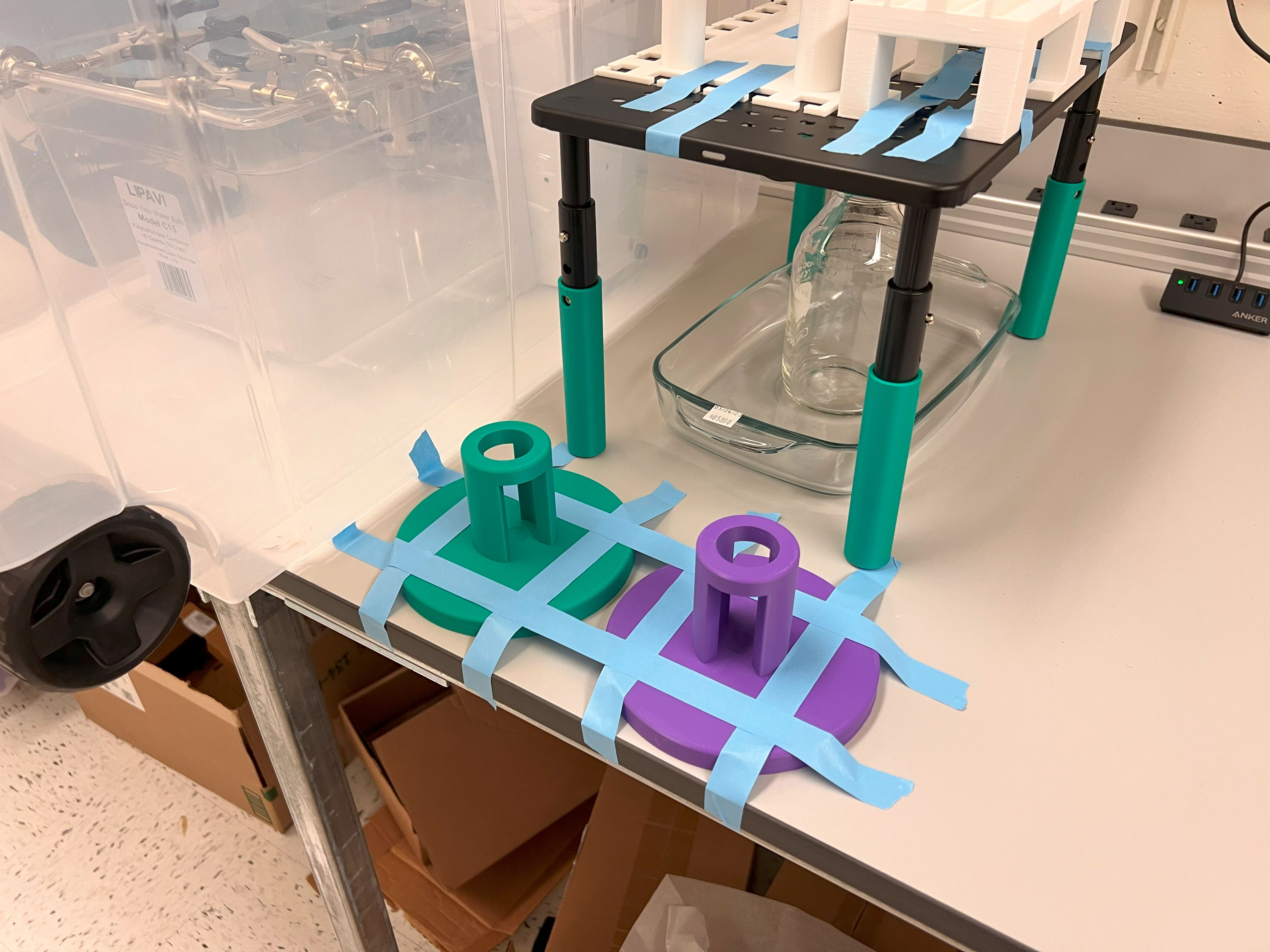

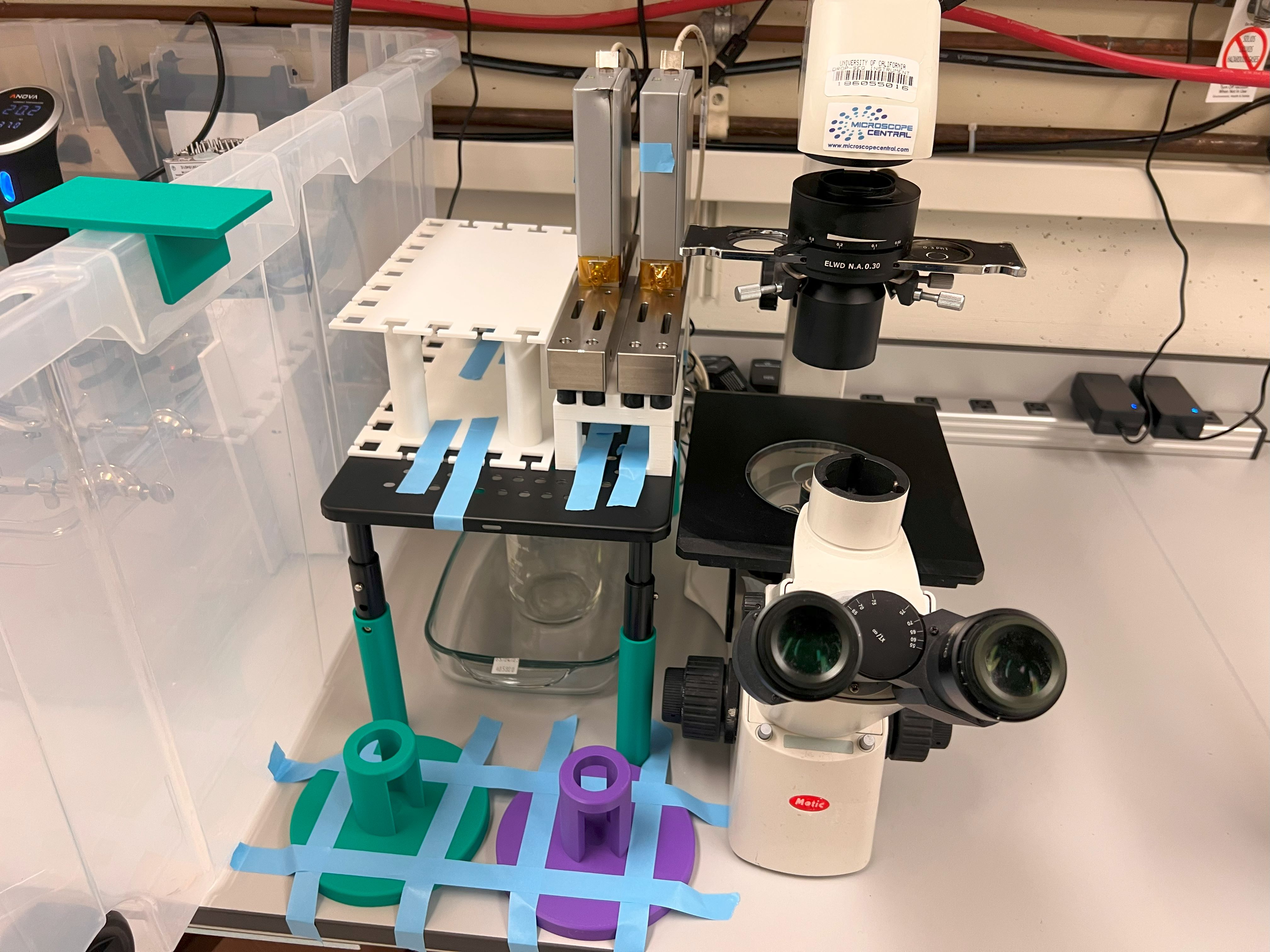

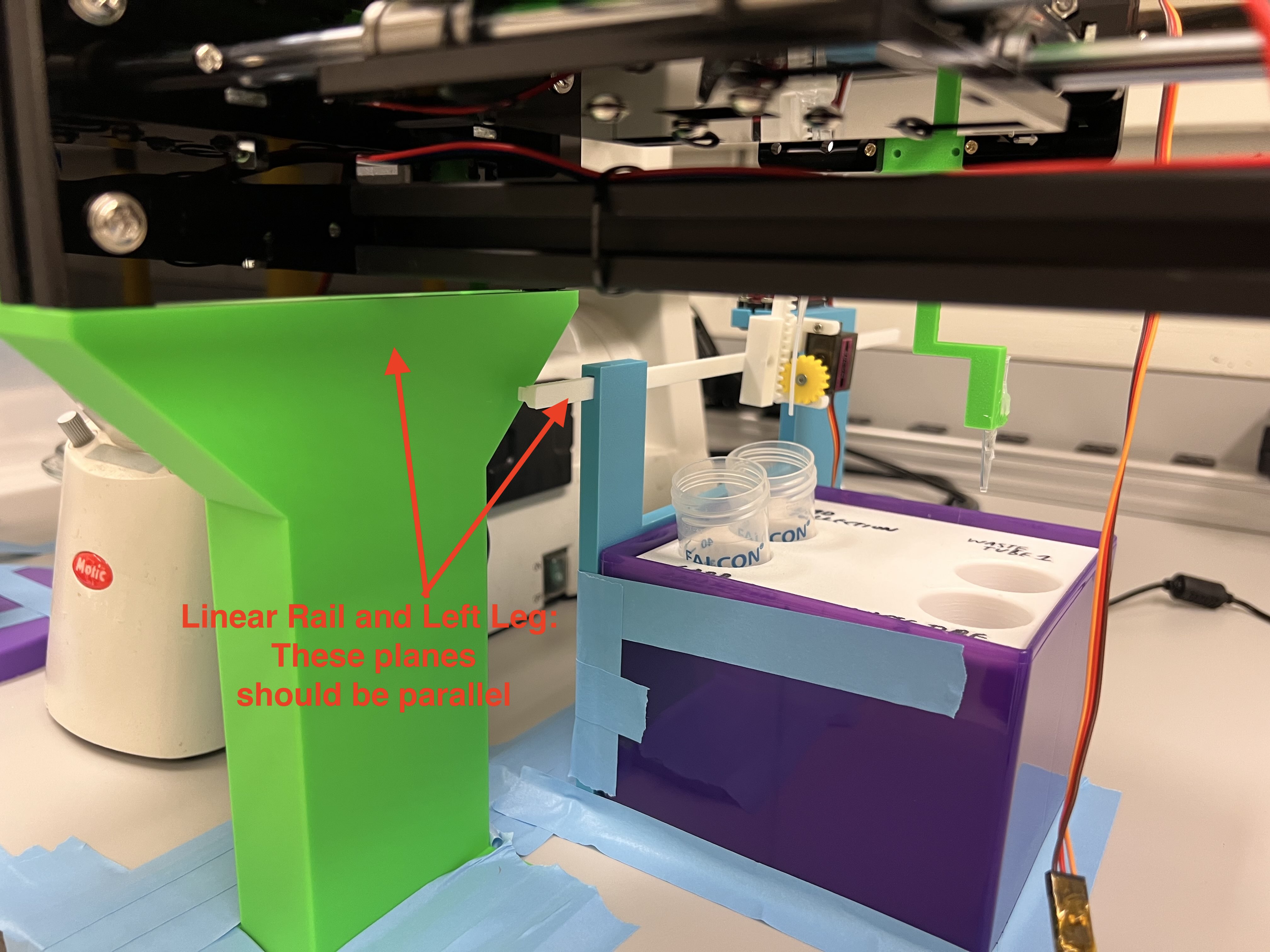

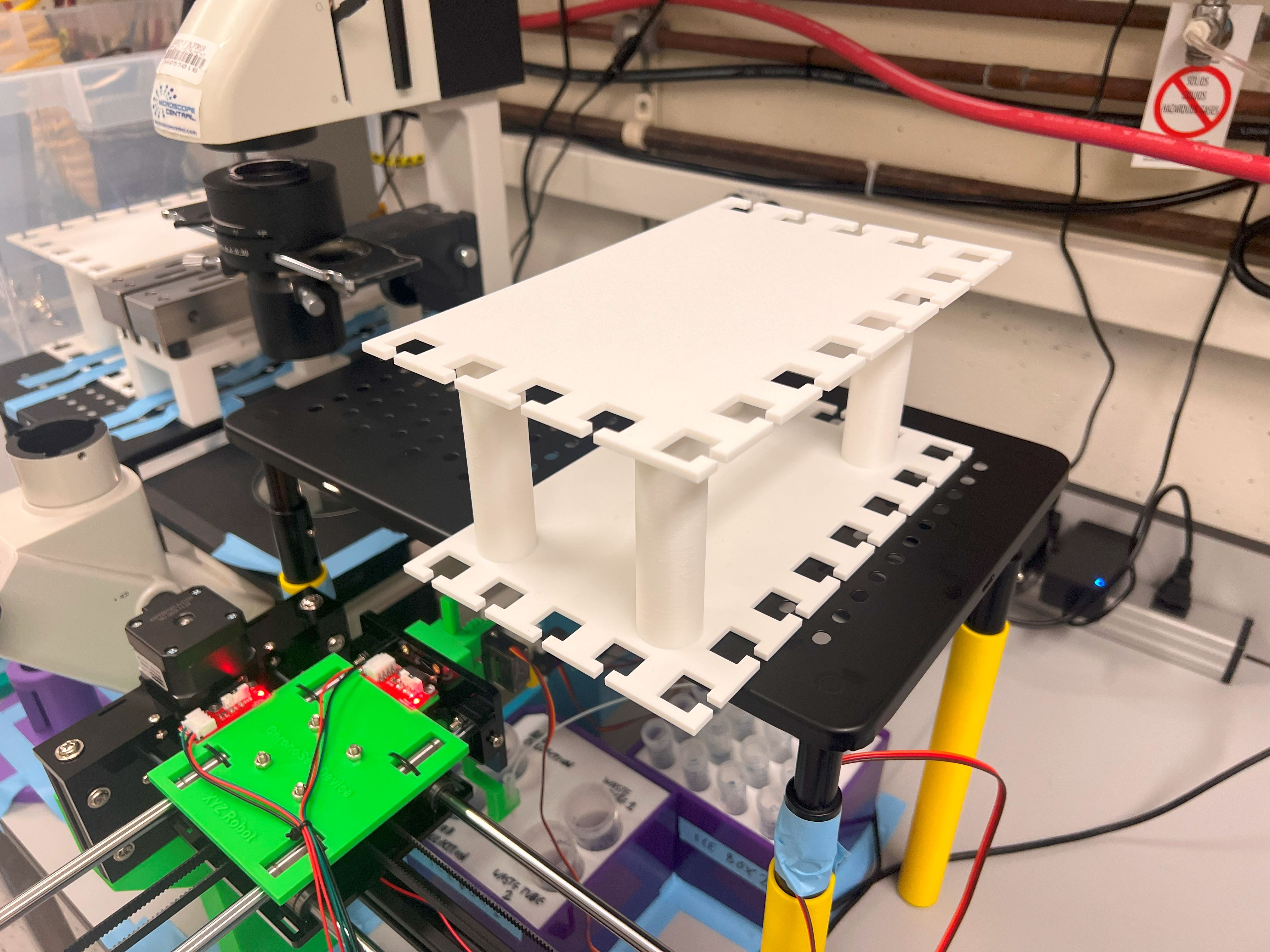

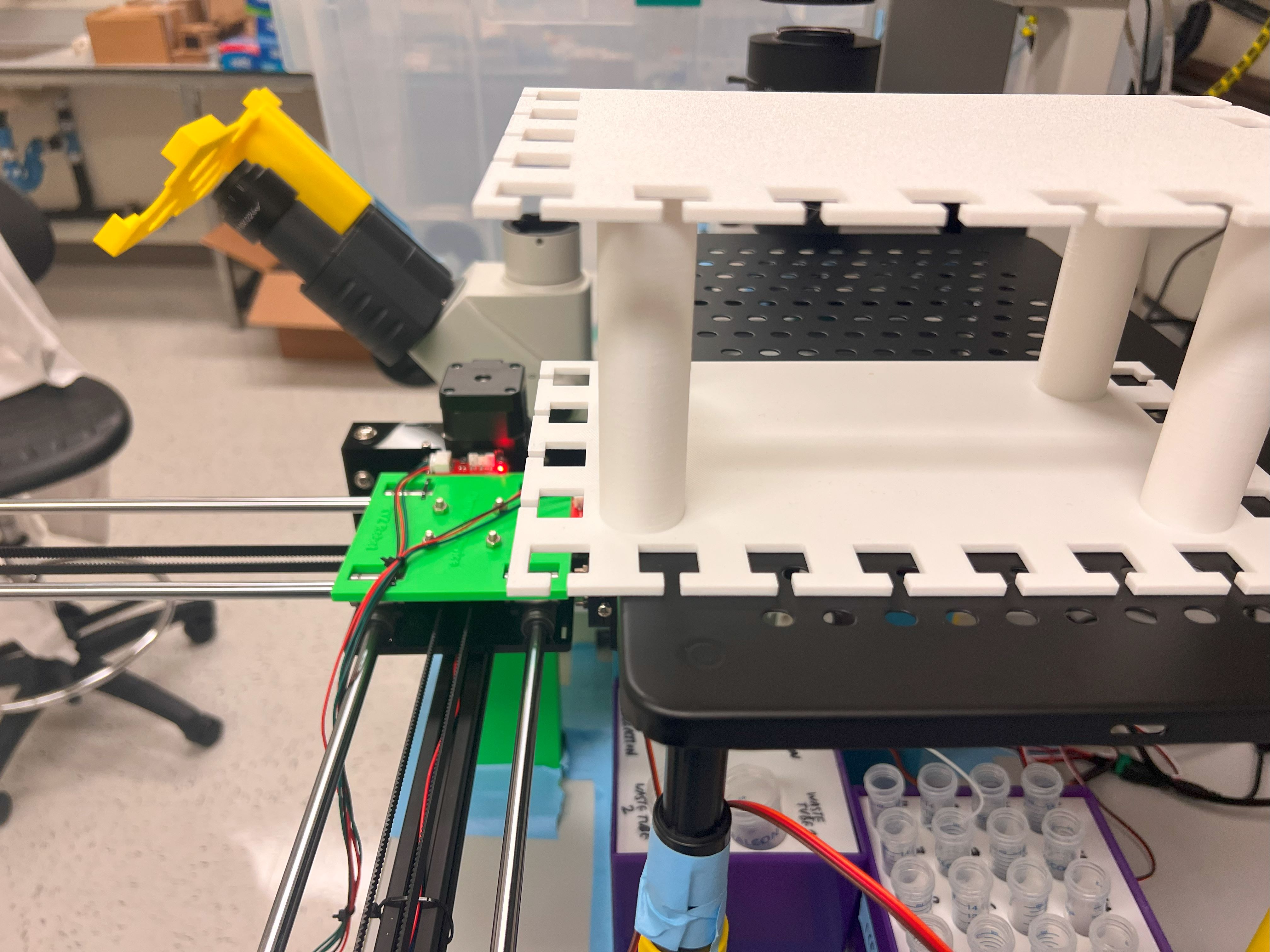

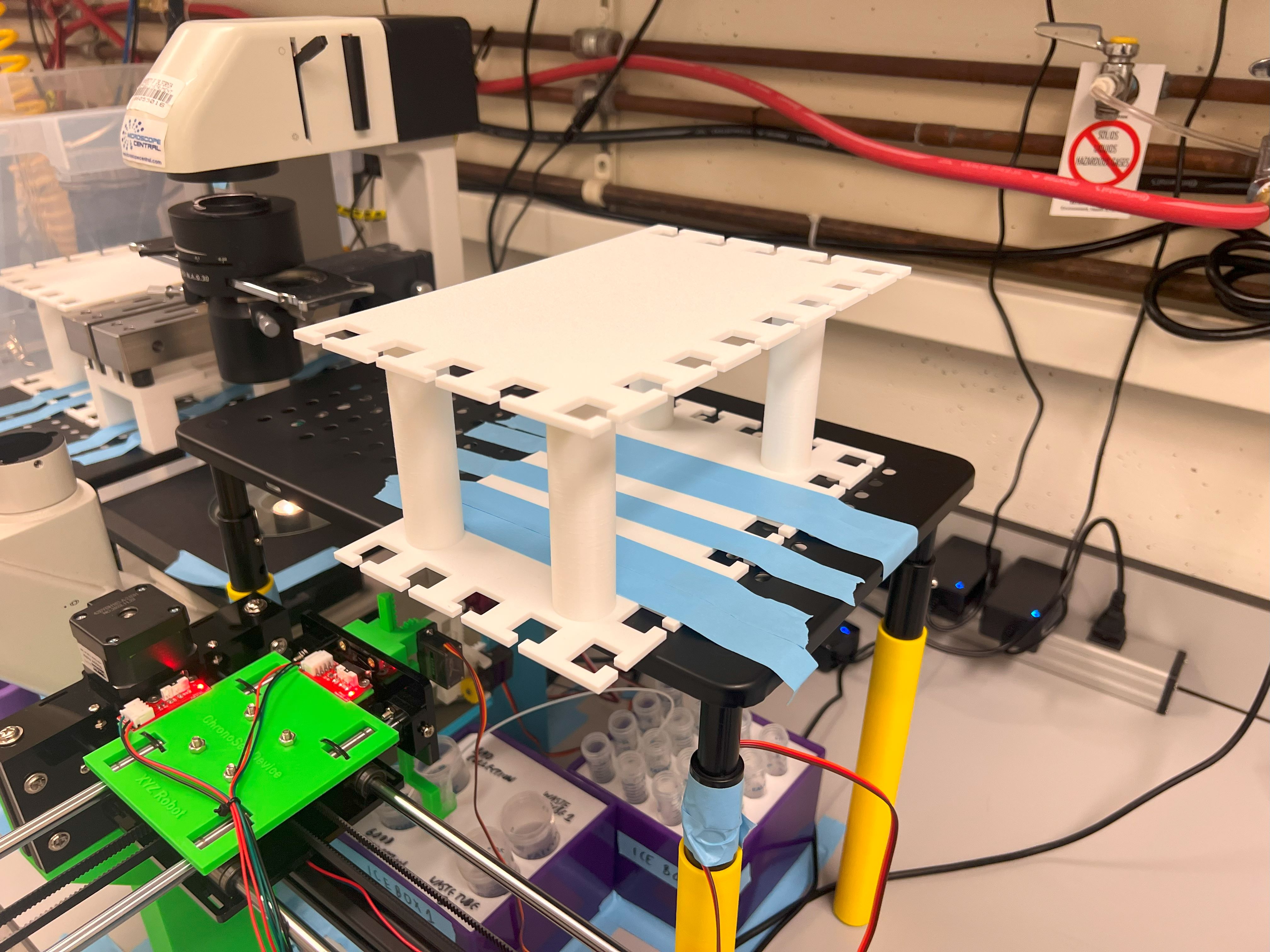

- We will need to increase the height of two Monitor Risers for some of the ChronoSeq device components.

- The riser on the right side of the ChronoSeq device is taller and you will need the Tallers legs for that one.

- The riser on the right side of the ChronoSeq device is shorter and you will need the Shorter legs for that one.

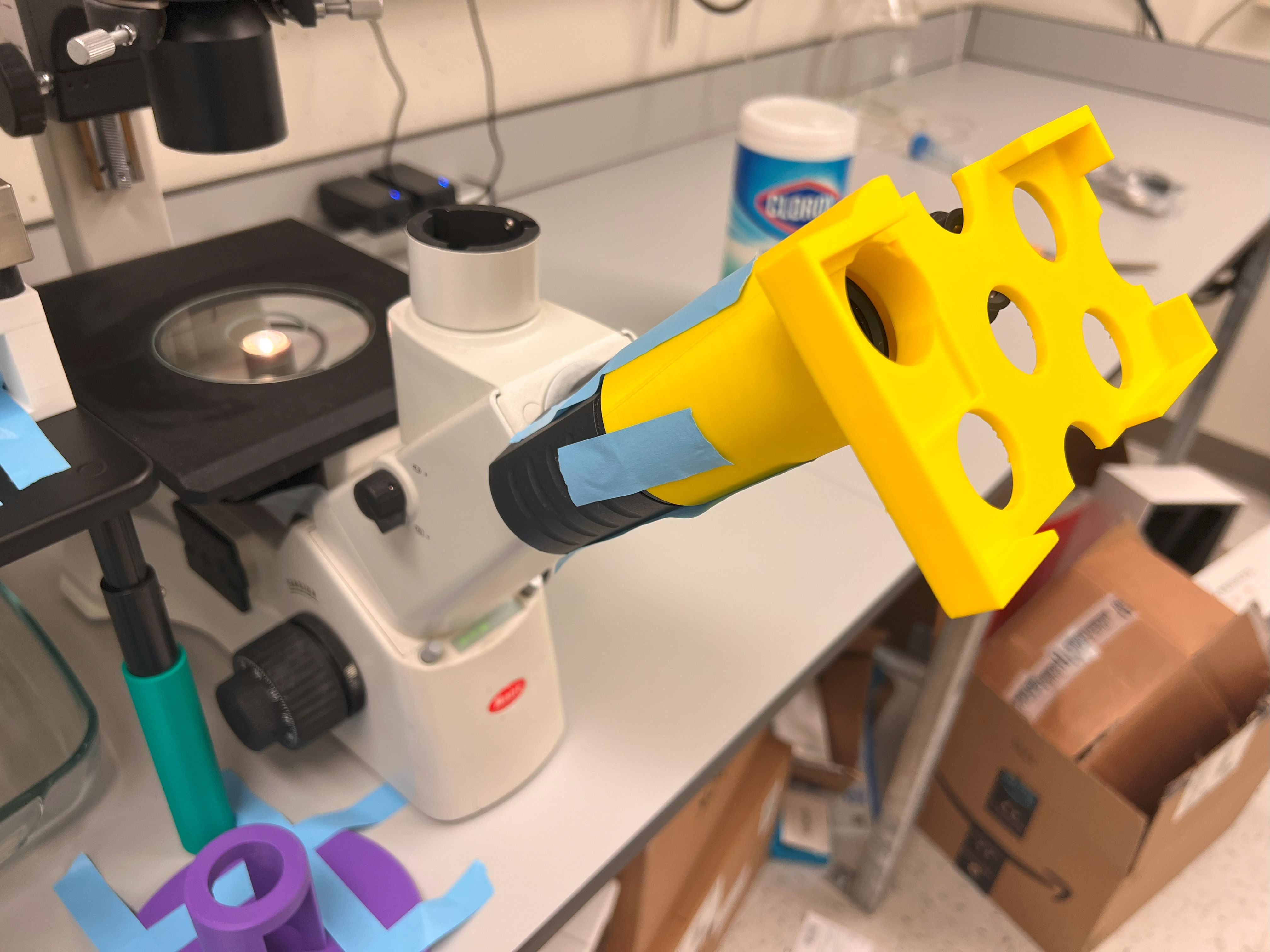

- You will also need a Pipette holder.

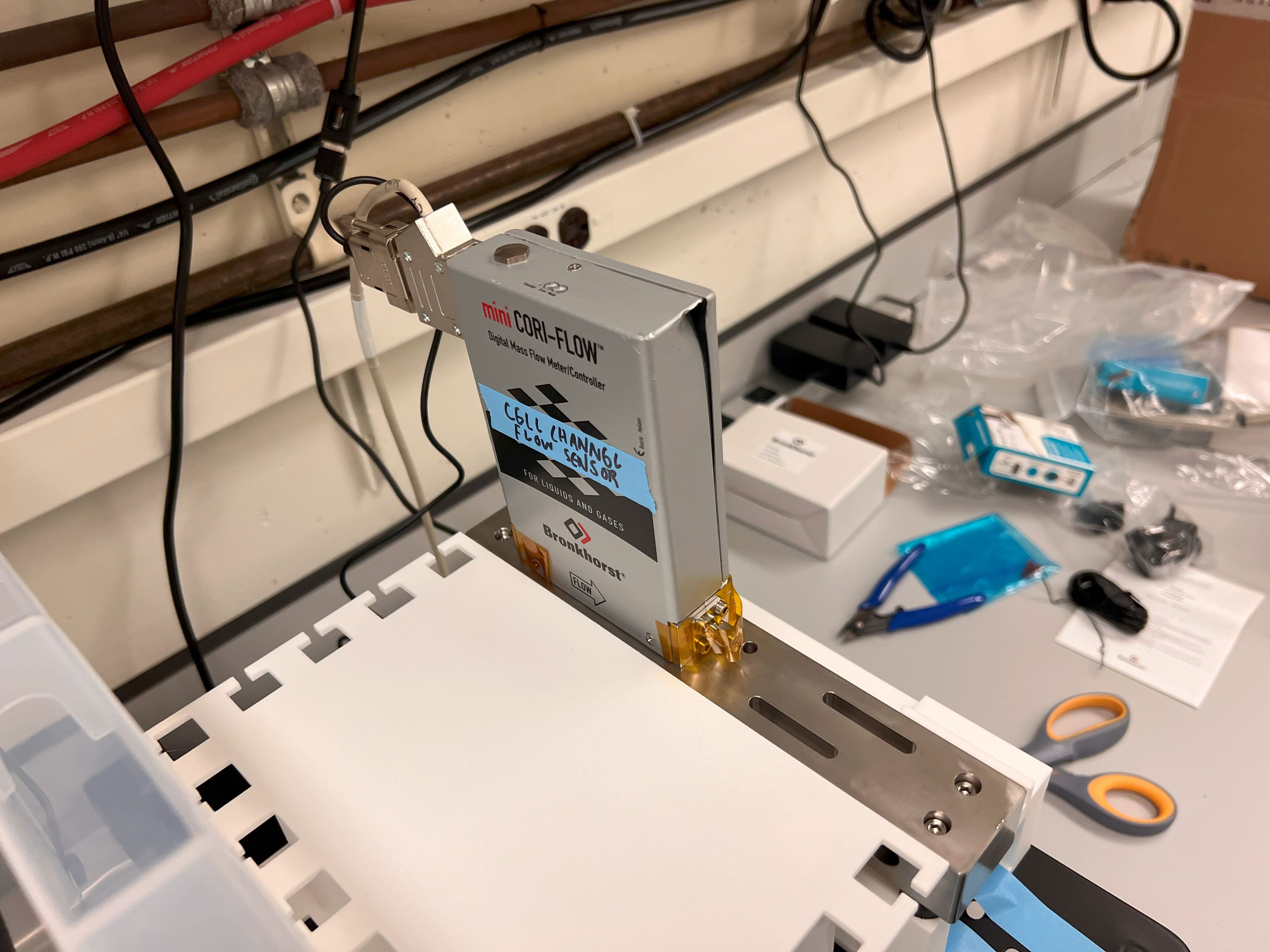

- You will also need a Holders for your Cell and Oil Channel Flow Sensors.

- We will need to increase the height of two Monitor Risers for some of the ChronoSeq device components.

- We also made an Iphone Holder to help record videos and photos of the microfluidic chip. The 3MF and CAD files for that can be found here.

- You will also need to print two Valve Holders.

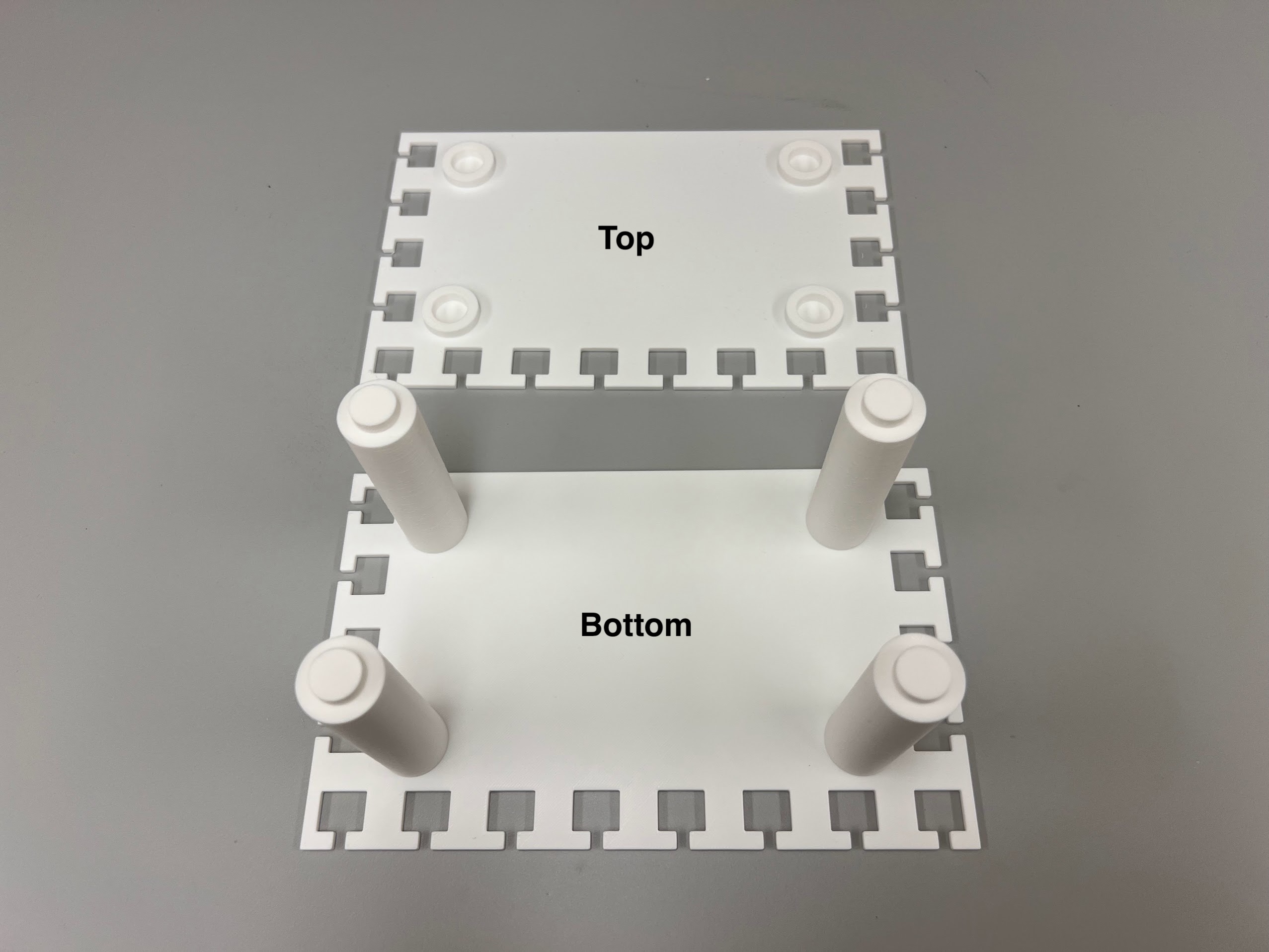

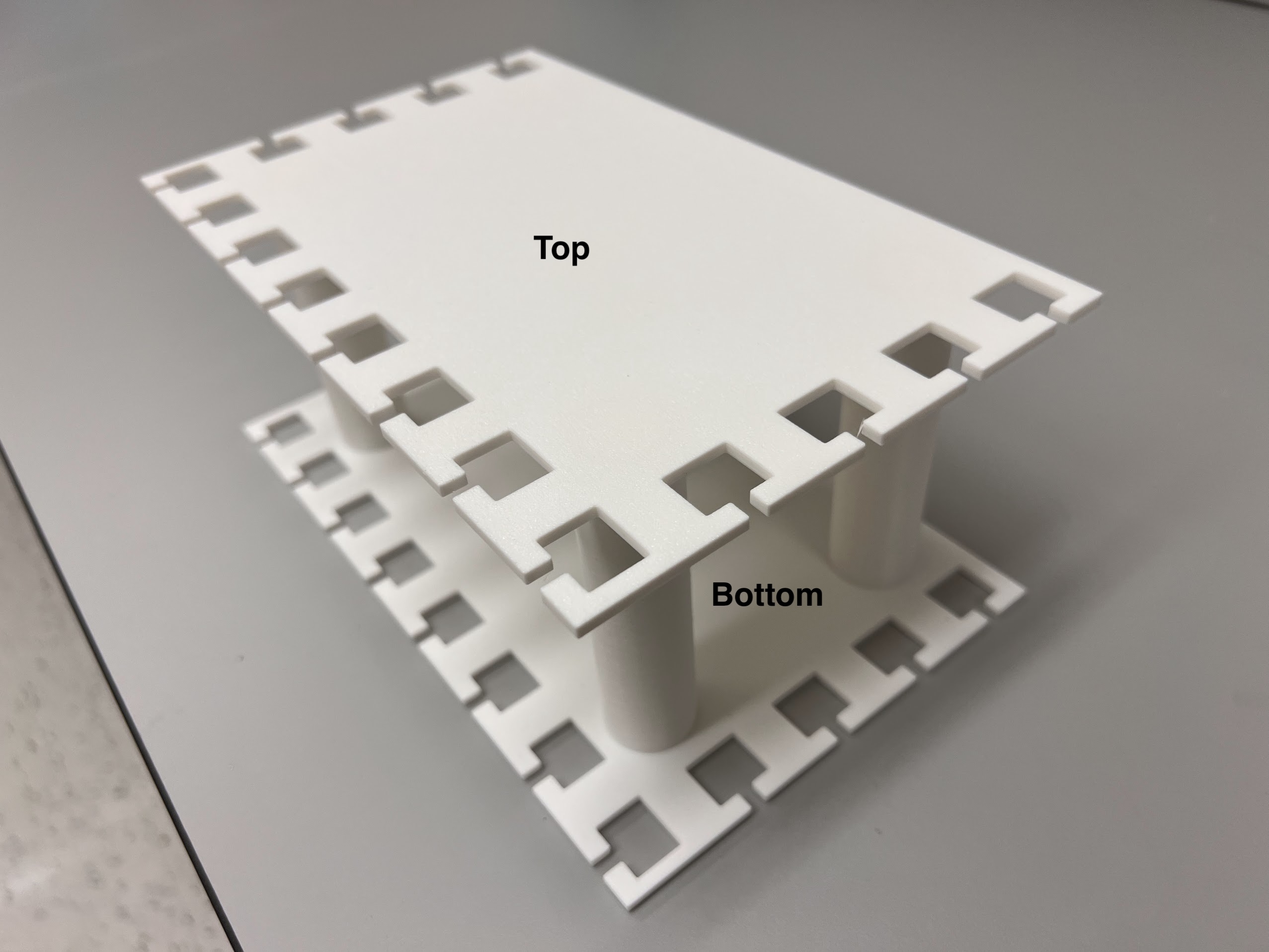

- Each Valve Holder has two parts. The Top and Bottom Parts.

- You can simply push the Bottom and Top together for a snap fit. This will make one complete valve holder.

- You can find the 3MF and CAD files for Valve Holders here.

- Use White Colored PLA for these Holders.

- We recommend getting a 3D Printing Accessories Kit if you haven't purchased one already.

- Its extremely helpful in removing supports and cleaning up the print.

Ordering Expensive components and Components with long lead times:¶

Expensive Components:¶

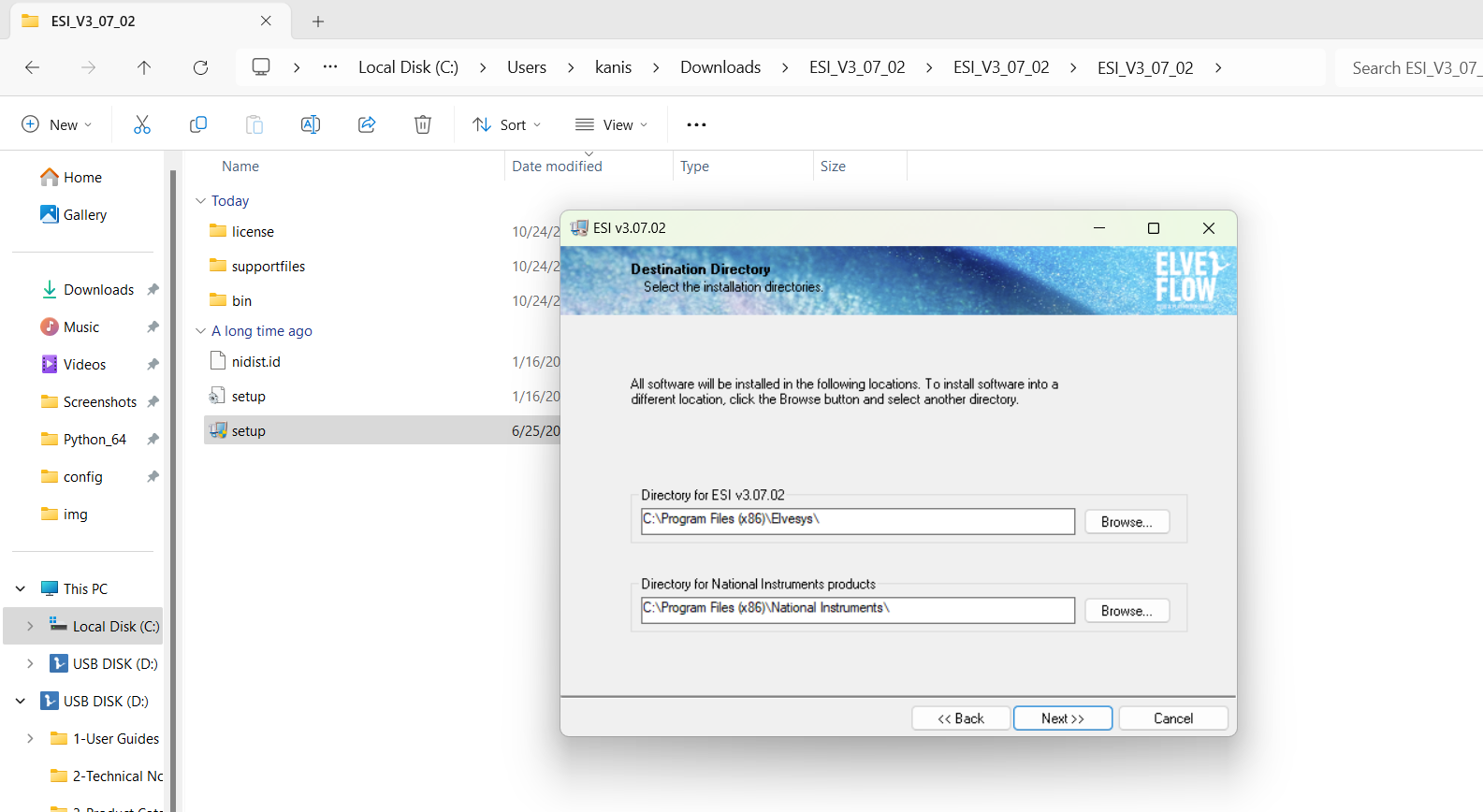

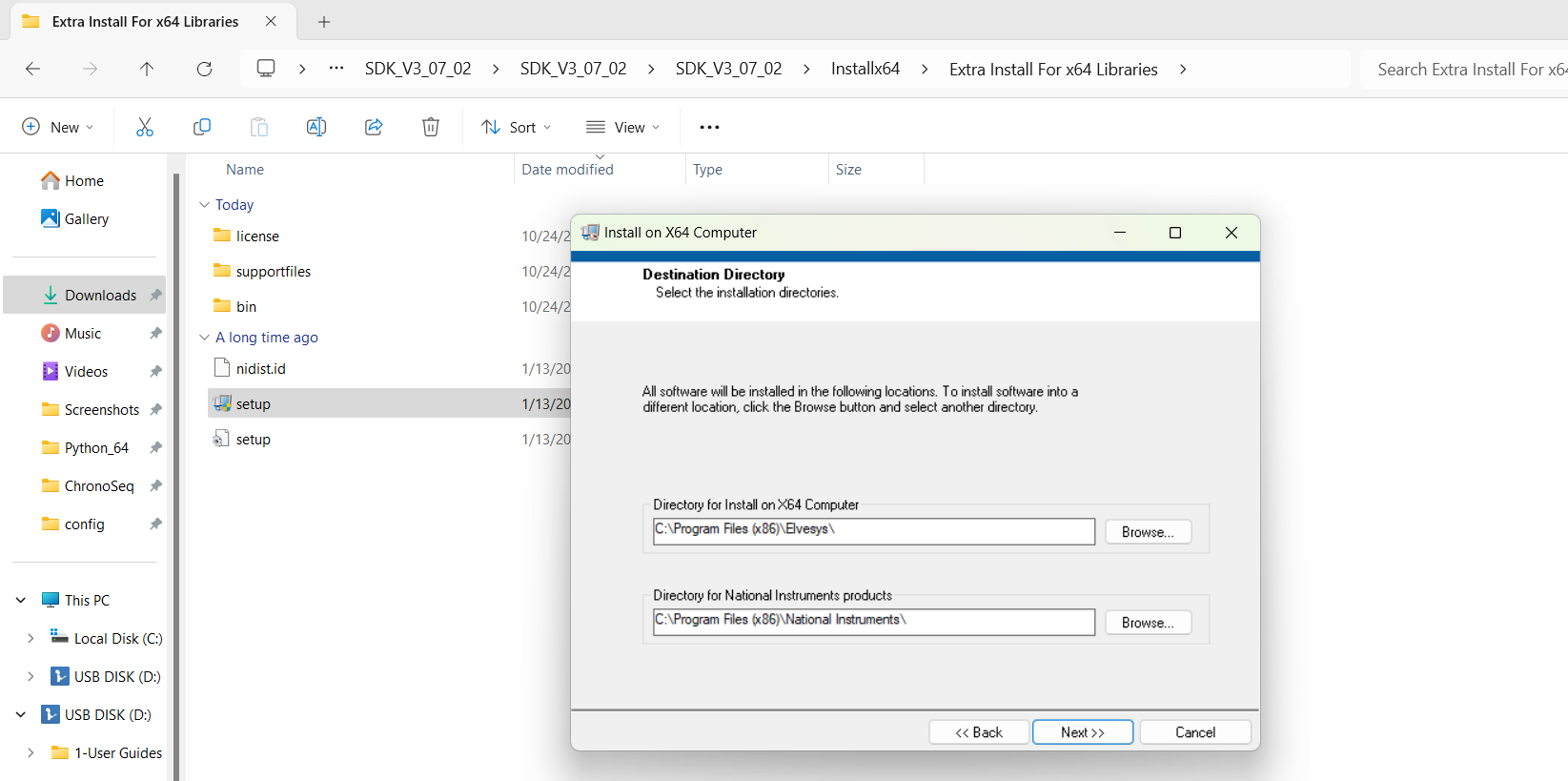

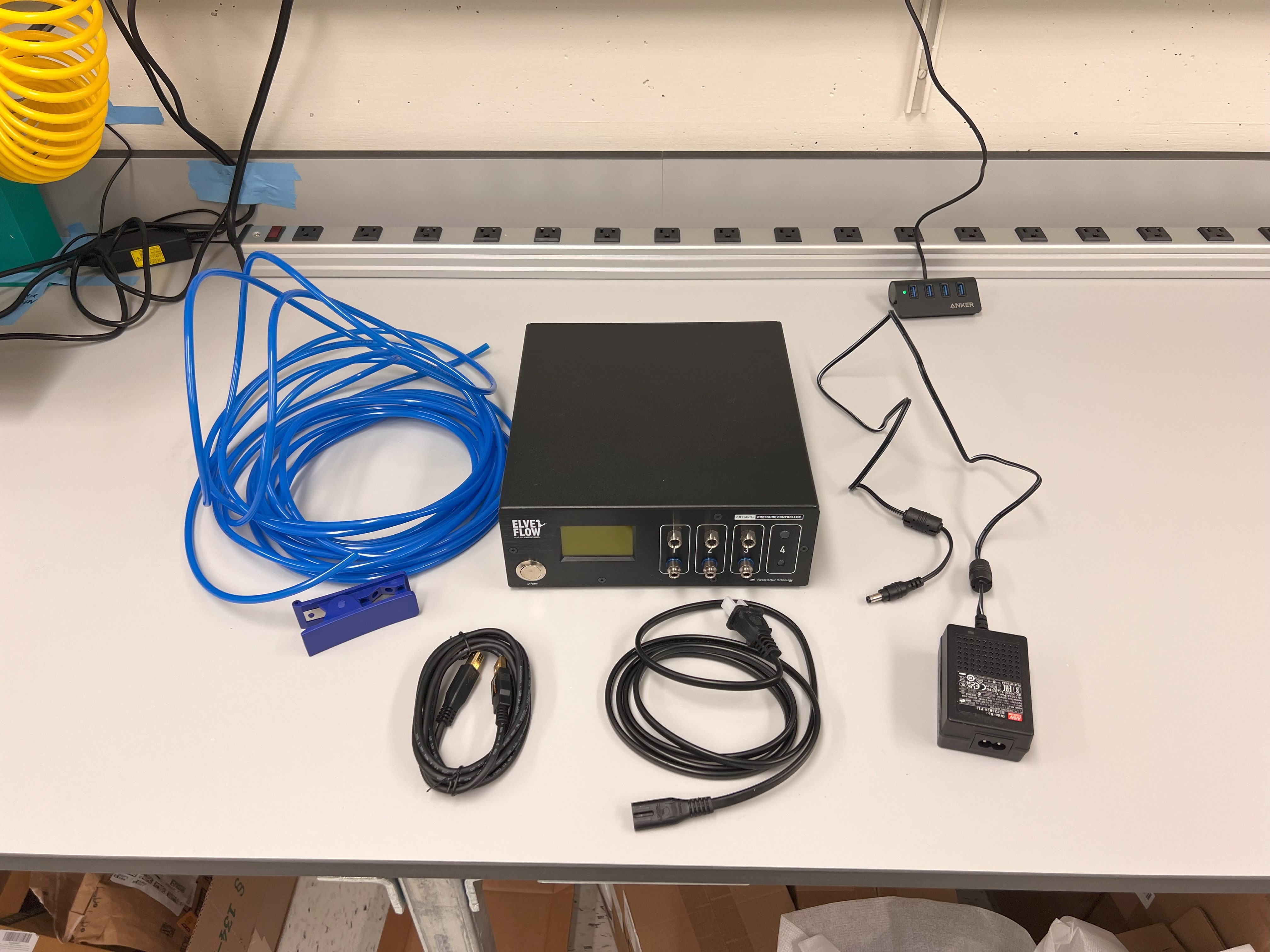

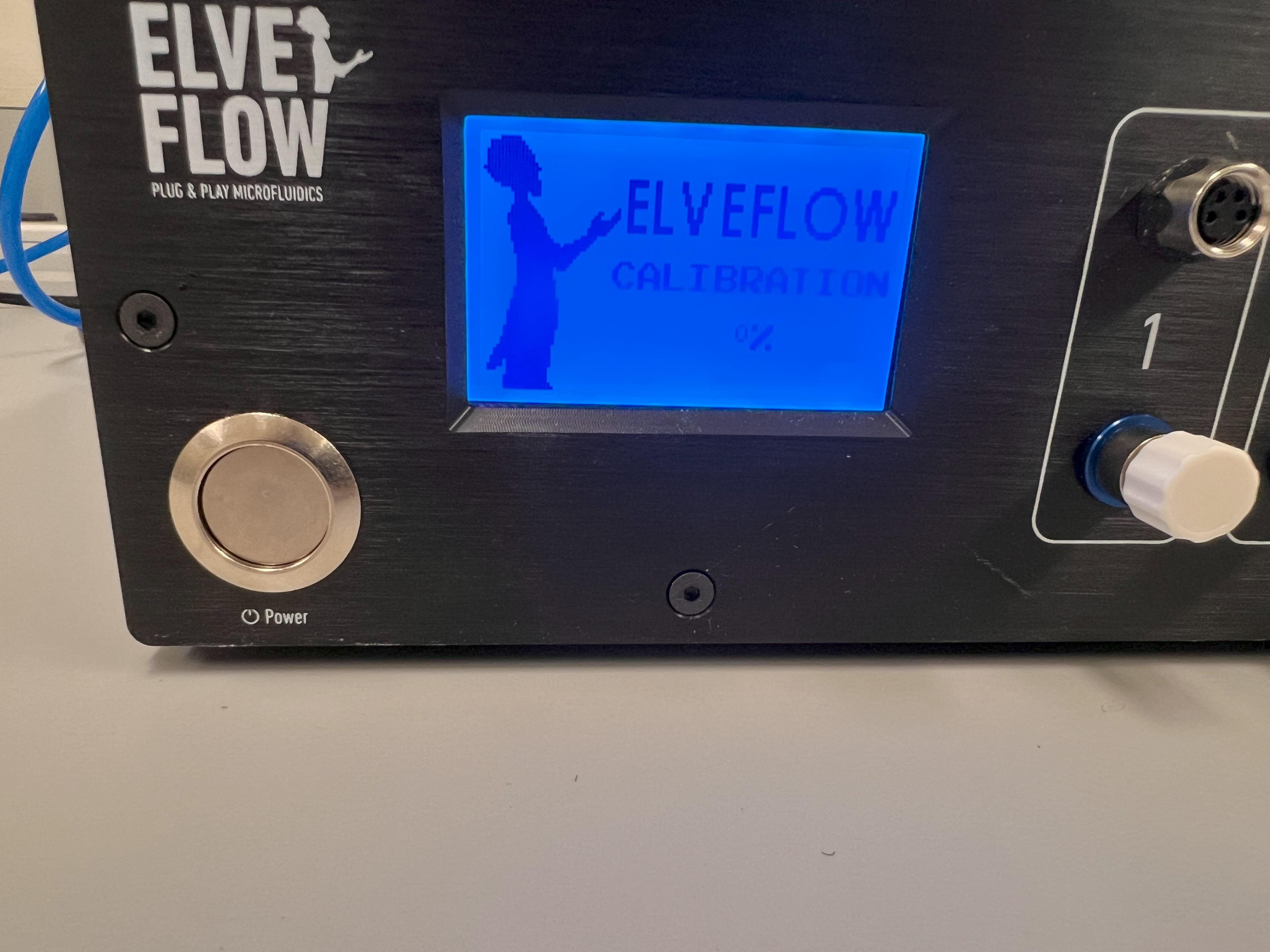

- We ordered the OB1 Flow Controller from Elveflow. The Configuration was as follows:

- 3 Channels only. All Channels were (0-2000mBar)

- You will also need an AC Power Cord for North American Outlets

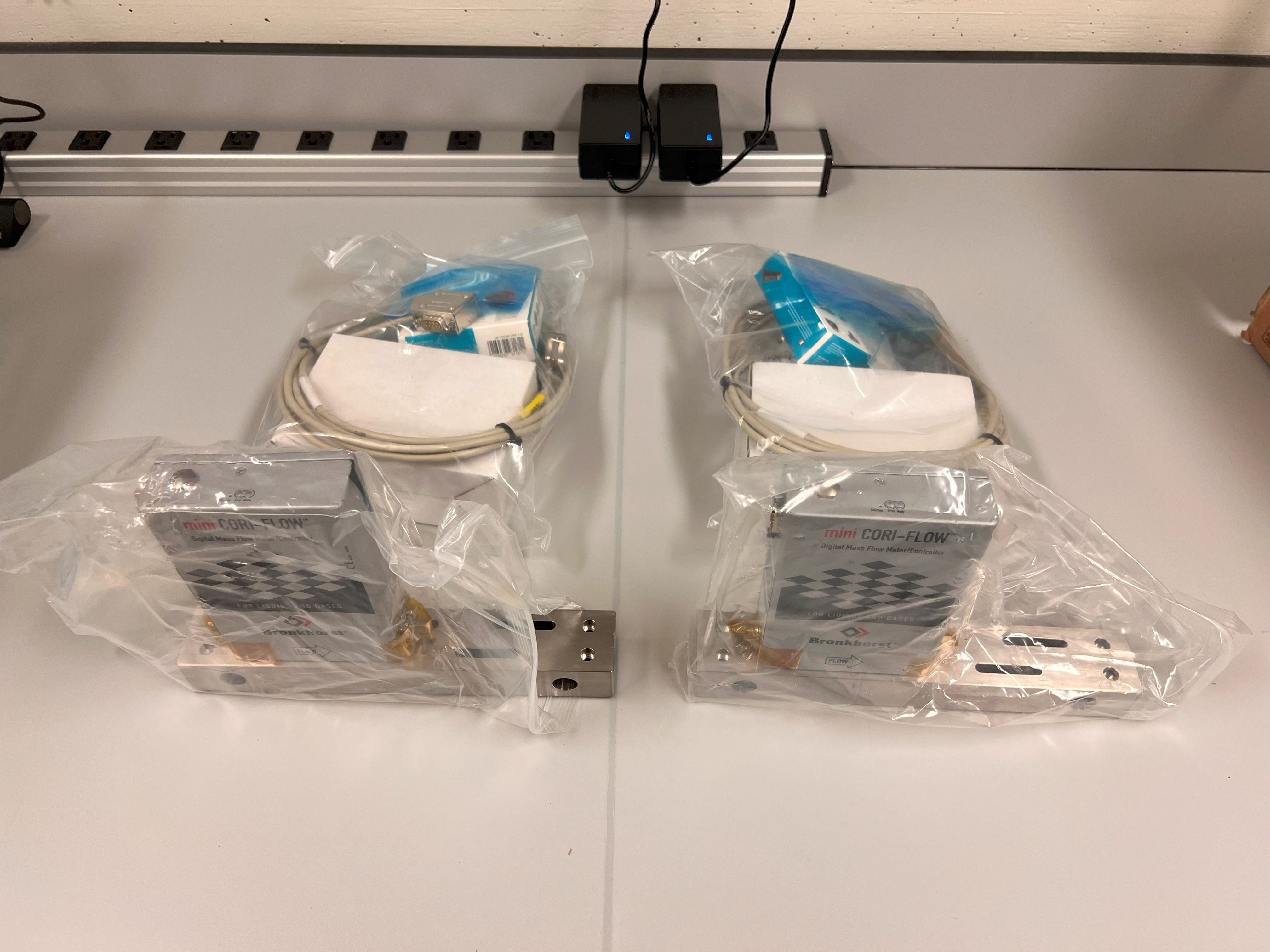

- We ordered two Coriolis Flow Sensors from Elveflow:

- BFS 1 Configuration. 2% Accuracy.

- Elveflow will try to sell you more features, components and additional kits. Politely refuse to buy anything else.

- I've included a copy of the Invoice page. You can see how much we paid for these components and what exact items we ordered.

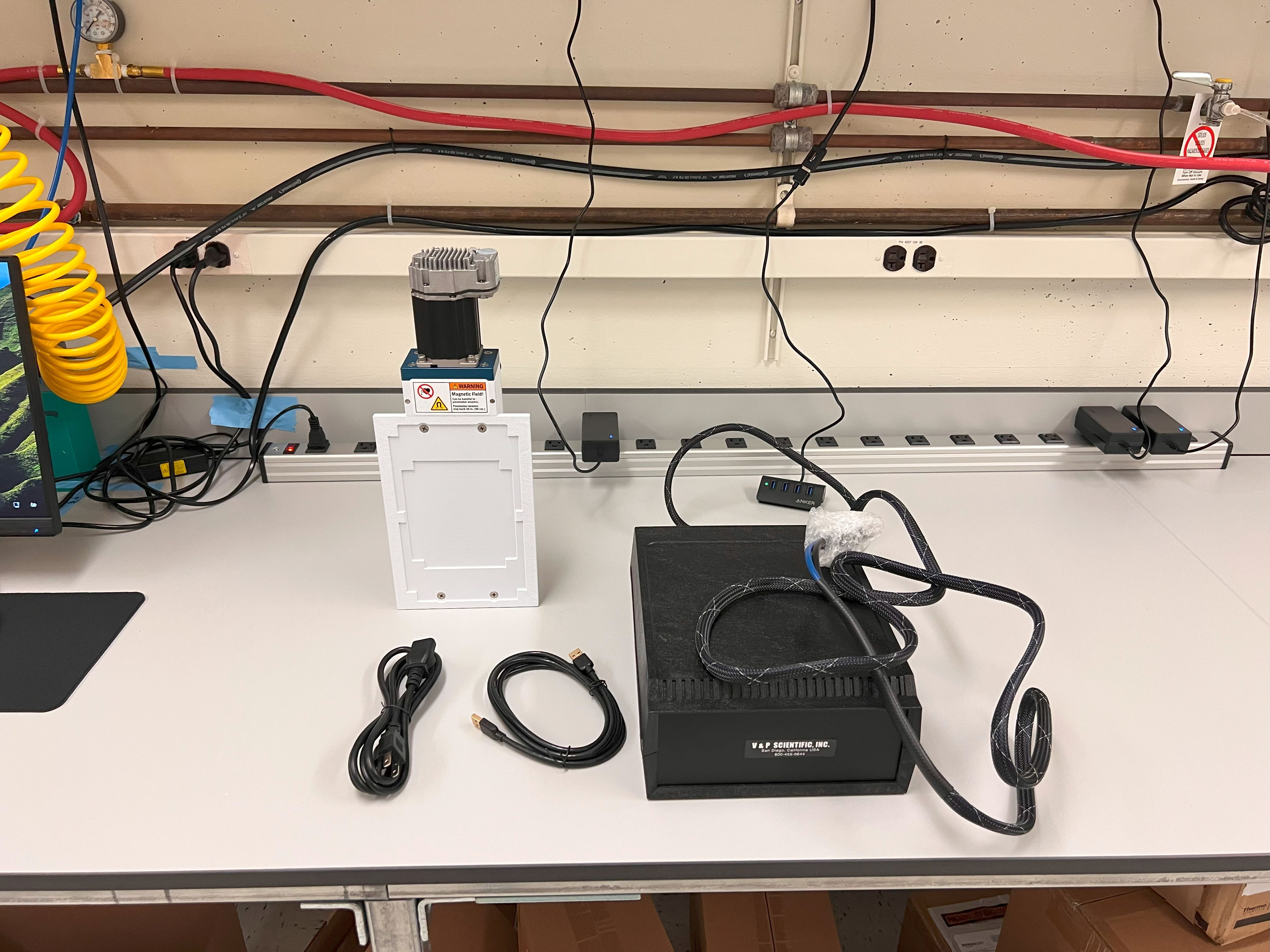

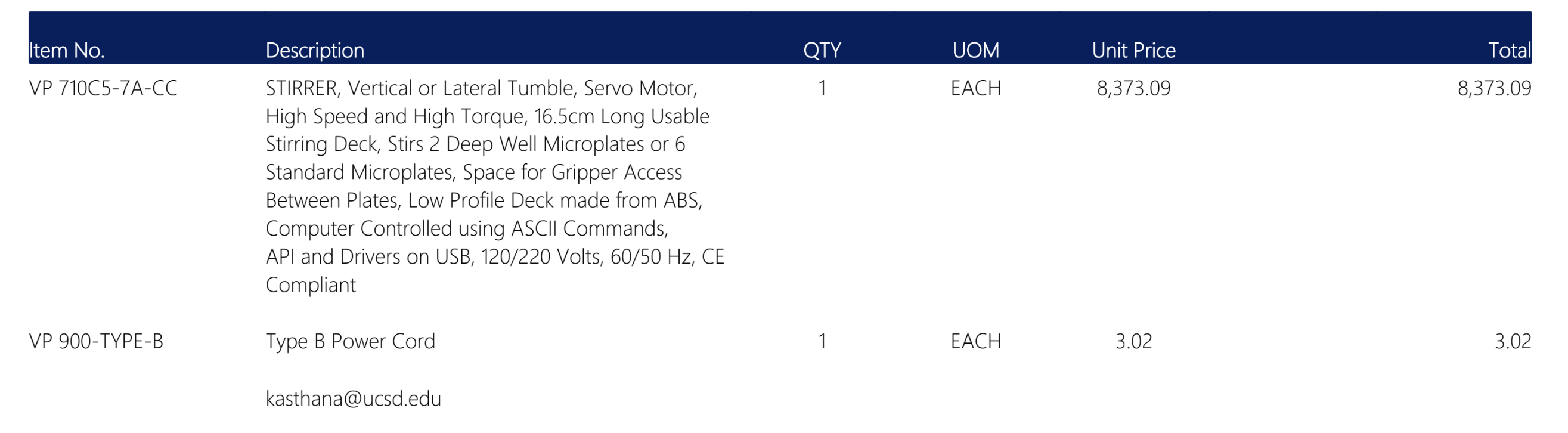

- We ordered the VP 710C5-7A-CC Vertical Computer Controlled Stirrer from V&P Scientific. Here is a screenshot of the Invoice from May 2024.

- We will strive to provide cheaper DIY versions or replacements for these expensive components in future versions of ChronoSeq.

- Help and contributions from community members is appreciated. Create a merge request when you are ready.

Long Lead Time Components:¶

- We ordered two VX-200 Vortex Mixers

- We ordered two 50ml Heads for the VX-200 Vortex Mixers

- We ordered a 3D Nutating Mixer.

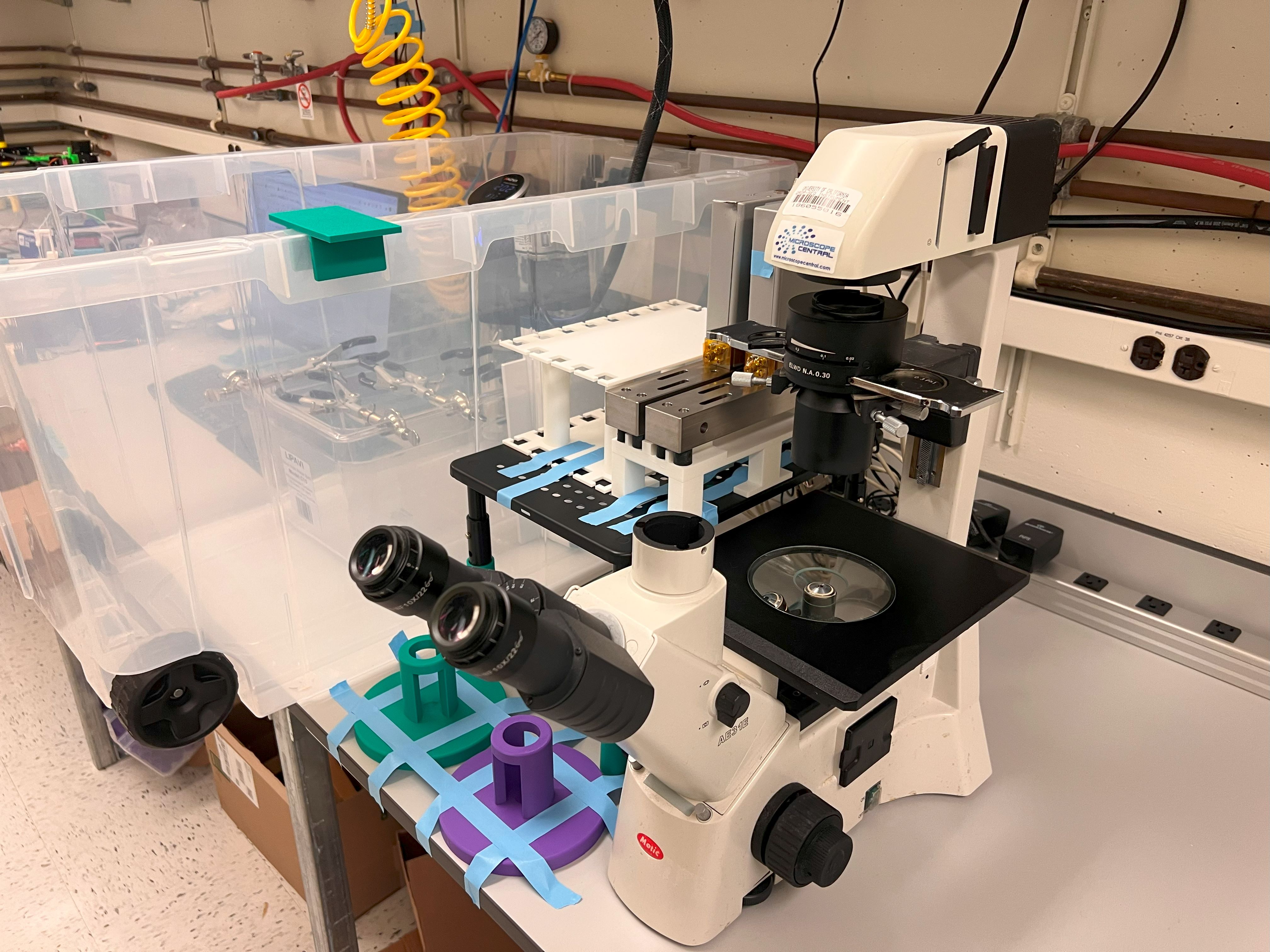

- We ordered the AE31 Elite 30W Trinocular Inverted Microscope

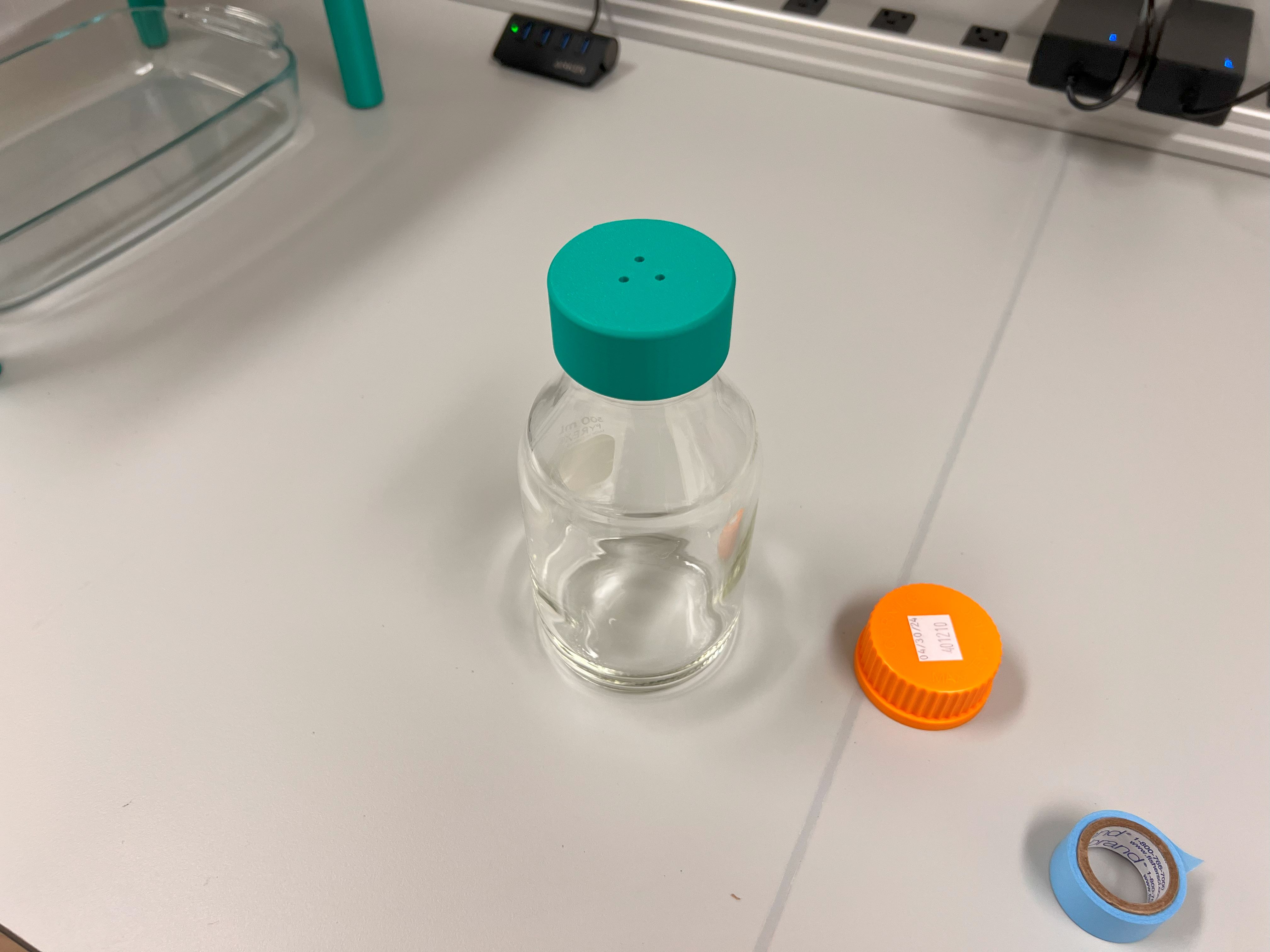

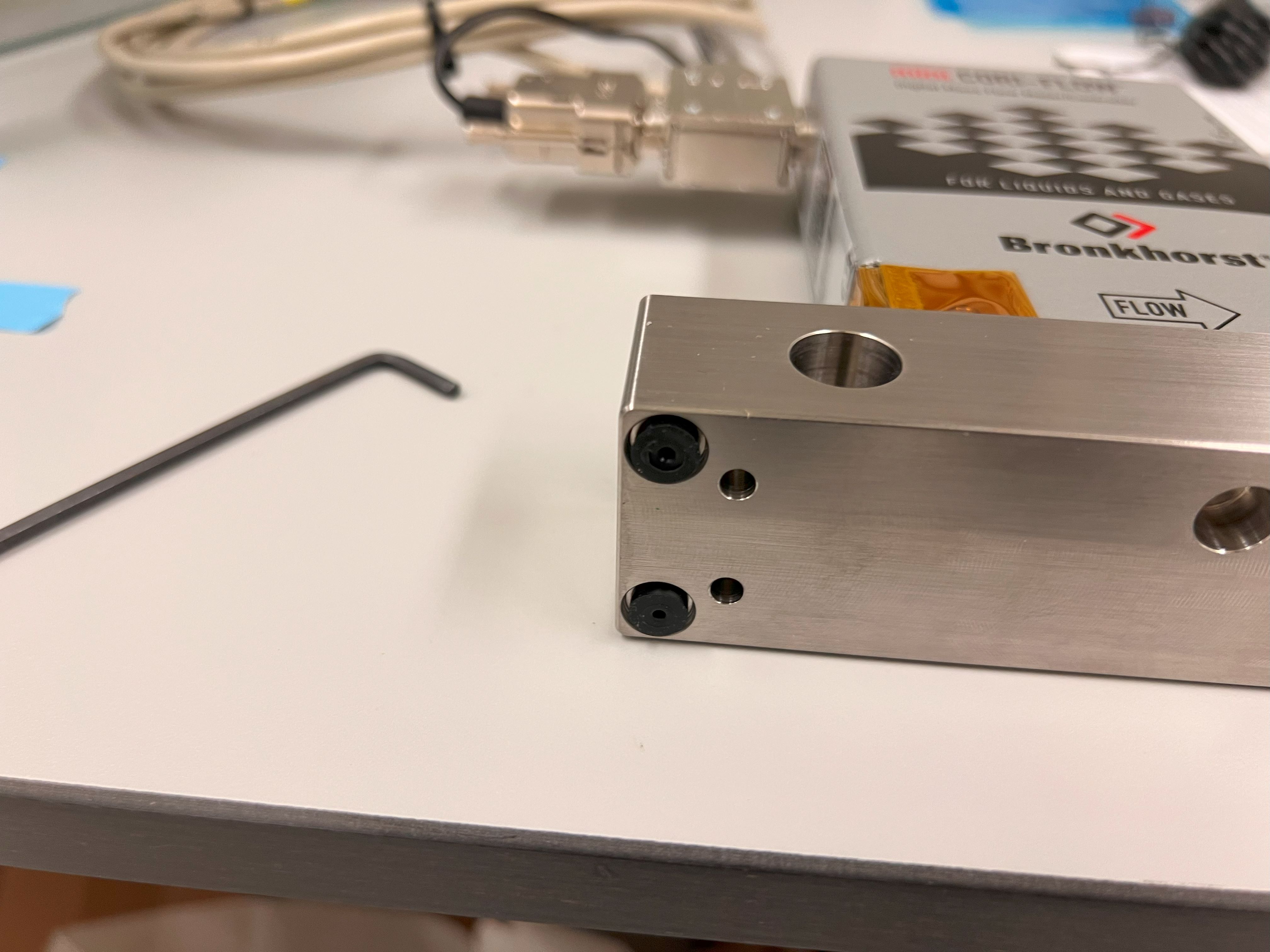

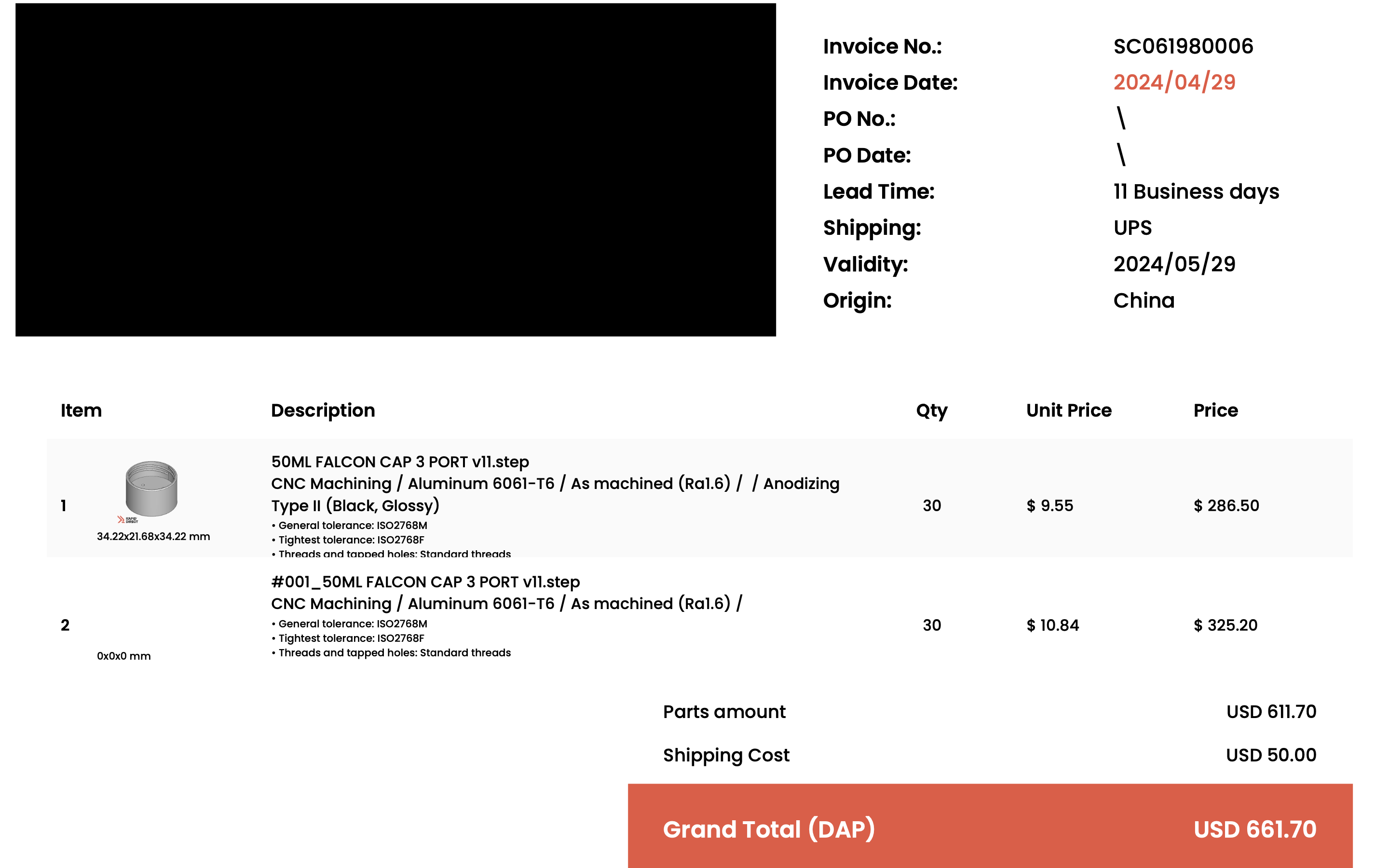

3 Port Reservoirs¶

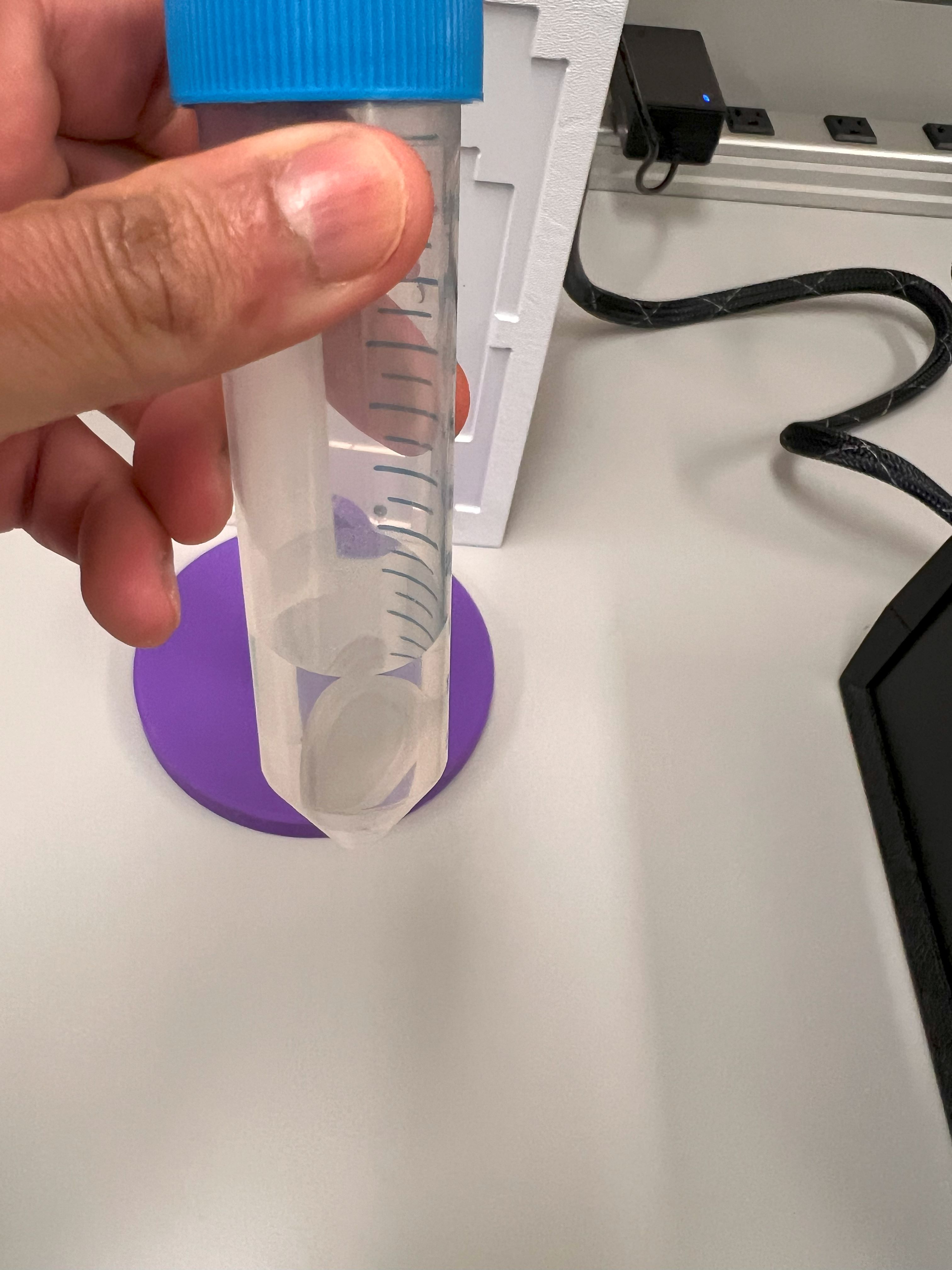

- You will also need to have reservoir caps manufactured for the 50ml Falcon Tubes.

- These reservoirs will contain the liquids that need to be moved through the ChronoSeq device.

- They have been designed and tested to be gas tight.

- They allow quick changes in pressure to be applied to the liquids stored in the reservoirs. This changes the flow rate of the liquids to also be changed.

- The CAD Files can be found in this directory. You can read the manufacturing instructions here.

- We had these parts manufactured by RapidDirect.

- Our Order number was SC061980006.

- Most likely they still have the CAD/CAM files from this project. So they should be able to quickly manufacture these parts for you.

- Just ask them to make the Black Anodized Version for you. You don't need the As-Machined version.

- If they refuse to do this, just follow the Manufacturing instructions linked above.

- Here is a screenshot of the invoice:

Manufacturing the Microfluidic Chips:¶

- We used SU-8 Photolithography followed by PDMS Molding for manufacturing the Microfluidic Chips.

- We then plasma bonded these Microfluidic Chips to 75mm Glass Slides.

- See the protocols below on how there were manufactured using the Core Facilities at UCSD:

Assembling Other Individual Components¶

Before getting started with this assembly protocol you need to assemble some of the individual components. Follow the instructions in the notebooks linked below before you move onto the next section:

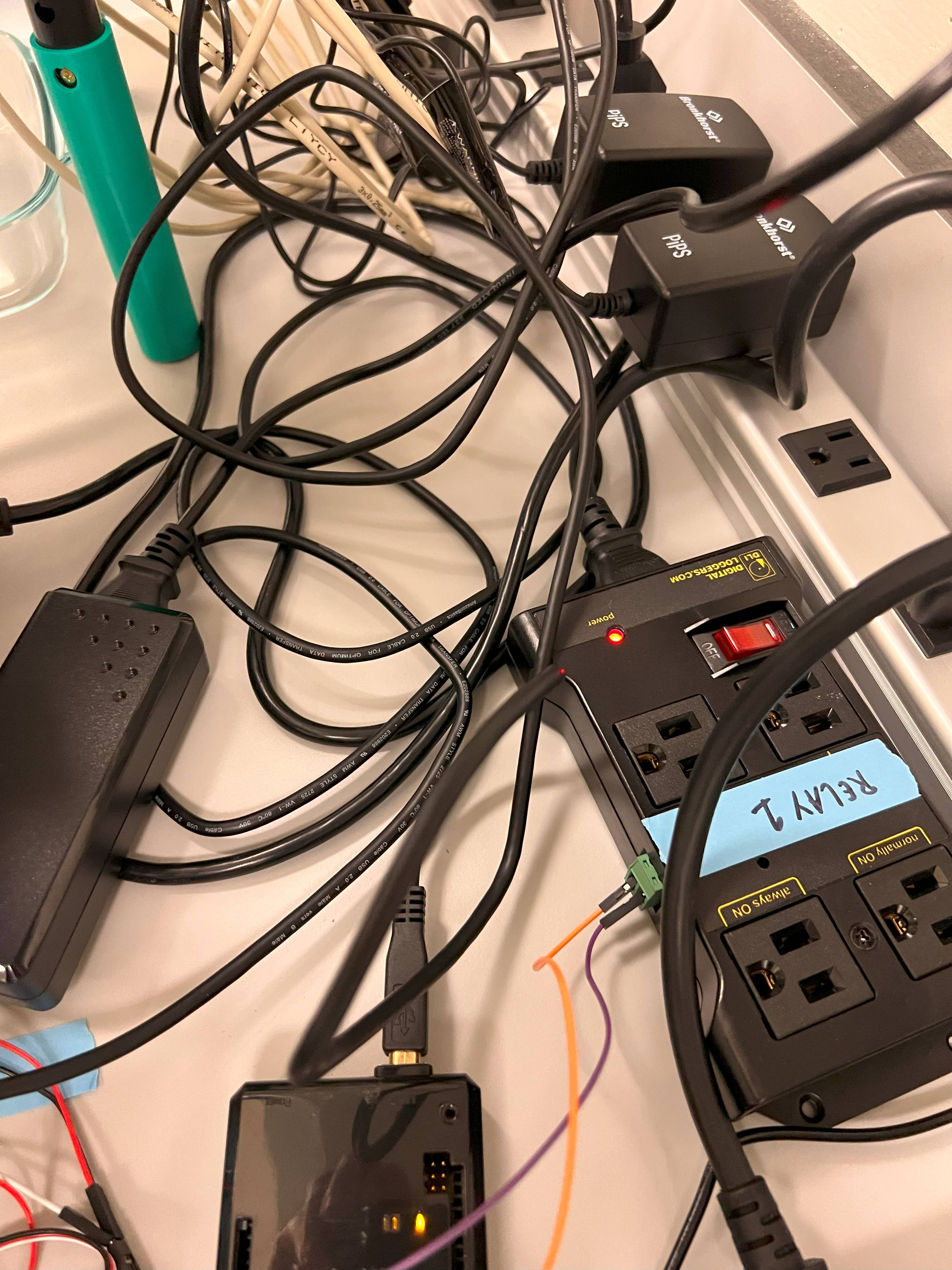

- Assemble three valve controllers and the SMC valves

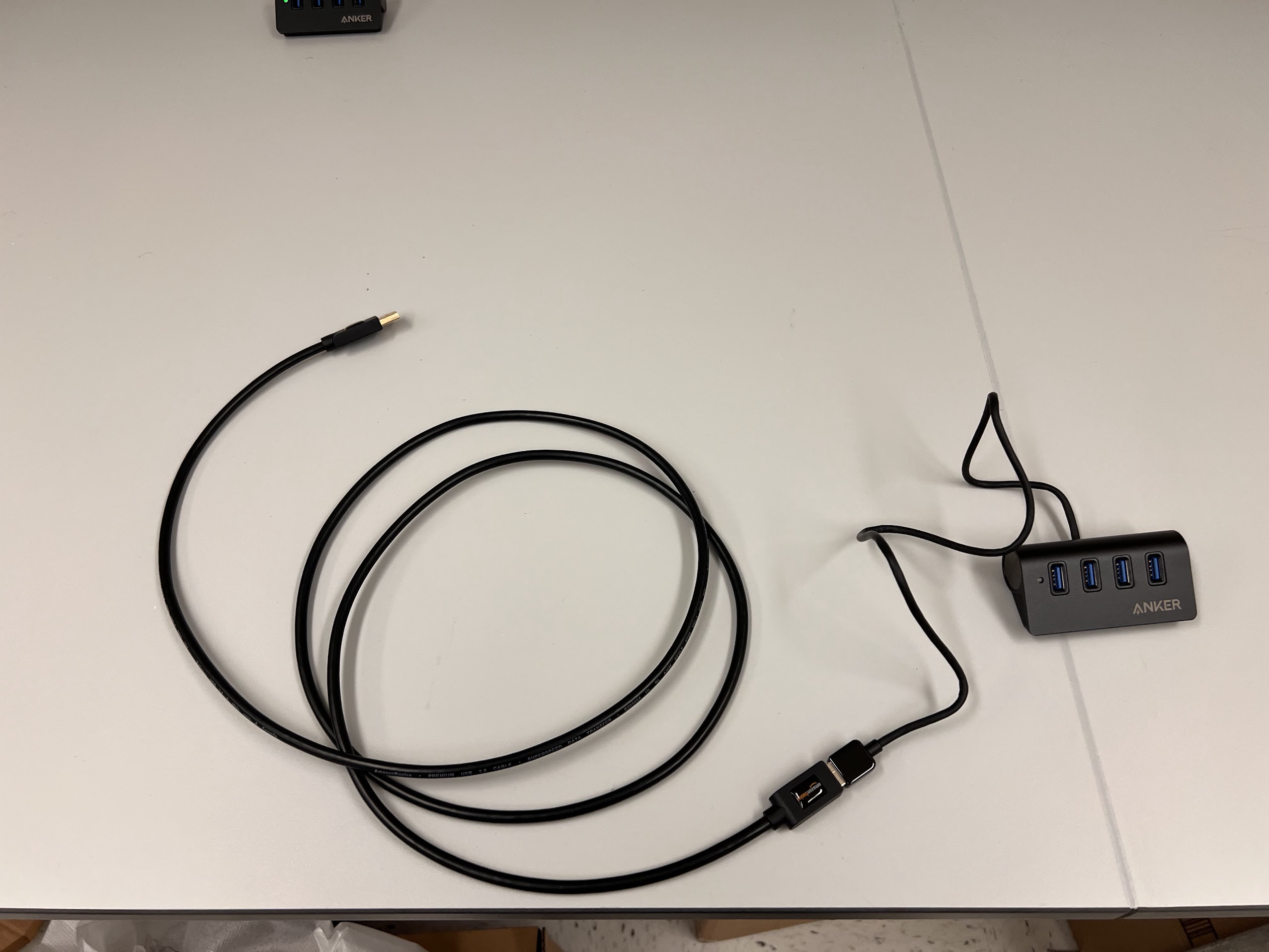

- Assemble one Sensirion Flow sensor

- Assemble the XYZ Robot

- Assemble the XY Robot and Ice Boxes

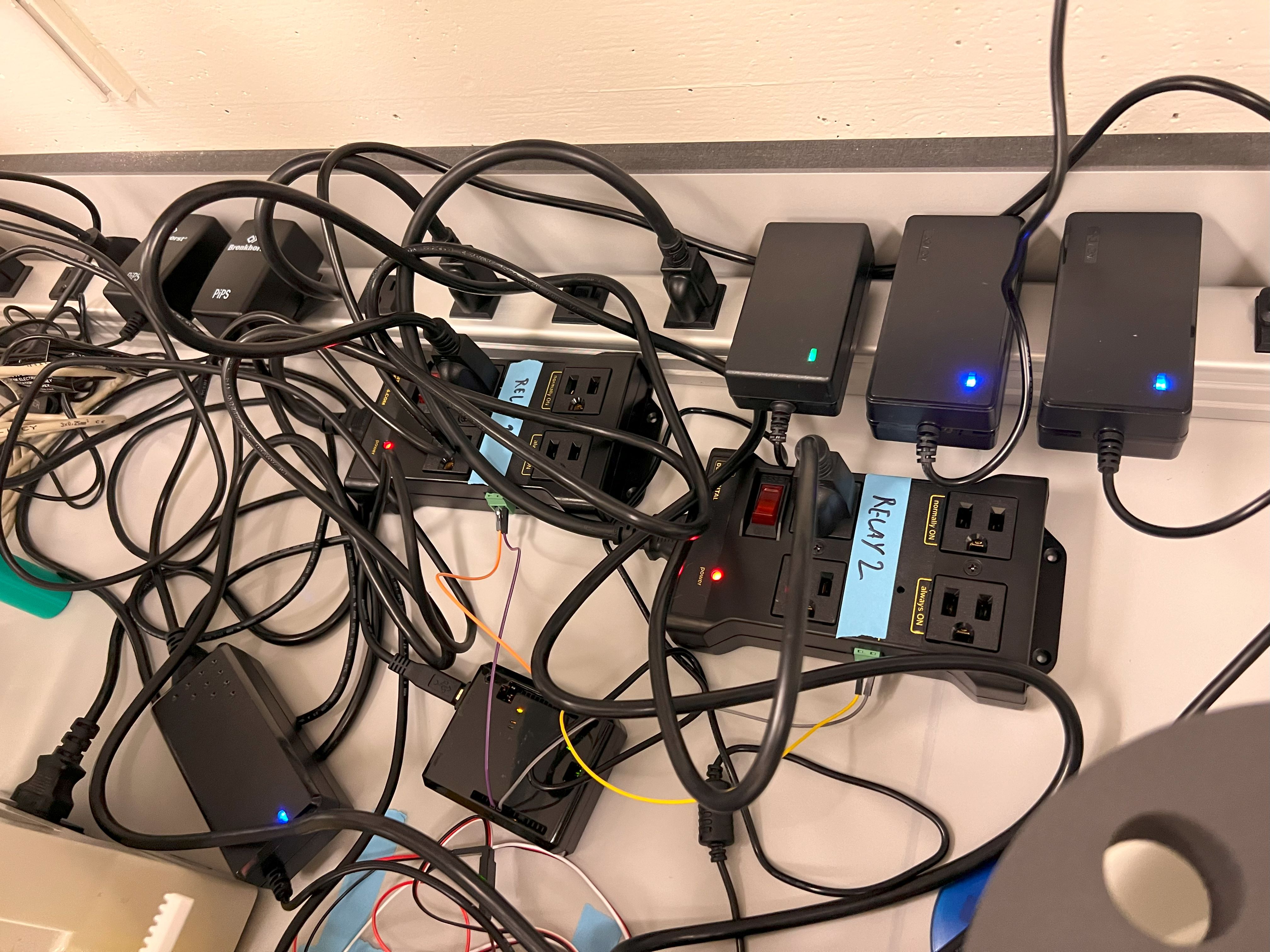

- Assemble the Vortex Relay Controller

ChronoSeq Device Assembly¶

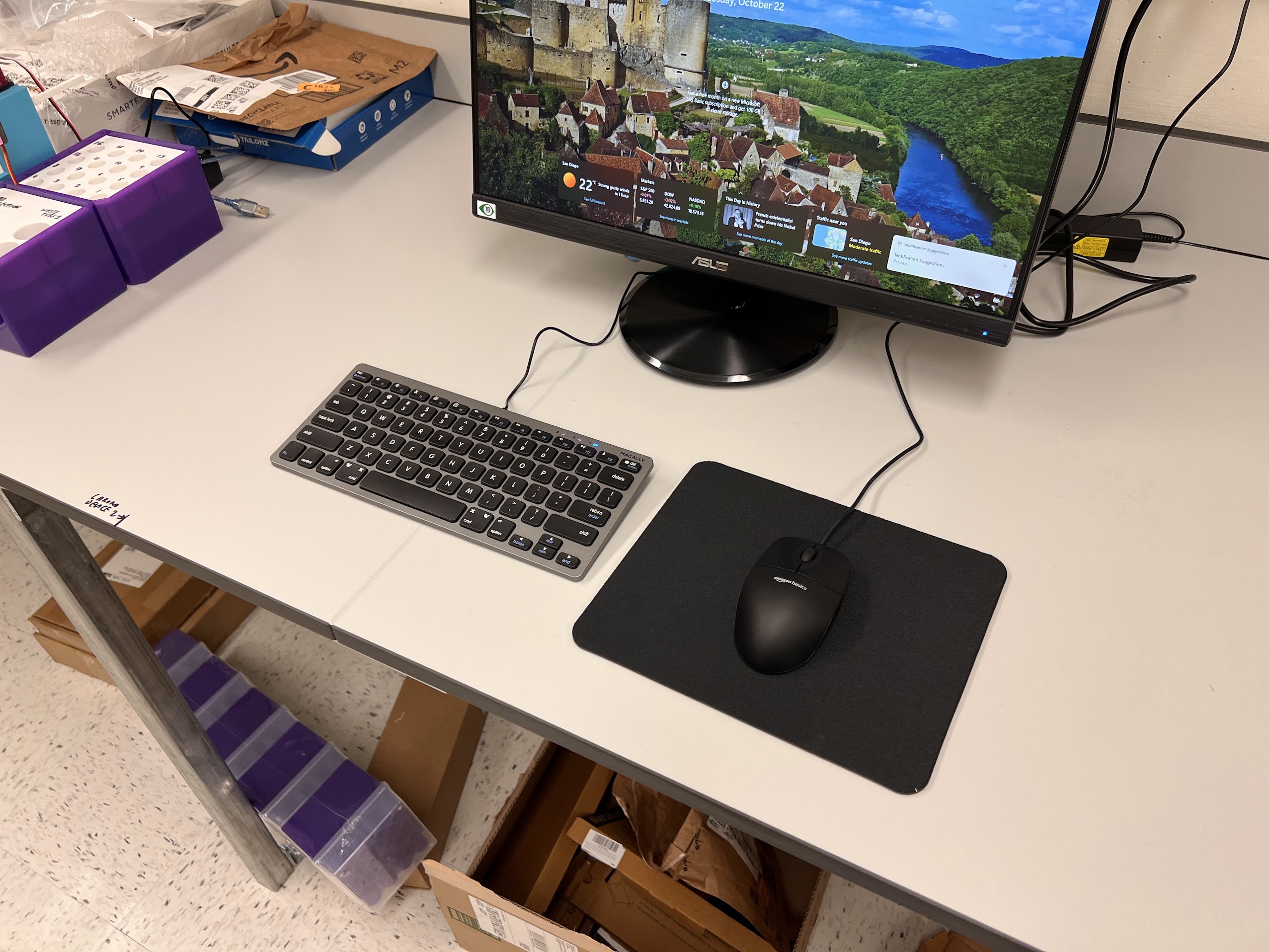

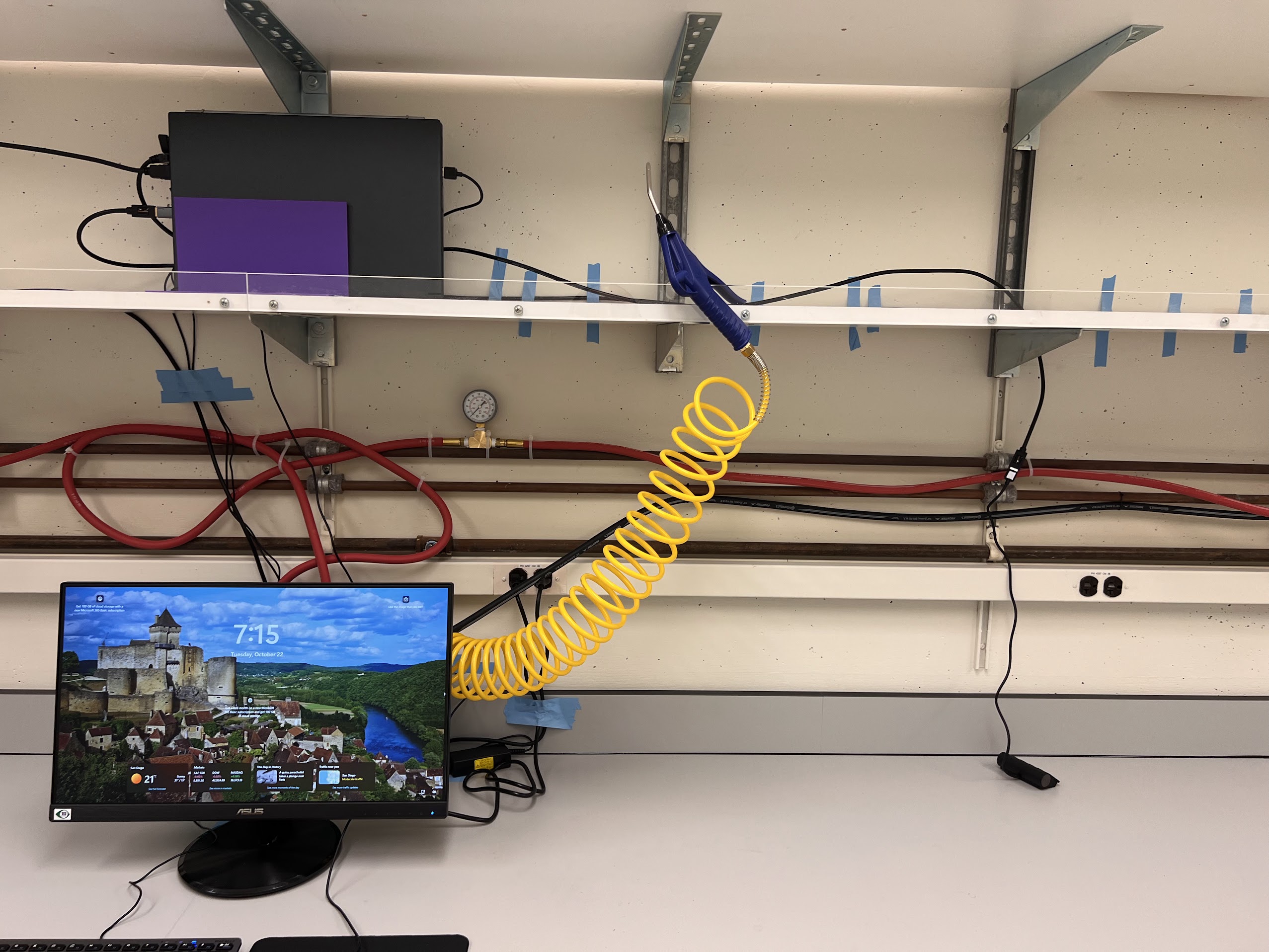

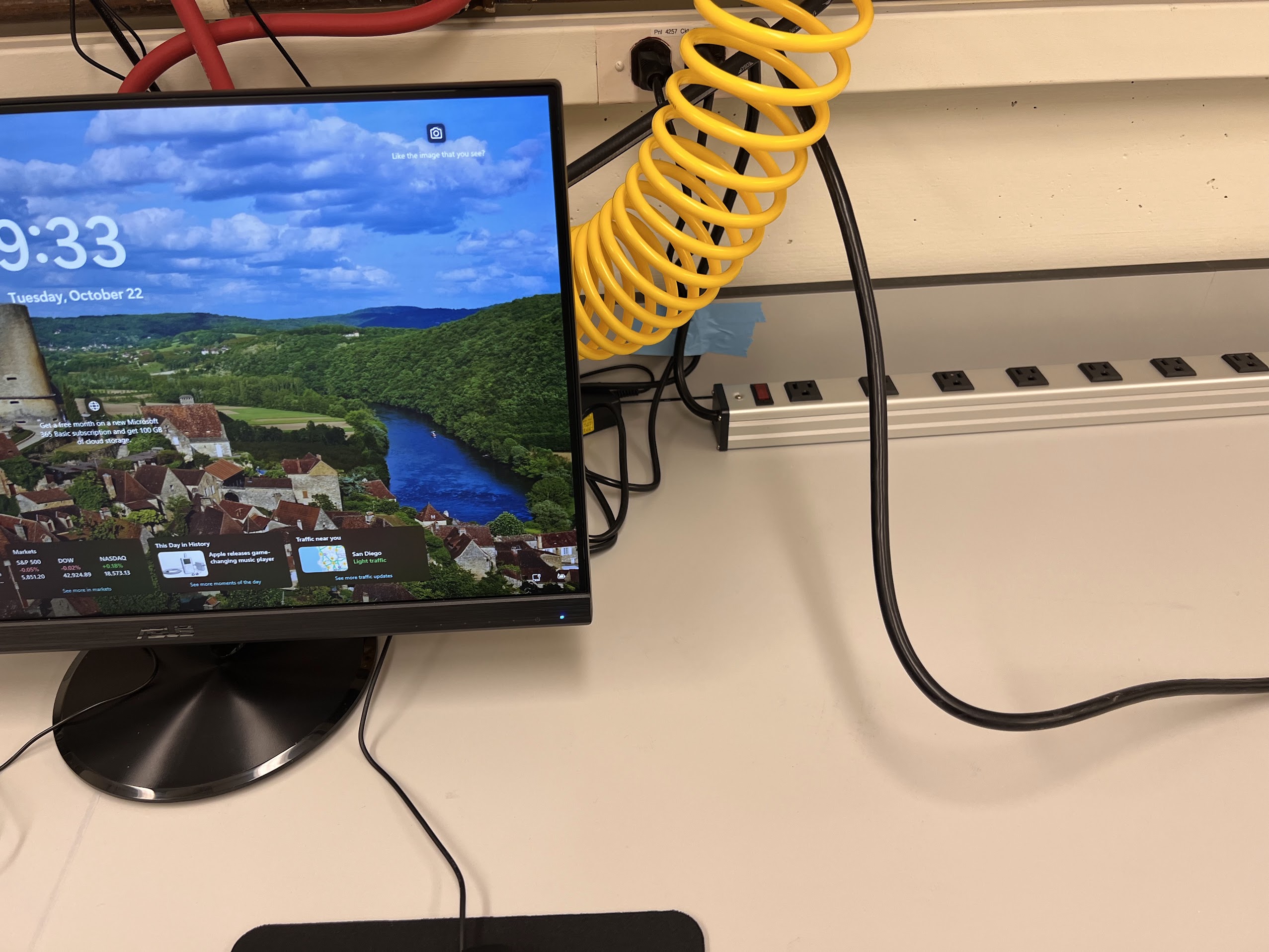

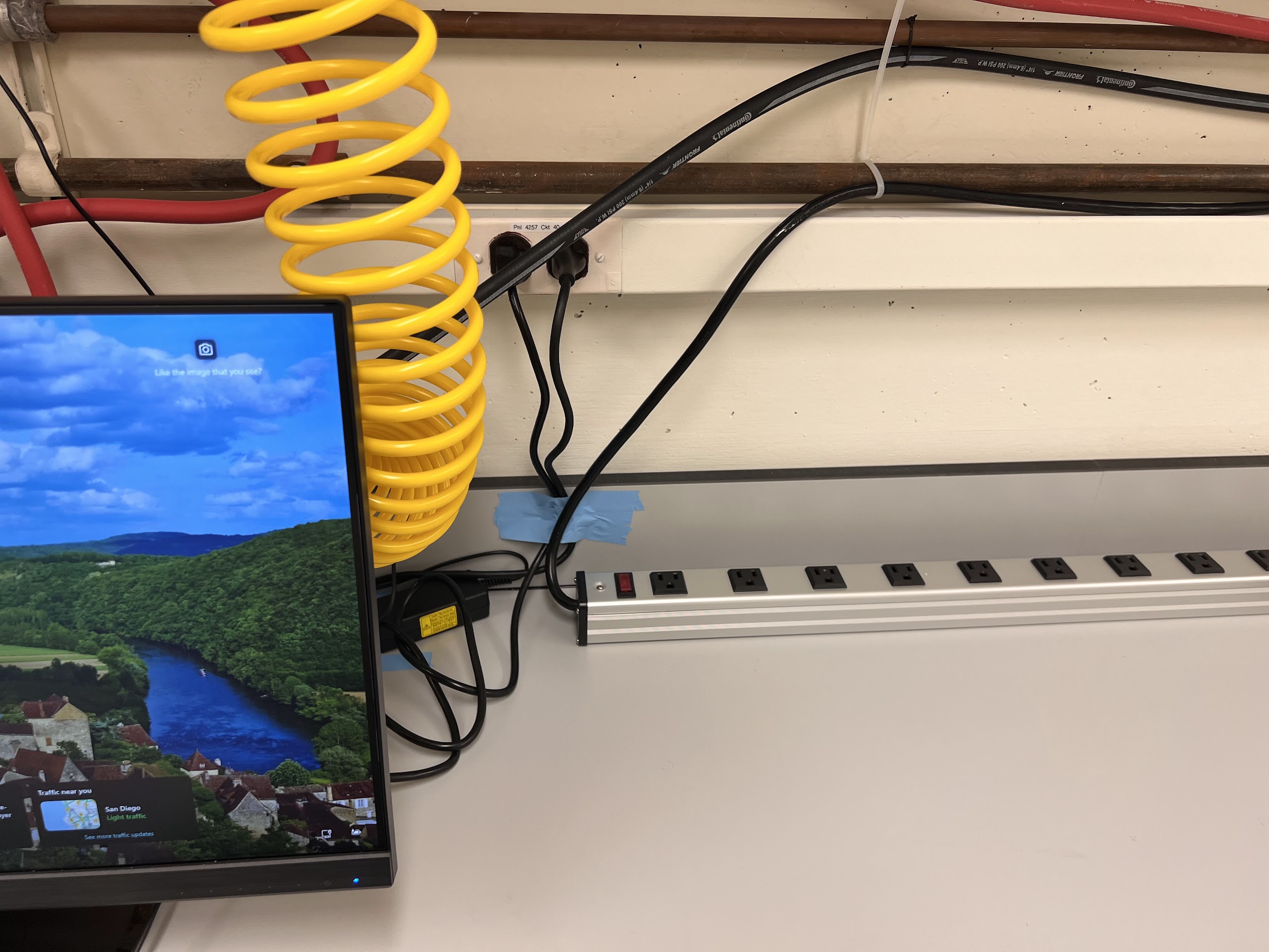

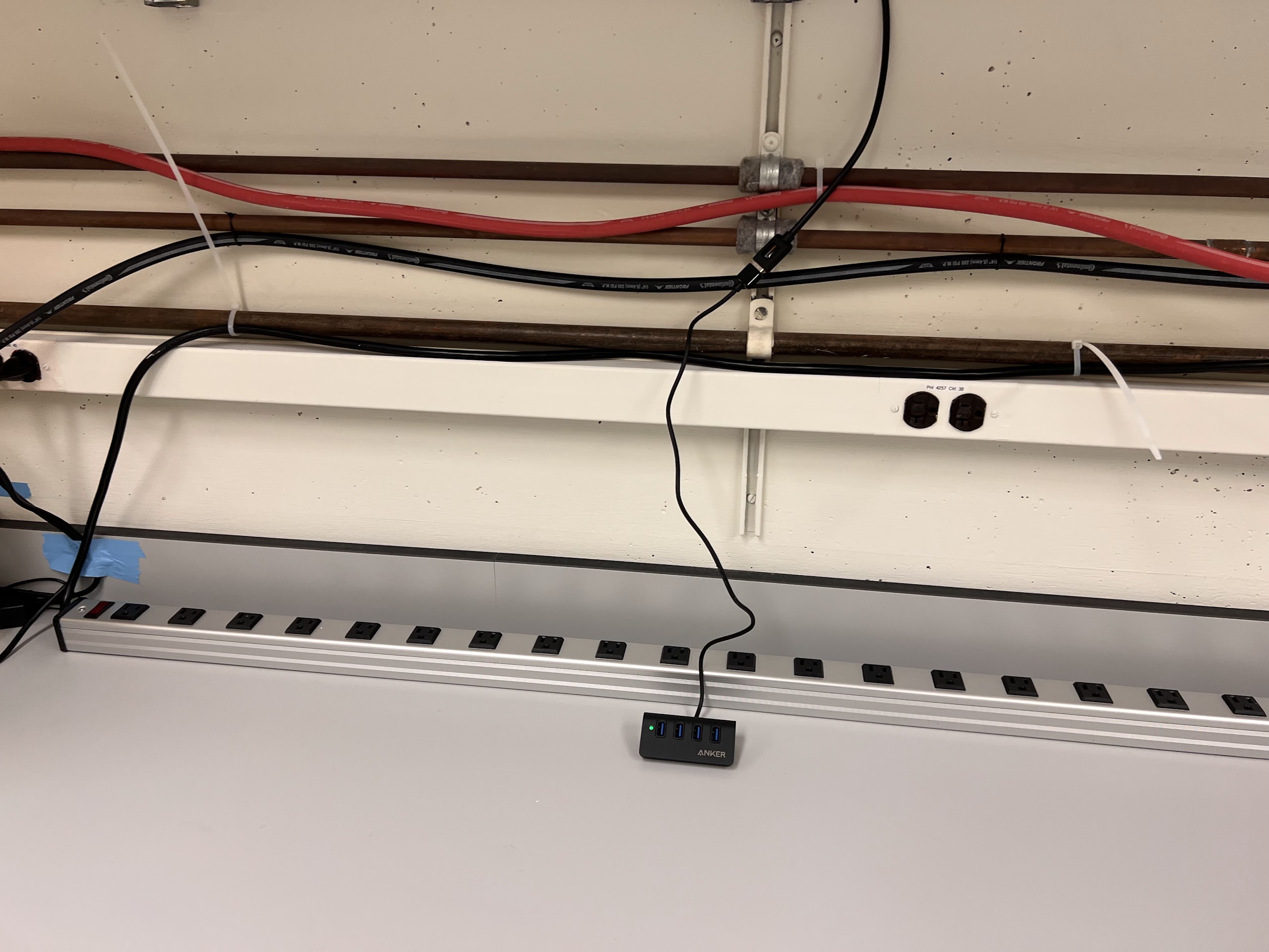

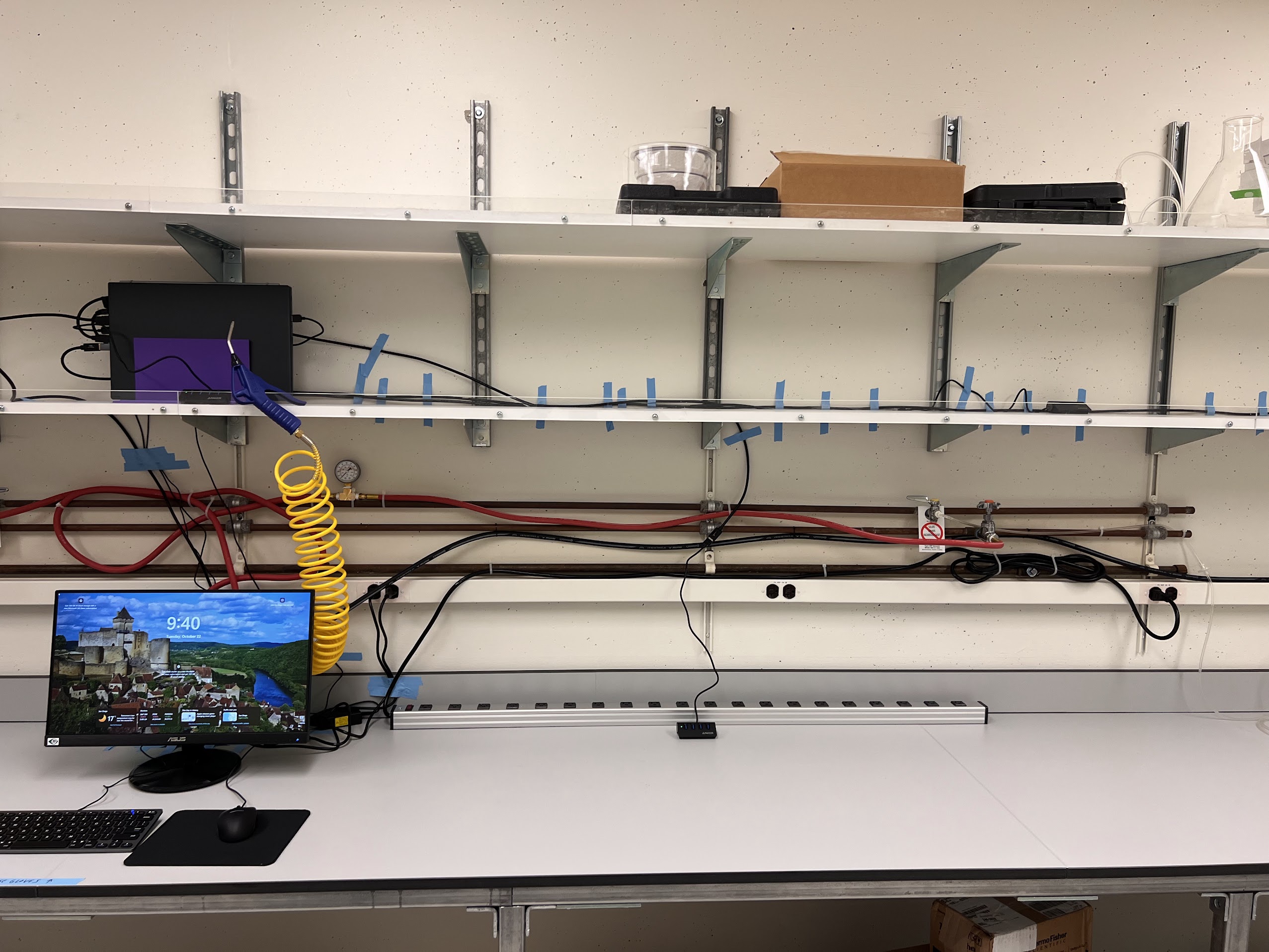

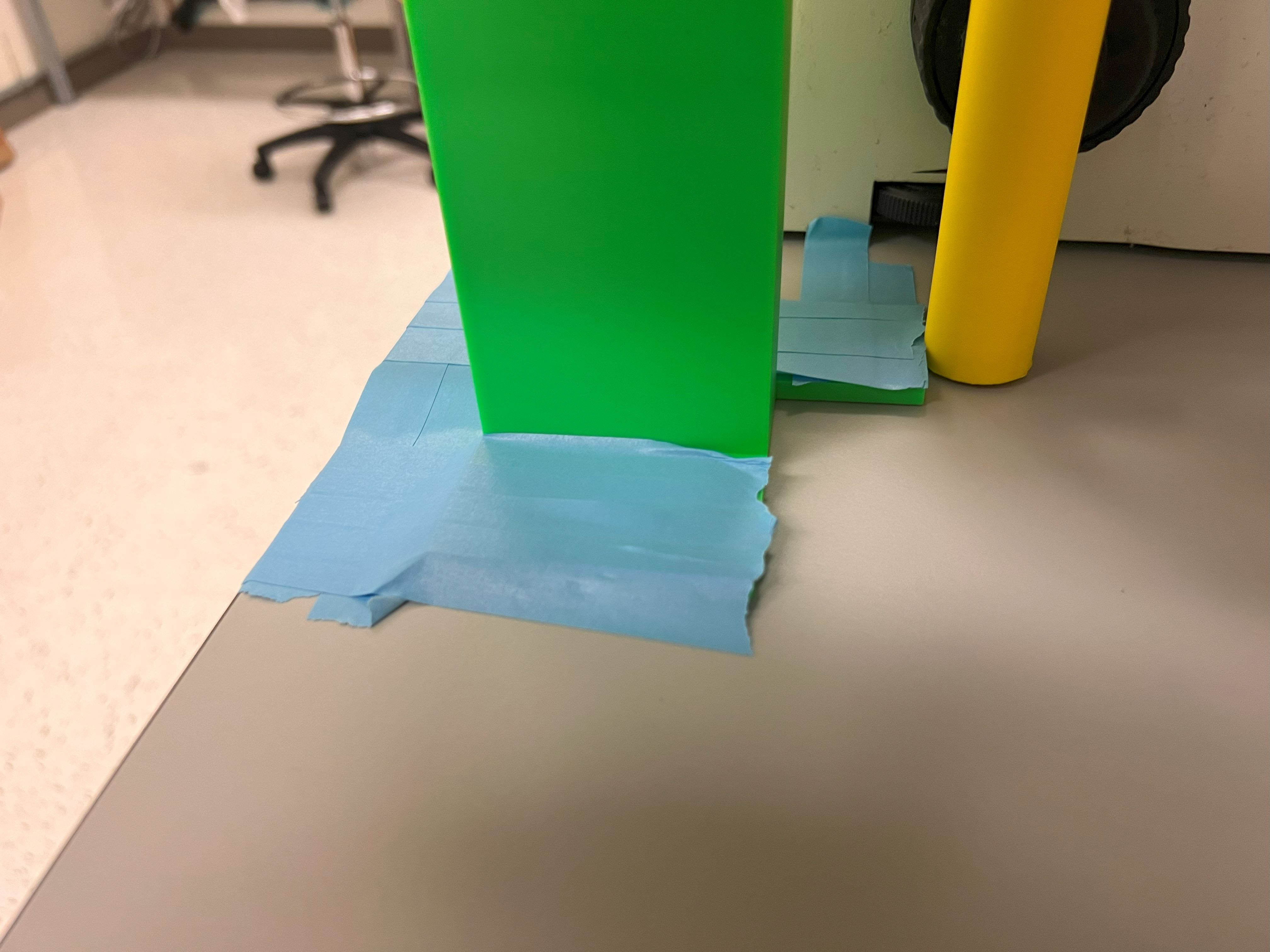

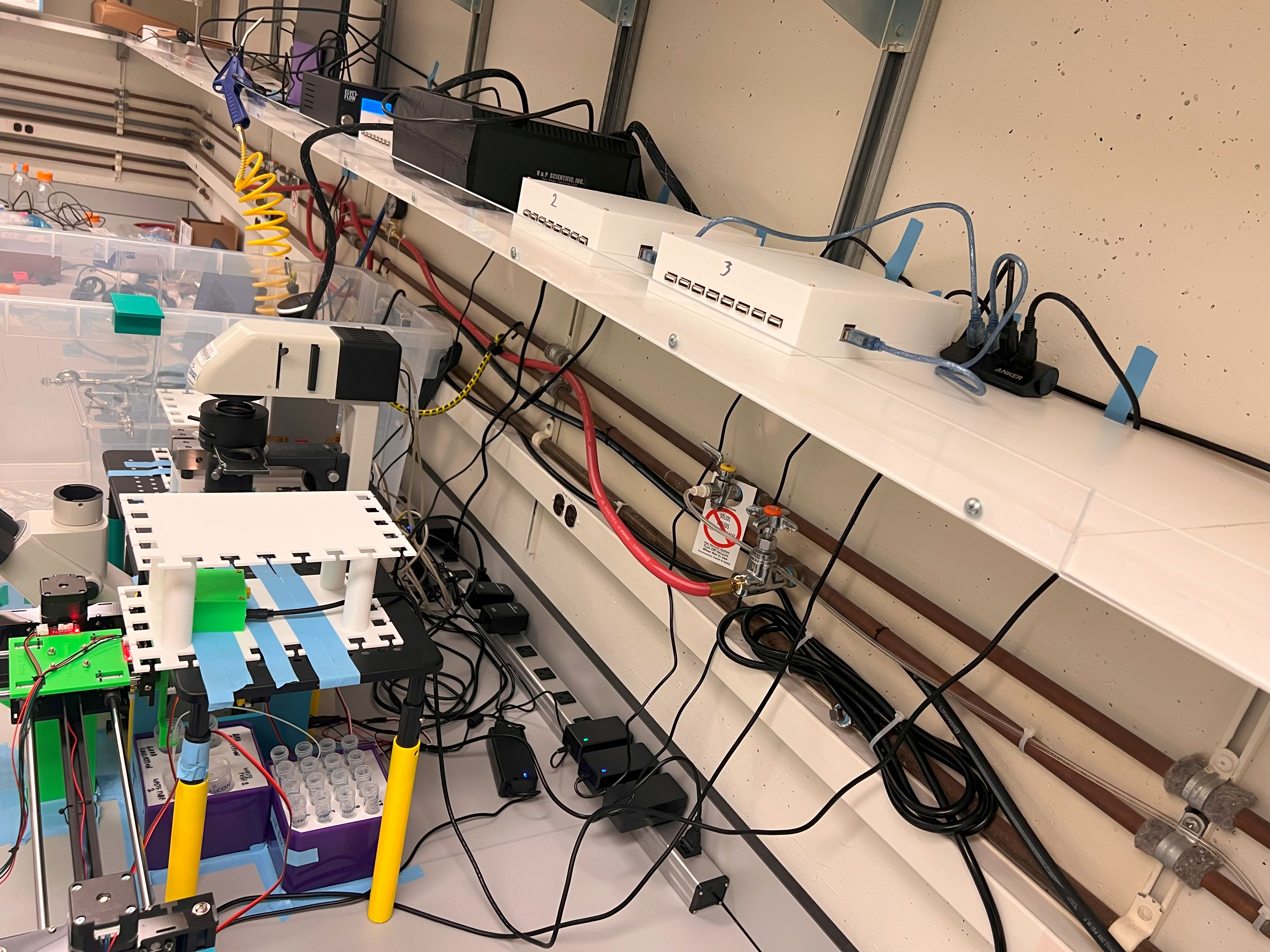

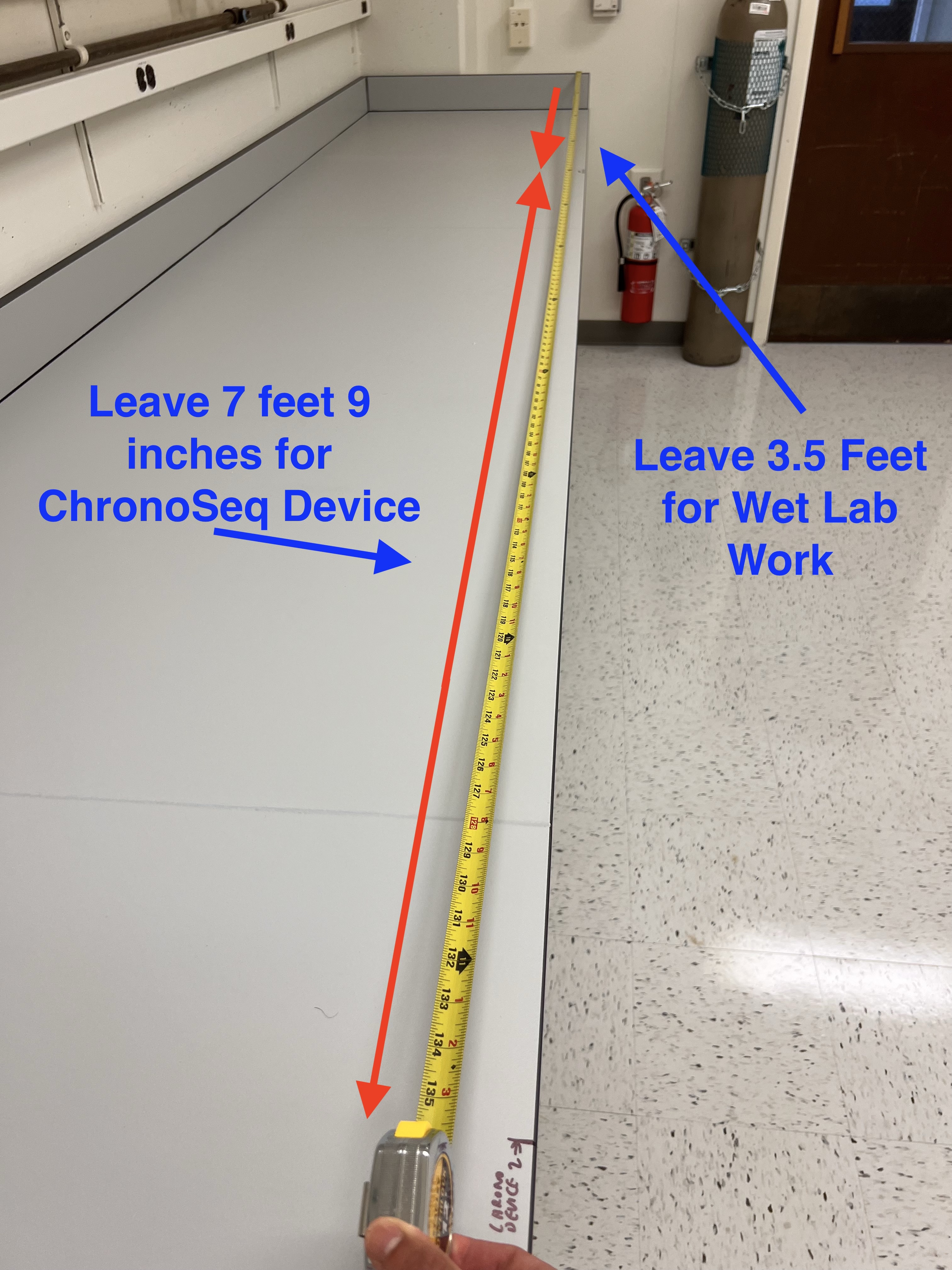

Setting up your Bench¶

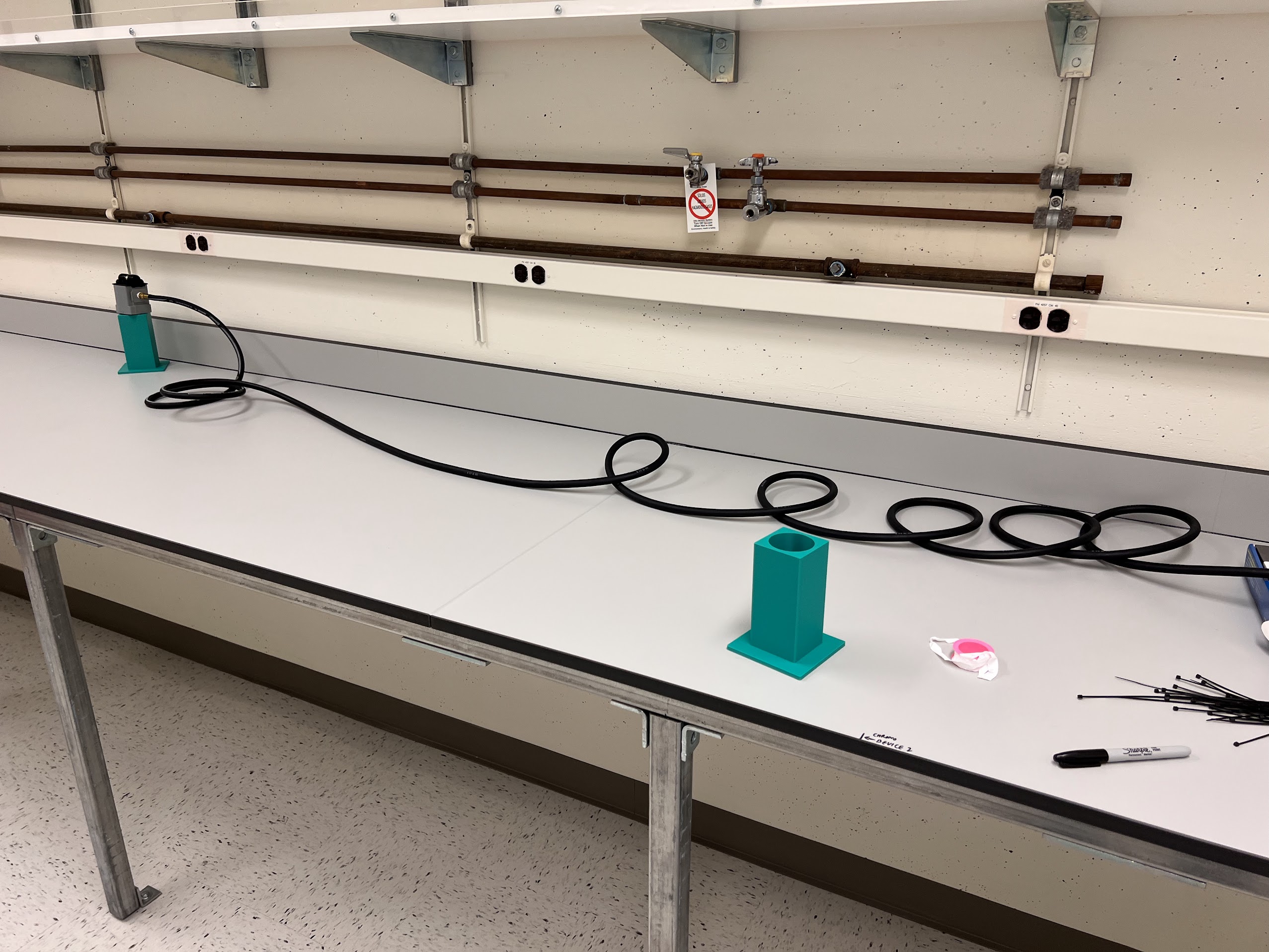

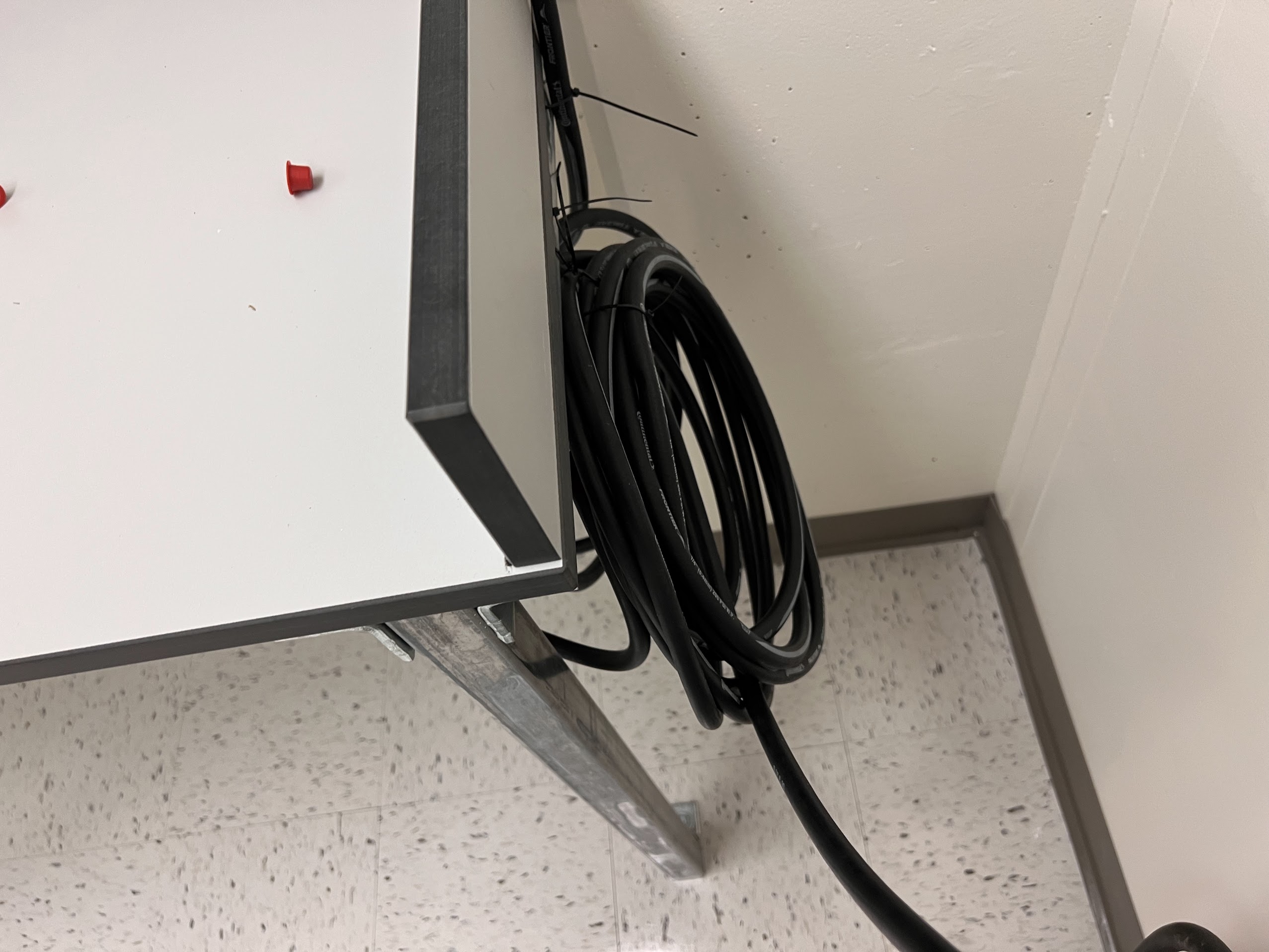

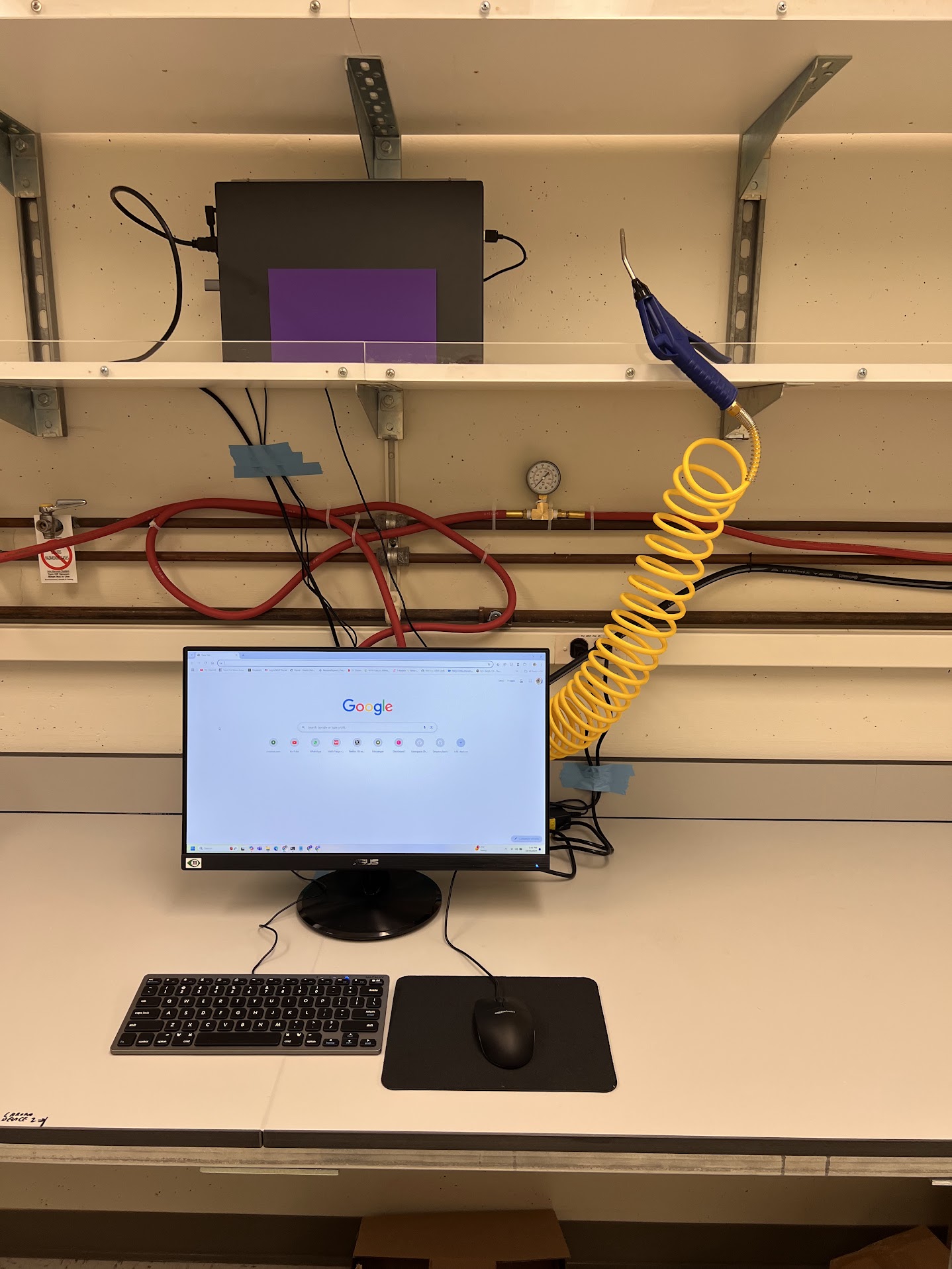

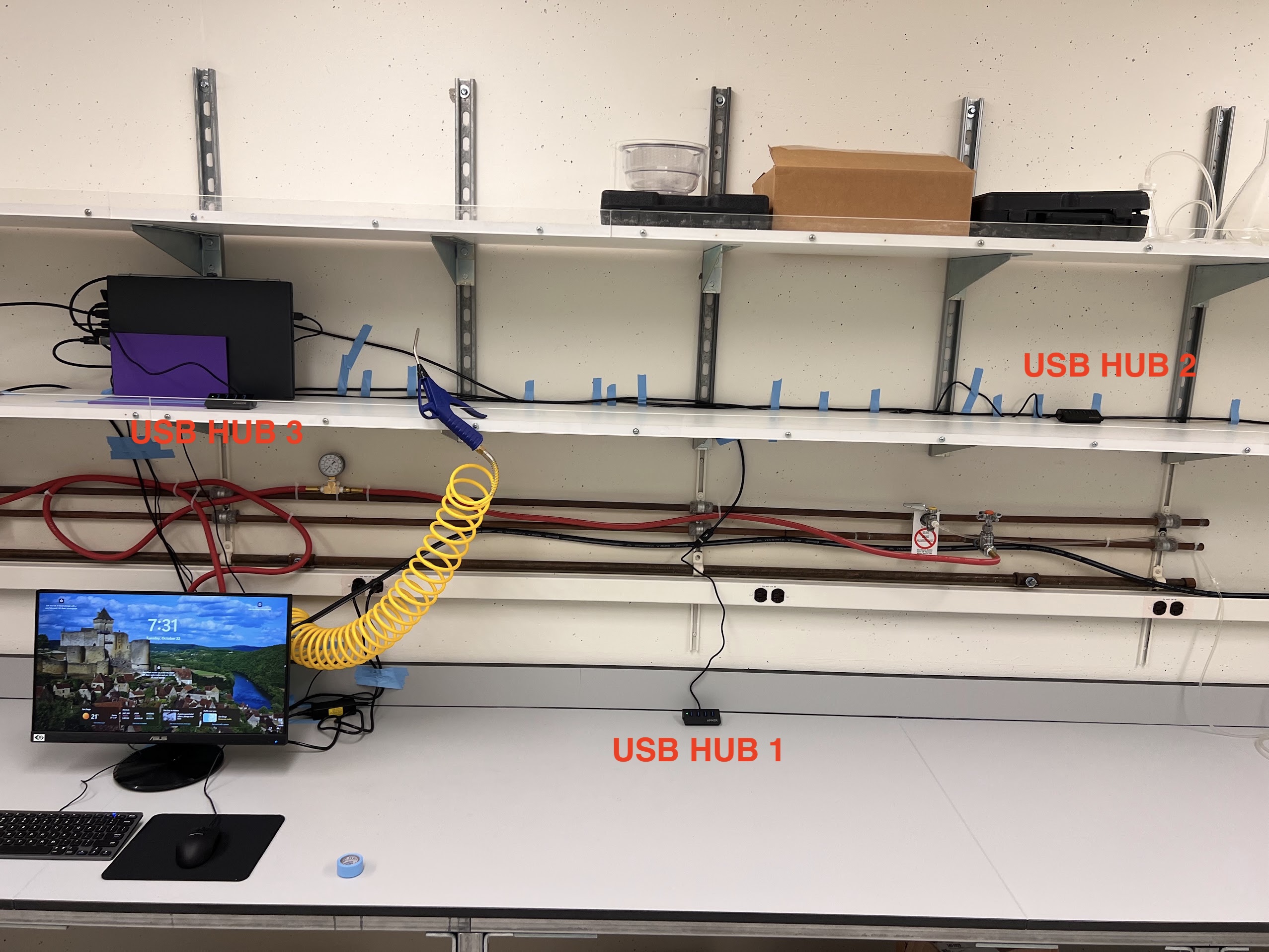

- The ChronoSeq device needs about 7 feet 9 inches of space on a Standard Wet Lab bench with no obstructions.

- Leave 3 feet 6 inches of space to the right of the device for the Wet lab parts of the protocol.

- You can use a 12 foot Tape measure to make the measurements.

- Our bench was 2 feet 5.25 inches deep.

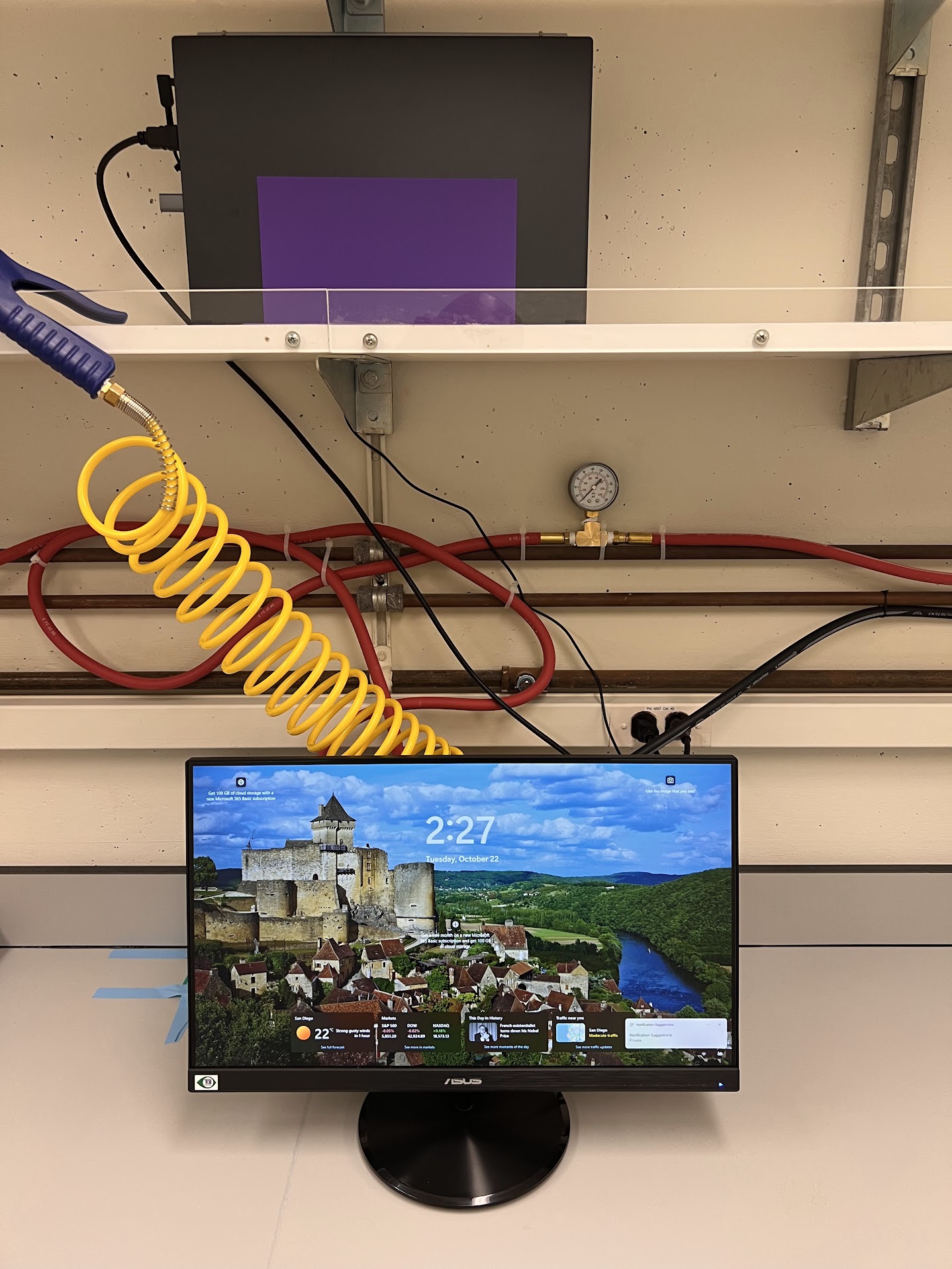

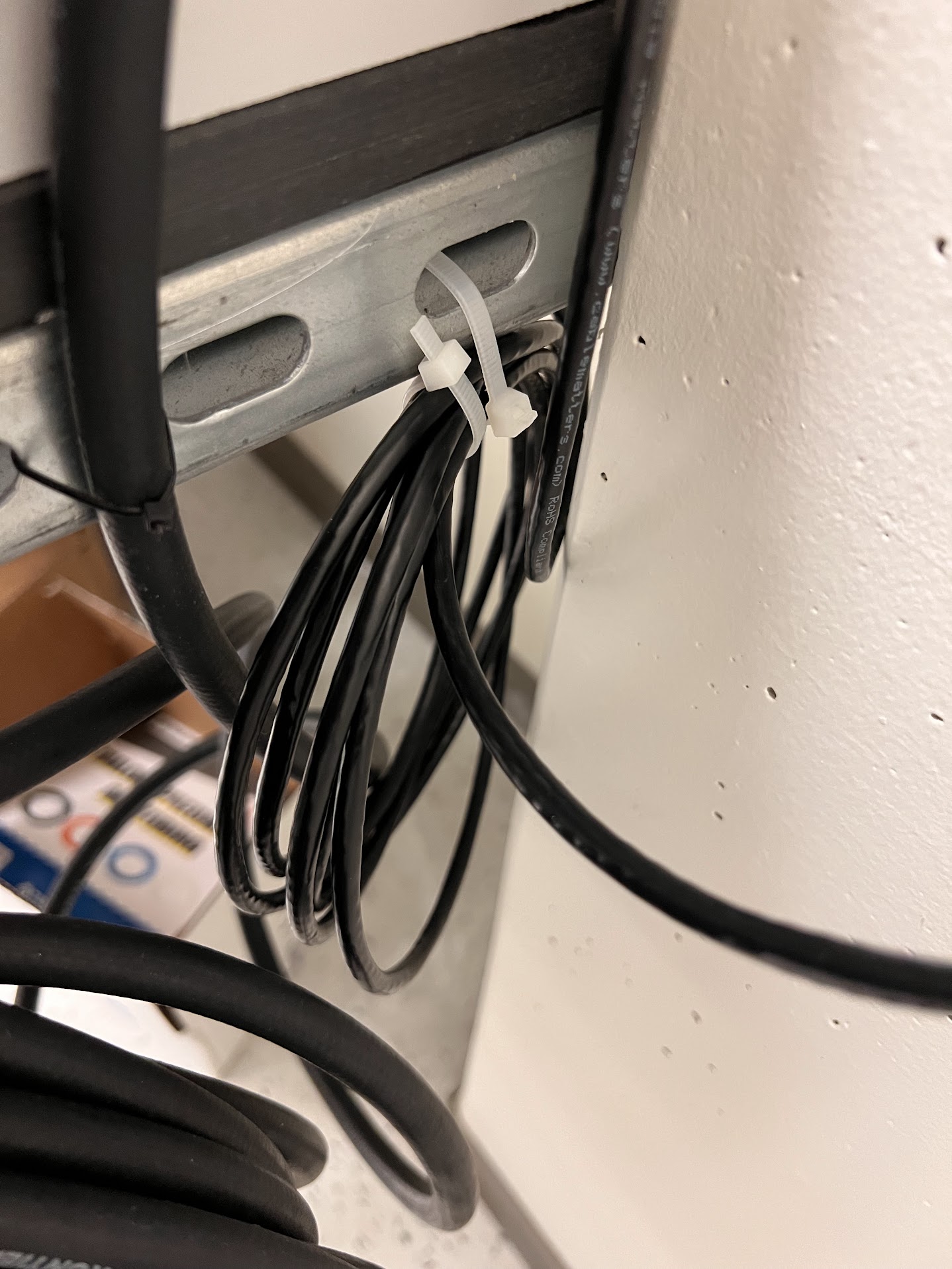

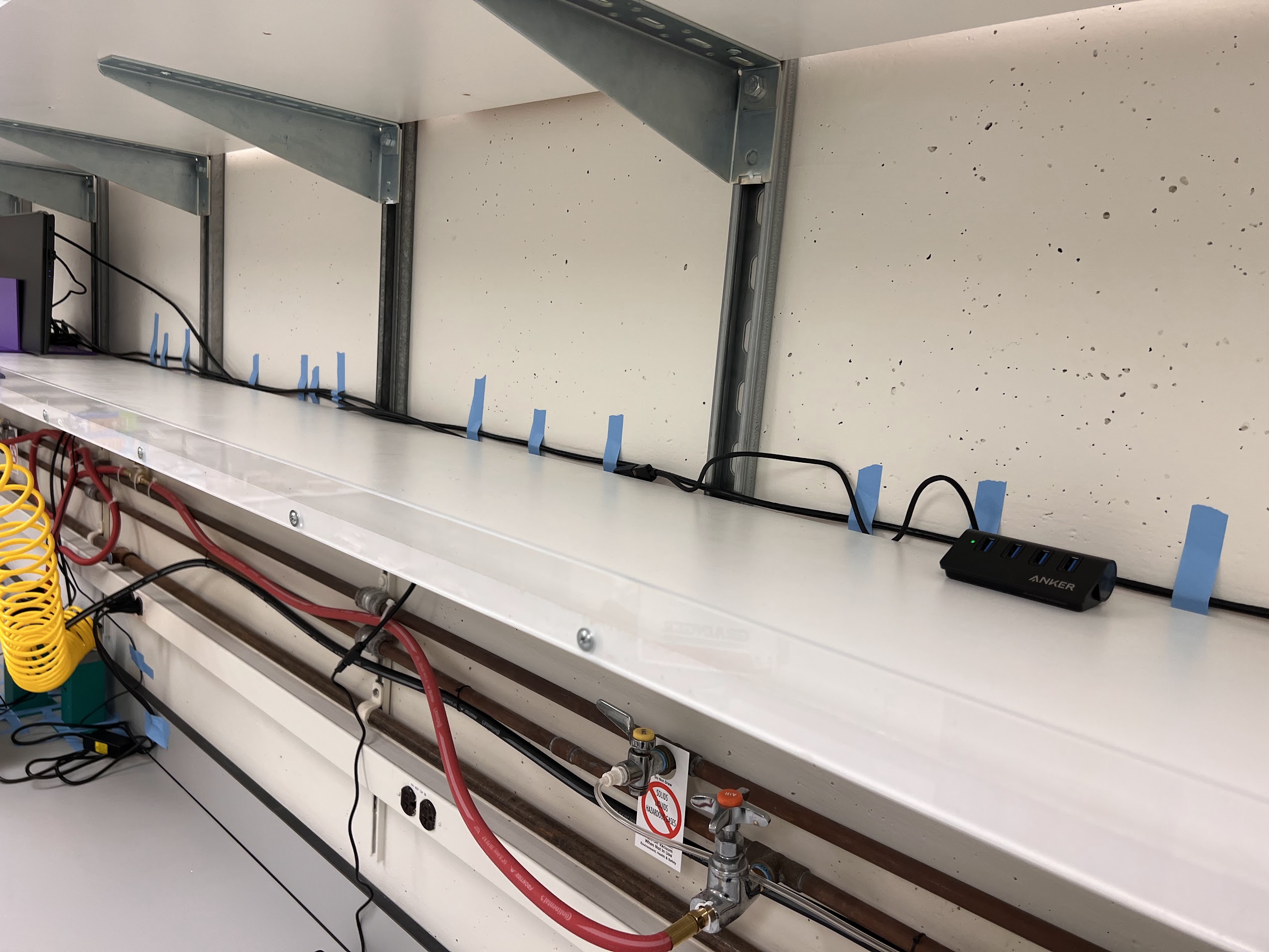

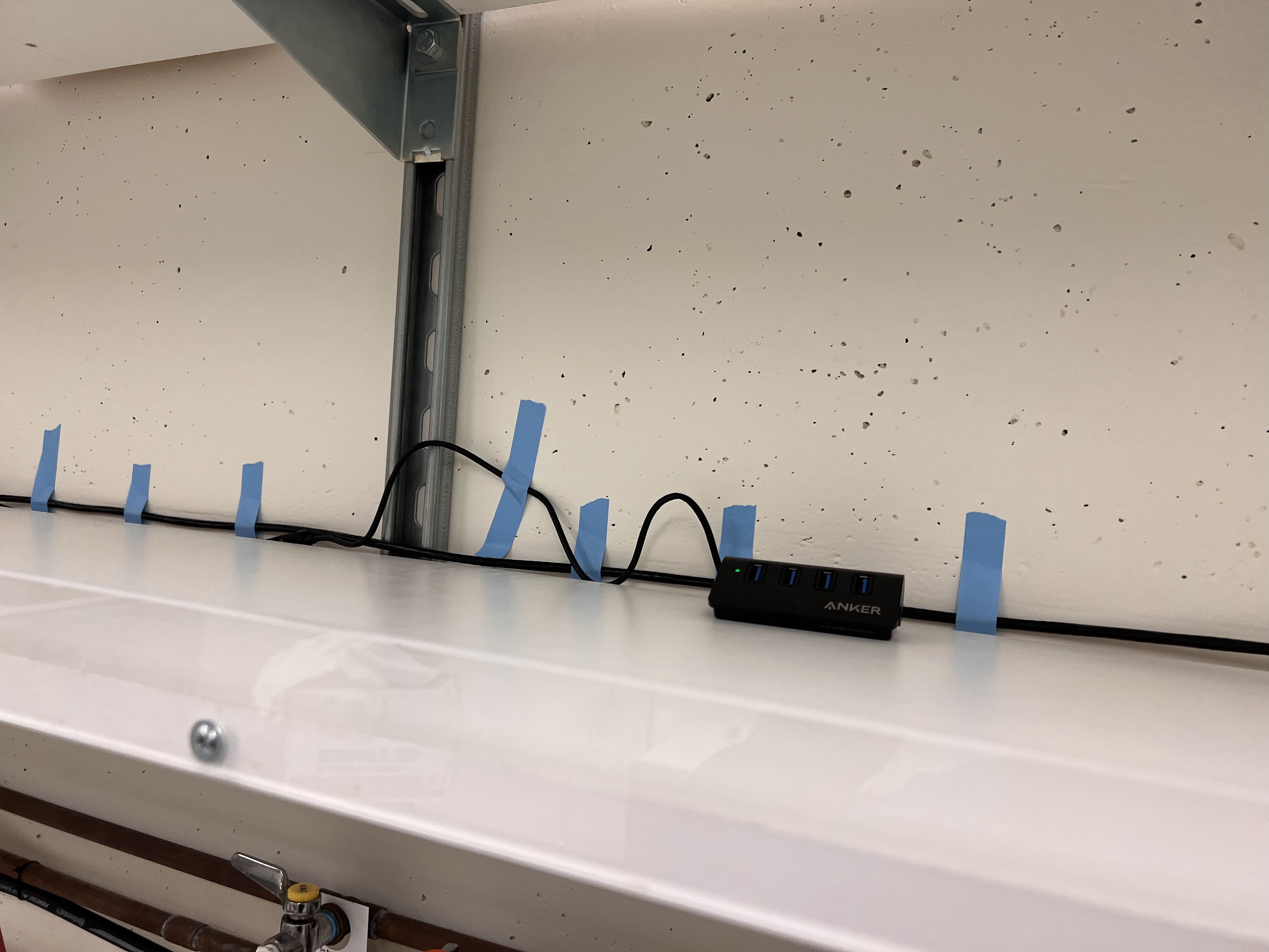

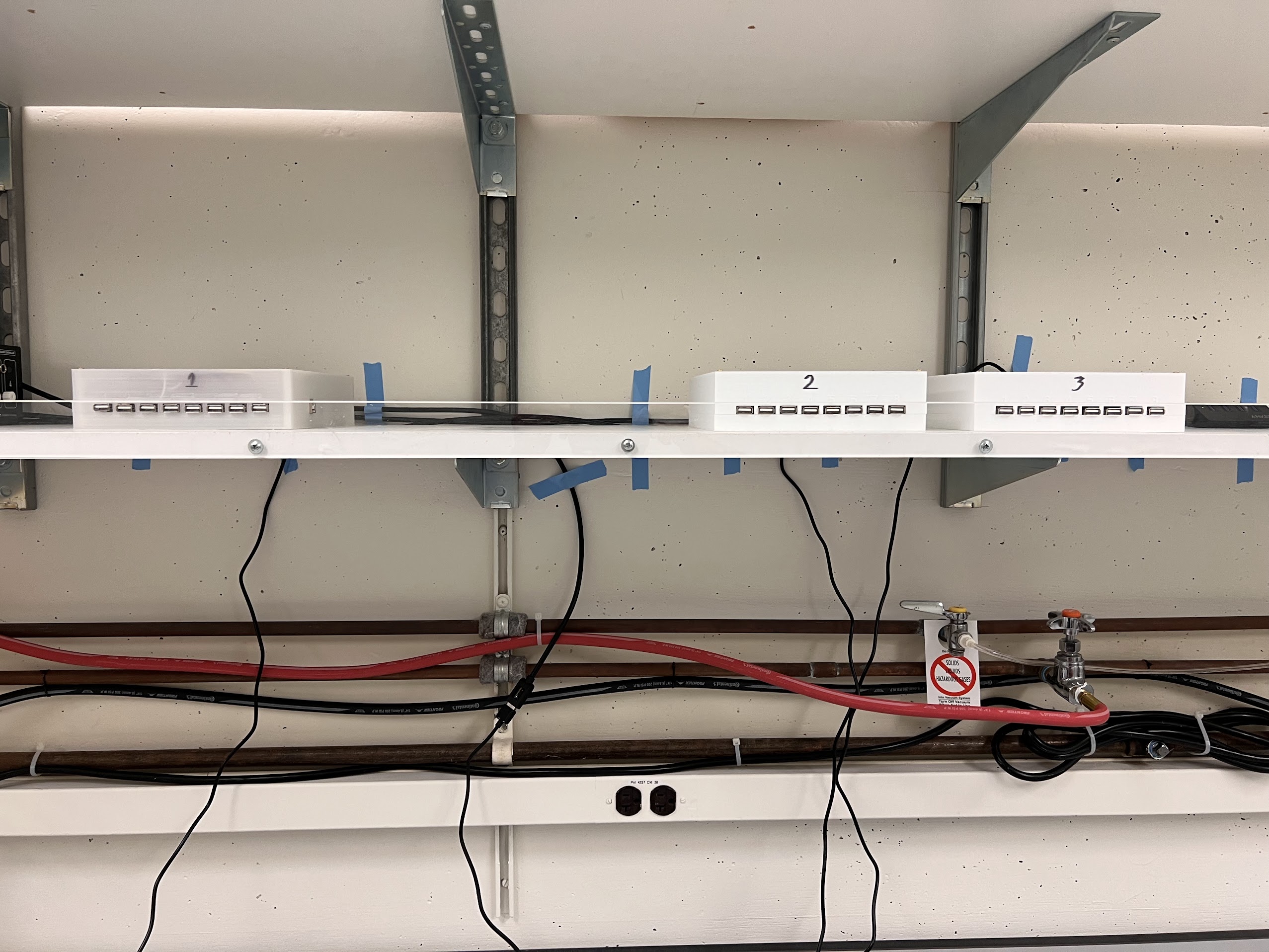

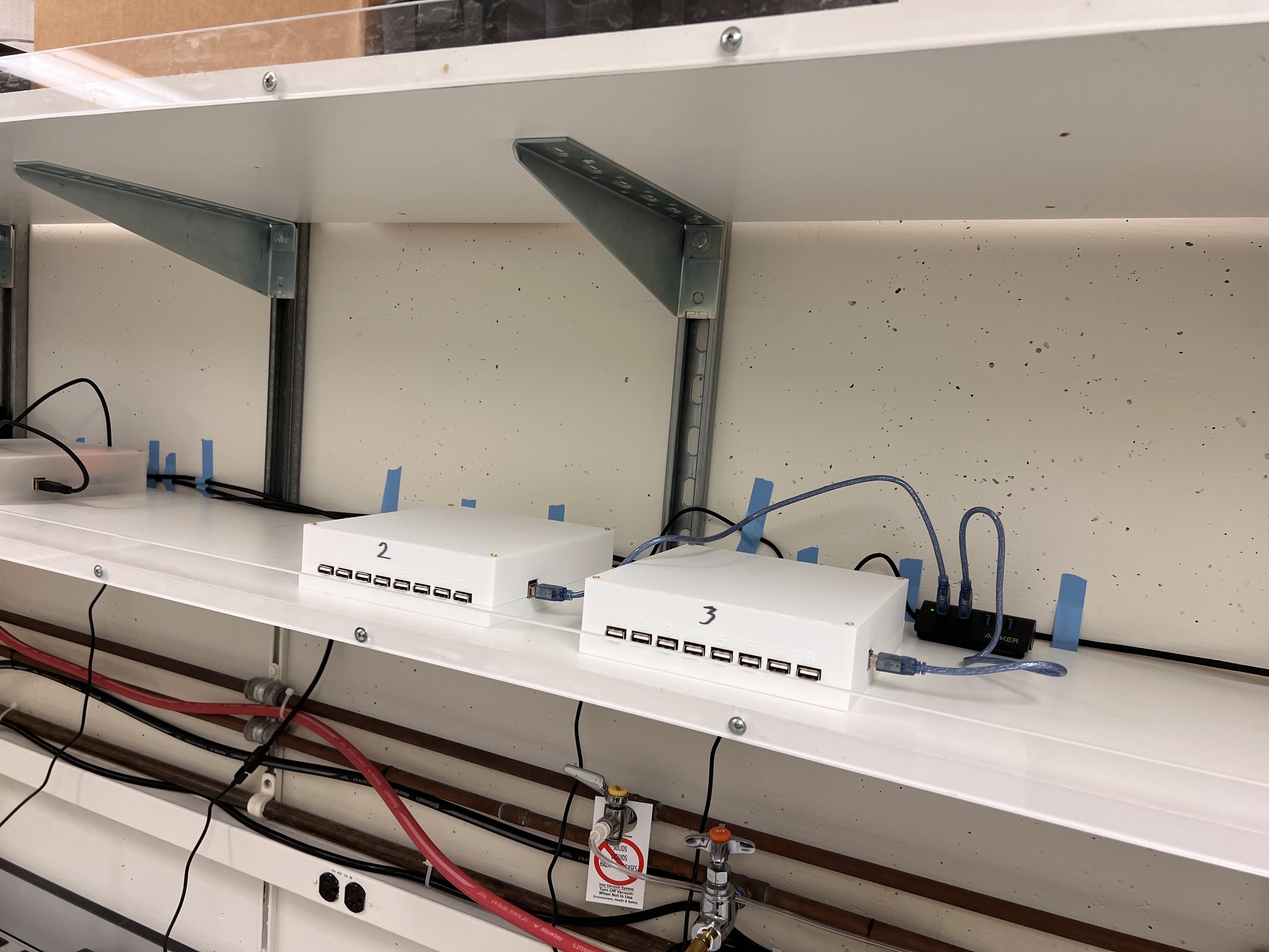

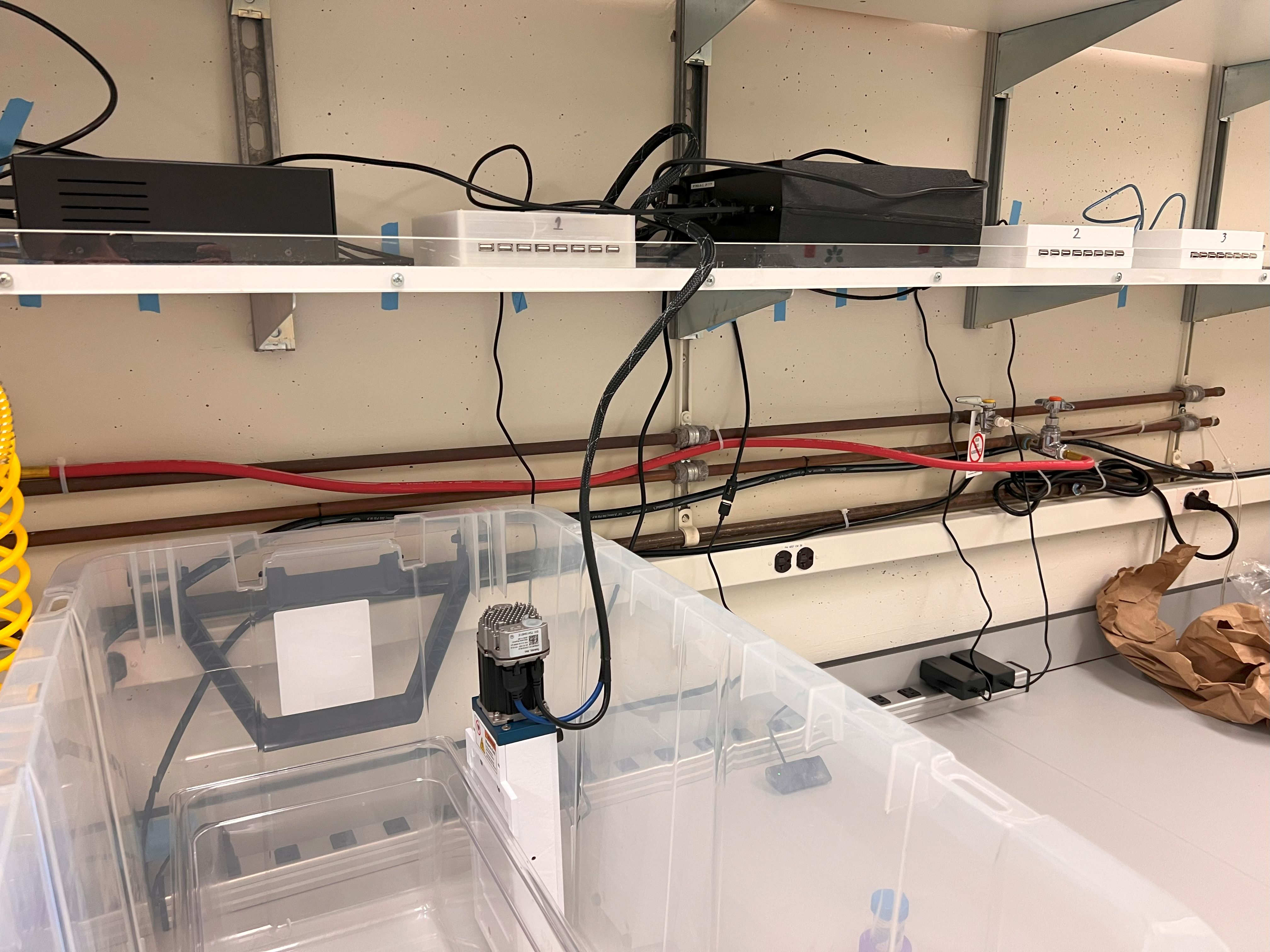

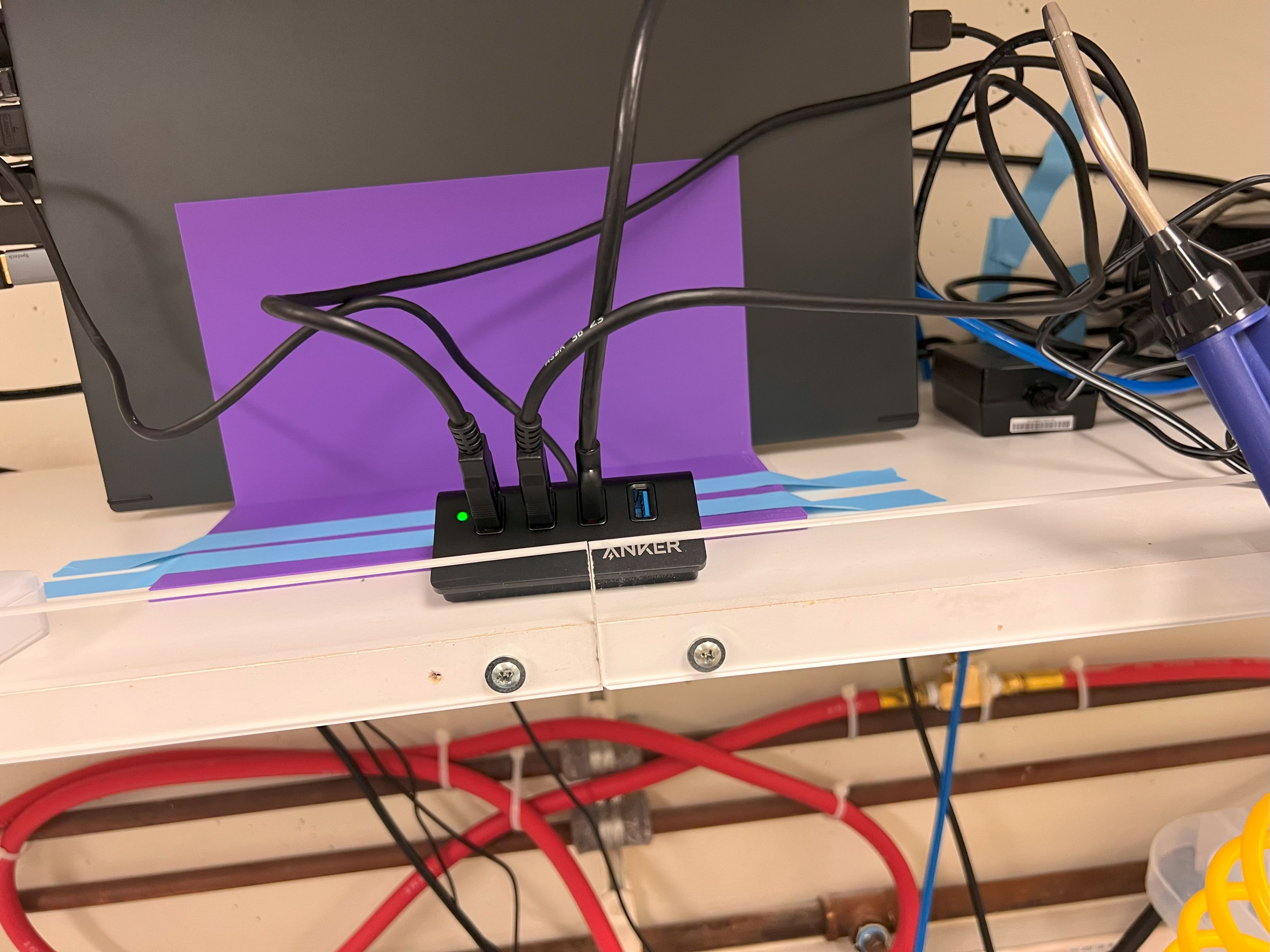

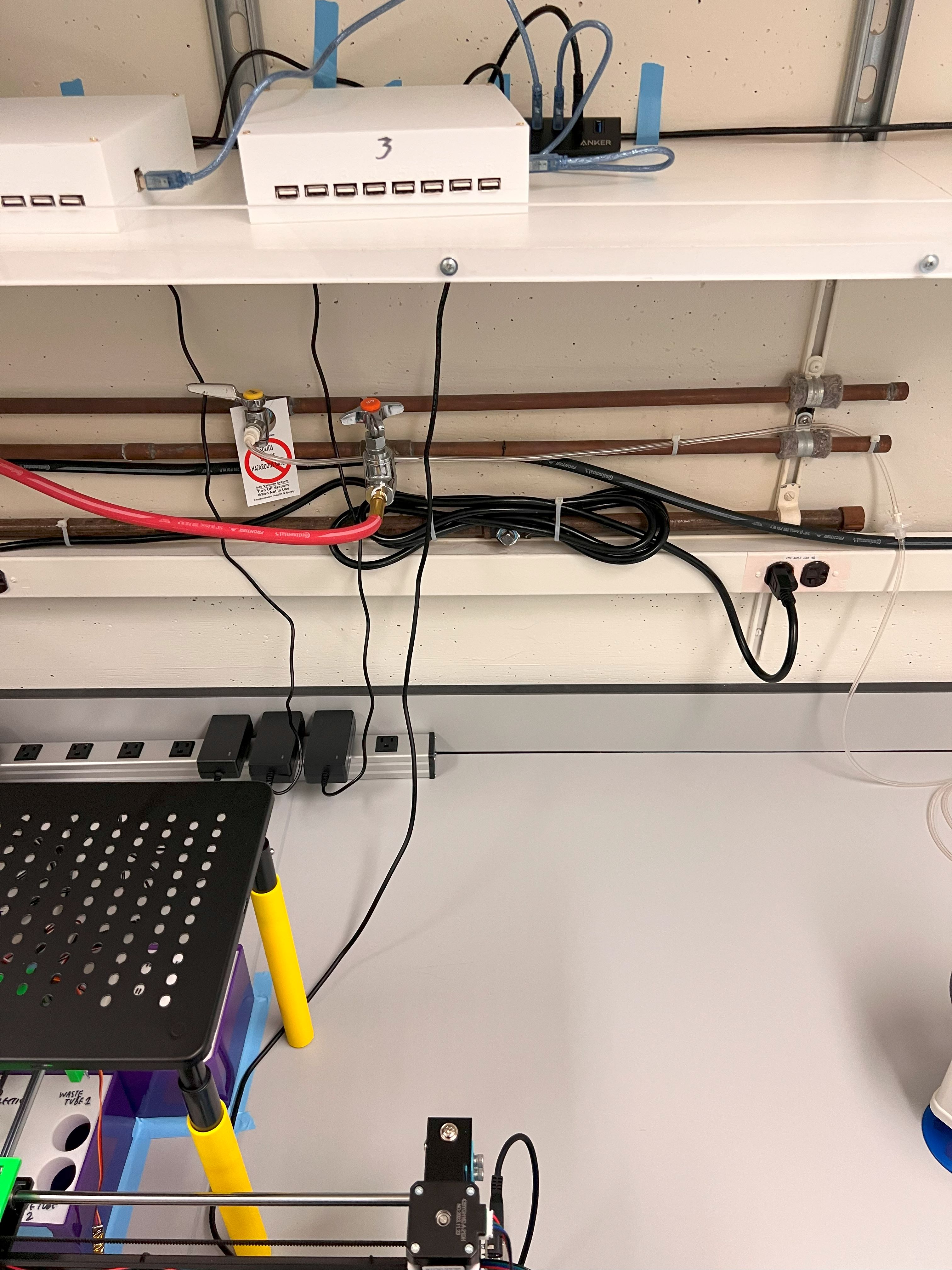

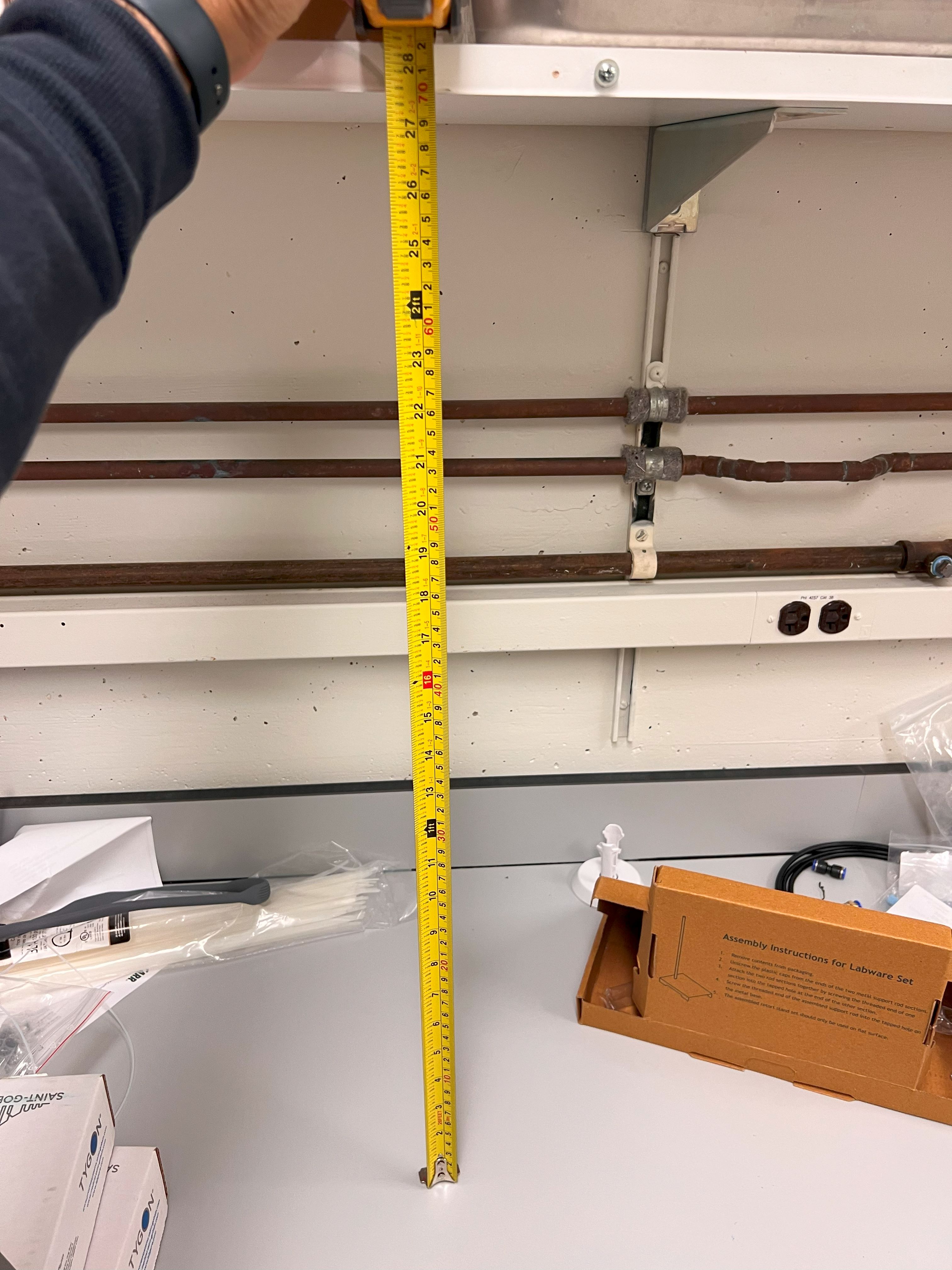

- The rack space directly above this space should also be kept empty for housing many components.

- The dimensions for the rack space is as follows:

- The distance between the support pieces is 21 inches.

- The distance between the racks is 13 inches.

- The depth of the racks is 13 inches.

| Distance between support pieces | Height/Distance between racks | Depth of rack |

|---|---|---|

|

|

|

The first rack is 28 inches above the bench.

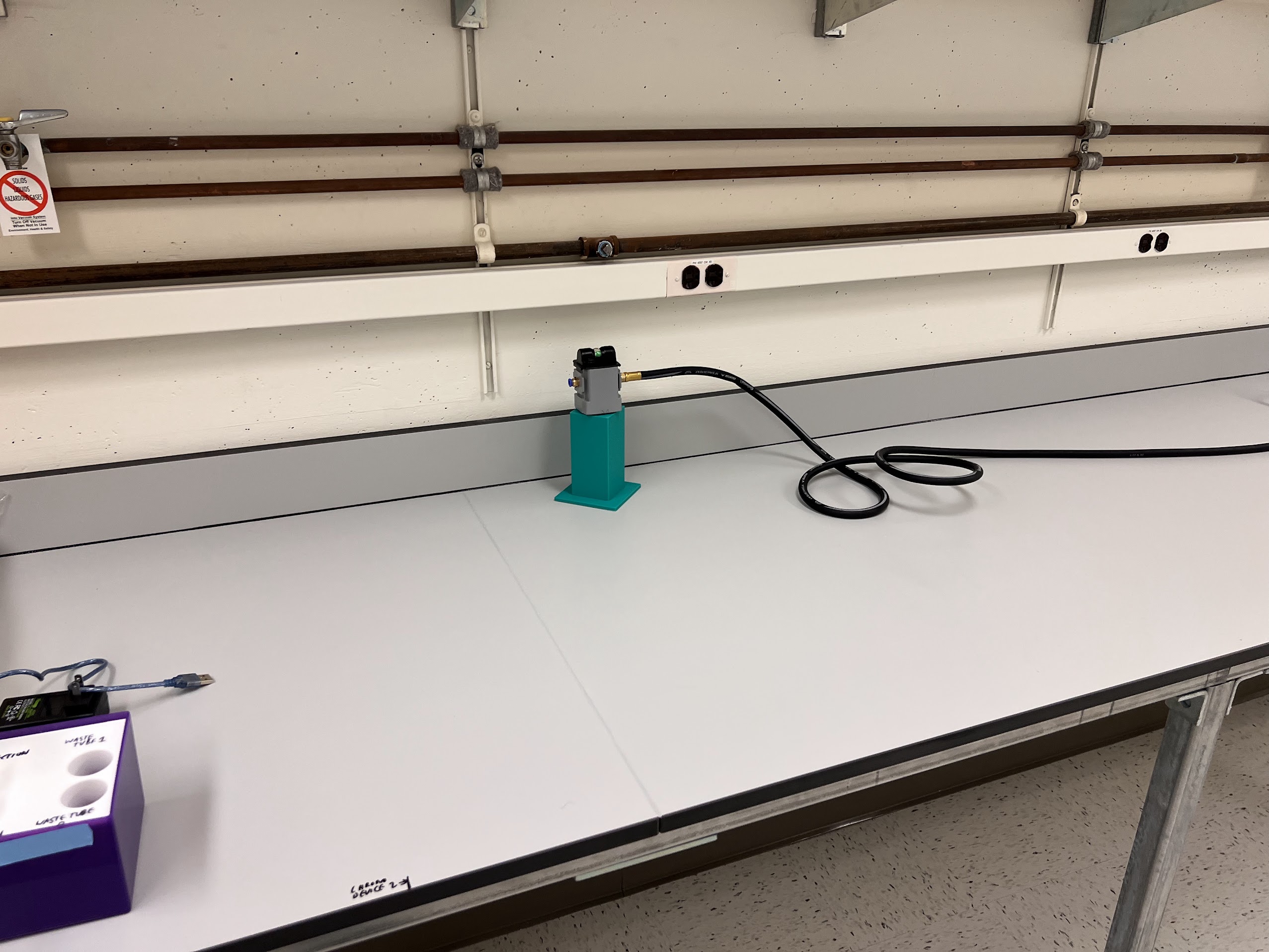

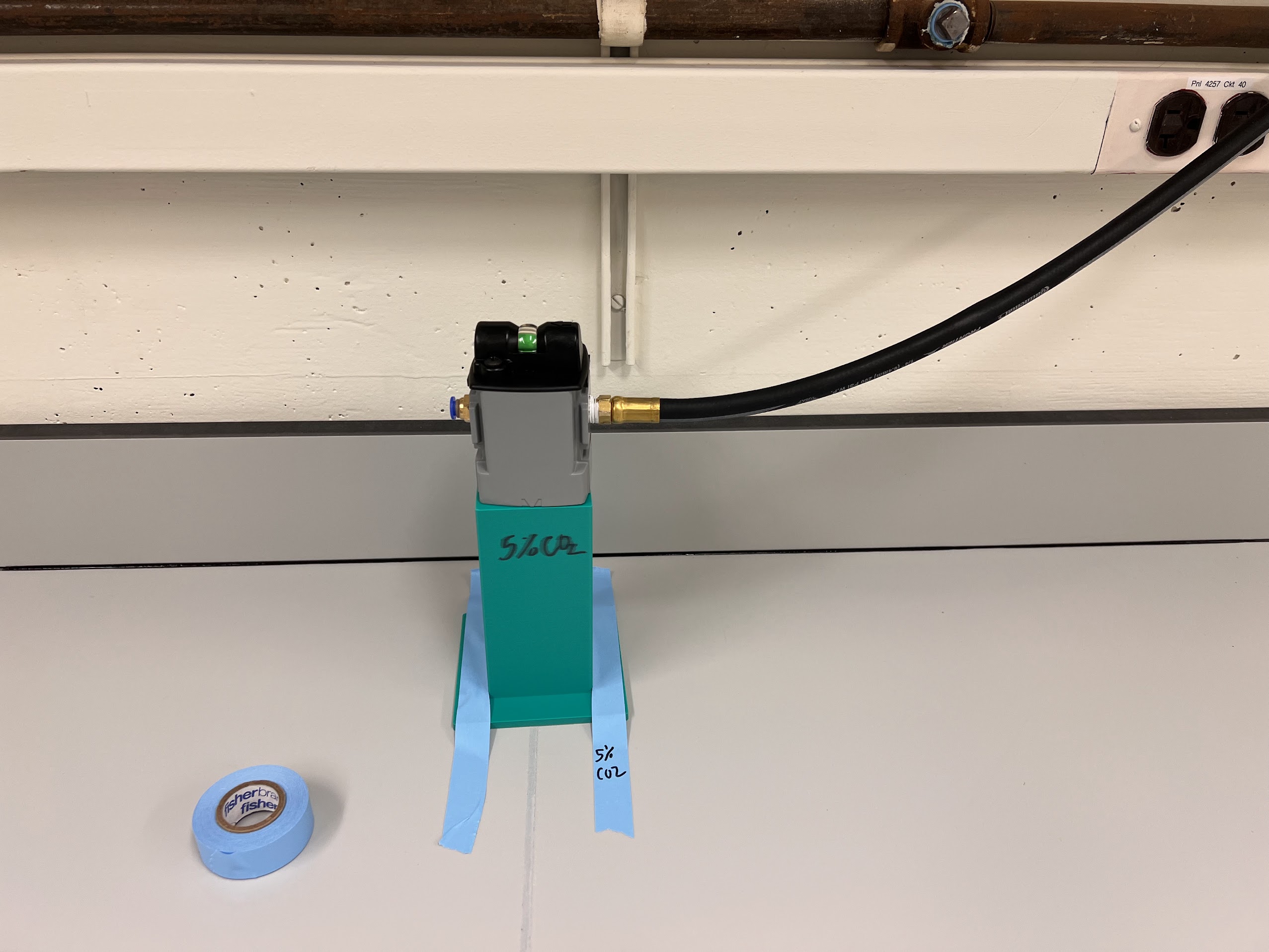

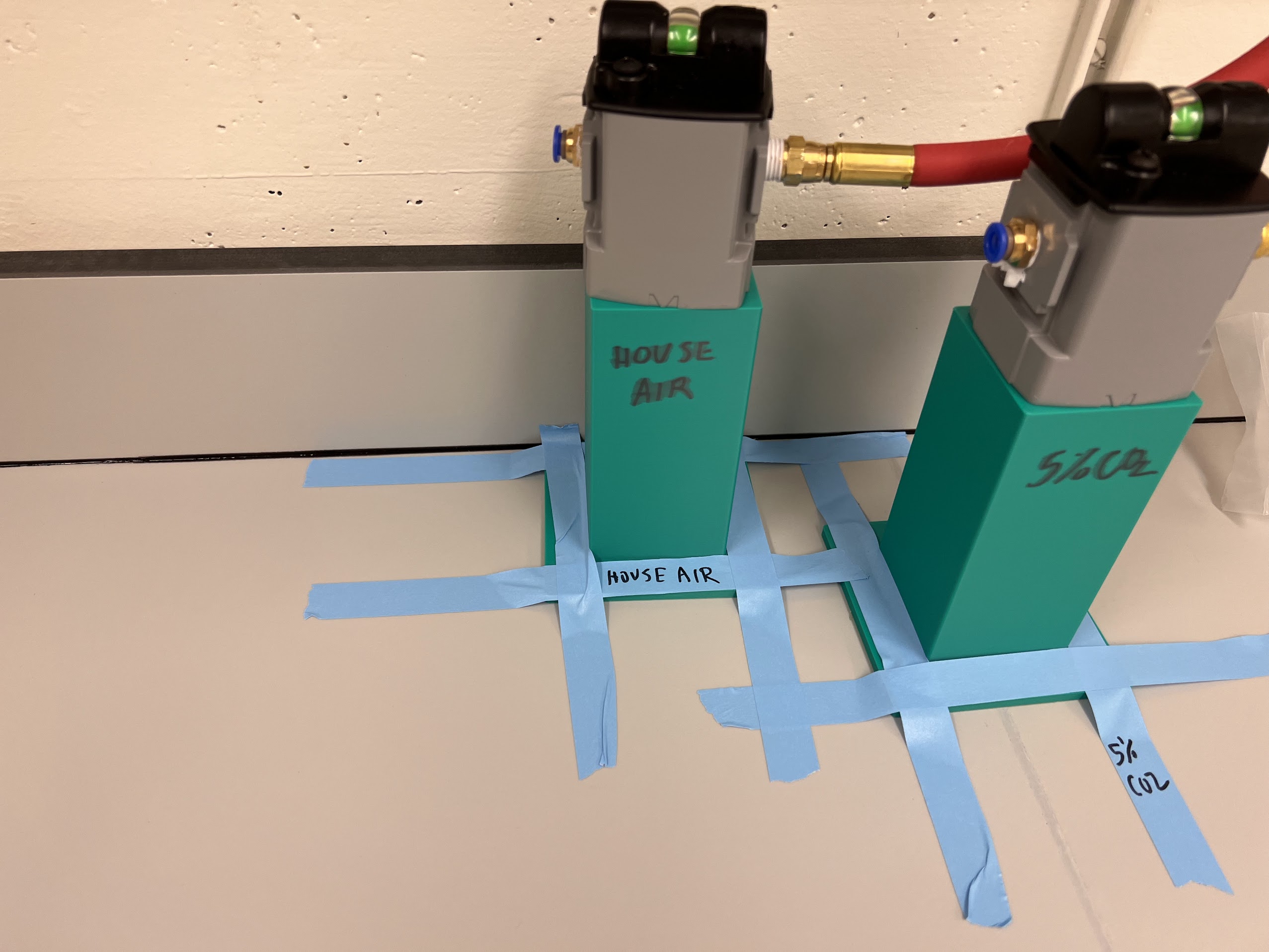

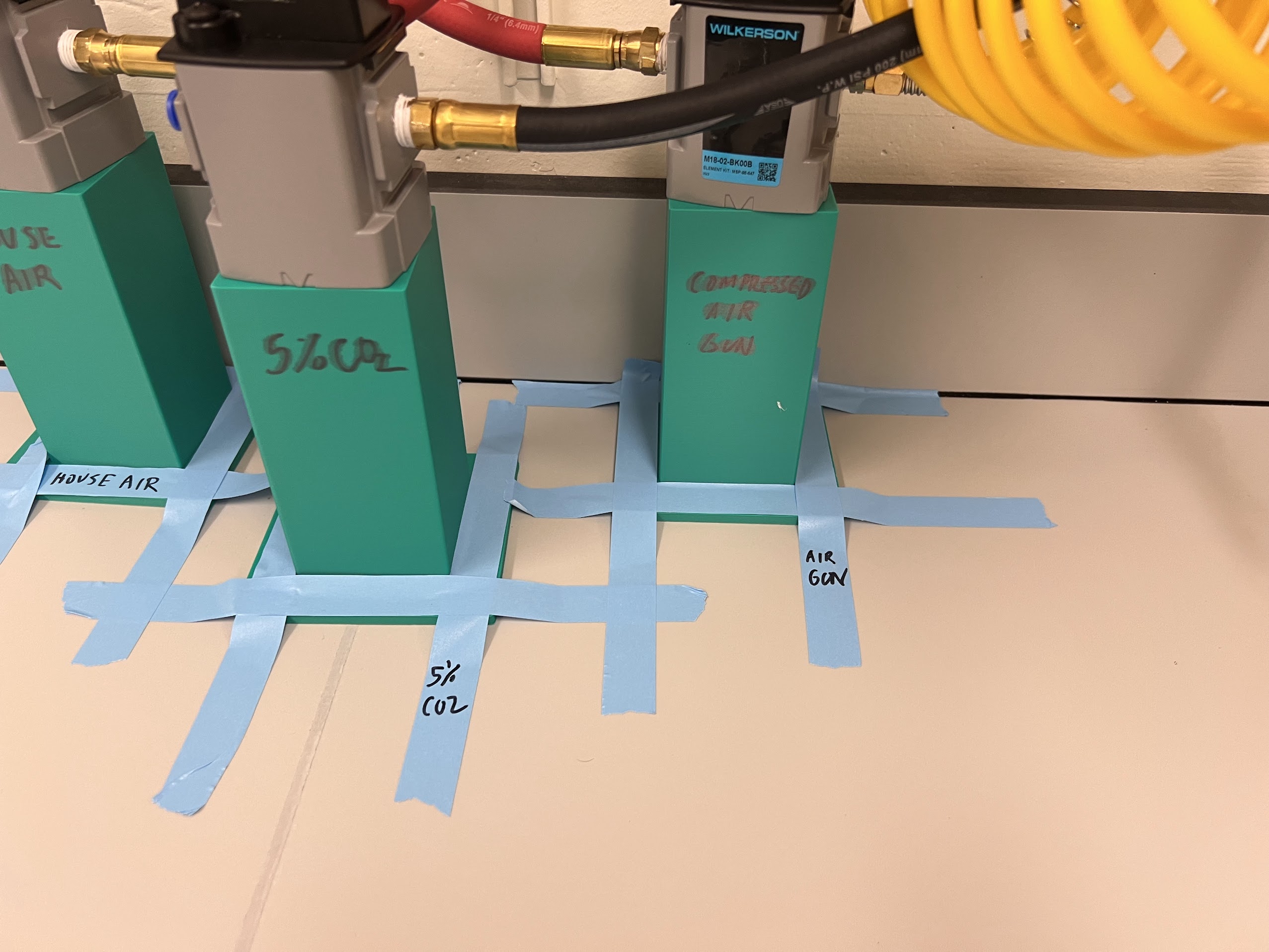

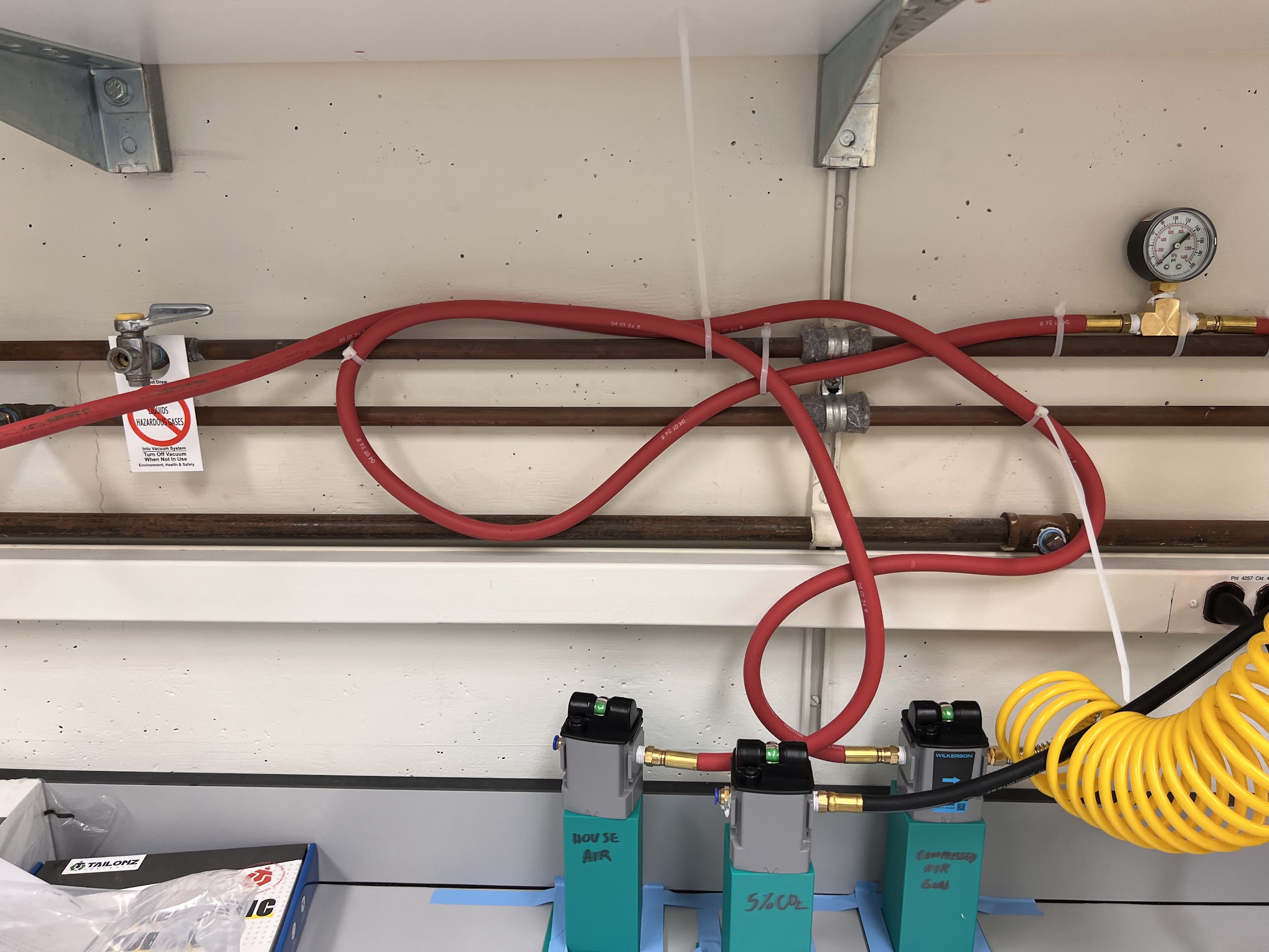

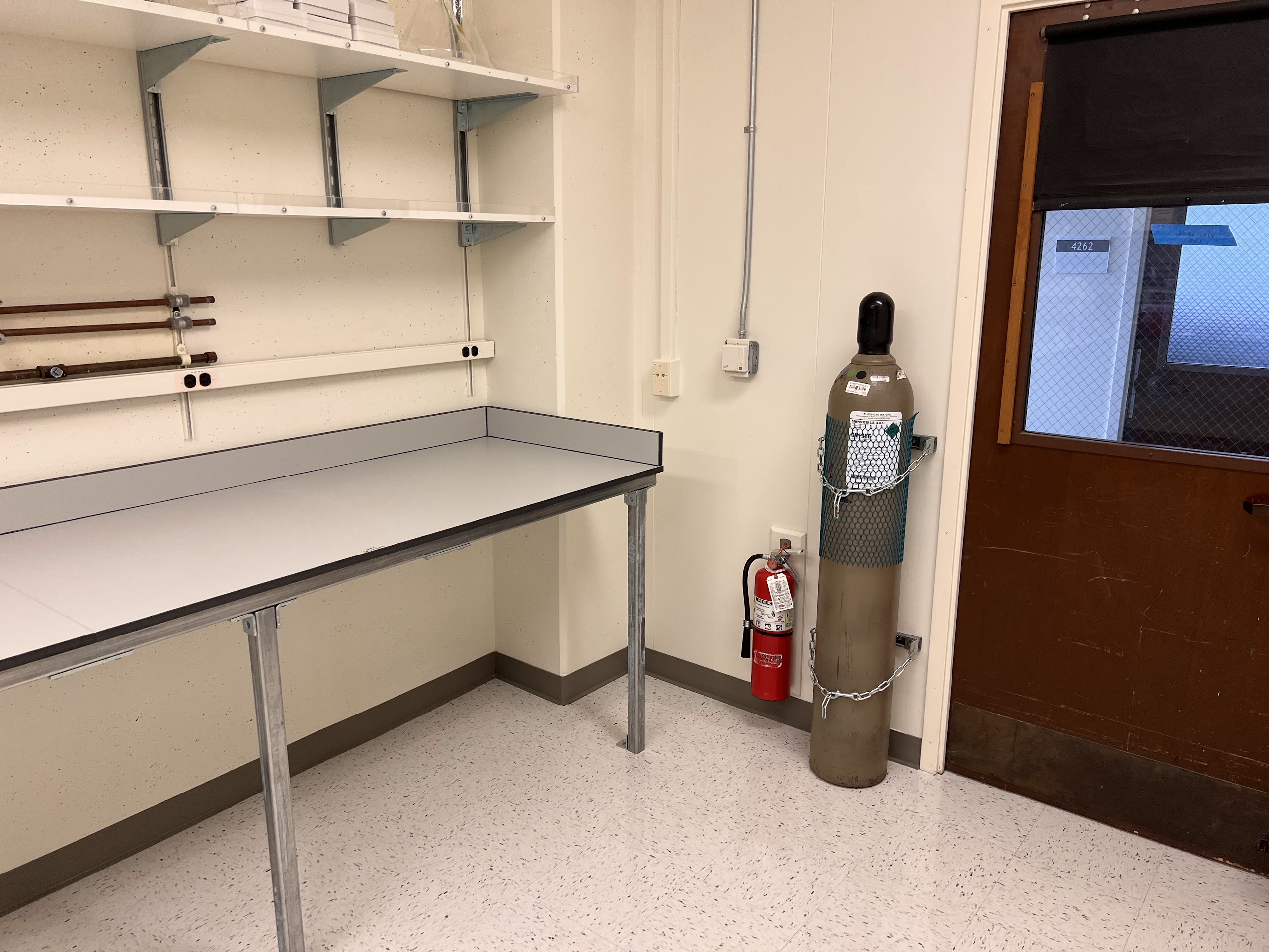

We also kept a 5%CO2 cylinder close to the bench.

- Cylinder was secured in place with restraints.

- Cylinder was secured in place with restraints.

An additional backup cylinder was also kept in the hallway secured with restraints.

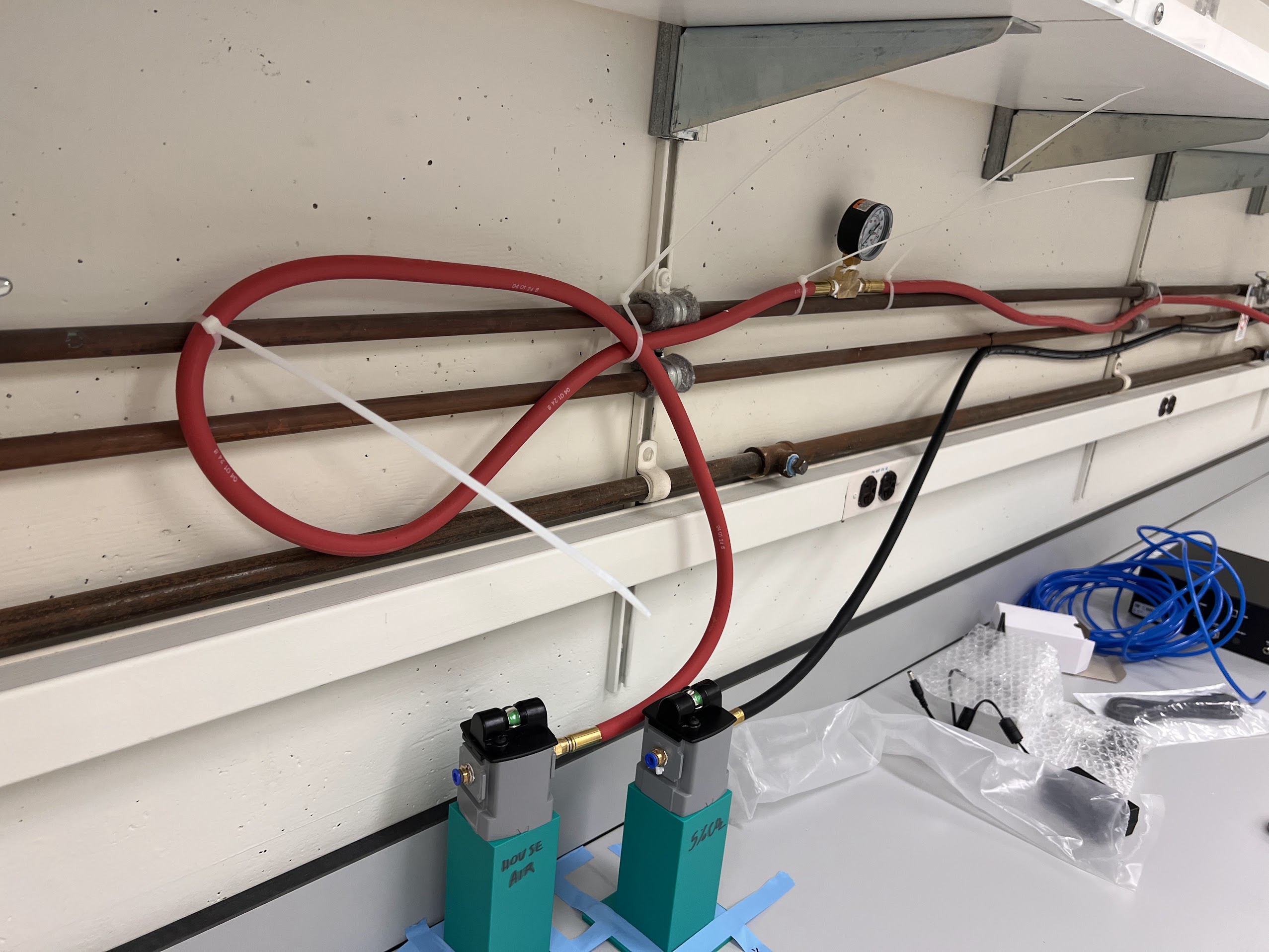

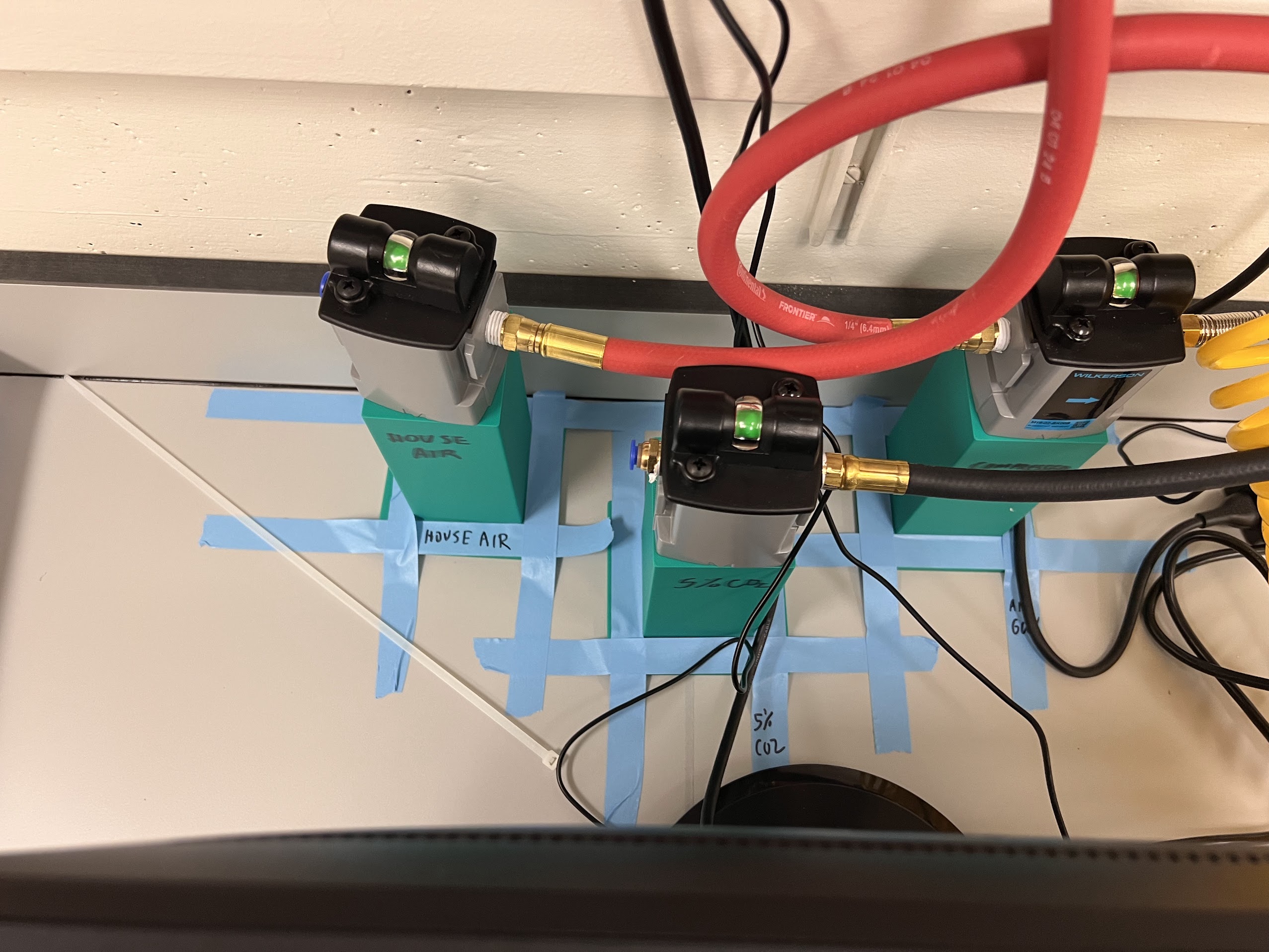

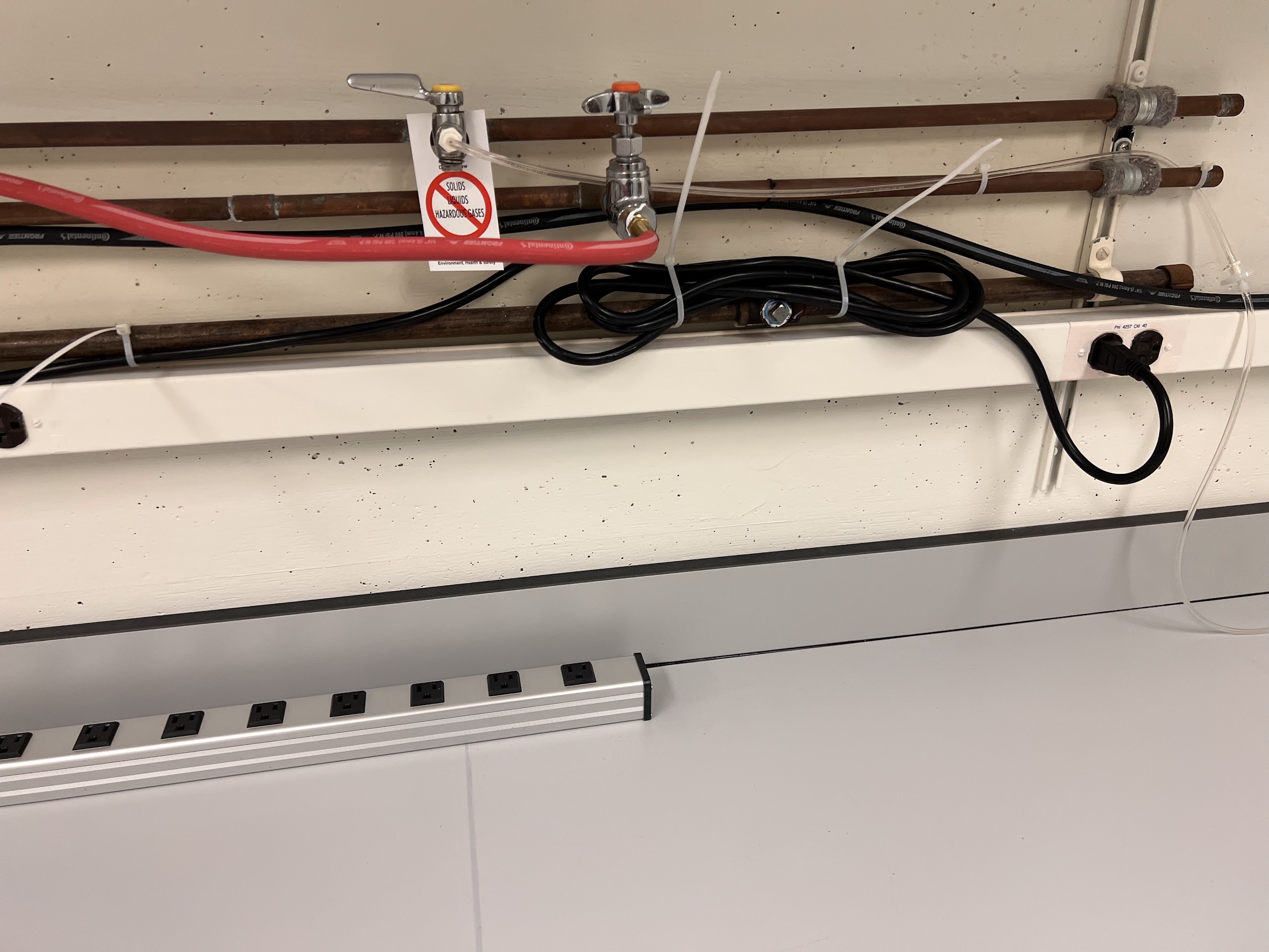

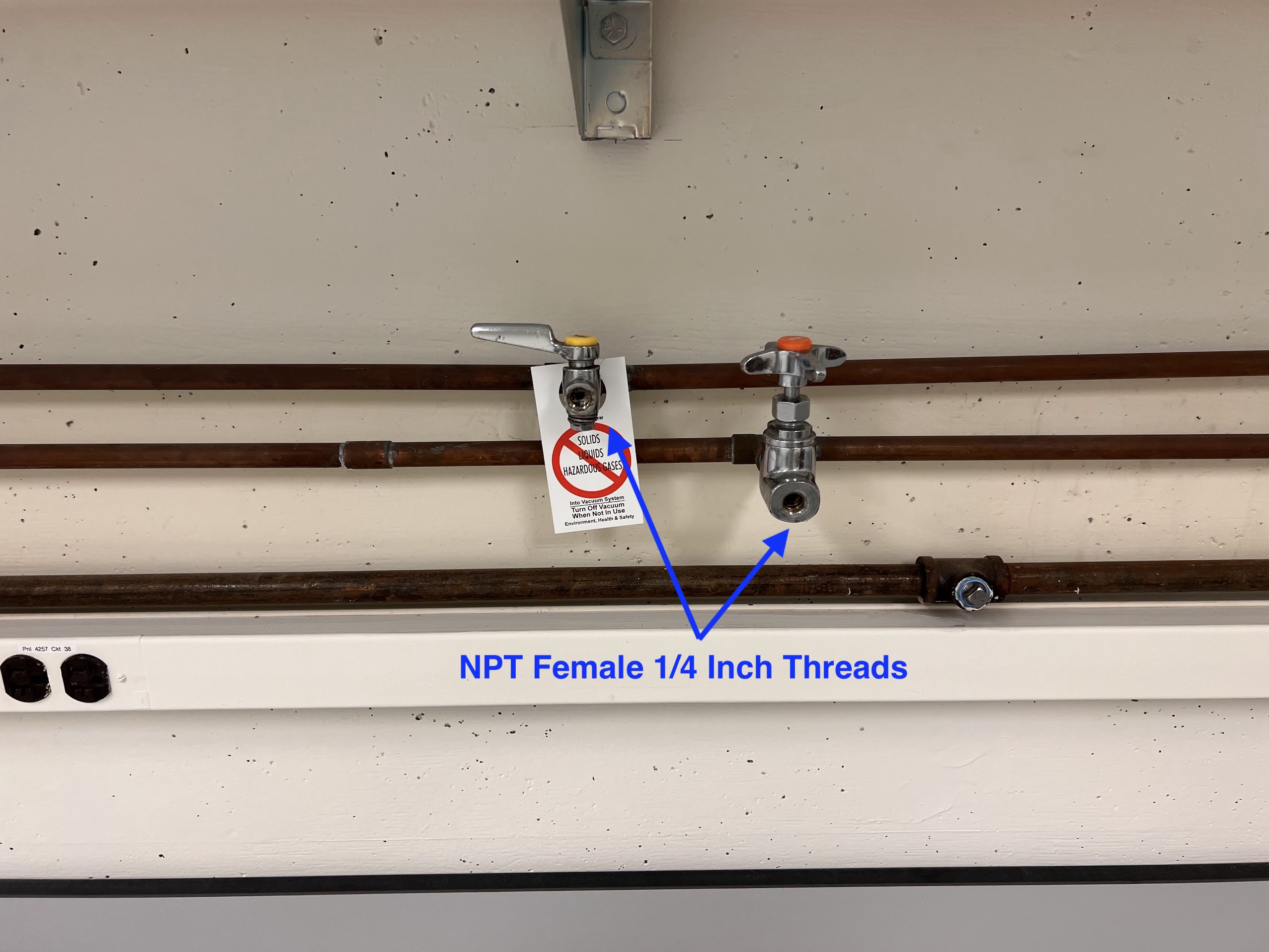

The barbs for the House Air and Vacuum sources were also removed. The input threads for sources in our building were Female NPT 1/4 Inch.

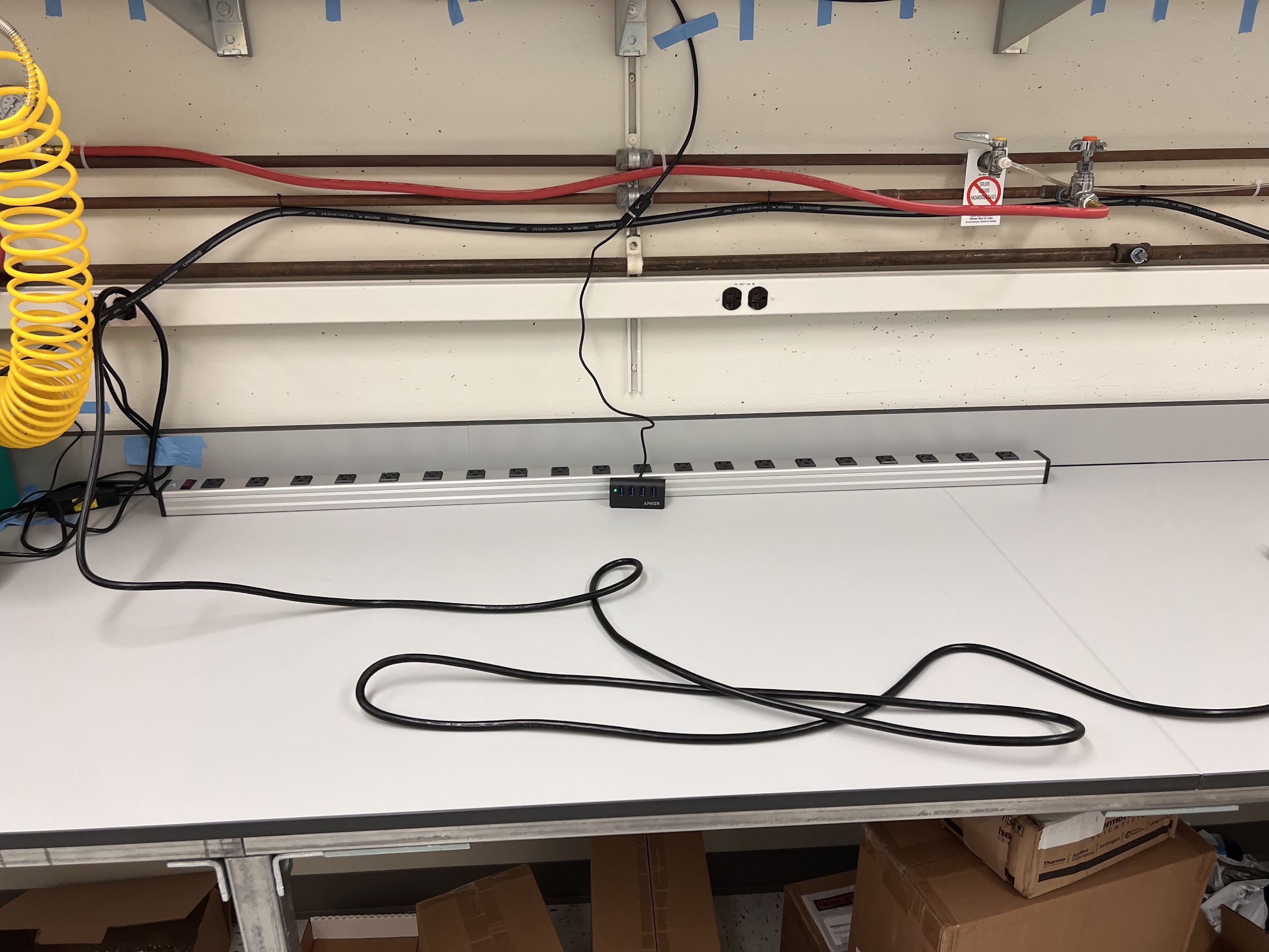

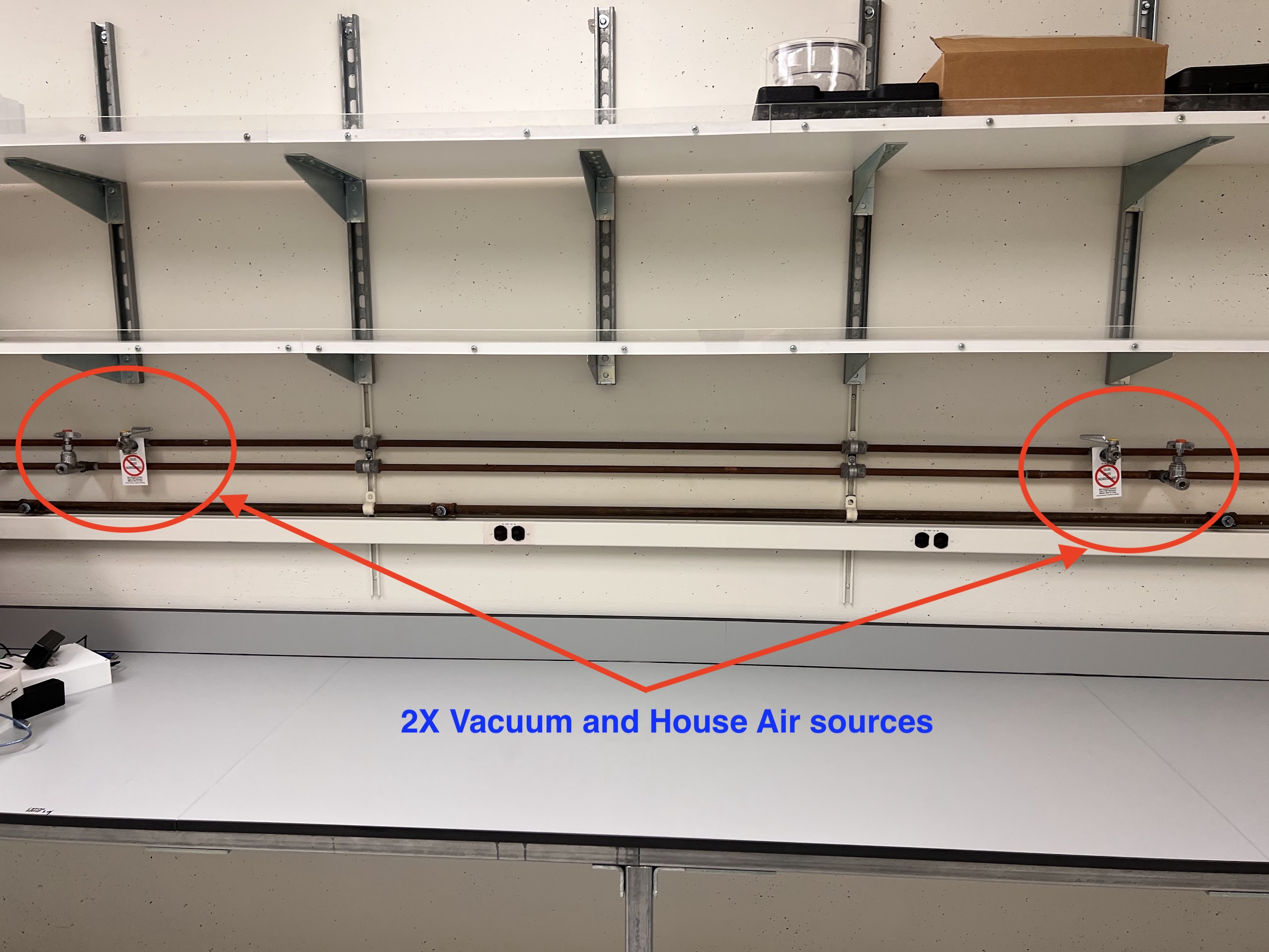

We had 2 each of Vacuum and House Air sources on our bench as shown.

- We need 2 House Air sources and one Vacuum source for our device.

- We need 2 House Air sources and one Vacuum source for our device.

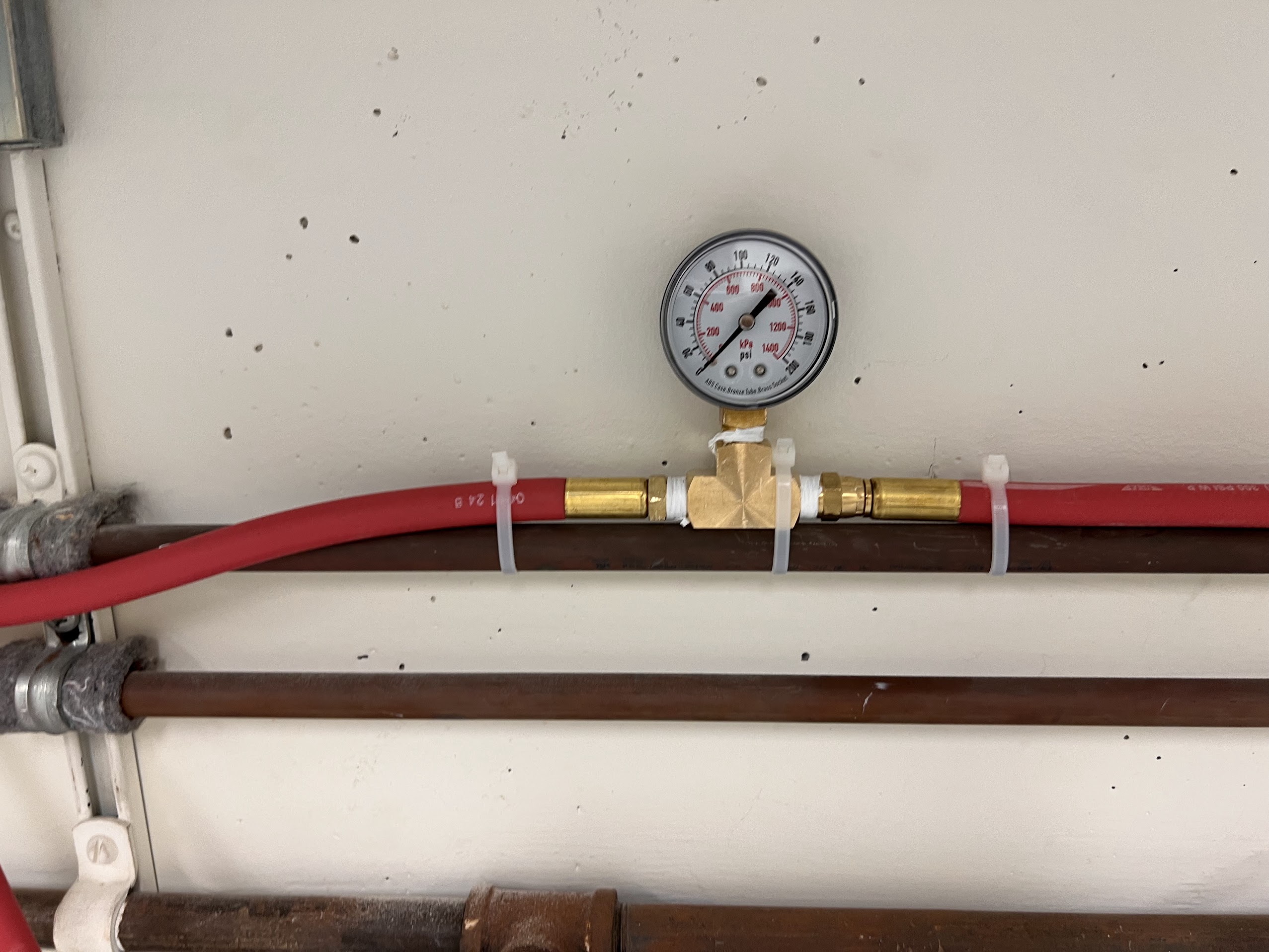

Setting up 5%CO2 Cylinder as Pressure source for ChronoSeq Device¶

WARNING: Make sure you wear safety glasses. Comressed Air can be dangerous. Please follow the Hazard Control Plans for your lab and institution.

- You will the following Items:

- Execute the cell below to watch a video on how to connect your Gas Regulator to the cylinder and then set the second stage pressure to 6.5Bars.