Protocol for Aquapel Treatment of PDMS-Glass Bonded ChronoSeq-V14 Microfluidic Chips¶

Purpose of Protocol¶

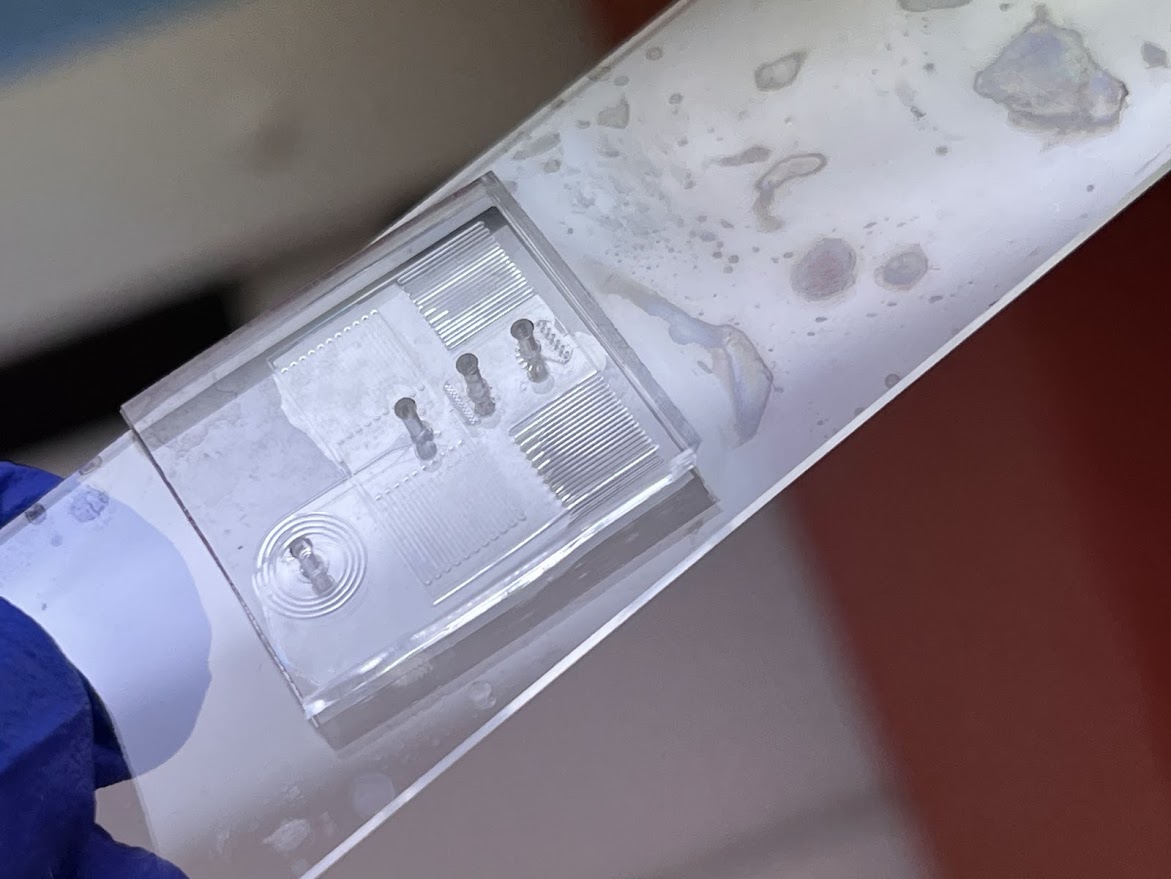

- Droplet Generation does not work without Aquapel Treatment of the Glass Bonded PDMS Microfluidic Chips.

- Aquapel has a Fluorinated Active ingredient that works well with Fluorinated Oil/Sufractants used in Droplet Microfluidics.

- This protocol has an additional benefit of Filtering out poorly bonded PDMS chips or identifying a bad batch of PDMS.

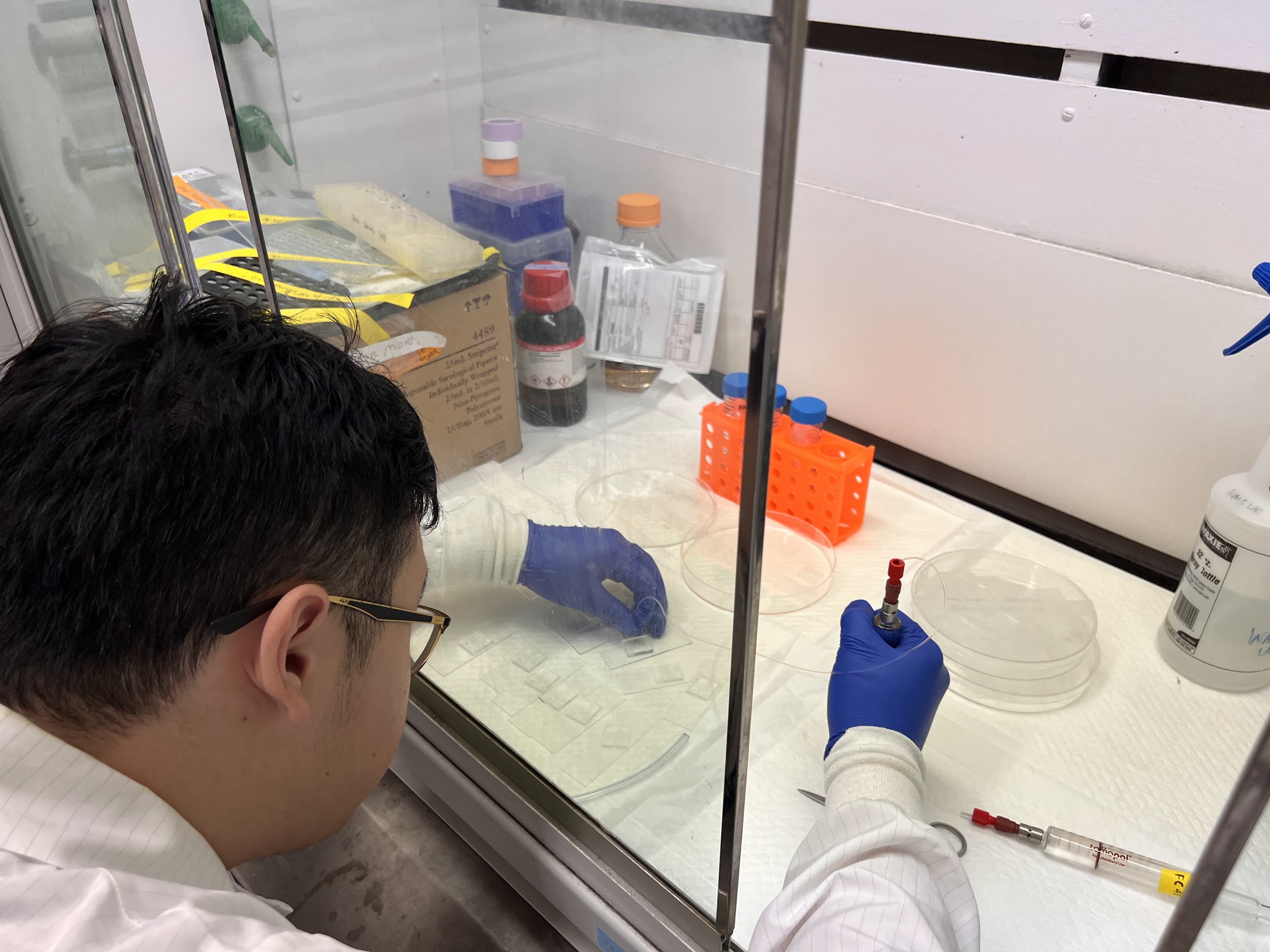

Prepare Fume Hood and Incubator¶

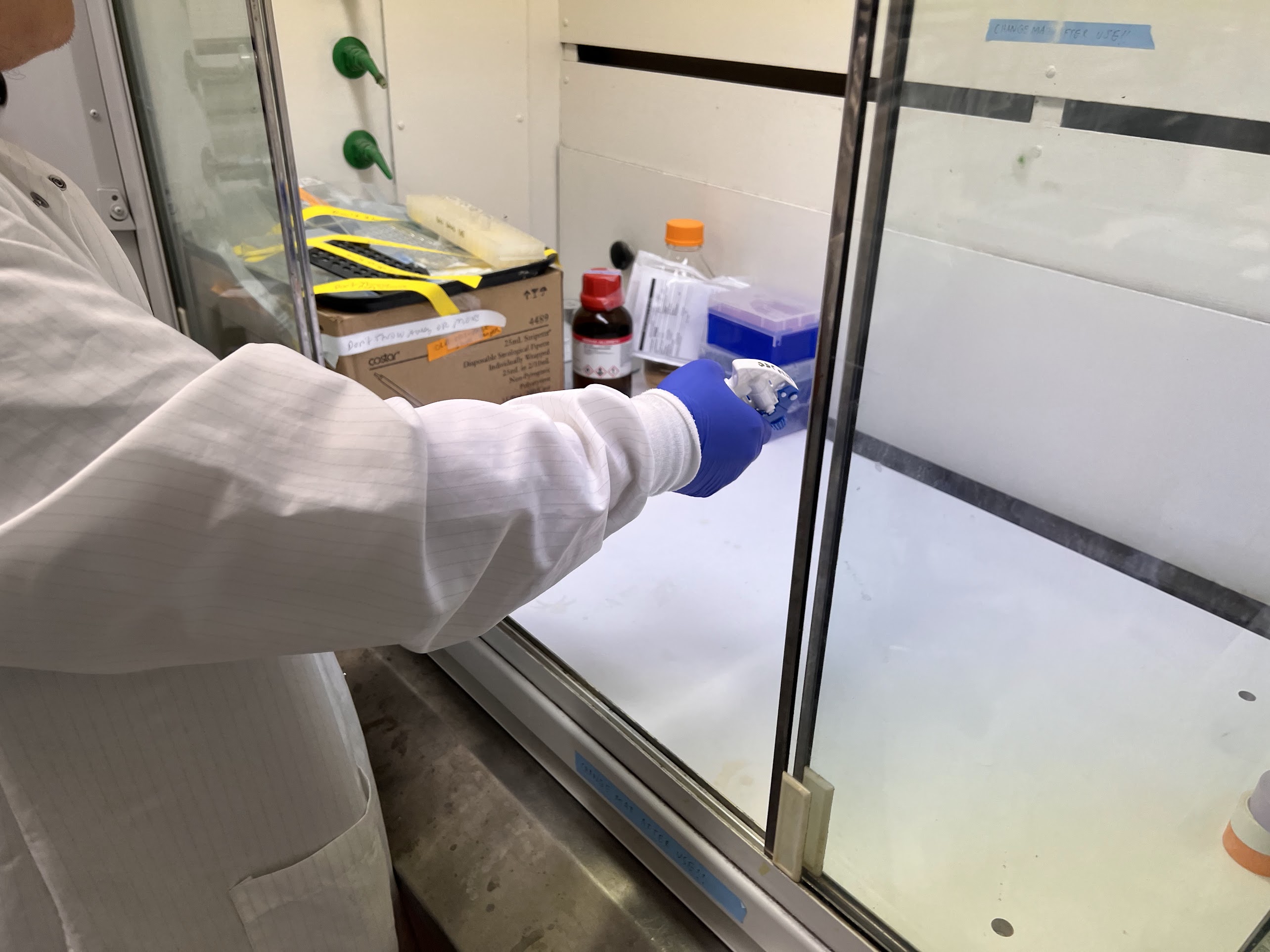

- Prepare the Fume Hood:

- Turn on the Fume Hood light.

- Before you begin, clean you Fume hood:

- Discard any previous absorbent mats in the Fume Hood in a large Blue Bin for Waste Contaminated with Chemicals.

- Spray the Working Area with 70% Ethanol.

- Use Paper Towels to Wipe the Area Clean.

- Discard the Paper Towels in the large Blue Bin for Waste Contaminated with Chemicals.

- Discard any previous absorbent mats in the Fume Hood in a large Blue Bin for Waste Contaminated with Chemicals.

- Lay down four absorbent mats inside the fume hood. These should quickly absorb any spills.

- Make sure there is enough space to work.

| Clean the Hood with Ethanol Spray and Wipe Clean | Lay Down Absorbent Mats |

|---|---|

|

|

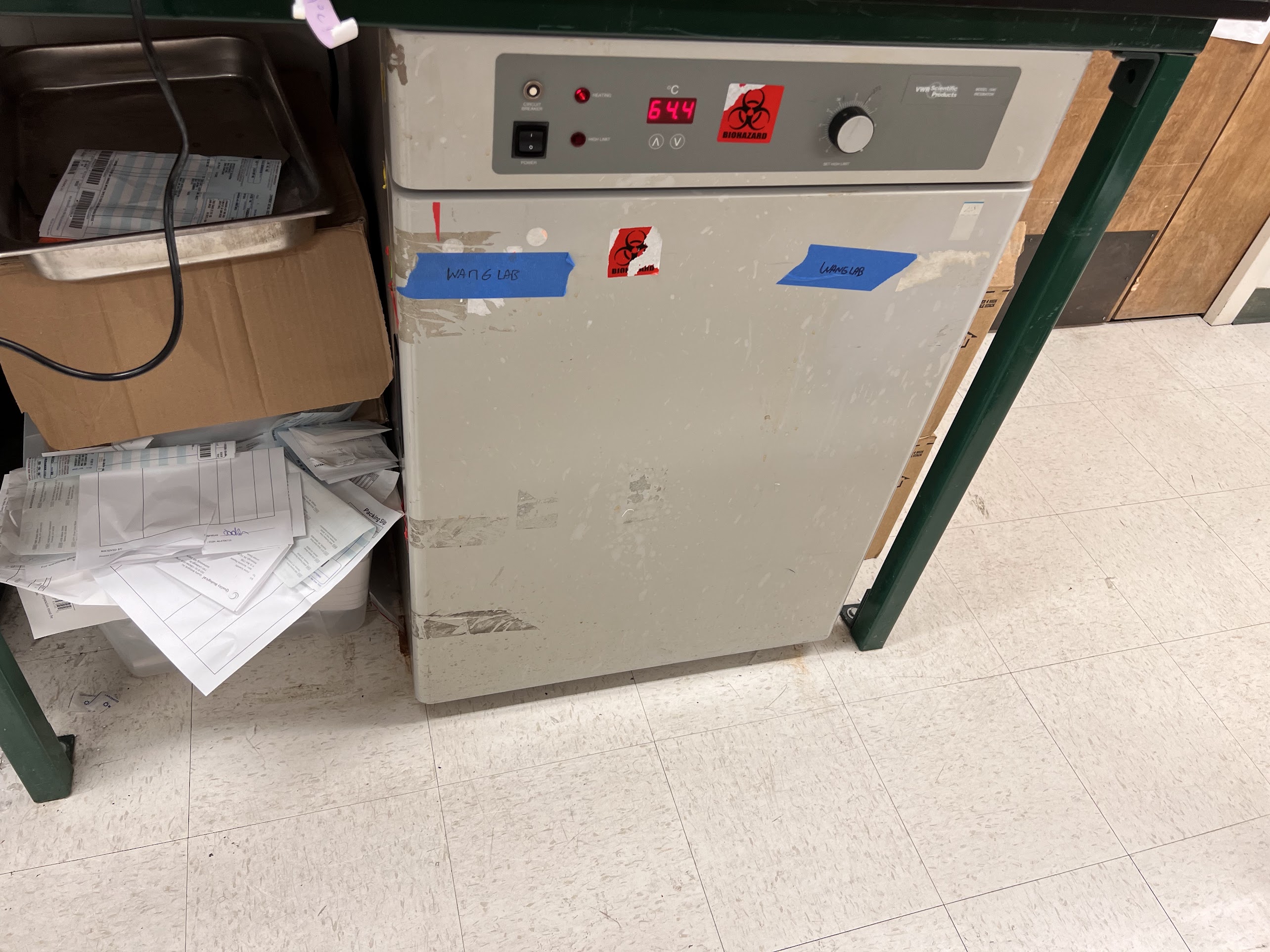

- Set a Laboratory incubator or oven to 65°C.

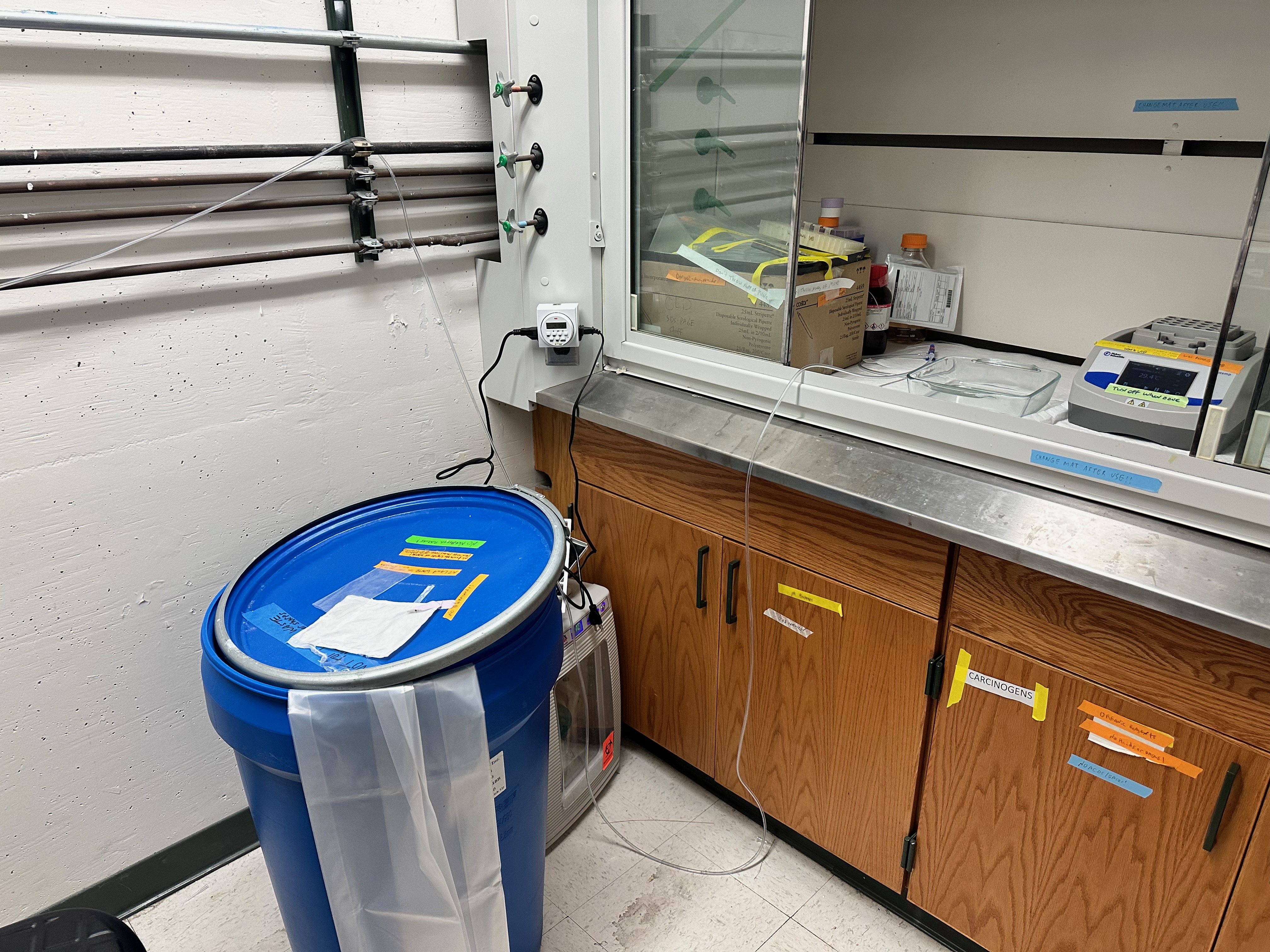

Pneumatics Assembly¶

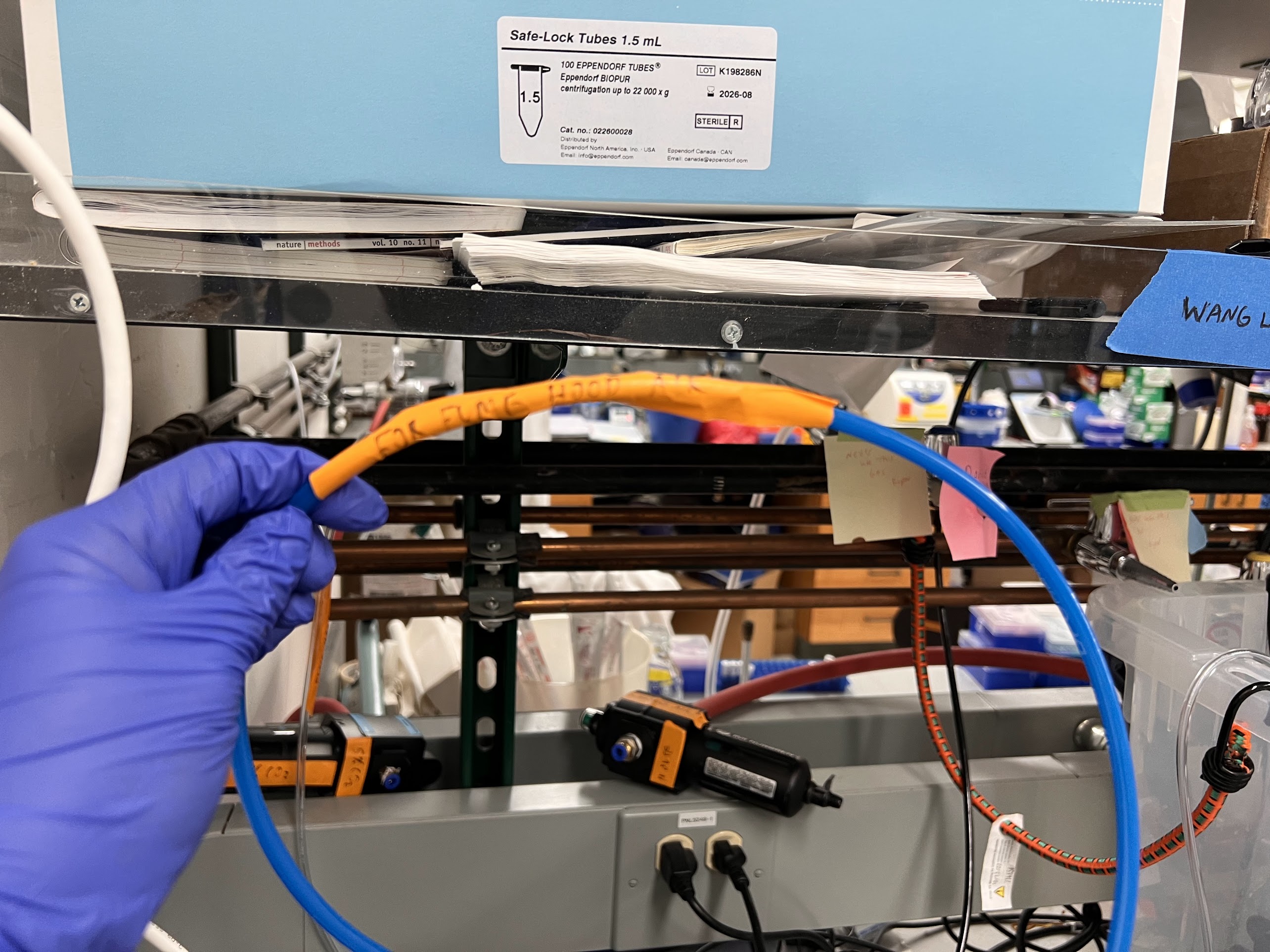

- Connect the house air to 6mm Pneumatic tubing.

- This 6mm Tubing should be labeled "For Fume Hood".

| Label the 6mm Pneumatic Tubing as "For Fume Hood" | Connect it to House Air |

|---|---|

|

|

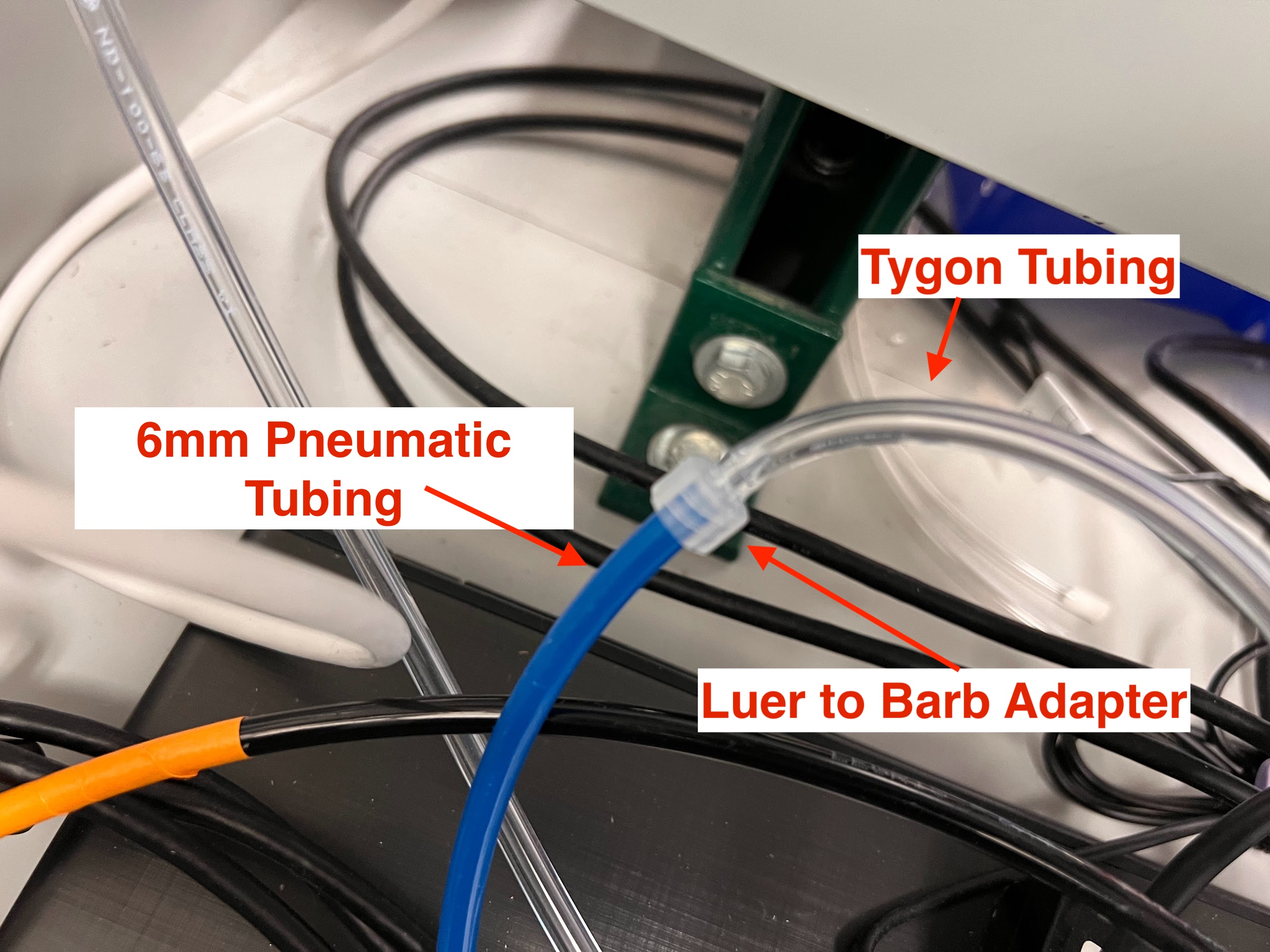

- Connect the 6mm Pneumatic Tubing to Tygon Tubing

- Push the Luer-Lock side of a P851-Luer to Barb Adapter into the 6mm tubing.

- Push the 6mm Tubing in a right-left twisting motion till it touches the inner wall of the Luer portion of the Adapter.

- Now Push the 3/32" ID Tygon Tubing onto the Barb Side of the Luer-Barb Adapter.

| This is what the Connection between the 6mm Pneumatic Tubing with the Tygon Tubing using the Luer-Barb Adapter look like |

|---|

|

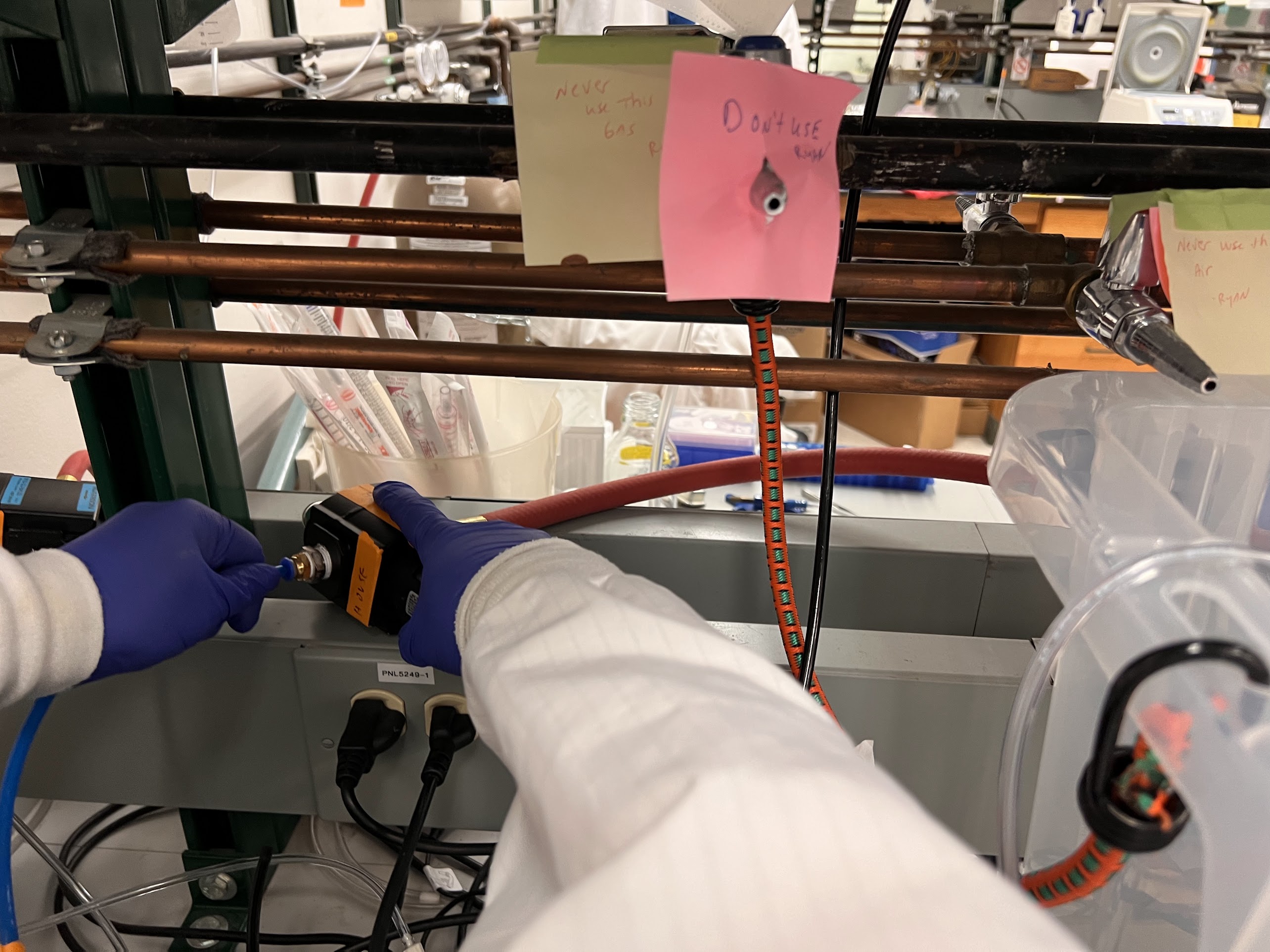

- Unroll Enough Tygon Tubing to reach the Fume Hood:

- Now cut a long enough segment of Tygon tubing that you can reach the Fume hood from the compressed air system location.

- Avoid tripping hazards by securely routing the tubing along the walls to the fume hood.

- Use large Scissors to cut the Tygon tubing.

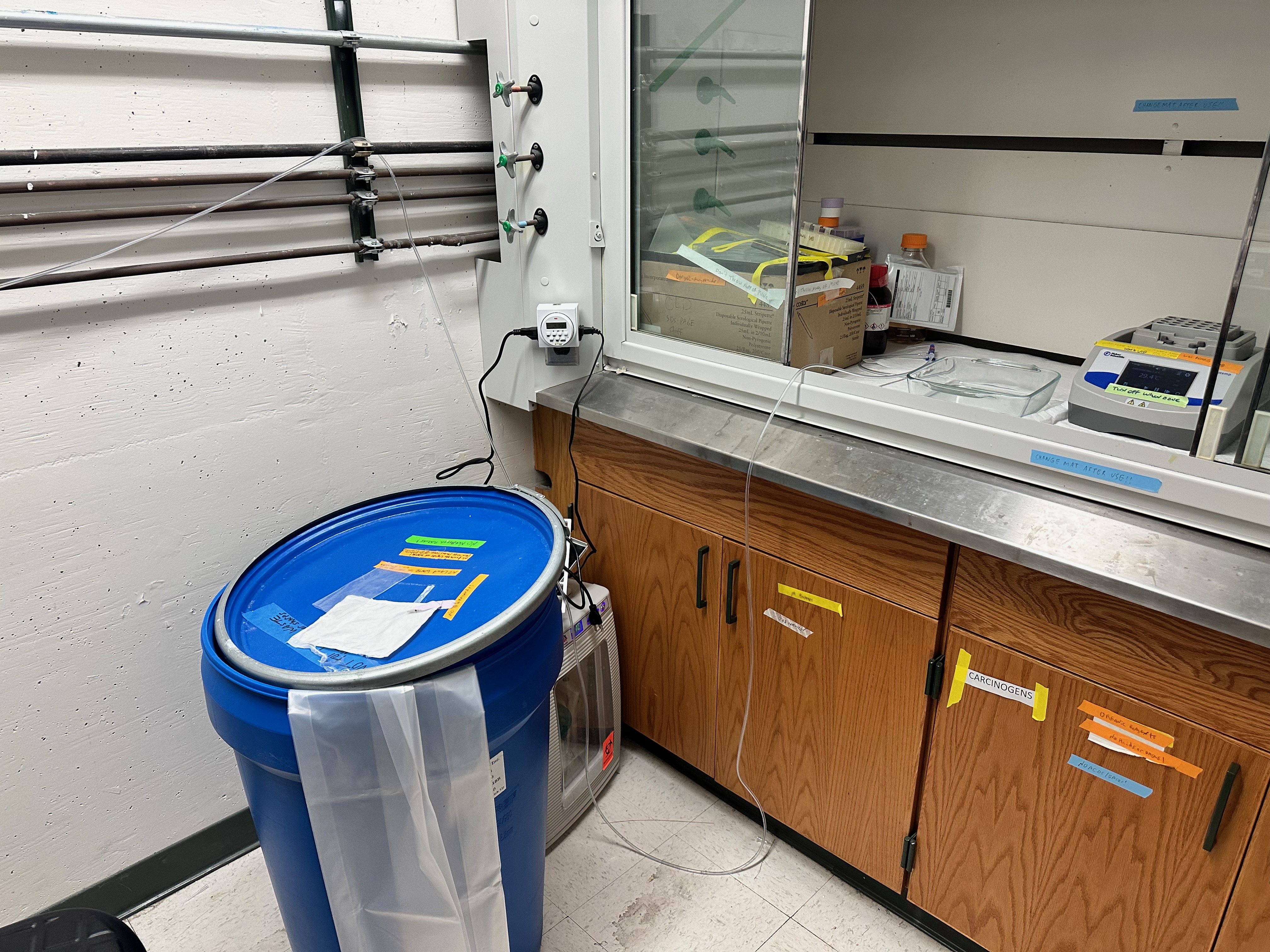

| Tygon Tubing Going from Pressure Source to Fume Hood | Tygon Tubing Going from Pressure Source to Fume Hood Continued.. |

|---|---|

|

|

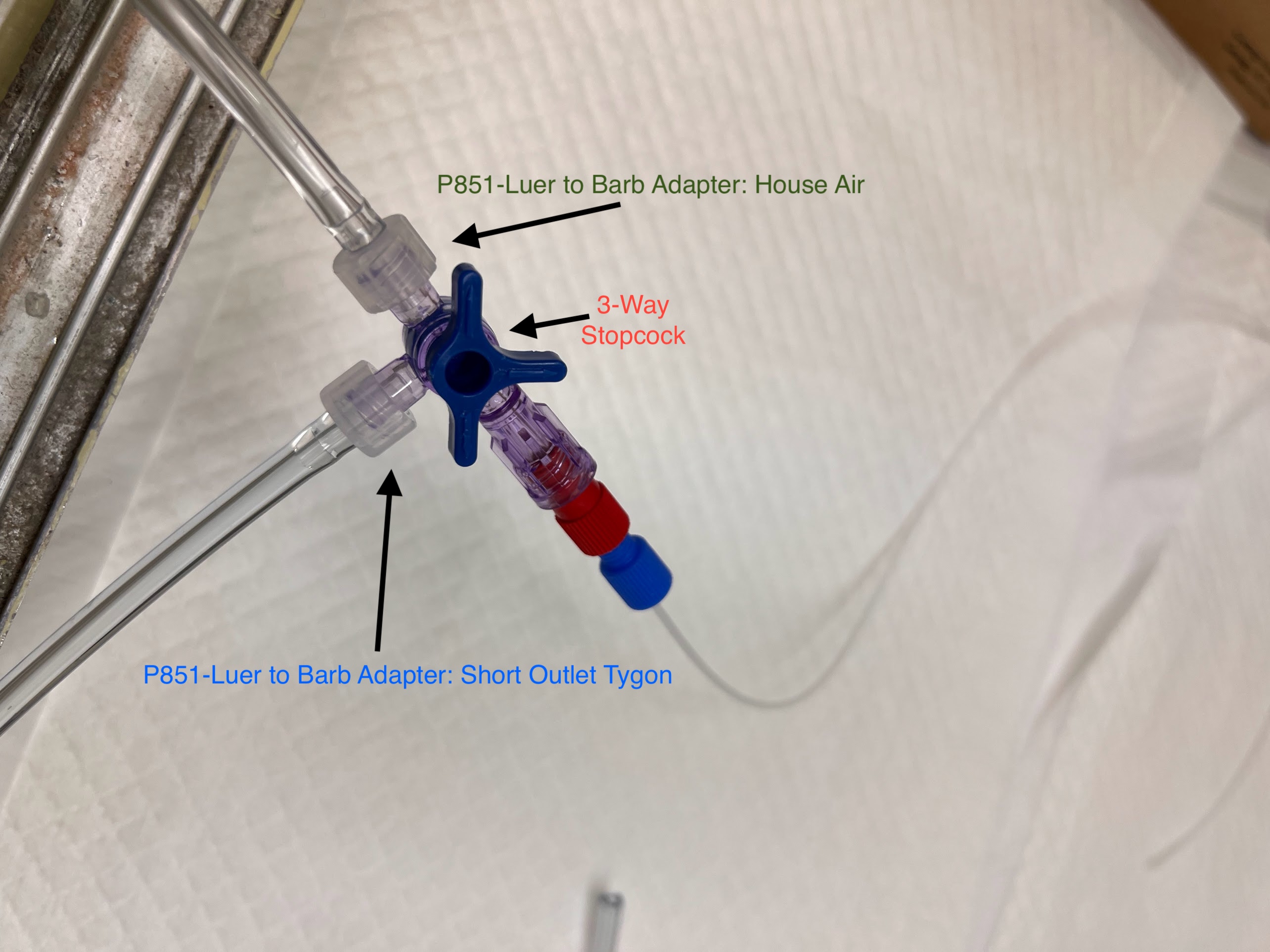

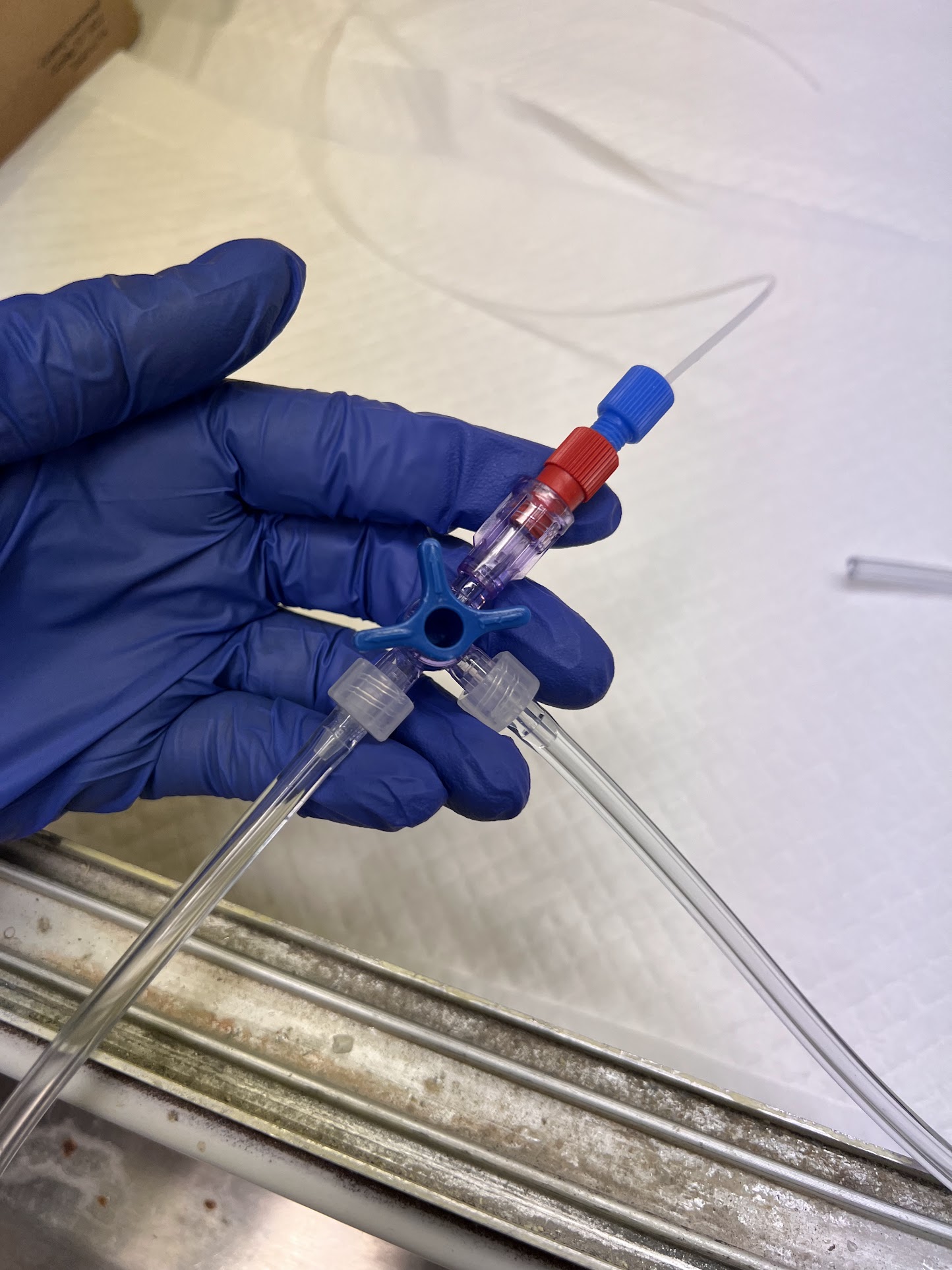

- Connect the Tygon tubing to a 3-way Stopcock inside the Fume hood using the P851-Luer to Barb Adapter.

- There are two Male Luer Locks and One Female Luer Lock on the 3-Way Stopcock.

- This Stopcock can be used to Turn the Air Pressure off or Redirect Air Flow towards the Female Luer Lock Direction or Male Luer Lock Direction.

- Connect Two P851- Luer to Barb Adapters on the Male Luer Locks on the Stopcock.

- One Side Connect the Tygon Tubing coming from the House Air supply.

- On the Second Side Connect a Short Tygon Segment.

| Tygon Connections Using the Luer Barb Adapter | Short Tygon Tubing for Second Male Luer Connection |

|---|---|

|

|

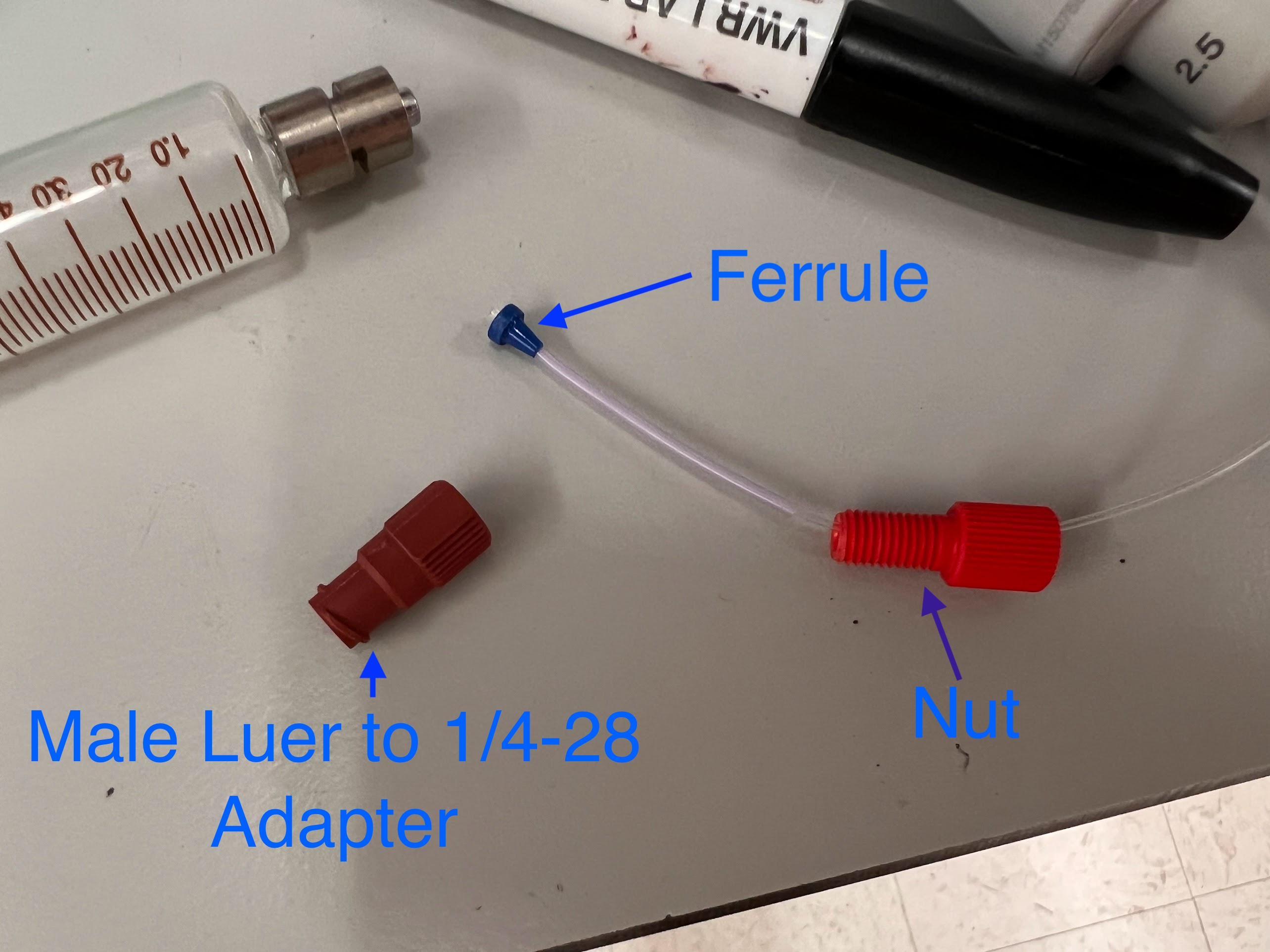

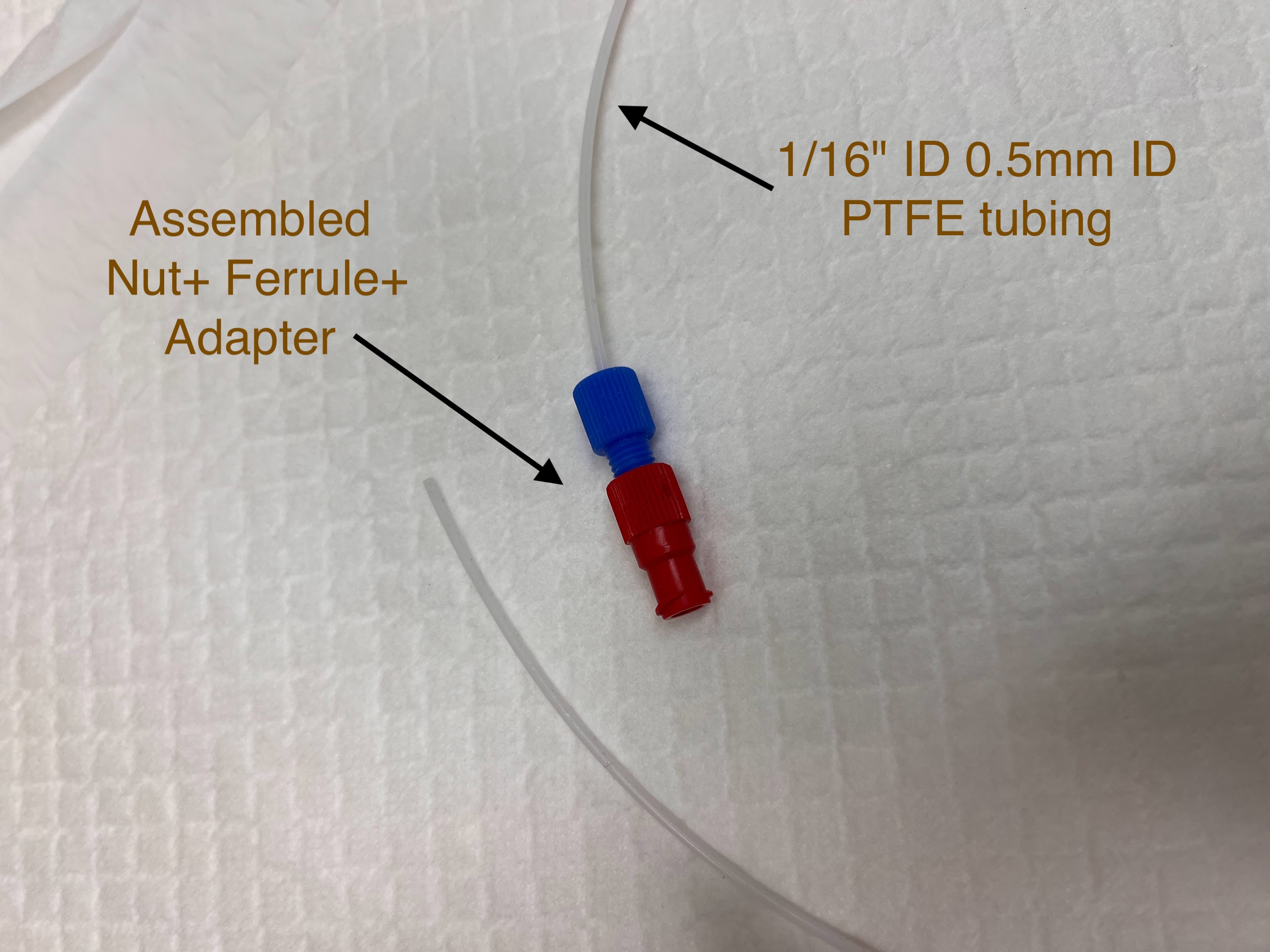

- Now using this Luer to 1/4-28 Adapter, a Nut and Ferrule you can connect the 1/16" ID 0.5mm ID PTFE tubing {CAT NO. JR-T-4183-M25} {email precision@vici.com for a Quote} to the 3-way stopcock.

- This tubing will be used to blow any liquid out of the Microfluidic chips.

- Cut about 1 meter of PTFE tubing using a Stanley Razor Blade.

- Connect to the Female Luer on the 3-Way Stopcock. Screw all the way in.

| Components | Assembled | Connected To 3-Way Stopcock |

|---|---|---|

|

|

|

- Make Sure the Stopcock is in the Closed Position same as the image above.

- Turn on the House Air. Make sure there are no leaks.

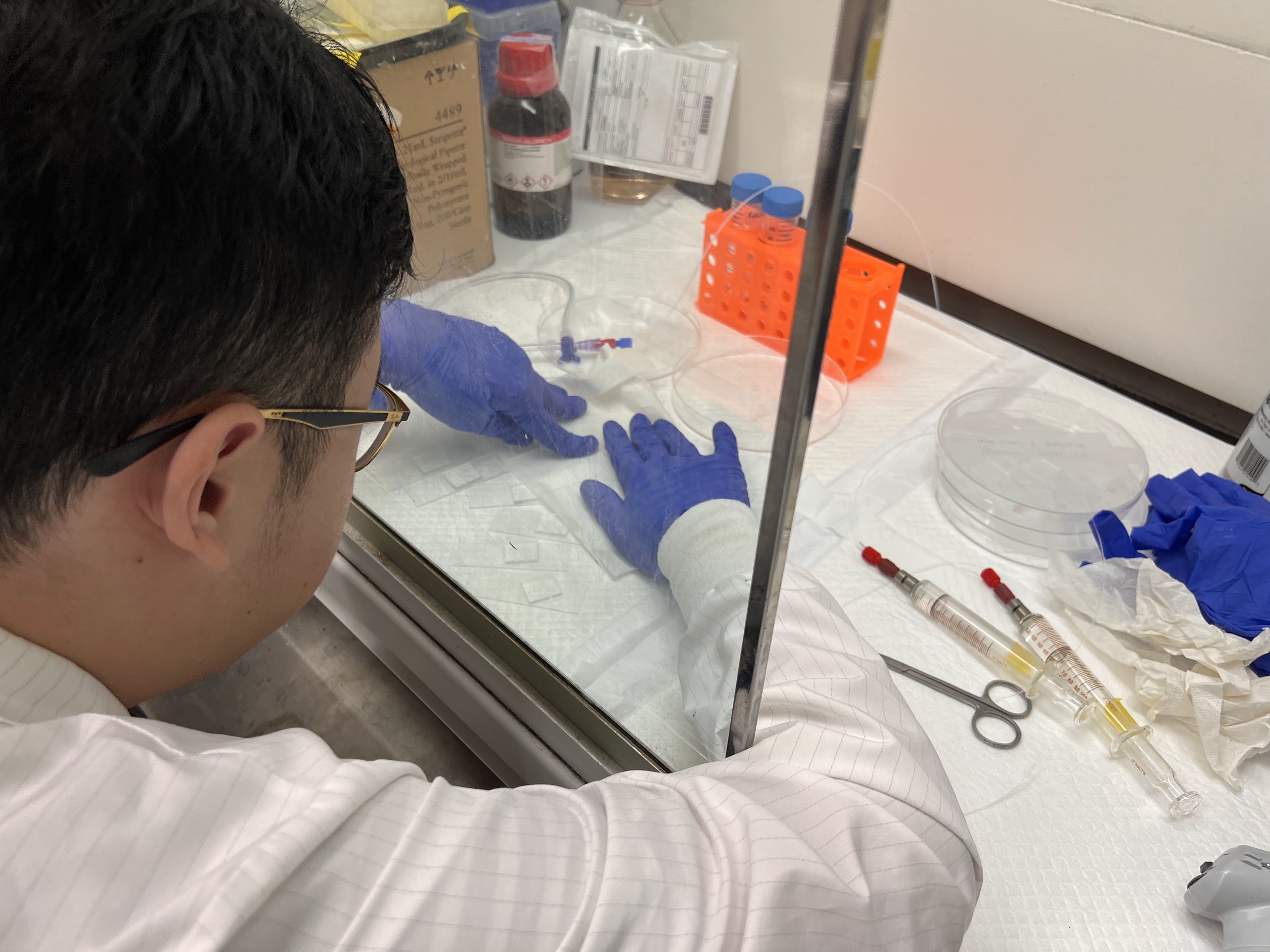

Prepare Syringe Assemblies¶

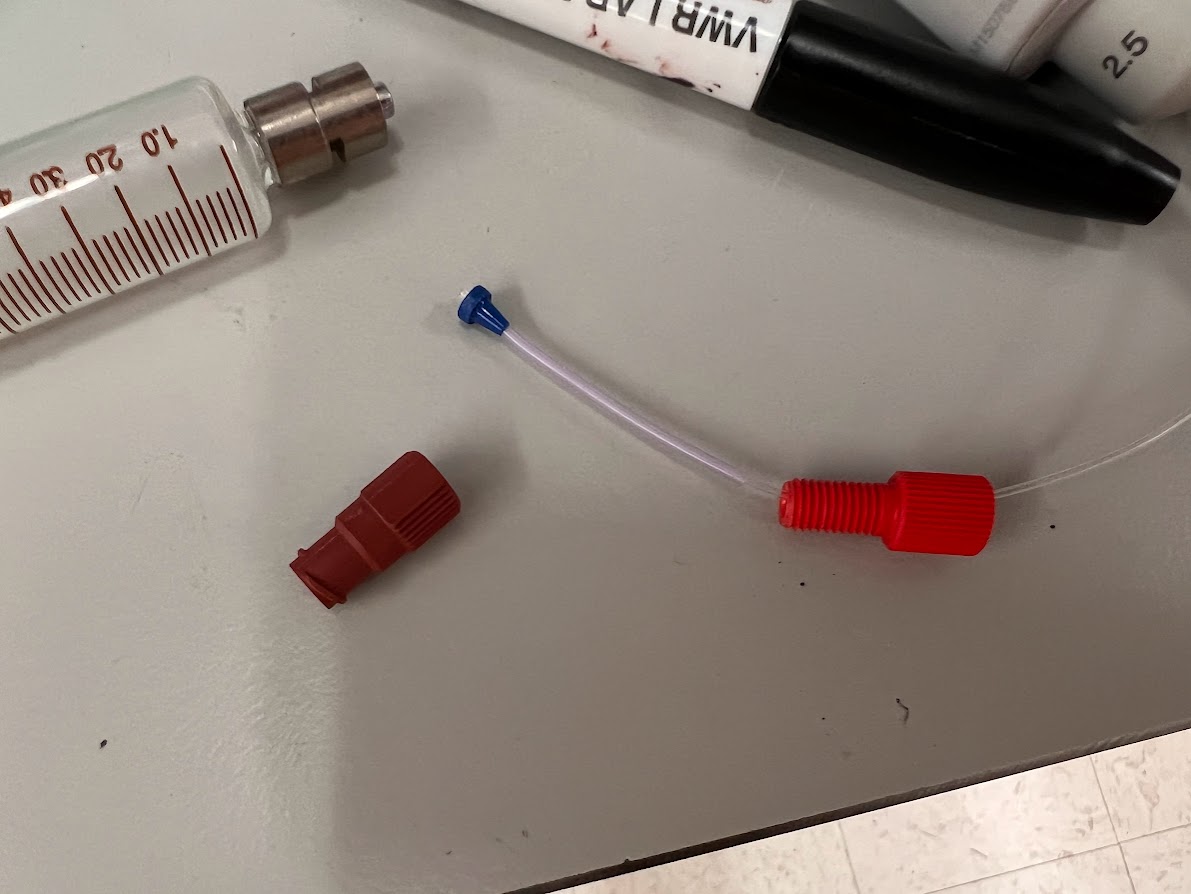

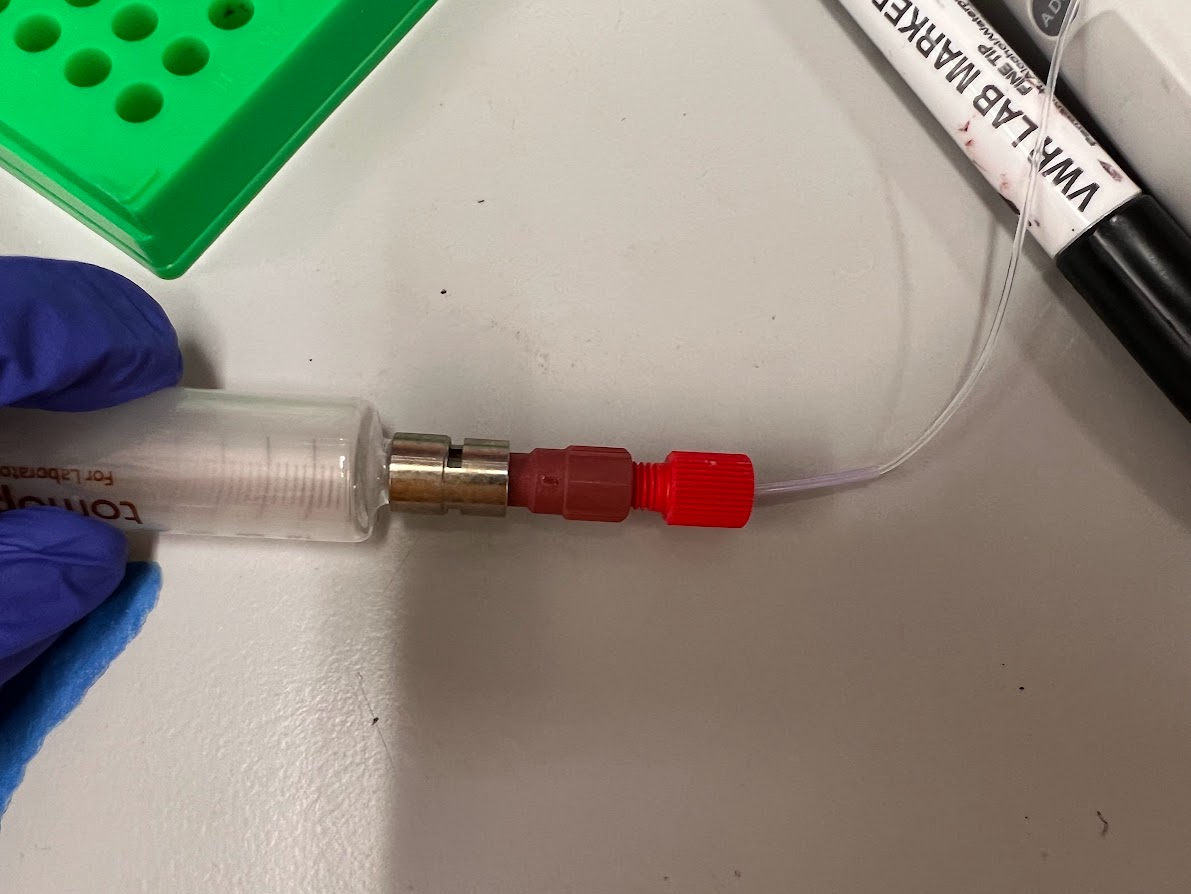

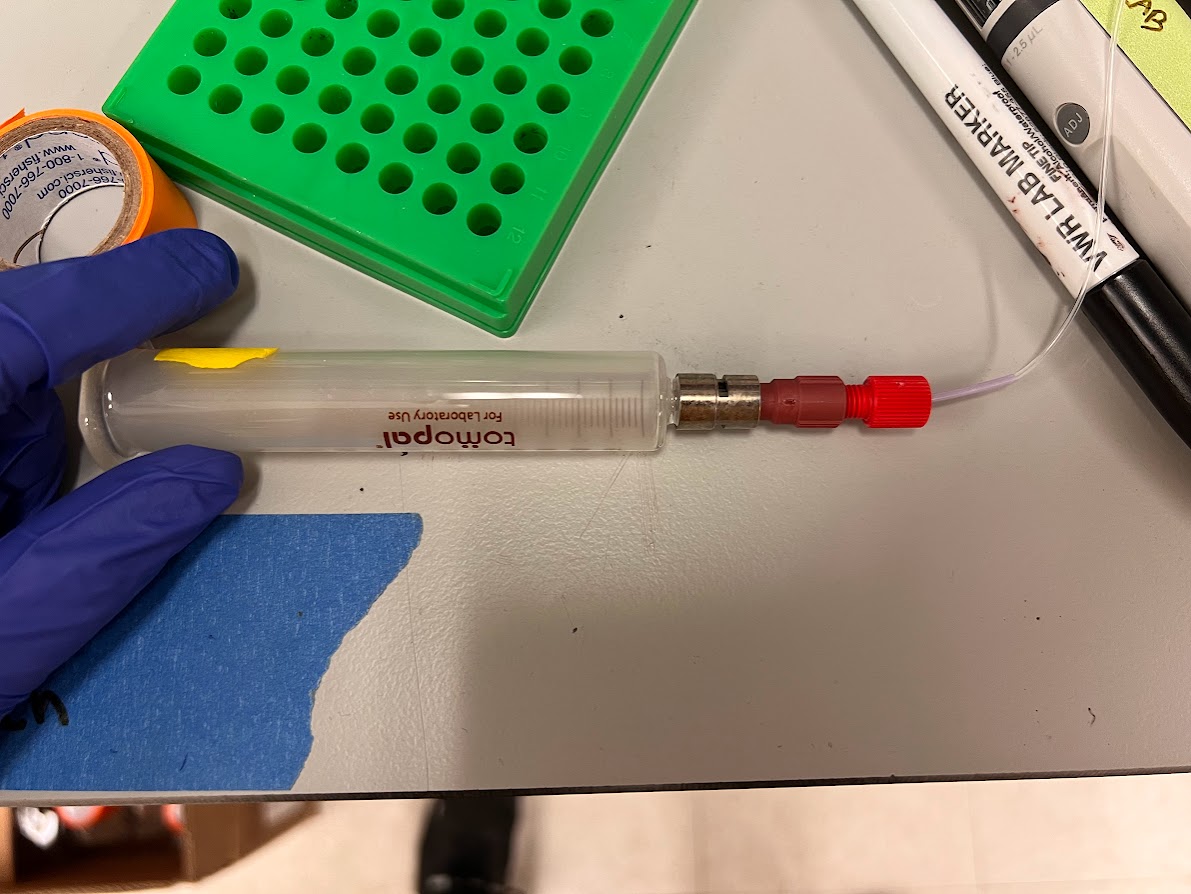

- Now cut two segments of about 50cm segments of the 1mm OD FEP tubing from VICI metronics {CAT NO. MT-F-40020} using Stanley Razor blades.

- Using the Luer to 1/4-28 Adapter, Nut, Ferrule and Nanotight Adapter you can connect to a Glass Syringe.

- Prepare Two Syringe Assemblies. Label one as "Aquapel" and the second one "FC-40".

- The FEP tubing should be sticking out slightly

- Make sure the seal is tight.

| 1mm OD FEP Tubing Should Stick Out Slightly | Main Components Before Assembly |

|---|---|

|

|

| Screw Everything In | Label The Syringe |

|---|---|

|

|

- Turn on the Compressed Air for the Short Tygon Section of the 3-Way Stopcock inside the Fume Hood.

- For Both Syringes:

- Remove the Plunger from the Syringe Body.

- Use Compressed Air to Blow Dust out from Inside the Syringe Body.

- Use Compressed Air to also Blow Dust off the Syringe Plunger.

- Insert the Plunger back into the Syringe Body.

- Turn off the Compressed Air using the 3-Way Stopcock.

FC-40 Syringe¶

- Place a Black Bin with the Correct Waste Tag inside the Fume Hood. We will discard all Aquapel and FC-40 Contaminated Items in this Bin.

- Filter 6ml of FC-40 {Cat No. F9755-100ML} using a 40μm Cell Strainer.

- Remove the plunger from the FC-40 Glass syringe and use a pipette to transfer the Filtered FC-40 into the Syringe Body.

- Reattach the plunger, flip the syringe and blow the air out.

- Keep pushing the plunger down still a little bit of FC-40 Comes out.

- Use the absorbent pad to catch any spilt FC-40.

- Execute the Cell Below to Watch a Video of the Process