def cell_clean():

cell_media_flush_valve.OPEN()

update_valve_states()

set_flush_pressures(2000.0,0.0,0.0)

time.sleep(20.0)

def prime_outlet_tubing():

waste_tube1.goToCoordinates()

bad_collection_tube.goToCoordinates()

time.sleep(2.5)

bead_lysis_buffer_flush_valve.OPEN()

bead_bypass_valve.OFF()

update_valve_states()

set_flush_pressures(0.0,2000.0,0.0)

time.sleep(60.0)

def cell_bypass_flush():

set_flush_pressures(2000.0,0.0,0.0)

cell_media_flush_valve.OPEN()

cell_bypass_valve.ON()

update_valve_states()

time.sleep(60.0)

def bead_bypass_flush():

waste_tube1.goToCoordinates()

time.sleep(2.5)

bead_lysis_buffer_flush_valve.OPEN()

bead_bypass_valve.ON()

update_valve_states()

set_flush_pressures(0.0,2000.0,0.0)

time.sleep(60.0)

def chip_test():

global record_data

record_data=True

print("Testing Chip:")

oil_bypass_valve.OFF()

cell_bypass_valve.OFF()

cell_media_flush_valve.OPEN()

bead_lysis_buffer_flush_valve.OPEN()

update_valve_states()

print(get_cell_channel_density())

set_oil_channel_scaling_factor(evagreenDropletOilScalingFactor)

time.sleep(5.0)

set_flush_pressures(300.0,300.0,0.0)

time.sleep(60.0)

stop_flushing_all_channels()

time.sleep(5.0)

record_data=False

def cell_channel_flush():

global record_data

record_data=True

print("Cell Channel Flush:")

oil_bypass_valve.ON()

cell_bypass_valve.ON()

bead_bypass_valve.ON()

cell_media_flush_valve.OPEN()

bead_lysis_buffer_flush_valve.CLOSE()

update_valve_states()

print(get_cell_channel_density())

#set_oil_channel_scaling_factor(evagreenDropletOilScalingFactor)

for i in range(0,6):

set_flush_pressures(2000.0,0.0,0.0)

time.sleep(2.5)

stop_flushing_all_channels()

time.sleep(2.5)

set_flush_pressures(2000.0,0.0,0.0)

record_data=False

def cell_and_oil_channel_flush():

print("Cell Channel Flush:")

oil_bypass_valve.ON()

cell_bypass_valve.ON()

bead_bypass_valve.ON()

cell_media_flush_valve.OPEN()

bead_lysis_buffer_flush_valve.CLOSE()

update_valve_states()

print(get_cell_channel_density())

print(get_oil_channel_density())

set_bead_channel_scaling_factor(digitalDistilledWaterScalingFactor)

set_flush_pressures(2000.0,0.0,1000.0)

time.sleep(20.0)

def bead_priming():

set_flush_pressures(0.0,2000.0,0.0)

bead_lysis_buffer_flush_valve.OPEN()

bead_bypass_valve.ON()

update_valve_states()

time.sleep(5.0)

bead_lysis_buffer_flush_valve.CLOSE()

for time_point in bead_time_points_valve_list:

time_point.OPEN()

update_valve_states()

time.sleep(5.0)

time_point.CLOSE()

bead_lysis_buffer_flush_valve.OPEN()

update_valve_states()

time.sleep(5.0)

bead_lysis_buffer_flush_valve.CLOSE()

stop_flushing_all_channels()

bead_lysis_buffer_flush_valve.CLOSE()

update_valve_states()

#Pressures are going to be off because no chip is connected. Have to rely on flow control to get the correct injection timing.

def bead_injection_only_priming():

setNewPIDKis(0.75,0.1,1.5)

outlet_bypass_valve.ON()

oil_bypass_valve.ON()

cell_bypass_valve.ON()

set_flow_rates(0.0,875.0,0.0)

bead_lysis_buffer_flush_valve.OPEN()

update_valve_states()

time.sleep(60.0)

bead_lysis_buffer_flush_valve.CLOSE()

for time_point in bead_time_points_valve_list:

time_point.OPEN()

update_valve_states()

time.sleep(time_point.get_time_to_manifold())

time_point.CLOSE()

bead_lysis_buffer_flush_valve.OPEN()

update_valve_states()

time.sleep(60.0)

bead_lysis_buffer_flush_valve.CLOSE()

set_flow_rates(0.0,0.0,0.0)

bead_lysis_buffer_flush_valve.CLOSE()

update_valve_states()

def tubing_clean():

set_flush_pressures(0.0,2000.0,0.0)

#outlet_bypass_valve.ON()

bead_lysis_buffer_flush_valve.OPEN()

bead_bypass_valve.OFF()

bead_air_flush_valve.CLOSE()

update_valve_states()

time.sleep(20.0)

bead_air_flush_valve.OPEN()

bead_lysis_buffer_flush_valve.CLOSE()

update_valve_states()

time.sleep(20.0)

bead_lysis_buffer_flush_valve.OPEN()

bead_air_flush_valve.CLOSE()

update_valve_states()

time.sleep(20.0)

def prime_the_cell_channel():

cell_sample_flush_valve1.OPEN()

cell_sample_flush_valve2.OPEN()

cell_sample_flush_valve3.OPEN()

cell_media_flush_valve.OPEN()

update_valve_states()

set_flush_pressures(2000.0,0.0,0.0)

time.sleep(60.0) #You can change this time by specifying a different flush period

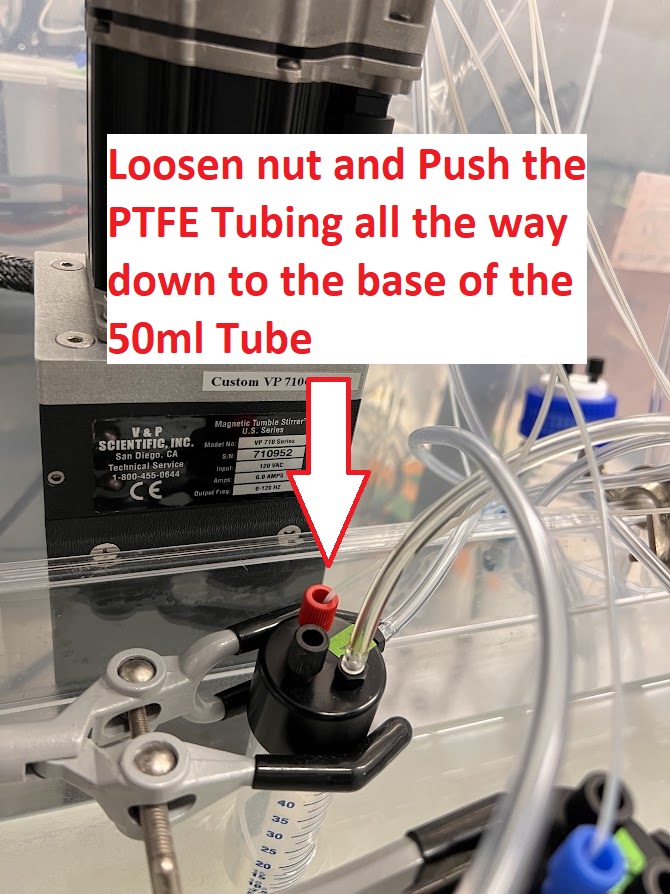

def prime_the_chip_tubing():

#Make sure the chip is not connected when you run this protocol. This is necessary everytime you change the liquid or chip.

#Run this to make sure there is no backflow and everything ramps up smoothly when priming the chip. Make sure you take all

#the tubing and but in a 50ml bottle cap or something to collect the run-off and prevent it from getting into the microscope.

waste_tube1.goToCoordinates()

time.sleep(2.5)

print("Priming Tubing that Connects to Chip:")

oil_bypass_valve.OFF()

cell_bypass_valve.OFF()

cell_media_flush_valve.OPEN()

bead_lysis_buffer_flush_valve.OPEN()

bead_bypass_valve.OFF()

update_valve_states()

print(get_cell_channel_density())

print(get_oil_channel_density())

set_bead_channel_scaling_factor(scalingFactor60ul)

set_flush_pressures(2000.0,2000.0,1000.0)

time.sleep(60.0) #You can change this time by specifying a different flush period for the chip.

def prime_the_chip():

global total_waste_collections

total_waste_collections+=1

waste_tube=waste_tube1

if total_waste_collections>8:

waste_tube=waste_tube2

robot_action.enableRobot()

waste_tube.goToCoordinates()

setNewPIDKis(1.0,1.0,1.0)

oil_val=200.0

bead_val=55.0

cell_val=15.0

global record_data

global store_chip_values

store_chip_values=True

record_data=True

storedCellPress,storedBeadPress,storedOilPress=get_chip_stored_pressure_calibration_values(False)

print("Testing Chip:")

set_bead_channel_scaling_factor(scalingFactor60ul)

#outlet_bypass_valve.ON()

oil_bypass_valve.ON()

cell_bypass_valve.ON()

cell_media_flush_valve.OPEN()

bead_lysis_buffer_flush_valve.OPEN()

bead_bypass_valve.ON()

update_valve_states()

print(get_cell_channel_density())

print(get_oil_channel_density())

time.sleep(2.5)

for i in range(0,4):

set_flush_pressures(2000.0,2000.0,1000.0)

time.sleep(2.5)

stop_flushing_all_channels()

time.sleep(2.5)

set_flush_pressures(2000.0,2000.0,0.0)

print(get_cell_channel_density())

print(get_oil_channel_density())

set_stirrer_speed(300)

cell_bypass_valve.OFF()

cell_media_flush_valve.OPEN()

bead_bypass_valve.OFF()

bead_lysis_buffer_flush_valve.OPEN()

update_valve_states()

set_flush_pressures(2000.0,2000.0,0.0)

time.sleep(10.0)

cell_media_flush_valve.OPEN()

cell_bypass_valve.ON()

update_valve_states()

time.sleep(16.75)

bead_bypass_valve.ON()

update_valve_states()

time.sleep(2.25)

set_flush_pressures(2000.0,2000.0,1000.0)

bead_bypass_valve.OFF()

cell_bypass_valve.OFF()

oil_bypass_valve.OFF()

update_valve_states()

#Controlling the Rocket engine for Soft landing

time.sleep(20.0)

set_flush_pressures(2.5*storedCellPress,0.0,storedOilPress)

bead_bypass_valve.ON()

cell_bypass_valve.OFF()

update_valve_states()

time.sleep(2.0)

set_flush_pressures(0.0,0.0,2000.00)

time.sleep(6.0)

set_stirrer_speed(0)

bead_bypass_valve.ON()

cell_bypass_valve.ON()

oil_bypass_valve.ON()

bead_lysis_buffer_flush_valve.OPEN()

cell_media_flush_valve.OPEN()

update_valve_states()

stop_flushing_all_channels()

time.sleep(7.5)

for i in range(0,3):

set_flush_pressures(2000.0,2000.0,0.0)

time.sleep(2.5)

stop_flushing_all_channels()

time.sleep(2.5)

set_flush_pressures(2000.0,2000.0,0.0)

time.sleep(2.5)

stop_flushing_all_channels()

bad_collection_tube.goToCoordinates()

bead_bypass_valve.OFF()

bead_lysis_buffer_flush_valve.CLOSE()

update_valve_states()

time.sleep(5.0)

bead_lysis_buffer_flush_valve.OPEN()

cell_bypass_valve.ON()

bead_bypass_valve.OFF()

oil_bypass_valve.ON()

update_valve_states()

set_flush_pressures(2.5*storedCellPress,storedBeadPress,storedOilPress) #Empirically Determined. Can be obtained before each run as part of a "Calibration run"

time.sleep(1.0)

oil_bypass_valve.OFF()

update_valve_states()

time.sleep(1.0)

cell_bypass_valve.OFF()

update_valve_states()

set_flush_pressures(2.5*storedCellPress,storedBeadPress,storedOilPress) #Leave it like this, I don't think it can get much better than this

time.sleep(3.0)

set_flush_pressures(storedCellPress,storedBeadPress,storedOilPress)

print(get_cell_channel_density())

print(get_oil_channel_density())

time.sleep(5.0)

cellPress,beadPress,oilPress=get_latest_pressure_measurements()

pidforOilChannel.restart_flow(oil_val,1.0,oilPress)

pidforCellChannel.restart_flow(cell_val,1.0,cellPress)

pidforBeadChannel.restart_flow(bead_val,0.3,beadPress)

#Add another 7-8 seconds.

time.sleep(18.0) #Empirically determine this to get the best time for when the droplets start emerging from the tubing.

good_collection_tube.goToCoordinatesFast()

time.sleep(45.0)

#Cleaning out any cells trapped in the Cell Channel

#before flushing again this should reduce cellular debris getting to the chip

oil_bypass_valve.OFF()

cell_bypass_valve.OFF()

bead_bypass_valve.ON()

update_valve_states()

set_flush_pressures(0.0,0.0,2000.0) #Oil starts emerging about 9-10 seconds from here.

#This oil is harmless so no problems collecting it I think.

time.sleep(5.0)

cell_bypass_valve.ON()

update_valve_states()

set_flush_pressures(0.0,0.0,1000.0)

time.sleep(8.0)

stop_flushing_all_channels()

time.sleep(2.0)

waste_tube.goToCoordinates()

time.sleep(2.0)

bead_bypass_valve.ON()

cell_bypass_valve.ON()

oil_bypass_valve.ON()

update_valve_states()

#Cleaning out any remaining Cells or Beads stuck in the tubing.

set_flush_pressures(2000.0,2000.0,0.0)

time.sleep(20.0)

#Cleaning out remaining Cells and Beads through the Chip and injection loops/tubing.

cell_media_flush_valve.OPEN()

cell_bypass_valve.OFF()

oil_bypass_valve.OFF()

bead_bypass_valve.OFF()

update_valve_states()

set_flush_pressures(2000.0,2000.0,1000.0)

time.sleep(20.0)

oil_bypass_valve.ON()

update_valve_states()

stop_flushing_all_channels()

time.sleep(1.5)

#Cleaning the tubing going into the chip through the bypass valves

for i in range(0,5):

set_flush_pressures(2000.0,2000.0,0.0)

time.sleep(18.5)

stop_flushing_all_channels()

time.sleep(1.5)

#Latest 9/27/22

def get_sample_from_multiple_cell_tubes_ficoll(time_and_cell_tuple):

time_point_number,cell_sample_flush_valve_number=time_and_cell_tuple

print("Time point is : "+str(time_point_number))

print("Cell Sample valve number is: "+str(cell_sample_flush_valve_number))

cell_sample_flush_valve=cell_sample_flush_valve1

if(cell_sample_flush_valve_number is 2):

cell_sample_flush_valve=cell_sample_flush_valve2

if(cell_sample_flush_valve_number is 3):

cell_sample_flush_valve=cell_sample_flush_valve3

global total_waste_collections

total_waste_collections+=1

waste_tube=waste_tube1

if total_waste_collections>8:

waste_tube=waste_tube2

time_point=time_point_valve.all_time_point_valves[time_point_number]

bead_tube=robot_action.all_time_points[time_point_number]

robot_action.enableRobot()

waste_tube.goToCoordinates()

bad_collection_tube.goToCoordinatesKeepTubeUp()

setNewPIDKis(1.0,1.0,1.0)

oil_val=200.0

bead_val=55.0

cell_val=55.0

global record_data

global store_chip_values

store_chip_values=True

record_data=True

storedCellPress,storedBeadPress,storedOilPress=get_chip_stored_pressure_calibration_values(False)

print("Testing Chip:")

set_bead_channel_scaling_factor(scalingFactor55ulFicoll)

#outlet_bypass_valve.ON()

oil_bypass_valve.ON()

cell_bypass_valve.ON()

cell_media_flush_valve.OPEN()

bead_lysis_buffer_flush_valve.OPEN()

bead_bypass_valve.ON()

update_valve_states()

print(get_cell_channel_density())

print(get_oil_channel_density())

time.sleep(2.5)

set_flush_pressures(2000.0,2000.0,1000.0)

time.sleep(12.5)

print(get_cell_channel_density())

print(get_oil_channel_density())

cell_bypass_valve.OFF()

cell_media_flush_valve.OPEN()

bead_bypass_valve.OFF()

bead_lysis_buffer_flush_valve.OPEN()

oil_bypass_valve.OFF()

update_valve_states()

#Mini-Priming to make chip change successfully

set_flush_pressures(2000.0,2000.0,1000.0)

time.sleep(10.0)

set_flush_pressures(storedCellPress,0.0,storedOilPress)

bead_bypass_valve.ON()

cell_bypass_valve.OFF()

update_valve_states()

time.sleep(2.0)

set_flush_pressures(0.0,0.0,2000.00)

time.sleep(4.0)

oil_bypass_valve.ON()

cell_bypass_valve.ON()

bead_bypass_valve.ON()

bead_lysis_buffer_flush_valve.CLOSE()

update_valve_states()

stop_flushing_all_channels()

time.sleep(2.5)

bead_lysis_buffer_flush_valve.OPEN()

update_valve_states()

set_flush_pressures(0.0,2000.0,0.0)

time.sleep(2.5)

bead_lysis_buffer_flush_valve.CLOSE()

update_valve_states()

stop_flushing_all_channels()

time.sleep(2.5)

bead_lysis_buffer_flush_valve.OPEN()

cell_bypass_valve.ON()

bead_bypass_valve.OFF()

oil_bypass_valve.ON()

update_valve_states()

bead_tube.goToCoordinates()

set_flush_pressures(storedCellPress,storedBeadPress,storedOilPress)

time.sleep(1.0)

oil_bypass_valve.OFF()

update_valve_states()

time.sleep(1.0)

cell_bypass_valve.OFF()

update_valve_states()

set_flush_pressures(storedCellPress,storedBeadPress,storedOilPress)

time.sleep(3.0)

set_flush_pressures(storedCellPress,storedBeadPress,storedOilPress)

print(get_cell_channel_density())

print(get_oil_channel_density())

time.sleep(5.0)

#Start stirring things up

set_stirrer_speed(100)

cellPress,beadPress,oilPress=get_latest_pressure_measurements()

pidforOilChannel.restart_flow(oil_val,1.0,oilPress)

pidforCellChannel.restart_flow(cell_val,1.0,cellPress)

pidforBeadChannel.restart_flow(bead_val,1.0,beadPress)

time.sleep(11.0)

print(get_cell_channel_density())

print(get_oil_channel_density())

cell_bypass_valve.OFF()

cell_media_flush_valve.OPEN()

bead_bypass_valve.OFF()

bead_lysis_buffer_flush_valve.OPEN()

oil_bypass_valve.ON()

update_valve_states()

set_flush_pressures(2000.0,2000.0,0.0)

time.sleep(5.0)

if time_point_number<9:

start_bead_vortex() #Use only with 1ml of beads. Anything else is not suspended properly

else:

start_bead_vortex2()

cell_media_flush_valve.CLOSE()

cell_sample_flush_valve.OPEN()

cell_bypass_valve.ON()

update_valve_states()

time.sleep(16.75)

time_point.OPEN()

bead_lysis_buffer_flush_valve.CLOSE()

bead_bypass_valve.ON()

update_valve_states()

time.sleep(7.0) #Doubled this time.

set_flush_pressures(2000.0,2000.0,1000.0)

bead_bypass_valve.OFF()

cell_bypass_valve.OFF()

oil_bypass_valve.OFF()

update_valve_states()

#Controlling the Rocket engine for Soft landing

time.sleep(35.0)#Increased this

set_flush_pressures(storedCellPress,0.0,storedOilPress)

bead_bypass_valve.ON()

cell_bypass_valve.OFF()

update_valve_states()

time.sleep(2.0)

set_flush_pressures(0.0,0.0,2000.00)

time.sleep(4.0)

#Let it keep stirring not much harm here.

#set_stirrer_speed(0)

if time_point_number<9:

stop_bead_vortex() #Use only with 1ml of beads. Anything else is not suspended properly

else:

stop_bead_vortex2()

bead_bypass_valve.ON()

cell_bypass_valve.ON()

oil_bypass_valve.ON()

time_point.CLOSE()

cell_sample_flush_valve.CLOSE()

bead_lysis_buffer_flush_valve.OPEN()

cell_media_flush_valve.OPEN()

update_valve_states()

stop_flushing_all_channels()

time.sleep(5.0)

bead_bypass_valve.OFF()

update_valve_states()

#bead_tube.goToCoordinates()

time.sleep(2.5)

bead_bypass_valve.ON()

update_valve_states()

set_flush_pressures(2000.0,2000.0,0.0)

time.sleep(7.5)

set_flush_pressures(storedCellPress,1.5*storedBeadPress,storedOilPress)

bead_bypass_valve.ON()

cell_bypass_valve.ON()

oil_bypass_valve.ON()

update_valve_states()

time.sleep(15.0)

#set_flush_pressures(2000.0,2000.0,0.0)

#time.sleep(2.5)

#stop_flushing_all_channels()

#bad_collection_tube.goToCoordinatesKeepTubeUp()

#bad_collection_tube.goToCoordinates()

#bead_bypass_valve.OFF()

#bead_lysis_buffer_flush_valve.OPEN()

#update_valve_states()

#bead_lysis_buffer_flush_valve.OPEN()

cell_bypass_valve.ON()

bead_bypass_valve.OFF()

oil_bypass_valve.ON()

update_valve_states()#Droplets start emerging 22 seconds from here. Approox. To this add some additional stabilization time. In this case 13-14 seconds.

set_flush_pressures(storedCellPress,1.5*storedBeadPress,storedOilPress) #Empirically Determined. Can be obtained before each run as part of a "Calibration run"

time.sleep(1.0)

oil_bypass_valve.OFF()

update_valve_states()

time.sleep(1.0)

cell_bypass_valve.OFF()

update_valve_states()

set_flush_pressures(storedCellPress,storedBeadPress,storedOilPress) #Leave it like this, I don't think it can get much better than this

time.sleep(3.0)

set_flush_pressures(storedCellPress,storedBeadPress,storedOilPress)

print(get_cell_channel_density())

print(get_oil_channel_density())

time.sleep(5.0)

cellPress,beadPress,oilPress=get_latest_pressure_measurements()

pidforOilChannel.restart_flow(oil_val,1.0,oilPress)

pidforCellChannel.restart_flow(cell_val,1.0,cellPress)

pidforBeadChannel.restart_flow(bead_val,1.0,beadPress)

time.sleep(24.0) #Empirically determine this to get the best time for when the droplets start emerging from the tubing.

good_collection_tube.goToCoordinatesSlowly()

#good_collection_tube.goToCoordinates()

time.sleep(50.0)

#Cleaning out any cells trapped in the Cell Channel

#before flushing again this should reduce cellular debris getting to the chip

oil_bypass_valve.OFF()

cell_bypass_valve.OFF()

bead_bypass_valve.ON()

update_valve_states()

set_flush_pressures(0.0,0.0,2000.0) #Oil starts emerging about 9-10 seconds from here.

#This oil is harmless so no problems collecting it I think.

time.sleep(5.0)

cell_bypass_valve.ON()

update_valve_states()

set_flush_pressures(0.0,0.0,1000.0)

time.sleep(12.0)#Increasing this for now. More oil should help flow more beads down where they belong.

stop_flushing_all_channels()

time.sleep(2.0)

bad_collection_tube.goToCoordinates()

time.sleep(2.0)

bead_bypass_valve.ON()

cell_bypass_valve.ON()

oil_bypass_valve.ON()

update_valve_states()

#Cleaning out any remaining Cells or Beads stuck in the tubing.

set_flush_pressures(2000.0,2000.0,0.0)

time.sleep(20.0)

#Cleaning out remaining Cells and Beads through the Chip and injection loops/tubing.

cell_media_flush_valve.OPEN()

cell_bypass_valve.OFF()

oil_bypass_valve.OFF()

bead_bypass_valve.OFF()

update_valve_states()

set_flush_pressures(2000.0,2000.0,1000.0)

time.sleep(20.0)

oil_bypass_valve.ON()

update_valve_states()

stop_flushing_all_channels()

time.sleep(1.5)

#Cleaning the tubing going into the chip through the bypass valves

for i in range(0,5):

set_flush_pressures(2000.0,2000.0,0.0)

time.sleep(18.5)

stop_flushing_all_channels()

time.sleep(1.5)

def get_sample_cells_only(time_and_cell_tuple):

time_point_number,cell_sample_flush_valve_number=time_and_cell_tuple

print("Time point is : "+str(time_point_number))

print("Cell Sample valve number is: "+str(cell_sample_flush_valve_number))

cell_sample_flush_valve=cell_sample_flush_valve1

if(cell_sample_flush_valve_number is 2):

cell_sample_flush_valve=cell_sample_flush_valve2

if(cell_sample_flush_valve_number is 3):

cell_sample_flush_valve=cell_sample_flush_valve3

global total_waste_collections

total_waste_collections+=1

waste_tube=waste_tube1

if total_waste_collections>8:

waste_tube=waste_tube1

time_point=time_point_valve.all_time_point_valves[time_point_number]

bead_tube=robot_action.all_time_points[time_point_number]

robot_action.enableRobot()

waste_tube.goToCoordinates()

good_collection_tube.goToCoordinates()

print(get_cell_channel_density())

global record_data

record_data=True

set_bead_channel_scaling_factor(scalingFactor55ulFicoll)

set_stirrer_speed(100)

time.sleep(3.0)

cell_bypass_valve.OFF()

cell_media_flush_valve.OPEN()

update_valve_states()

set_flush_pressures(2000.0,0.0,0.0)

time.sleep(15.0)

cell_media_flush_valve.CLOSE()

cell_sample_flush_valve.OPEN()

update_valve_states()

time.sleep(20.0)

cell_bypass_valve.ON()

update_valve_states()

bead_tube.goToCoordinates()

#stop_flushing_all_channels()

time.sleep(5.0)

set_flush_pressures(2000.0,0.0,0.0)

cell_bypass_valve.OFF()

cell_sample_flush_valve.OPEN()

update_valve_states()

print(get_cell_channel_density())

time.sleep(5.0)

cell_bypass_valve.ON()

cell_sample_flush_valve.CLOSE()

cell_media_flush_valve.OPEN()

update_valve_states()

waste_tube.goToCoordinates()

time.sleep(5.0)

cell_bypass_valve.OFF()

update_valve_states()

time.sleep(10.0)

def get_sample_from_multiple_cell_tubes(time_and_cell_tuple):

time_point_number,cell_sample_flush_valve_number=time_and_cell_tuple

print("Time point is : "+str(time_point_number))

print("Cell Sample valve number is: "+str(cell_sample_flush_valve_number))

cell_sample_flush_valve=cell_sample_flush_valve1

if(cell_sample_flush_valve_number is 2):

cell_sample_flush_valve=cell_sample_flush_valve2

if(cell_sample_flush_valve_number is 3):

cell_sample_flush_valve=cell_sample_flush_valve3

global total_waste_collections

total_waste_collections+=1

waste_tube=waste_tube1

if total_waste_collections>8:

waste_tube=waste_tube2

time_point=time_point_valve.all_time_point_valves[time_point_number]

bead_tube=robot_action.all_time_points[time_point_number]

robot_action.enableRobot()

waste_tube.goToCoordinates()

setNewPIDKis(1.0,1.0,1.0)

oil_val=200.0

bead_val=55.0

cell_val=55.0

global record_data

global store_chip_values

store_chip_values=True

record_data=True

storedCellPress,storedBeadPress,storedOilPress=get_chip_stored_pressure_calibration_values(False)

print("Testing Chip:")

set_bead_channel_scaling_factor(scalingFactor60ul)

#outlet_bypass_valve.ON()

oil_bypass_valve.ON()

cell_bypass_valve.ON()

cell_media_flush_valve.OPEN()

bead_lysis_buffer_flush_valve.OPEN()

bead_bypass_valve.ON()

update_valve_states()

print(get_cell_channel_density())

print(get_oil_channel_density())

time.sleep(2.5)

for i in range(0,4):

set_flush_pressures(2000.0,2000.0,1000.0)

time.sleep(2.5)

stop_flushing_all_channels()

time.sleep(2.5)

print(get_cell_channel_density())

print(get_oil_channel_density())

cell_bypass_valve.OFF()

cell_media_flush_valve.OPEN()

bead_bypass_valve.OFF()

bead_lysis_buffer_flush_valve.OPEN()

oil_bypass_valve.OFF()

update_valve_states()

#Mini-Priming to make chip change successfully

set_flush_pressures(2000.0,2000.0,1000.0)

time.sleep(10.0)

set_flush_pressures(storedCellPress,0.0,storedOilPress)

bead_bypass_valve.ON()

cell_bypass_valve.OFF()

update_valve_states()

time.sleep(2.0)

set_flush_pressures(0.0,0.0,2000.00)

time.sleep(4.0)

oil_bypass_valve.ON()

cell_bypass_valve.ON()

bead_bypass_valve.ON()

bead_lysis_buffer_flush_valve.CLOSE()

update_valve_states()

stop_flushing_all_channels()

time.sleep(2.5)

bead_lysis_buffer_flush_valve.OPEN()

update_valve_states()

set_flush_pressures(0.0,2000.0,0.0)

time.sleep(2.5)

bead_lysis_buffer_flush_valve.CLOSE()

update_valve_states()

stop_flushing_all_channels()

time.sleep(2.5)

bead_lysis_buffer_flush_valve.OPEN()

cell_bypass_valve.ON()

bead_bypass_valve.OFF()

oil_bypass_valve.ON()

update_valve_states()

set_flush_pressures(storedCellPress,storedBeadPress,storedOilPress)

time.sleep(1.0)

oil_bypass_valve.OFF()

update_valve_states()

time.sleep(1.0)

cell_bypass_valve.OFF()

update_valve_states()

set_flush_pressures(storedCellPress,storedBeadPress,storedOilPress)

time.sleep(3.0)

set_flush_pressures(storedCellPress,storedBeadPress,storedOilPress)

print(get_cell_channel_density())

print(get_oil_channel_density())

time.sleep(5.0)

#Start stirring things up

set_stirrer_speed(300)

if time_point_number<9:

start_bead_vortex() #Use only with 1ml of beads. Anything else is not suspended properly

else:

start_bead_vortex2()

cellPress,beadPress,oilPress=get_latest_pressure_measurements()

pidforOilChannel.restart_flow(oil_val,1.0,oilPress)

pidforCellChannel.restart_flow(cell_val,1.0,cellPress)

pidforBeadChannel.restart_flow(bead_val,1.0,beadPress)

time.sleep(11.0)

print(get_cell_channel_density())

print(get_oil_channel_density())

cell_bypass_valve.OFF()

cell_media_flush_valve.OPEN()

bead_bypass_valve.OFF()

bead_lysis_buffer_flush_valve.OPEN()

oil_bypass_valve.ON()

update_valve_states()

set_flush_pressures(2000.0,2000.0,0.0)

time.sleep(5.0)

cell_media_flush_valve.CLOSE()

cell_sample_flush_valve.OPEN()

cell_bypass_valve.ON()

update_valve_states()

time.sleep(16.75)

time_point.OPEN()

bead_lysis_buffer_flush_valve.CLOSE()

bead_bypass_valve.ON()

update_valve_states()

time.sleep(2.25)

set_flush_pressures(2000.0,2000.0,1000.0)

bead_bypass_valve.OFF()

cell_bypass_valve.OFF()

oil_bypass_valve.OFF()

update_valve_states()

#Controlling the Rocket engine for Soft landing

time.sleep(20.0)

set_flush_pressures(storedCellPress,0.0,storedOilPress)

bead_bypass_valve.ON()

cell_bypass_valve.OFF()

update_valve_states()

time.sleep(2.0)

set_flush_pressures(0.0,0.0,2000.00)

time.sleep(4.0)

set_stirrer_speed(0)

if time_point_number<9:

stop_bead_vortex() #Use only with 1ml of beads. Anything else is not suspended properly

else:

stop_bead_vortex2()

bead_bypass_valve.ON()

cell_bypass_valve.ON()

oil_bypass_valve.ON()

time_point.CLOSE()

cell_sample_flush_valve.CLOSE()

bead_lysis_buffer_flush_valve.OPEN()

cell_media_flush_valve.OPEN()

update_valve_states()

stop_flushing_all_channels()

time.sleep(5.0)

bead_bypass_valve.OFF()

update_valve_states()

bead_tube.goToCoordinates()

time.sleep(2.5)

bead_bypass_valve.ON()

update_valve_states()

for i in range(0,3):

set_flush_pressures(2000.0,2000.0,0.0)

time.sleep(2.5)

stop_flushing_all_channels()

time.sleep(2.5)

set_flush_pressures(2000.0,2000.0,0.0)

time.sleep(2.5)

stop_flushing_all_channels()

bad_collection_tube.goToCoordinatesKeepTubeUp()

#bad_collection_tube.goToCoordinates()

bead_bypass_valve.OFF()

bead_lysis_buffer_flush_valve.CLOSE()

update_valve_states()

time.sleep(5.0)

bead_lysis_buffer_flush_valve.OPEN()

cell_bypass_valve.ON()

bead_bypass_valve.OFF()

oil_bypass_valve.ON()

update_valve_states()#Droplets start emerging 22 seconds from here. Approox. To this add some additional stabilization time. In this case 13-14 seconds.

set_flush_pressures(storedCellPress,storedBeadPress,storedOilPress) #Empirically Determined. Can be obtained before each run as part of a "Calibration run"

time.sleep(1.0)

oil_bypass_valve.OFF()

update_valve_states()

time.sleep(1.0)

cell_bypass_valve.OFF()

update_valve_states()

set_flush_pressures(storedCellPress,storedBeadPress,storedOilPress) #Leave it like this, I don't think it can get much better than this

time.sleep(3.0)

set_flush_pressures(storedCellPress,storedBeadPress,storedOilPress)

print(get_cell_channel_density())

print(get_oil_channel_density())

time.sleep(5.0)

cellPress,beadPress,oilPress=get_latest_pressure_measurements()

pidforOilChannel.restart_flow(oil_val,1.0,oilPress)

pidforCellChannel.restart_flow(cell_val,1.0,cellPress)

pidforBeadChannel.restart_flow(bead_val,1.0,beadPress)

time.sleep(24.0) #Empirically determine this to get the best time for when the droplets start emerging from the tubing.

good_collection_tube.goToCoordinatesSmoothly()

#good_collection_tube.goToCoordinates()

time.sleep(50.0)

#Cleaning out any cells trapped in the Cell Channel

#before flushing again this should reduce cellular debris getting to the chip

oil_bypass_valve.OFF()

cell_bypass_valve.OFF()

bead_bypass_valve.ON()

update_valve_states()

set_flush_pressures(0.0,0.0,2000.0) #Oil starts emerging about 9-10 seconds from here.

#This oil is harmless so no problems collecting it I think.

time.sleep(5.0)

cell_bypass_valve.ON()

update_valve_states()

set_flush_pressures(0.0,0.0,1000.0)

time.sleep(12.0)#Increasing this for now. More oil should help flow more beads down where they belong.

stop_flushing_all_channels()

time.sleep(2.0)

waste_tube.goToCoordinates()

time.sleep(2.0)

bead_bypass_valve.ON()

cell_bypass_valve.ON()

oil_bypass_valve.ON()

update_valve_states()

#Cleaning out any remaining Cells or Beads stuck in the tubing.

set_flush_pressures(2000.0,2000.0,0.0)

time.sleep(20.0)

#Cleaning out remaining Cells and Beads through the Chip and injection loops/tubing.

cell_media_flush_valve.OPEN()

cell_bypass_valve.OFF()

oil_bypass_valve.OFF()

bead_bypass_valve.OFF()

update_valve_states()

set_flush_pressures(2000.0,2000.0,1000.0)

time.sleep(20.0)

oil_bypass_valve.ON()

update_valve_states()

stop_flushing_all_channels()

time.sleep(1.5)

#Cleaning the tubing going into the chip through the bypass valves

for i in range(0,5):

set_flush_pressures(2000.0,2000.0,0.0)

time.sleep(18.5)

stop_flushing_all_channels()

time.sleep(1.5)

def get_sample(time_point_number):

global total_waste_collections

total_waste_collections+=1

waste_tube=waste_tube1

if total_waste_collections>8:

waste_tube=waste_tube2

time_point=time_point_valve.all_time_point_valves[time_point_number]

bead_tube=robot_action.all_time_points[time_point_number]

robot_action.enableRobot()

waste_tube.goToCoordinates()

setNewPIDKis(1.0,1.0,1.0)

oil_val=200.0

bead_val=55.0

cell_val=15.0

global record_data

global store_chip_values

store_chip_values=True

record_data=True

storedCellPress,storedBeadPress,storedOilPress=get_chip_stored_pressure_calibration_values(False)

print("Testing Chip:")

set_bead_channel_scaling_factor(scalingFactor55ulFicoll)

#outlet_bypass_valve.ON()

oil_bypass_valve.ON()

cell_bypass_valve.ON()

cell_media_flush_valve.OPEN()

bead_lysis_buffer_flush_valve.OPEN()

bead_bypass_valve.ON()

update_valve_states()

print(get_cell_channel_density())

print(get_oil_channel_density())

time.sleep(2.5)

for i in range(0,4):

set_flush_pressures(2000.0,2000.0,1000.0)

time.sleep(2.5)

stop_flushing_all_channels()

time.sleep(2.5)

set_flush_pressures(2000.0,2000.0,0.0)

print(get_cell_channel_density())

print(get_oil_channel_density())

if time_point_number<9:

start_bead_vortex() #Use only with 1ml of beads. Anything else is not suspended properly

else:

start_bead_vortex2()

set_stirrer_speed(300)

cell_bypass_valve.OFF()

cell_media_flush_valve.OPEN()

bead_bypass_valve.OFF()

bead_lysis_buffer_flush_valve.OPEN()

update_valve_states()

set_flush_pressures(2000.0,2000.0,0.0)

time.sleep(10.0)

cell_media_flush_valve.CLOSE()

cell_sample_flush_valve1.OPEN()

cell_bypass_valve.ON()

update_valve_states()

time.sleep(16.75)

time_point.OPEN()

bead_lysis_buffer_flush_valve.CLOSE()

bead_bypass_valve.ON()

update_valve_states()

time.sleep(2.25)

bead_bypass_valve.OFF()

cell_bypass_valve.OFF()

update_valve_states()

#Controlling the Rocket engine for Soft landing

time.sleep(18.0) #-2 seconds here

set_flush_pressures(2000.0,2000.0,storedOilPress)

oil_bypass_valve.OFF()

update_valve_states()

time.sleep(2.00) #Add 2 seconds here.

set_flush_pressures(2.5*storedCellPress,0.0,storedOilPress)

bead_bypass_valve.ON()

cell_bypass_valve.OFF()

update_valve_states()

time.sleep(2.0)

set_flush_pressures(0.0,0.0,2000.00)

time.sleep(6.0)

set_stirrer_speed(0)

if time_point_number<9:

stop_bead_vortex() #Use only with 1ml of beads. Anything else is not suspended properly

else:

stop_bead_vortex2()

bead_bypass_valve.ON()

cell_bypass_valve.ON()

oil_bypass_valve.ON()

time_point.CLOSE()

cell_sample_flush_valve1.CLOSE()

bead_lysis_buffer_flush_valve.OPEN()

cell_media_flush_valve.OPEN()

update_valve_states()

stop_flushing_all_channels()

time.sleep(2.5)

bead_tube.goToCoordinates()

time.sleep(2.5)

for i in range(0,3):

set_flush_pressures(2000.0,2000.0,200.0)

time.sleep(2.5)

stop_flushing_all_channels()

time.sleep(2.5)

set_flush_pressures(2000.0,2000.0,200.0)

time.sleep(2.5)

stop_flushing_all_channels()

bad_collection_tube.goToCoordinates()

time.sleep(2.5)

#Droplets start emerging 27 seconds after this

#This will make the oil flow stable before we turn the bead channel and the outlet valve ON

bead_lysis_buffer_flush_valve.CLOSE()

cell_bypass_valve.OFF()

bead_bypass_valve.ON()

oil_bypass_valve.OFF()

#outlet_bypass_valve.OFF()

update_valve_states()

set_flush_pressures(2.5*storedCellPress,storedBeadPress,storedOilPress) #Empirically Determined. Can be obtained before each run as part of a "Calibration run"

print(get_cell_channel_density())

print(get_oil_channel_density())

time.sleep(10.0) #Keep this 10 to minimize cell loss.

bead_bypass_valve.OFF()

bead_lysis_buffer_flush_valve.OPEN()#Takes 19 seconds for droplets to emerge from here.

update_valve_states()

set_flush_pressures(storedCellPress,storedBeadPress,storedOilPress) #Leave it like this, I don't think it can get much better than this

time.sleep(5.0)

cellPress,beadPress,oilPress=get_latest_pressure_measurements()

pidforOilChannel.restart_flow(oil_val,1.0,oilPress)

pidforCellChannel.restart_flow(cell_val,1.0,cellPress)

pidforBeadChannel.restart_flow(bead_val,0.3,beadPress)

#Add another 10 seconds to this to make sure you don't capture those shitty droplets.

time.sleep(23.0) #Empirically determine this to get the best time for when the droplets start emerging from the tubing.

good_collection_tube.goToCoordinatesFast()

time.sleep(40.0)

#outlet_bypass_valve.ON()

oil_bypass_valve.ON()

cell_bypass_valve.ON()

cell_media_flush_valve.CLOSE()#Venting inside the schedule duration

cell_sample_flush_valve1.CLOSE()

cell_gas_vent_valve.OPEN()

update_valve_states()

set_flush_pressures(200.0,600.0,0.0)

#At this flow rate it takes 25 seconds for water to emerge after droplets. I think this is perfect

time.sleep(15.0)#Empirically determine this to find the best time for when all the droplets have been collected.

stop_flushing_all_channels()

time.sleep(2.0)

waste_tube.goToCoordinates()

time.sleep(2.0)

cell_media_flush_valve.OPEN()#Stop Venting

cell_sample_flush_valve1.CLOSE()

cell_gas_vent_valve.CLOSE()

cell_bypass_valve.OFF()

update_valve_states()

set_flush_pressures(2000.0,2000.0,0.0)

time.sleep(12.0)

stop_flushing_all_channels()

time.sleep(1.5)

#Cleaning the tubing going into the chip through the bypass valves

for i in range(0,6):

set_flush_pressures(2000.0,2000.0,0.0)

time.sleep(18.5)

stop_flushing_all_channels()

time.sleep(1.5)

bead_bypass_valve.ON()

cell_bypass_valve.ON()

update_valve_states()

#Cleaning out any remaining Cells or Beads stuck in the tubing.

for i in range(0,4):

set_flush_pressures(2000.0,2000.0,0.0)

time.sleep(2.5)

stop_flushing_all_channels()

time.sleep(2.5)

def bead_injection_optimization_run(time_point_number):

global total_waste_collections

total_waste_collections+=1

waste_tube=waste_tube1

if total_waste_collections>8:

waste_tube=waste_tube2

time_point=time_point_valve.all_time_point_valves[time_point_number]

bead_tube=robot_action.all_time_points[time_point_number]

robot_action.enableRobot()

waste_tube.goToCoordinates()

setNewPIDKis(1.0,1.0,1.0)

oil_val=0.0

bead_val=55.0

cell_val=0.0

global record_data

global store_chip_values

store_chip_values=True

record_data=True

storedCellPress,storedBeadPress,storedOilPress=get_chip_stored_pressure_calibration_values(False)

print("Testing Chip:")

set_bead_channel_scaling_factor(scalingFactor60ul)

#outlet_bypass_valve.ON()

oil_bypass_valve.ON()

cell_bypass_valve.ON()

cell_media_flush_valve.OPEN()

bead_lysis_buffer_flush_valve.OPEN()

bead_bypass_valve.ON()

update_valve_states()

print(get_cell_channel_density())

print(get_oil_channel_density())

time.sleep(2.5)

for i in range(0,4):

set_flush_pressures(0.0,2000.0,0.0)

time.sleep(2.5)

stop_flushing_all_channels()

time.sleep(2.5)

set_flush_pressures(0.0,2000.0,0.0)

print(get_cell_channel_density())

print(get_oil_channel_density())

if time_point_number<9:

start_bead_vortex() #Use only with 1ml of beads. Anything else is not suspended properly

else:

start_bead_vortex2()

set_stirrer_speed(300)

cell_bypass_valve.ON()

cell_media_flush_valve.CLOSE()

bead_bypass_valve.OFF()

bead_lysis_buffer_flush_valve.OPEN()

update_valve_states()

set_flush_pressures(0.0,2000.0,0.0)

time.sleep(10.0)

cell_media_flush_valve.CLOSE()

cell_sample_flush_valve1.CLOSE()

cell_bypass_valve.ON()

update_valve_states()

time.sleep(16.75)

time_point.OPEN()

bead_lysis_buffer_flush_valve.CLOSE()

bead_bypass_valve.ON()

update_valve_states()

time.sleep(2.25)

bead_bypass_valve.OFF()

cell_bypass_valve.ON()

update_valve_states()

time.sleep(20.00)

set_stirrer_speed(0)

if time_point_number<9:

stop_bead_vortex() #Use only with 1ml of beads. Anything else is not suspended properly

else:

stop_bead_vortex2()

bead_bypass_valve.ON()

cell_bypass_valve.ON()

time_point.CLOSE()

cell_sample_flush_valve1.CLOSE()

bead_lysis_buffer_flush_valve.OPEN()

cell_media_flush_valve.CLOSE()

update_valve_states()

stop_flushing_all_channels()

time.sleep(5.0)

bead_tube.goToCoordinates()

time.sleep(2.5)

for i in range(0,3):

set_flush_pressures(0.0,2000.0,0.0)

time.sleep(2.5)

stop_flushing_all_channels()

time.sleep(2.5)

set_flush_pressures(0.0,2000.0,0.0)

time.sleep(2.5)

stop_flushing_all_channels()

bad_collection_tube.goToCoordinates()

time.sleep(2.5)

#Droplets start emerging 27 seconds after this

#This will make the oil flow stable before we turn the bead channel and the outlet valve ON

bead_lysis_buffer_flush_valve.CLOSE()

cell_bypass_valve.ON()

bead_bypass_valve.ON()

oil_bypass_valve.ON()

#outlet_bypass_valve.OFF()

update_valve_states()

set_flush_pressures(0.0,27.5,0.0) #Empirically Determined. Can be obtained before each run as part of a "Calibration run"

print(get_cell_channel_density())

print(get_oil_channel_density())

time.sleep(10.0) #Keep this 10 to minimize cell loss.

bead_bypass_valve.OFF()

bead_lysis_buffer_flush_valve.OPEN()#Takes 19 seconds for droplets to emerge from here.

update_valve_states()

set_flush_pressures(0,27.5,0) #Leave it like this, I don't think it can get much better than this

time.sleep(5.0)

cellPress,beadPress,oilPress=get_latest_pressure_measurements()

#pidforOilChannel.restart_flow(oil_val,1.0,oilPress)

#pidforCellChannel.restart_flow(cell_val,1.0,cellPress)

pidforBeadChannel.restart_flow(bead_val,0.1,beadPress)

#Add another 10 seconds to this to make sure you don't capture those shitty droplets.

time.sleep(25.0) #Empirically determine this to get the best time for when the droplets start emerging from the tubing.

good_collection_tube.goToCoordinatesFast()

time.sleep(35.0)

#outlet_bypass_valve.ON()

oil_bypass_valve.ON()

cell_bypass_valve.ON()

cell_media_flush_valve.CLOSE()#Venting inside the schedule duration

cell_sample_flush_valve1.CLOSE()

cell_gas_vent_valve.OPEN()

update_valve_states()

set_flush_pressures(0.0,0.0,0.0)

#At this flow rate it takes 25 seconds for water to emerge after droplets. I think this is perfect

time.sleep(20.0)#Empirically determine this to find the best time for when all the droplets have been collected.

stop_flushing_all_channels()

time.sleep(2.0)

waste_tube.goToCoordinates()

time.sleep(2.0)

cell_media_flush_valve.OPEN()#Stop Venting

cell_sample_flush_valve1.CLOSE()

cell_gas_vent_valve.CLOSE()

cell_bypass_valve.ON()

update_valve_states()

set_flush_pressures(0.0,2000.0,0.0)

time.sleep(12.0)

stop_flushing_all_channels()

time.sleep(1.5)

#Cleaning the tubing going into the chip through the bypass valves

for i in range(0,6):

set_flush_pressures(0.0,2000.0,0.0)

time.sleep(18.5)

stop_flushing_all_channels()

time.sleep(1.5)

bead_bypass_valve.ON()

cell_bypass_valve.ON()

update_valve_states()

#Cleaning out any remaining Cells or Beads stuck in the tubing.

for i in range(0,4):

set_flush_pressures(0.0,2000.0,0.0)

time.sleep(2.5)

stop_flushing_all_channels()

time.sleep(2.5)

def cell_injection_optimization_run(time_point_number):

global total_waste_collections

total_waste_collections+=1

waste_tube=waste_tube1

if total_waste_collections>8:

waste_tube=waste_tube2

time_point=time_point_valve.all_time_point_valves[time_point_number]

bead_tube=robot_action.all_time_points[time_point_number]

robot_action.enableRobot()

waste_tube.goToCoordinates()

setNewPIDKis(1.0,1.0,1.0)

oil_val=0.0

bead_val=0.0

cell_val=15.0

global record_data

global store_chip_values

store_chip_values=True

record_data=True

storedCellPress,storedBeadPress,storedOilPress=get_chip_stored_pressure_calibration_values(False)

print("Testing Chip:")

set_bead_channel_scaling_factor(scalingFactor60ul)

#outlet_bypass_valve.ON()

oil_bypass_valve.ON()

cell_bypass_valve.ON()

cell_media_flush_valve.OPEN()

bead_lysis_buffer_flush_valve.OPEN()

bead_bypass_valve.ON()

update_valve_states()

print(get_cell_channel_density())

print(get_oil_channel_density())

time.sleep(2.5)

for i in range(0,4):

set_flush_pressures(2000.0,0.0,0.0)

time.sleep(2.5)

stop_flushing_all_channels()

time.sleep(2.5)

set_flush_pressures(2000.0,0.0,0.0)

print(get_cell_channel_density())

print(get_oil_channel_density())

if time_point_number<9:

start_bead_vortex() #Use only with 1ml of beads. Anything else is not suspended properly

else:

start_bead_vortex2()

set_stirrer_speed(300)

cell_bypass_valve.OFF()

cell_media_flush_valve.OPEN()

bead_bypass_valve.ON()

bead_lysis_buffer_flush_valve.OPEN()

update_valve_states()

set_flush_pressures(2000.0,0.0,0.0)

time.sleep(10.0)

cell_media_flush_valve.CLOSE()

cell_sample_flush_valve1.OPEN()

cell_bypass_valve.ON()

update_valve_states()

time.sleep(16.75)

time_point.OPEN()

bead_lysis_buffer_flush_valve.CLOSE()

bead_bypass_valve.ON()

update_valve_states()

time.sleep(2.25)

bead_bypass_valve.ON()

cell_bypass_valve.OFF()

update_valve_states()

time.sleep(20.00)

set_stirrer_speed(0)

if time_point_number<9:

stop_bead_vortex() #Use only with 1ml of beads. Anything else is not suspended properly

else:

stop_bead_vortex2()

bead_bypass_valve.ON()

cell_bypass_valve.ON()

time_point.CLOSE()

cell_sample_flush_valve1.CLOSE()

bead_lysis_buffer_flush_valve.OPEN()

cell_media_flush_valve.OPEN()

update_valve_states()

stop_flushing_all_channels()

time.sleep(5.0)

bead_tube.goToCoordinates()

time.sleep(2.5)

for i in range(0,3):

set_flush_pressures(2000.0,0.0,0.0)

time.sleep(2.5)

stop_flushing_all_channels()

time.sleep(2.5)

set_flush_pressures(2000.0,0.0,0.0)

time.sleep(2.5)

stop_flushing_all_channels()

bad_collection_tube.goToCoordinates()

time.sleep(2.5)

#Droplets start emerging 27 seconds after this

#This will make the oil flow stable before we turn the bead channel and the outlet valve ON

bead_lysis_buffer_flush_valve.CLOSE()

cell_bypass_valve.OFF()

bead_bypass_valve.ON()

oil_bypass_valve.ON()

#outlet_bypass_valve.OFF()

update_valve_states()

set_flush_pressures(15.0,0.0,0.0) #Empirically Determined. Can be obtained before each run as part of a "Calibration run"

print(get_cell_channel_density())

print(get_oil_channel_density())

time.sleep(10.0) #Keep this 10 to minimize cell loss.

bead_bypass_valve.ON()

bead_lysis_buffer_flush_valve.OPEN()

update_valve_states()

set_flush_pressures(15.0,0.0,0.0)#Also empirically determined.

time.sleep(5.0)

cellPress,beadPress,oilPress=get_latest_pressure_measurements()

#pidforBeadChannel.restart_flow(bead_val,1.0,beadPress)

pidforCellChannel.restart_flow(cell_val,0.1,cellPress)

#pidforOilChannel.restart_flow(oil_val,1.0,oilPress)

#Add another 10 seconds to this to make sure you don't capture those shitty droplets.

time.sleep(25.0) #Empirically determine this to get the best time for when the droplets start emerging from the tubing.

good_collection_tube.goToCoordinatesFast()

time.sleep(35.0)

#outlet_bypass_valve.ON()

oil_bypass_valve.ON()

cell_bypass_valve.ON()

cell_media_flush_valve.CLOSE()#Venting inside the schedule duration

cell_sample_flush_valve1.CLOSE()

cell_gas_vent_valve.OPEN()

update_valve_states()

set_flush_pressures(200.0,0.0,0.0)

#At this flow rate it takes 25 seconds for water to emerge after droplets. I think this is perfect

time.sleep(22.0)#Empirically determine this to find the best time for when all the droplets have been collected.

stop_flushing_all_channels()

time.sleep(2.0)

waste_tube.goToCoordinates()

time.sleep(2.0)

cell_media_flush_valve.OPEN()#Stop Venting

cell_sample_flush_valve1.CLOSE()

cell_gas_vent_valve.CLOSE()

cell_bypass_valve.OFF()

update_valve_states()

set_flush_pressures(2000.0,0.0,0.0)

time.sleep(12.0)

stop_flushing_all_channels()

time.sleep(1.5)

#Cleaning the tubing going into the chip through the bypass valves

for i in range(0,6):

set_flush_pressures(2000.0,0.0,0.0)

time.sleep(18.5)

stop_flushing_all_channels()

time.sleep(1.5)

bead_bypass_valve.ON()

cell_bypass_valve.ON()

update_valve_states()

#Cleaning out any remaining Cells or Beads stuck in the tubing.

for i in range(0,4):

set_flush_pressures(2000.0,0.0,0.0)

time.sleep(2.5)

stop_flushing_all_channels()

time.sleep(2.5)

#Remember to load 2ml of lysis buffer in eppendorf tubes for all the time points you want to recover before you begin

def recover_beads(time_point_number_list):

waste_tube=waste_tube1

robot_action.enableRobot()

waste_tube.goToCoordinates()

time.sleep(2.5)

bead_bypass_valve.ON()

bead_lysis_buffer_flush_valve.OPEN()

update_valve_states()

for i in range(0,4):

set_flush_pressures(0.0,2000.0,0.0)

time.sleep(2.5)

stop_flushing_all_channels()

time.sleep(2.5)

for time_point_number in time_point_number_list:

print("Recovering time point "+ str(time_point_number)+ " beads.")

time_point=time_point_valve.all_time_point_valves[time_point_number]

bead_tube=robot_action.all_time_points[time_point_number]

bead_tube.goToCoordinates()

time.sleep(2.5)

bead_lysis_buffer_flush_valve.CLOSE()

time_point.OPEN()

update_valve_states()

set_flush_pressures(0.0,2000.0,0.0)

time.sleep(95.0)

time_point.CLOSE()

bead_lysis_buffer_flush_valve.OPEN()

update_valve_states()

for i in range(0,2):

set_flush_pressures(0.0,2000.0,0.0)

time.sleep(2.5)

stop_flushing_all_channels()

time.sleep(2.5)

def first_clean(time_point_number_list):

start_bead_vortex()

start_bead_vortex2()

time.sleep(20.0)

waste_tube=waste_tube2

robot_action.enableRobot()

waste_tube.goToCoordinates()

time.sleep(2.5)

bead_bypass_valve.ON()

bead_lysis_buffer_flush_valve.OPEN()

update_valve_states()

for i in range(0,4):

set_flush_pressures(0.0,2000.0,0.0)

time.sleep(2.5)

stop_flushing_all_channels()

time.sleep(2.5)

for time_point_number in time_point_number_list:

print("Cleaning tubing for time point "+ str(time_point_number))

time_point=time_point_valve.all_time_point_valves[time_point_number]

time.sleep(2.5)

bead_lysis_buffer_flush_valve.CLOSE()

time_point.OPEN()

update_valve_states()

set_flush_pressures(0.0,2000.0,0.0)

time.sleep(17.5)

time_point.CLOSE()

bead_lysis_buffer_flush_valve.OPEN()

update_valve_states()

for i in range(0,2):

set_flush_pressures(0.0,2000.0,0.0)

time.sleep(2.5)

stop_flushing_all_channels()

time.sleep(2.5)

stop_bead_vortex()

stop_bead_vortex2()

def blow_dry(time_point_number_list):

waste_tube=waste_tube1

robot_action.enableRobot()

waste_tube.goToCoordinates()

time.sleep(2.5)

for time_point_number in time_point_number_list:

print("Drying container for time point "+ str(time_point_number))

time_point=time_point_valve.all_time_point_valves[time_point_number]

time_point.OPEN()

update_valve_states()

set_flush_pressures(0.0,2000.0,0.0)

time.sleep(120.0) #Drying each container for 2 minutes

time_point.CLOSE()

update_valve_states()

time.sleep(2.5)

def second_clean(time_point_number_list):

waste_tube=waste_tube1

robot_action.enableRobot()

waste_tube.goToCoordinates()

time.sleep(2.5)

bead_bypass_valve.ON()

bead_lysis_buffer_flush_valve.OPEN()

update_valve_states()

for i in range(0,4):

set_flush_pressures(0.0,2000.0,0.0)

time.sleep(2.5)

stop_flushing_all_channels()

time.sleep(2.5)

for time_point_number in time_point_number_list:

print("Cleaning tubing for time point "+ str(time_point_number))

time_point=time_point_valve.all_time_point_valves[time_point_number]

time.sleep(2.5)

bead_lysis_buffer_flush_valve.CLOSE()

time_point.OPEN()

update_valve_states()

set_flush_pressures(0.0,2000.0,0.0)

time.sleep(15.0)

time_point.CLOSE()

bead_lysis_buffer_flush_valve.OPEN()

update_valve_states()

for i in range(0,2):

set_flush_pressures(0.0,2000.0,0.0)

time.sleep(2.5)

stop_flushing_all_channels()

time.sleep(2.5)

def time_point_sampling_run(time_point_number):

max_flow_rate_through_chip=875.4577

time_point=time_point_valve.all_time_point_valves[time_point_number]

new_time_to_manifold=(max_flow_rate_through_chip/400.0)*time_point.get_time_to_manifold()

new_time_to_injection_loop=(max_flow_rate_through_chip/400.0)*11.0

total_time_to_injection=new_time_to_injection_loop+new_time_to_manifold

setNewPIDKis(0.75,1.5,1.5)

oil_val=210.0

aq_phase_val=100.0

global record_data

record_data=True

print("Testing Chip:")

droplet_sampling_start_time=datetime.now()

cell_channel_start_time=droplet_sampling_start_time-timedelta(seconds=30.0)

bead_channel_start_time=droplet_sampling_start_time-timedelta(seconds=total_time_to_injection+40.0)

cell_channel_exec_list=[]

bead_channel_exec_list=[]

#Planning Bead Channel Independently

bead_channel_exec_list.append(("outlet_bypass_valve.ON()\n"+

"oil_bypass_valve.ON()\n"+

"cell_bypass_valve.ON()\n"+

"cell_media_flush_valve.OPEN()\n"+

"bead_lysis_buffer_flush_valve.OPEN()\n"+

"update_valve_states()\n"+

"print(get_cell_channel_density())\n"+

"set_oil_channel_scaling_factor(evagreenDropletOilScalingFactor)\n"+

"set_flow_rates(0.0,400.0,0.0)\n",bead_channel_start_time))

newTime=bead_channel_start_time+timedelta(seconds=15.0)

bead_channel_exec_list.append(("time_point.OPEN()\n"+

"bead_lysis_buffer_flush_valve.CLOSE()\n"+

"update_valve_states()\n",newTime))

newTime+=timedelta(seconds=5.0)

bead_channel_exec_list.append(("set_stirrer_speed(175)\n"+

"bead_lysis_buffer_flush_valve.OPEN()\n"+

"time_point.CLOSE()\n"+

"update_valve_states()\n",newTime))

newTime+=timedelta(seconds=20.0)

bead_channel_exec_list.append(("time_point.OPEN()\n"+

"bead_lysis_buffer_flush_valve.CLOSE()\n"+

"update_valve_states()\n",newTime))

newTime+=timedelta(seconds=(new_time_to_manifold+15.0)) #Get 100ul of beads

bead_channel_exec_list.append(("time_point.CLOSE()\n"+

"bead_lysis_buffer_flush_valve.OPEN()\n"+

"update_valve_states()\n",newTime))

bead_channel_exec_list.append(("set_flow_rates(aq_phase_val,aq_phase_val,oil_val)\n"+

"outlet_bypass_valve.OFF()\n"+

"update_valve_states()\n"+

"set_stirrer_speed(0)\n",droplet_sampling_start_time))

#Planning Cell Channel Independently

cell_channel_exec_list.append(("cell_bypass_valve.OFF()\n"+

"update_valve_states()\n"+

"cellPress,beadPress,oilPress=get_latest_pressure_measurements()\n"+

"pidforCellChannel.restart_flow(400.0,0.75,cellPress)\n",cell_channel_start_time))

newTime=cell_channel_start_time+timedelta(seconds=15.0)

cell_channel_exec_list.append(("oil_bypass_valve.OFF()\n"+

"update_valve_states()\n"+

"cellPress,beadPress,oilPress=get_latest_pressure_measurements()\n"+

"pidforOilChannel.restart_flow(oil_val,1.5,oilPress)\n",newTime))

#Merge and Execute Schedules for these Channels

execution_list=bead_channel_exec_list+cell_channel_exec_list

exec(getMergedExecutionSchedule(execution_list))

#Continue with Normal Schedule

time.sleep(40.0)

setNewPIDKis(0.01,0.01,0.01)

time.sleep(80.0)

setNewPIDKis(0.75,1.5,1.5)

outlet_bypass_valve.ON()

update_valve_states()

set_flow_rates(400.0,400.0,aq_phase_val)

time.sleep(10.0)

set_flow_rates(400.0,400.0,0.0)

oil_bypass_valve.ON()

update_valve_states()

time.sleep(15.0)

set_flow_rates(0.0,400.0,0.0)

cell_bypass_valve.ON()

update_valve_states()

time.sleep(15.0)

set_flow_rates(0.0,0.0,0.0)

bead_lysis_buffer_flush_valve.CLOSE()

update_valve_states()

record_data=False

def chip_calibration_run():

setNewPIDKis(0.75,1.5,1.5)

oil_val=210.0

aq_phase_val=70.0

global record_data

record_data=True

print("Testing Chip:")

outlet_bypass_valve.ON()

oil_bypass_valve.ON()

cell_bypass_valve.ON()

cell_media_flush_valve.OPEN()

bead_lysis_buffer_flush_valve.OPEN()

update_valve_states()

print(get_cell_channel_density())

set_oil_channel_scaling_factor(evagreenDropletOilScalingFactor)

set_flow_rates(0.0,400.0,0.0)

time.sleep(15.0)

cell_bypass_valve.OFF()

update_valve_states()

cellPress,beadPress,oilPress=get_latest_pressure_measurements()

pidforCellChannel.restart_flow(400.0,0.75,cellPress)

time.sleep(15.0)

oil_bypass_valve.OFF()

update_valve_states()

cellPress,beadPress,oilPress=get_latest_pressure_measurements()

pidforOilChannel.restart_flow(oil_val,1.5,oilPress)

time.sleep(15.0)

set_flow_rates(aq_phase_val,aq_phase_val,oil_val)

outlet_bypass_valve.OFF()

update_valve_states()

time.sleep(40.0)

cellPress,beadPress,oilPress=get_latest_pressure_measurements()

setNewPIDKis(0.01,0.01,0.01)

time.sleep(80.0)

cellPress,beadPress,oilPress=get_latest_pressure_measurements()

setNewPIDKis(0.75,1.5,1.5)

outlet_bypass_valve.ON()

update_valve_states()

set_flow_rates(400.0,400.0,aq_phase_val)

time.sleep(10.0)

set_flow_rates(400.0,400.0,0.0)

oil_bypass_valve.ON()

update_valve_states()

time.sleep(15.0)

set_flow_rates(0.0,400.0,0.0)

cell_bypass_valve.ON()

update_valve_states()

time.sleep(15.0)

set_flow_rates(0.0,0.0,0.0)

bead_lysis_buffer_flush_valve.CLOSE()

update_valve_states()

record_data=False

def chip_test_PID():

#Turning the flows and valves on step by step and also closing them step by step to prevent backflow

#Backflow is a major problem and hopefully this will be a great solution to that problem.

oil_val=210.0

aq_phase_val=70.0

global record_data

record_data=True

print("Testing Chip:")

outlet_bypass_valve.ON()

oil_bypass_valve.ON()

cell_bypass_valve.ON()

cell_media_flush_valve.OPEN()

bead_lysis_buffer_flush_valve.OPEN()

update_valve_states()

print(get_cell_channel_density())

set_oil_channel_scaling_factor(evagreenDropletOilScalingFactor)

set_flow_rates(0.0,400.0,0.0)

time.sleep(15.0)

cell_bypass_valve.OFF()

update_valve_states()

pidforCellChannel.clear()

set_flow_rates(400.0,400.0,0.0)

time.sleep(15.0)

oil_bypass_valve.OFF()

update_valve_states()

pidforOilChannel.clear()

set_flow_rates(400.0,400.0,oil_val)

time.sleep(15.0)

cellPress,beadPress,oilPress=get_average_pressure_measurments_for_previous_run(135,140)

set_flush_pressures(cellPress,beadPress,oilPress)

outlet_bypass_valve.OFF()

update_valve_states()

time.sleep(120.0)

stop_flushing_all_channels()

outlet_bypass_valve.ON()

update_valve_states()

set_flow_rates(400.0,400.0,aq_phase_val)

time.sleep(10.0)

set_flow_rates(400.0,400.0,0.0)

oil_bypass_valve.ON()

update_valve_states()

time.sleep(15.0)

set_flow_rates(0.0,400.0,0.0)

cell_bypass_valve.ON()

update_valve_states()

time.sleep(15.0)

set_flow_rates(0.0,0.0,0.0)

bead_lysis_buffer_flush_valve.CLOSE()

update_valve_states()

record_data=False

def chip_bead_channel_flush():

waste_tube1.goToCoordinates()

time.sleep(2.5)

global record_data

record_data=True

print("Testing Chip:")

oil_bypass_valve.ON()

cell_bypass_valve.ON()

cell_media_flush_valve.CLOSE()

bead_lysis_buffer_flush_valve.OPEN()

bead_bypass_valve.OFF()

update_valve_states()

print(get_cell_channel_density())

print(get_oil_channel_density())

set_bead_channel_scaling_factor(scalingFactor60ul)

set_flush_pressures(0.0,2000.0,0.0)

time.sleep(60.0)

stop_flushing_all_channels()

bead_lysis_buffer_flush_valve.CLOSE()

update_valve_states()

record_data=False

def bead_channel_flush():

global record_data

record_data=True

print("Testing Chip:")

oil_bypass_valve.ON()

cell_bypass_valve.ON()

cell_media_flush_valve.CLOSE()

bead_lysis_buffer_flush_valve.OPEN()

bead_bypass_valve.ON()

update_valve_states()

print(get_cell_channel_density())

print(get_oil_channel_density())

#set_cell_channel_scaling_factor(digitalDistilledWaterScalingFactor60_75ulPIDRange)

set_bead_channel_scaling_factor(digitalDistilledWaterScalingFactor)

for i in range(0,6):

set_flush_pressures(0.0,2000.0,0.0)

time.sleep(2.5)

stop_flushing_all_channels()

time.sleep(2.5)

stop_flushing_all_channels()

bead_lysis_buffer_flush_valve.CLOSE()

update_valve_states()

record_data=False

def first_time_point_flush(var):

global record_data

record_data=True

time_point=time_point_valve.all_time_point_valves[1]

print("Testing Chip:")

oil_bypass_valve.ON()

cell_bypass_valve.ON()

cell_media_flush_valve.CLOSE()

time_point.OPEN()

update_valve_states()

print(get_cell_channel_density())

set_oil_channel_scaling_factor(evagreenDropletOilScalingFactor)

set_bead_channel_scaling_factor(distilledWaterScalingFactor)

set_flush_pressures(0.0,2000.0,0.0)

time.sleep(60.0)

print(var)

stop_flushing_all_channels()

time_point.CLOSE()

update_valve_states()

record_data=False

def chip_cell_channel_flush():

global record_data

record_data=True

print("Testing Chip:")

oil_bypass_valve.ON()

cell_bypass_valve.OFF()

cell_media_flush_valve.OPEN()

bead_lysis_buffer_flush_valve.CLOSE()

bead_bypass_valve.ON()

update_valve_states()

#print(get_cell_channel_density())

#print(get_oil_channel_density())

#set_bead_channel_scaling_factor(digitalDistilledWaterScalingFactor)

set_flush_pressures(2000.0,0.0,0.0)

time.sleep(60.0)

stop_flushing_all_channels()

cell_media_flush_valve.CLOSE()

cell_bypass_valve.ON()

update_valve_states()

record_data=False

def chip_bead_and_cell_channel_flush():

global record_data

record_data=True

print("Testing Chip:")

oil_bypass_valve.ON()

cell_bypass_valve.OFF()

bead_bypass_valve.OFF()

cell_media_flush_valve.OPEN()

bead_lysis_buffer_flush_valve.OPEN()

update_valve_states()

#set_bead_channel_scaling_factor(analogDistilledWaterScalingFactor)

#set_cell_channel_scaling_factor(digitalDistilledWaterScalingFactor60_75ulPIDRange)

#print(get_cell_channel_density())

set_flush_pressures(2000.0,2000.0,0.0)

time.sleep(60.0)

stop_flushing_all_channels()

bead_lysis_buffer_flush_valve.CLOSE()

cell_media_flush_valve.CLOSE()

cell_bypass_valve.ON()

bead_bypass_valve.ON()

update_valve_states()

record_data=False

def simple_flush():

#global record_data

#record_data=True

print("Flushing Oil and Water through Oil and Cell Bypass valves:")

oil_bypass_valve.ON()

cell_bypass_valve.ON()

cell_media_flush_valve.OPEN()

print(get_cell_channel_density())

set_oil_channel_scaling_factor(evagreenDropletOilScalingFactor)

update_valve_states()

time.sleep(5.0)

sin_pressure_wave(1800.0,1800.0,250.0,60.0)

time.sleep(5.0)

#record_data=False

def bead_channel_calibration():

set_bead_channel_scaling_factor(scalingFactor55ulFicoll)

global record_data

setNewPIDKis(0.1,1.0,0.1)

print("Bead Channel Calibration")

update_valve_states()

for i in range(0,4):

set_flush_pressures(0.0,2000.0,0.0)

time.sleep(2.5)

set_flush_pressures(0.0,0.0,0.0)

time.sleep(2.5)

print(get_cell_channel_density())

print(get_oil_channel_density())

stop_flushing_all_channels()

record_data=True

time.sleep(5.0)

set_flow_rates(0.0,55.0,0.0)

time.sleep(120.0)

def PID_test():

global record_data

print("PID test through Bypass valves")

cell_ipa_flush_valve.CLOSE()

cell_aceticAcidSDS_flush_valve.CLOSE()

cell_air_flush_valve.CLOSE()

cell_media_flush_valve.OPEN()

cell_sample_flush_valve1.CLOSE()

cell_bypass_valve.ON()

bead_bypass_valve.ON()

bead_ipa_flush_valve.CLOSE()

bead_lysis_buffer_flush_valve.OPEN()

bead_air_flush_valve.CLOSE()

oil_bypass_valve.ON()

update_valve_states()

record_data=True

#print(get_bead_channel_density())

print(get_cell_channel_density())

time.sleep(5.0)

set_oil_channel_scaling_factor(evagreenDropletOilScalingFactor)

#set_bead_channel_scaling_factor(distilledWaterScalingFactor)

set_flow_rates(65.0,65.0,0.0)

time.sleep(60.0)

set_flow_rates(0.0,0.0,0.0)

time.sleep(5.0)

def sampling_schedule():

simple_flush() #Gets rid of Bubbles in the Flow meters and pumps clean liquid through

reset_valve_states()

set_stirrer_speed(175)

time.sleep(5.0)

PID_flush_though_chip()

reset_valve_states()

time.sleep(5.0)

prime_the_tubing()

stop_stirrer()

def bead_flush_test():

set_stirrer_speed(250)

time.sleep(15.0)

prime_the_tubing()

stop_stirrer()

def initial_flush():

print("Flushing Water and Oil through bypass valves")

cell_ipa_flush_valve.CLOSE()

cell_aceticAcidSDS_flush_valve.CLOSE()

cell_air_flush_valve.CLOSE()

cell_media_flush_valve.OPEN()

cell_sample_flush_valve1.CLOSE()

cell_bypass_valve.ON()

bead_bypass_valve.ON()

bead_ipa_flush_valve.CLOSE()

bead_lysis_buffer_flush_valve.OPEN()

bead_air_flush_valve.CLOSE()

oil_bypass_valve.ON()

update_valve_states()

time.sleep(5.0)

sin_pressure_wave(1800.0,1800.0,0.0,60.0)

time.sleep(5.0)

def smoothPID():

global record_data

print("Fast Flush")

cell_ipa_flush_valve.CLOSE()

cell_aceticAcidSDS_flush_valve.CLOSE()

cell_air_flush_valve.CLOSE()

cell_media_flush_valve.OPEN()

cell_sample_flush_valve1.CLOSE()

cell_bypass_valve.ON()

bead_bypass_valve.ON()

bead_ipa_flush_valve.CLOSE()

bead_lysis_buffer_flush_valve.OPEN()

bead_air_flush_valve.CLOSE()

oil_bypass_valve.ON()

update_valve_states()

record_data=True

#print(get_bead_channel_density())

print(get_cell_channel_density())

time.sleep(5.0)

set_oil_channel_scaling_factor(evagreenDropletOilScalingFactor)

set_bead_channel_scaling_factor(distilledWaterScalingFactor)

set_flow_rates(500.0,500.0,0.0)

time.sleep(60.0)

set_flow_rates(0.0,0.0,0.0)

time.sleep(5.0)

print("Slow Flush")

cell_ipa_flush_valve.CLOSE()

cell_aceticAcidSDS_flush_valve.CLOSE()

cell_air_flush_valve.CLOSE()

cell_media_flush_valve.OPEN()

cell_sample_flush_valve1.CLOSE()

cell_bypass_valve.ON()

bead_bypass_valve.ON()

bead_ipa_flush_valve.CLOSE()

bead_lysis_buffer_flush_valve.OPEN()

bead_air_flush_valve.CLOSE()

oil_bypass_valve.ON()

update_valve_states()

record_data=True

#print(get_bead_channel_density())

print(get_cell_channel_density())

time.sleep(5.0)

set_oil_channel_scaling_factor(evagreenDropletOilScalingFactor)

#set_bead_channel_scaling_factor(distilledWaterScalingFactor)

clear_PID_controllers()

set_flow_rates(65.0,65.0,0.0)

time.sleep(60.0)

set_flow_rates(0.0,0.0,0.0)

time.sleep(5.0)

def oil_calibration():

global record_data

record_data=True

print("Calibration Data collection Started")

set_oil_channel_scaling_factor(evagreenDropletOilScalingFactor)

print(get_cell_channel_density())

set_flow_rates(200.0,0.0,0.0)

time.sleep(60.0)

set_flow_rates(0.0,0.0,0.0)

record_data=False

def smootherPIDTest():

global record_data

print("Fast Flush")

cell_ipa_flush_valve.CLOSE()

cell_aceticAcidSDS_flush_valve.CLOSE()

cell_air_flush_valve.CLOSE()

cell_media_flush_valve.OPEN()

cell_sample_flush_valve1.CLOSE()

cell_bypass_valve.ON()

bead_bypass_valve.ON()

bead_ipa_flush_valve.CLOSE()

bead_lysis_buffer_flush_valve.OPEN()

bead_air_flush_valve.CLOSE()

oil_bypass_valve.ON()

update_valve_states()

record_data=True

#print(get_bead_channel_density())

print(get_cell_channel_density())

time.sleep(5.0)

set_oil_channel_scaling_factor(evagreenDropletOilScalingFactor)

set_bead_channel_scaling_factor(distilledWaterScalingFactor)

set_flow_rates(500.0,500.0,0.0)

time.sleep(60.0)

set_flow_rates(65.0,65.0,0.0)

time.sleep(60.0)

set_flow_rates(0.0,0.0,0.0)

time.sleep(5.0)

def clear_second_time_point():

second=time_point_valve.all_time_point_valves[2]

second.OPEN()

update_valve_states()

set_flush_pressures(0.0,2000.0,0.0)

for i in range(0,5):

set_flush_pressures(0.0,2000.0,0.0)

time.sleep(2.5)

stop_flushing_all_channels()

time.sleep(2.5)

reset_valve_states()

def get_priming_timing():

second=time_point_valve.all_time_point_valves[2]

second.OPEN()

update_valve_states()

set_flush_pressures(0.0,2000.0,0.0)

time.sleep(1.5)

stop_flushing_all_channels()

def test_pulsatile_chip():

cellPress=0.0

beadPress=170.0

oilPress=0.0

for i in range(0,5):

bead_air_flush_valve.CLOSE()

bead_lysis_buffer_flush_valve.OPEN()

bead_bypass_valve.ON()

update_valve_states()

set_flush_pressures(0.0,2000.0,0.0)

time.sleep(5.0)

set_flush_pressures(2*cellPress,2*beadPress,2*oilPress)

bead_bypass_valve.OFF()

update_valve_states()

time.sleep(5.0)

bead_air_flush_valve.OPEN()

bead_lysis_buffer_flush_valve.CLOSE()

bead_bypass_valve.ON()

update_valve_states()

set_flush_pressures(0.0,2000.0,0.0)

time.sleep(5.0)

set_flush_pressures(2*cellPress,2*beadPress,2*oilPress)

bead_bypass_valve.OFF()

update_valve_states()

time.sleep(5.0)

def keep_suspension():

cell_gas_vent_valve.OPEN()

update_valve_states()

set_flush_pressures(2000.0,0.0,0.0)

time.sleep(10.0)

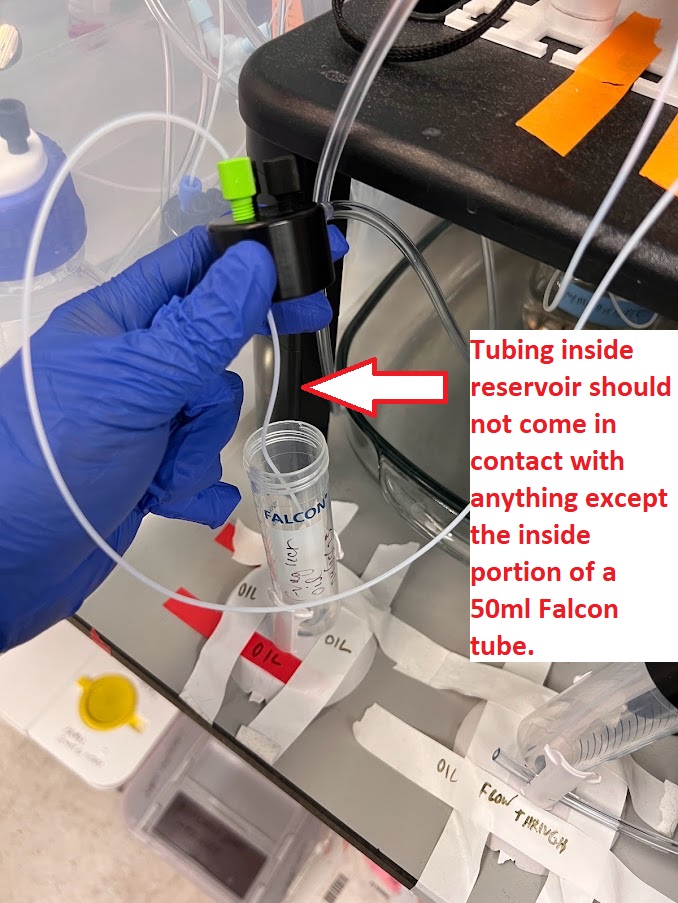

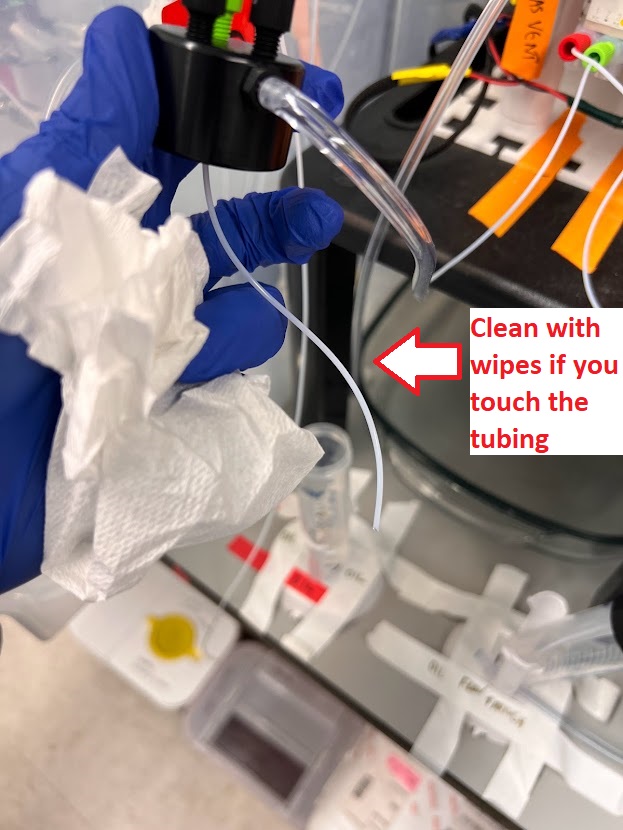

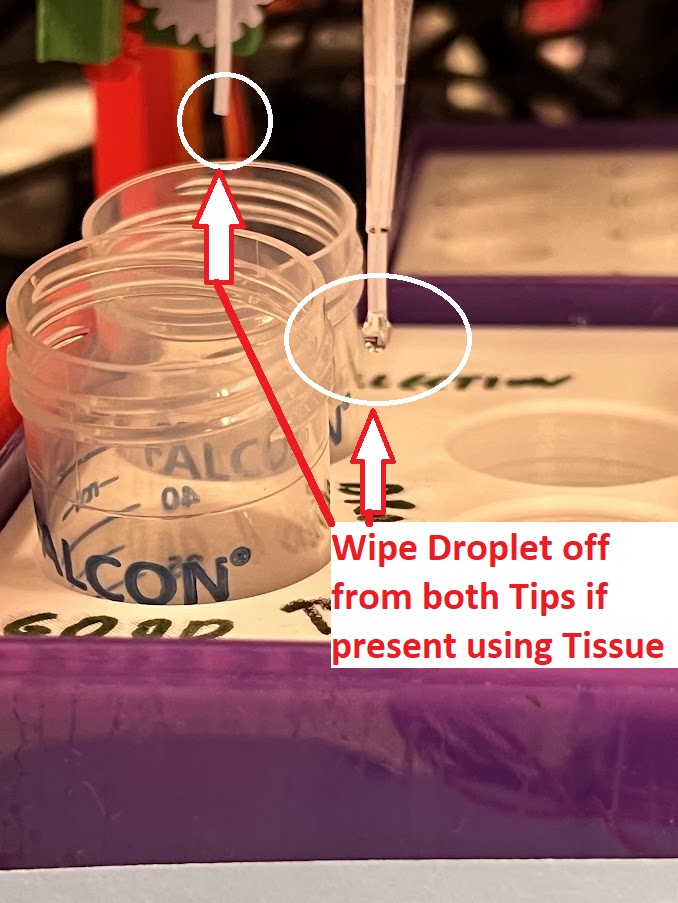

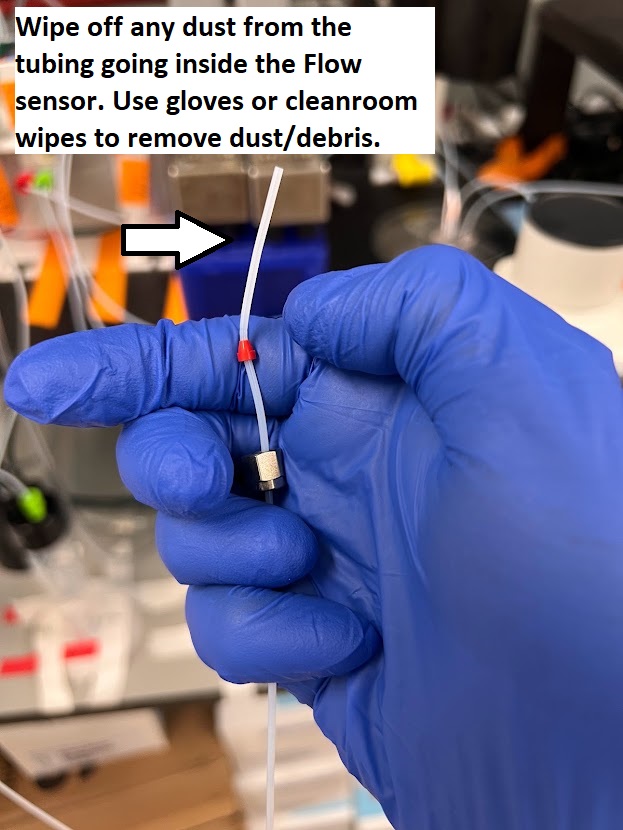

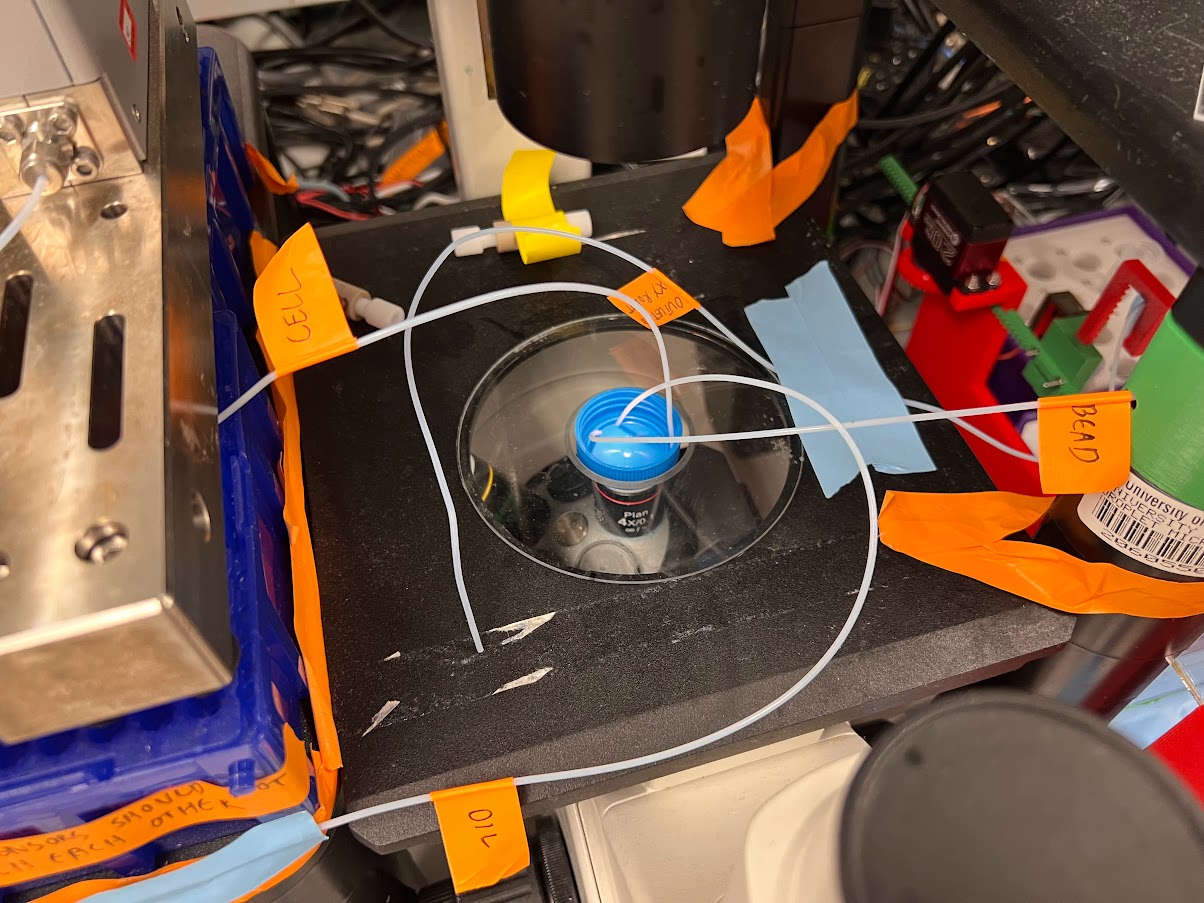

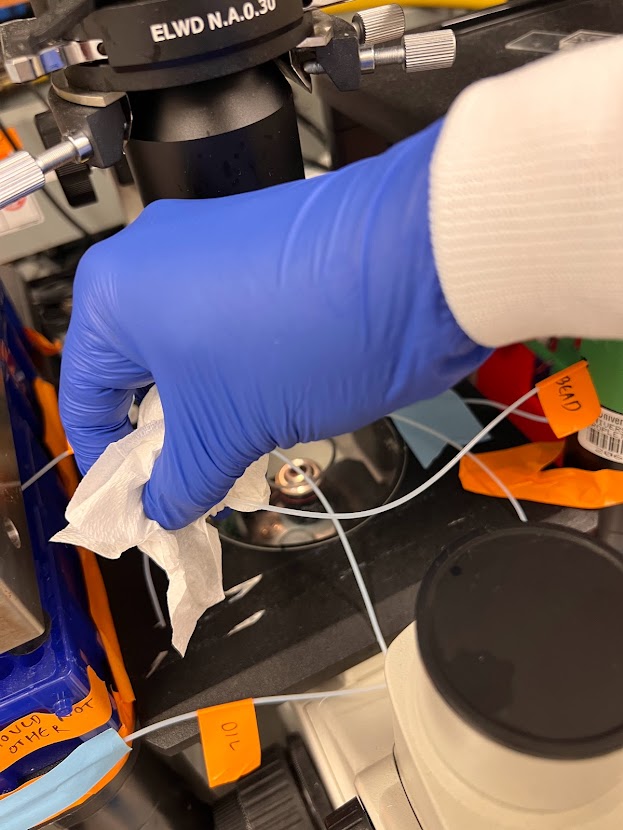

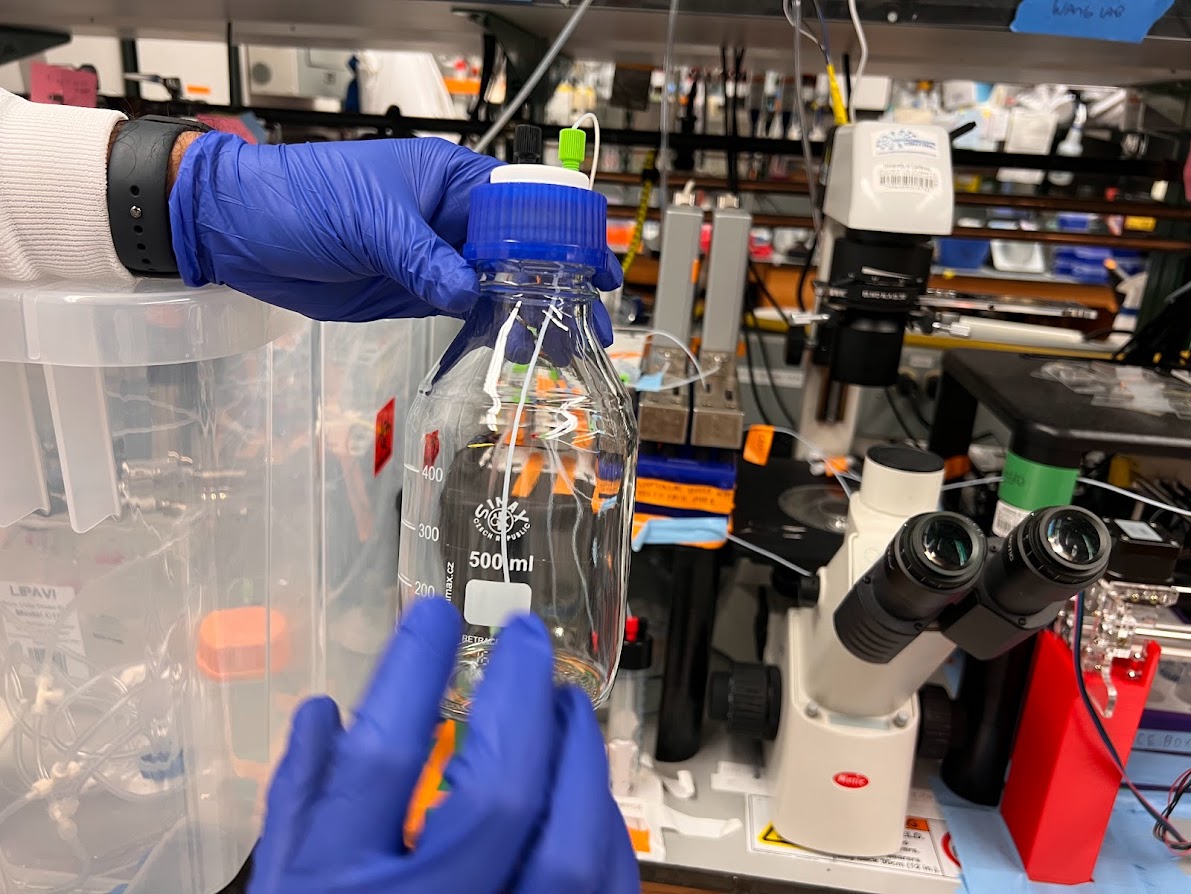

+ If you accidently touch the Tubing please clean it with Wipes.You should use your gloves and [Scott Slimfold Towels](https://www.kcprofessional.com/en-us/products/restroom-and-hygiene/paper-towels/folded-paper/slimfold/scott-pro-plus-slimfold-towels/04442).

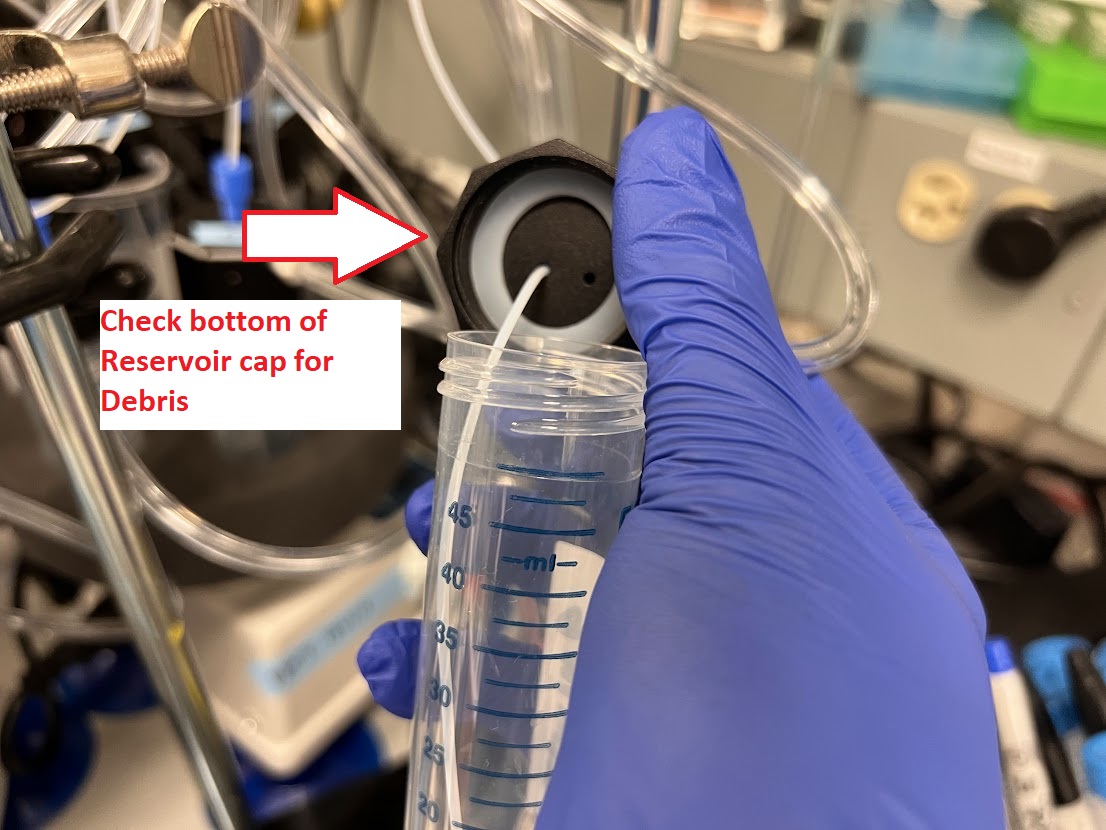

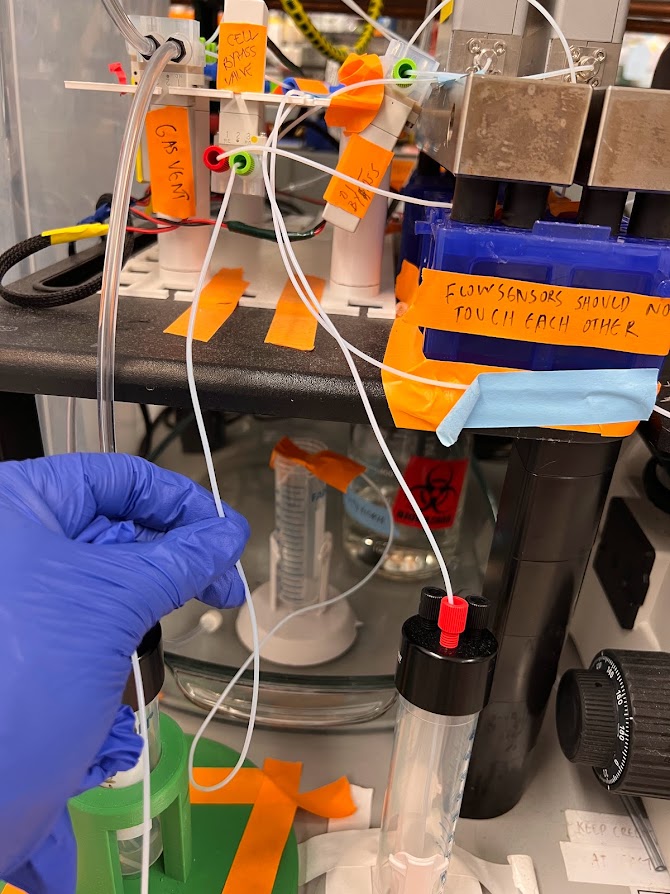

+ If you accidently touch the Tubing please clean it with Wipes.You should use your gloves and [Scott Slimfold Towels](https://www.kcprofessional.com/en-us/products/restroom-and-hygiene/paper-towels/folded-paper/slimfold/scott-pro-plus-slimfold-towels/04442). + If you see any particles on the inside portion of the Reservoir cap, then blow them away using either:

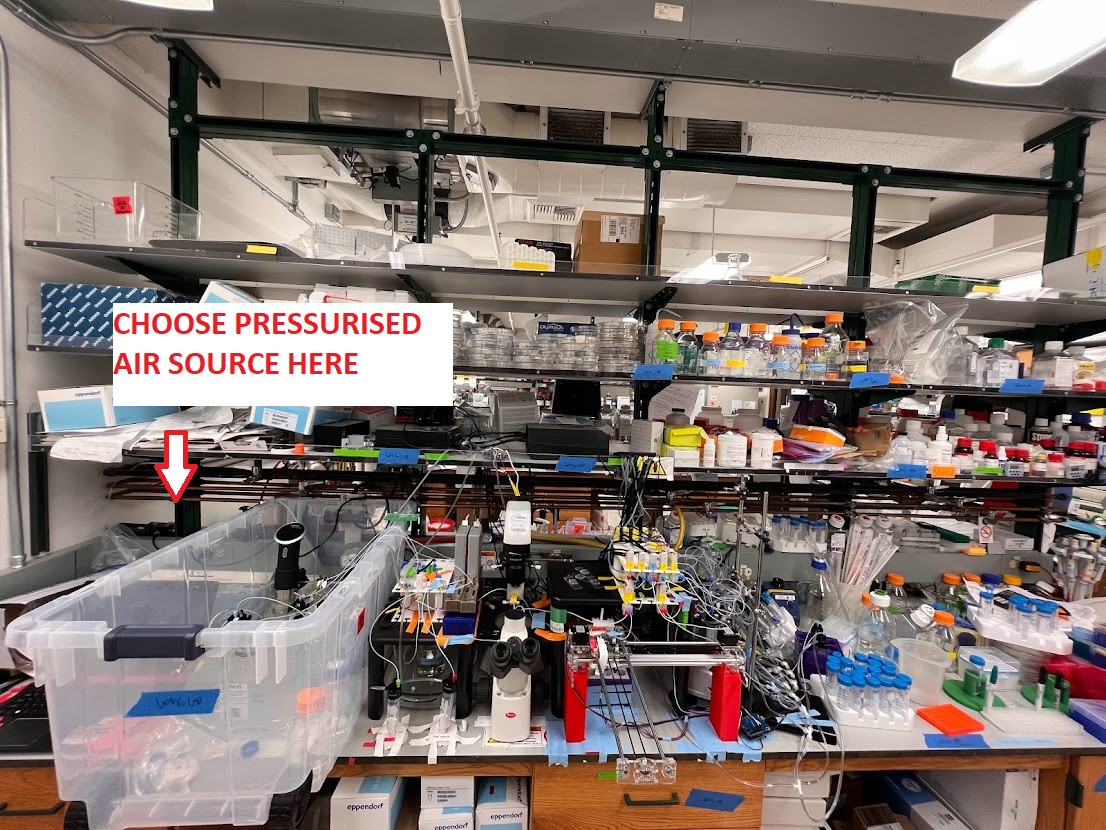

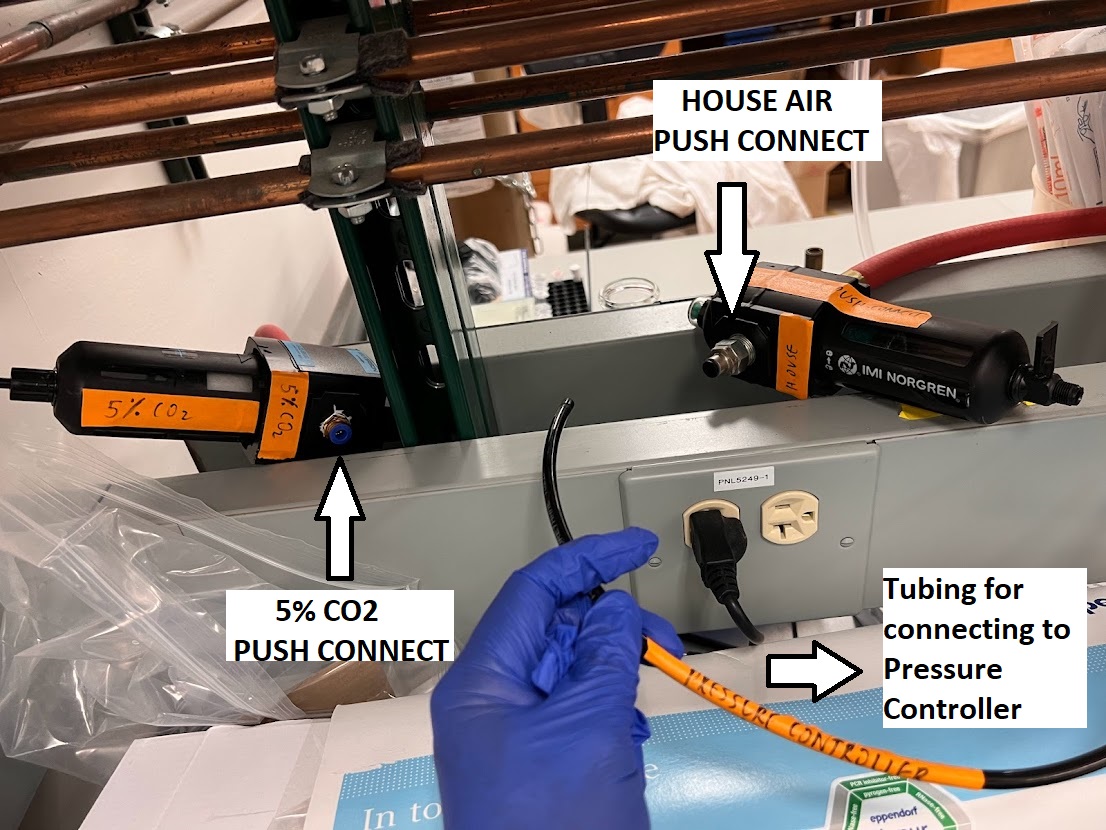

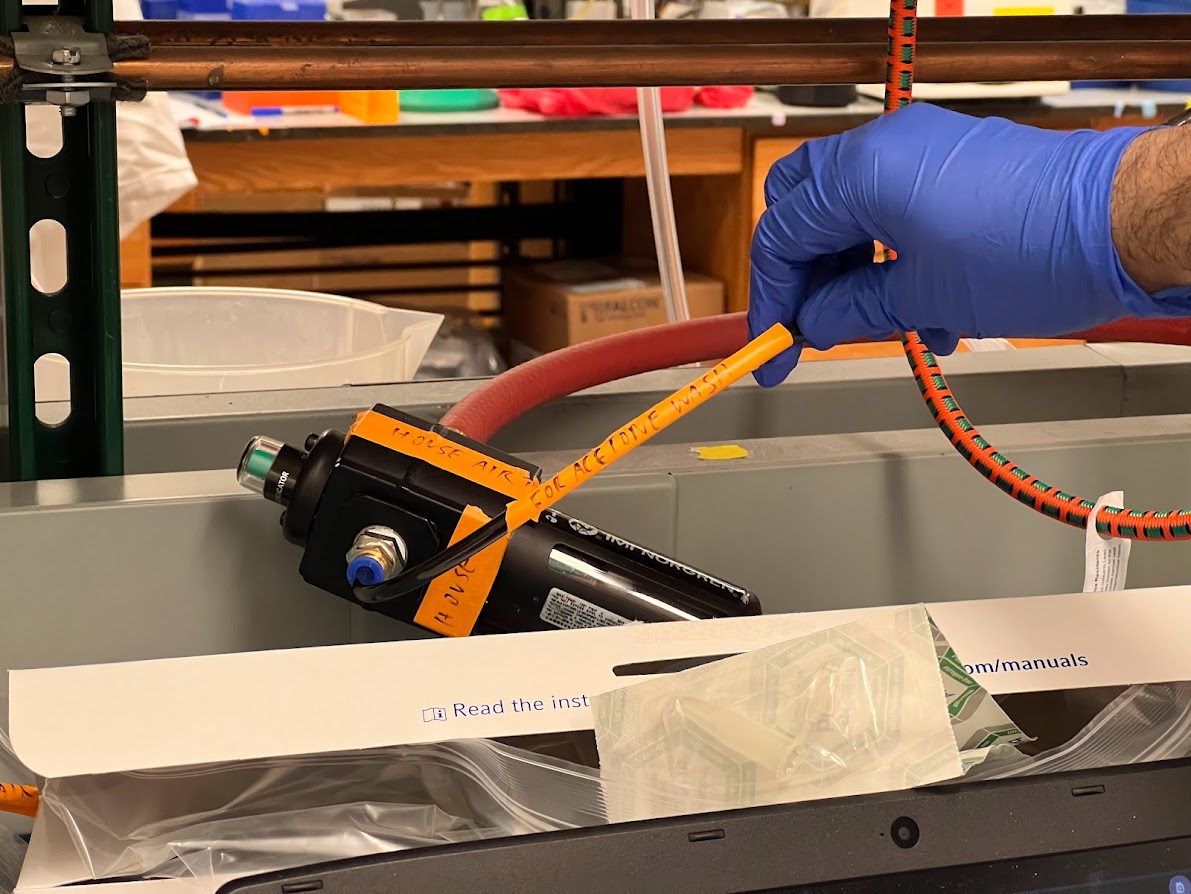

+ [Compressed Air Gun](https://www.mcmaster.com/5186K81/) and [Hose](https://www.grainger.com/product/SPEEDAIRE-Coiled-Air-Hose-1-4-in-Hose-1VEH8?opr=PDPRRDSP&analytics=dsrrItems_1VEJ9) connected to House Air.

+ [Cleaning Duster Spray](https://www.officedepot.com/a/products/911245/Office-Depot-Brand-Cleaning-Duster-10/)

+ [See this section of the notebook and its associated video on how to use the Compressed Air Gun](#Prime-Bead-Time-Point-Reservoirs)

+ If you see any particles on the inside portion of the Reservoir cap, then blow them away using either:

+ [Compressed Air Gun](https://www.mcmaster.com/5186K81/) and [Hose](https://www.grainger.com/product/SPEEDAIRE-Coiled-Air-Hose-1-4-in-Hose-1VEH8?opr=PDPRRDSP&analytics=dsrrItems_1VEJ9) connected to House Air.

+ [Cleaning Duster Spray](https://www.officedepot.com/a/products/911245/Office-Depot-Brand-Cleaning-Duster-10/)

+ [See this section of the notebook and its associated video on how to use the Compressed Air Gun](#Prime-Bead-Time-Point-Reservoirs)

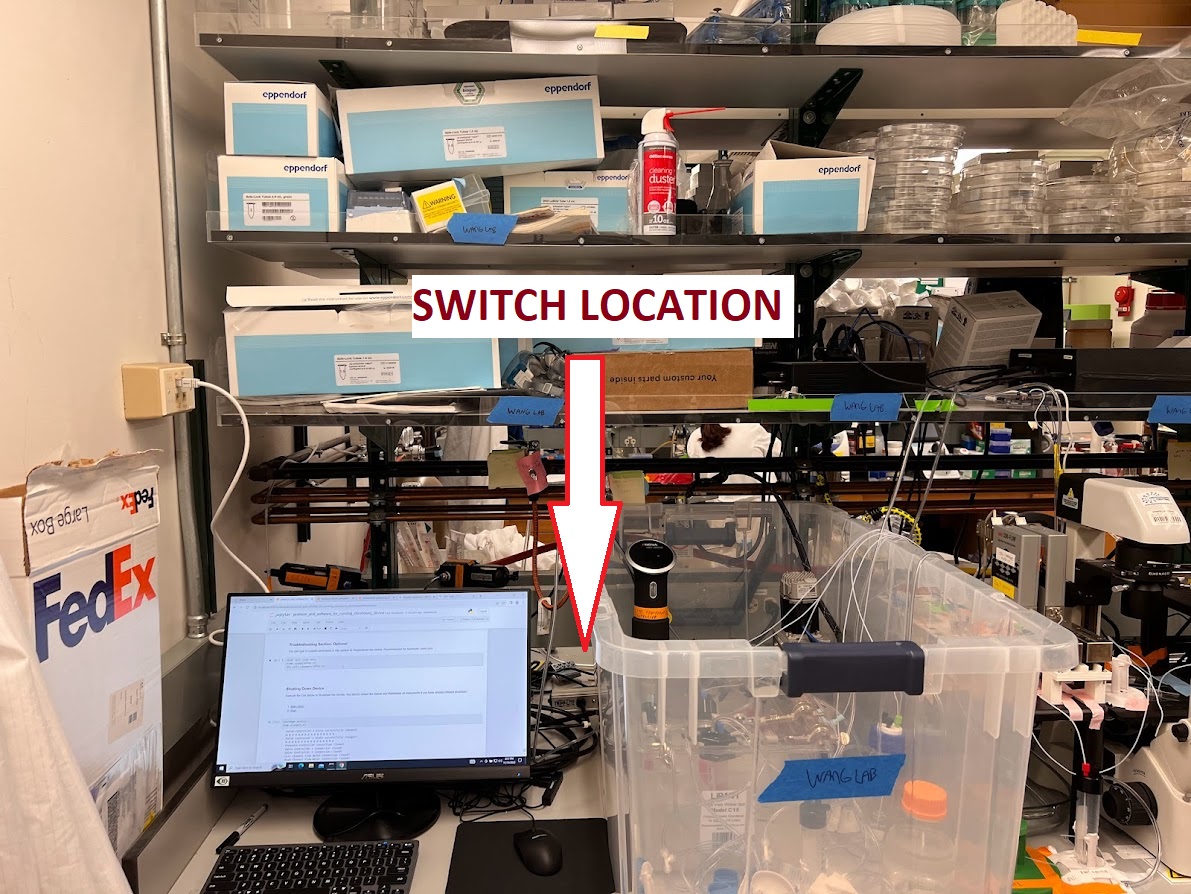

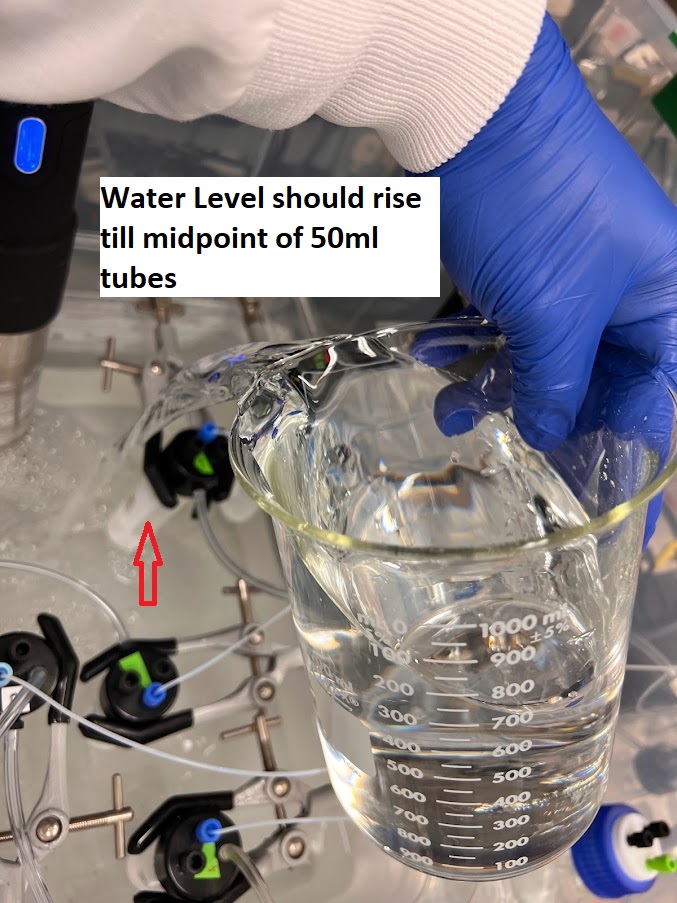

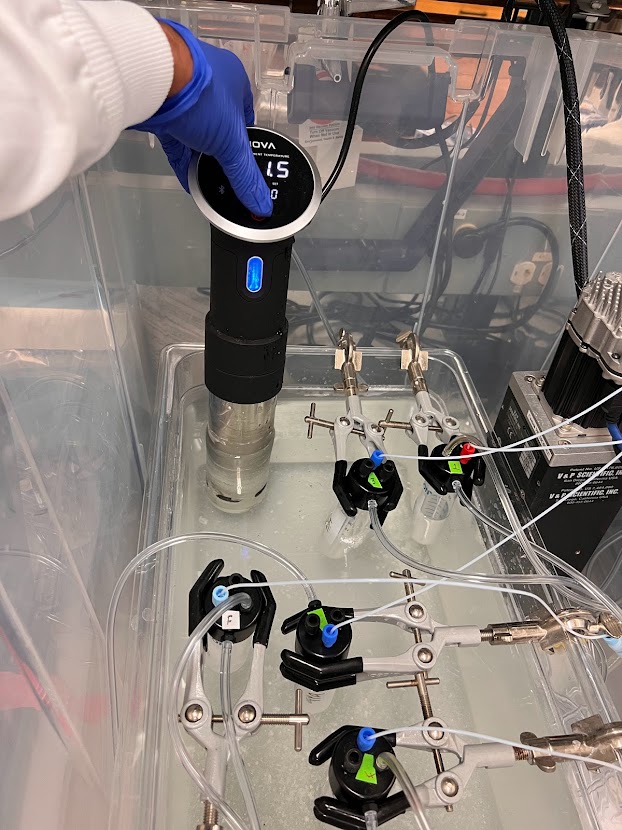

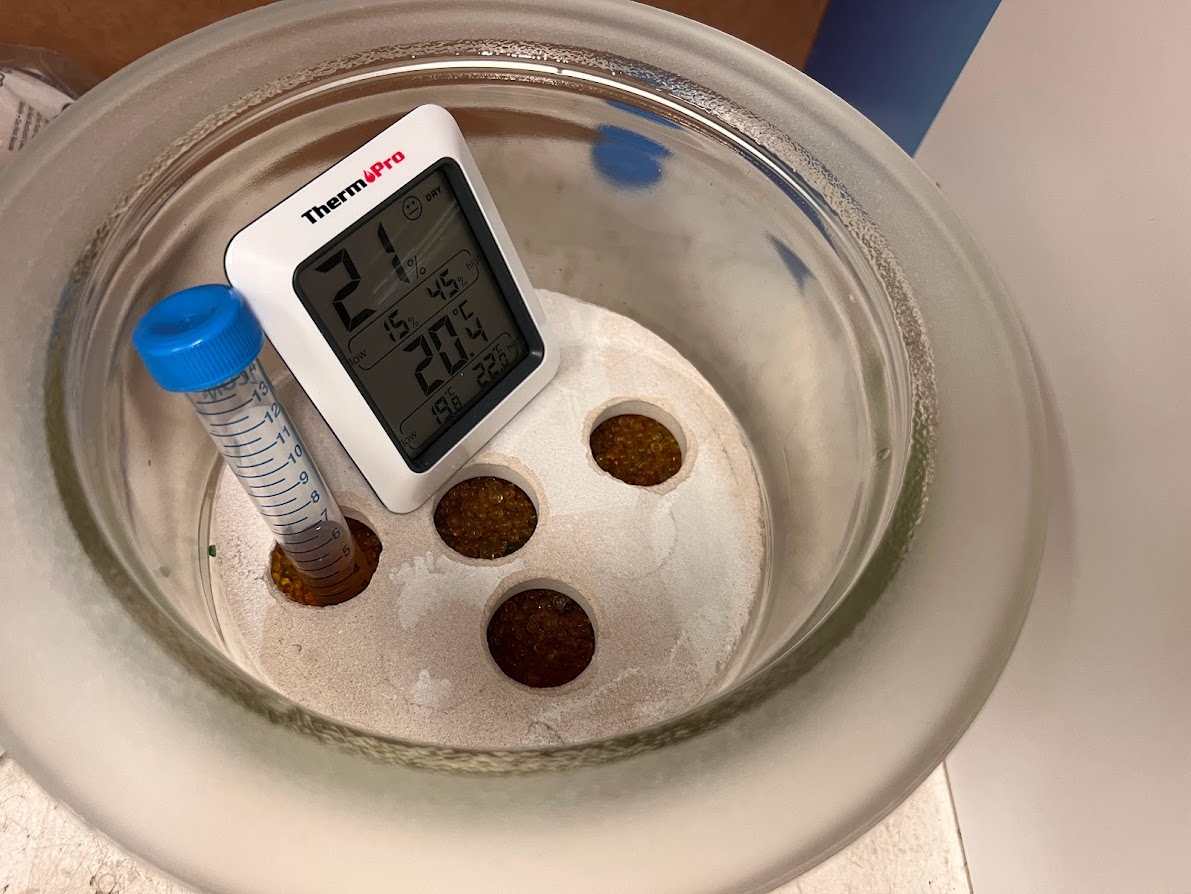

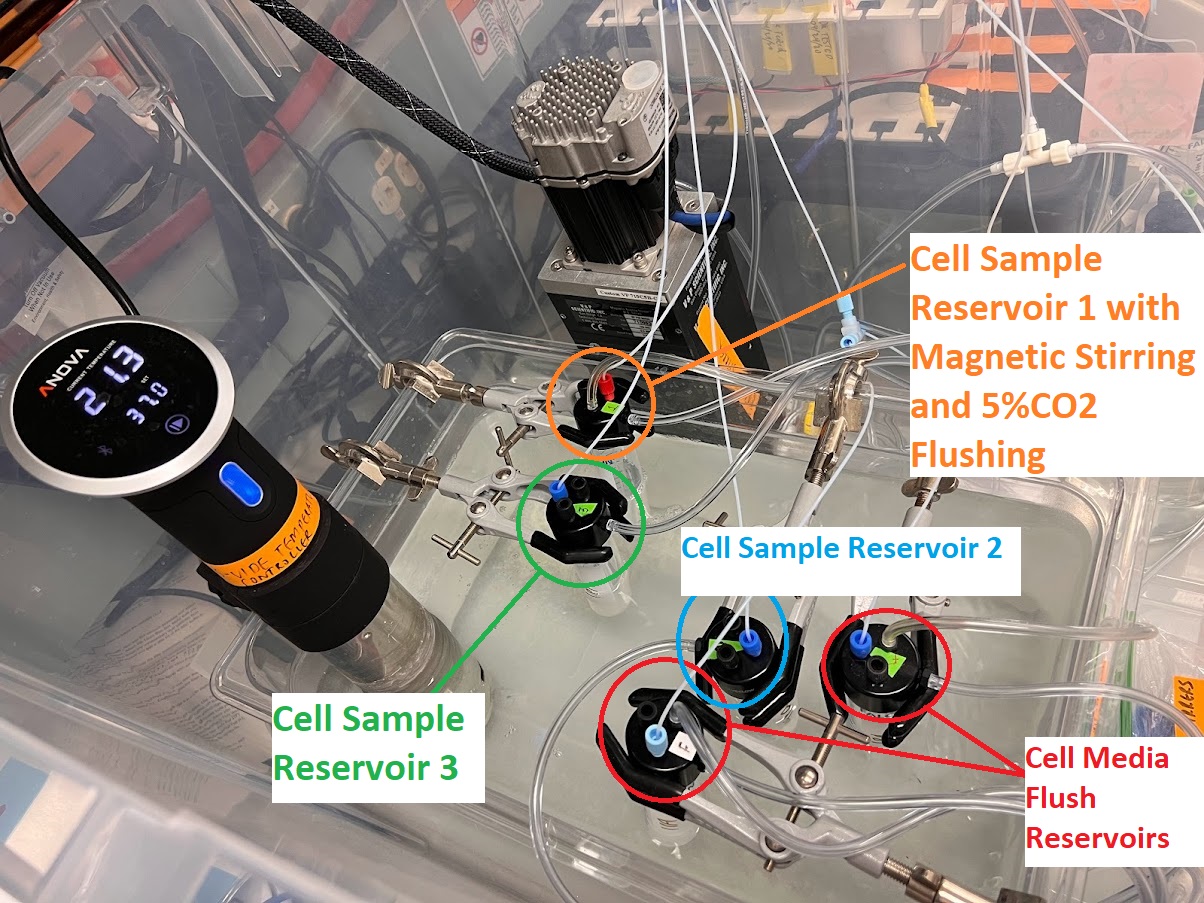

+ **Turn the Power on for [Sous-Vide Temperature Controller](https://www.amazon.com/gp/product/B00UKPBXM4/) and Keep Temperature at 37°C.**

+ [Download the Anova App](https://anovaculinary.com/pages/apps) to Switch Units to Celcius if necessary.

+ **Turn the Power on for [Sous-Vide Temperature Controller](https://www.amazon.com/gp/product/B00UKPBXM4/) and Keep Temperature at 37°C.**

+ [Download the Anova App](https://anovaculinary.com/pages/apps) to Switch Units to Celcius if necessary.

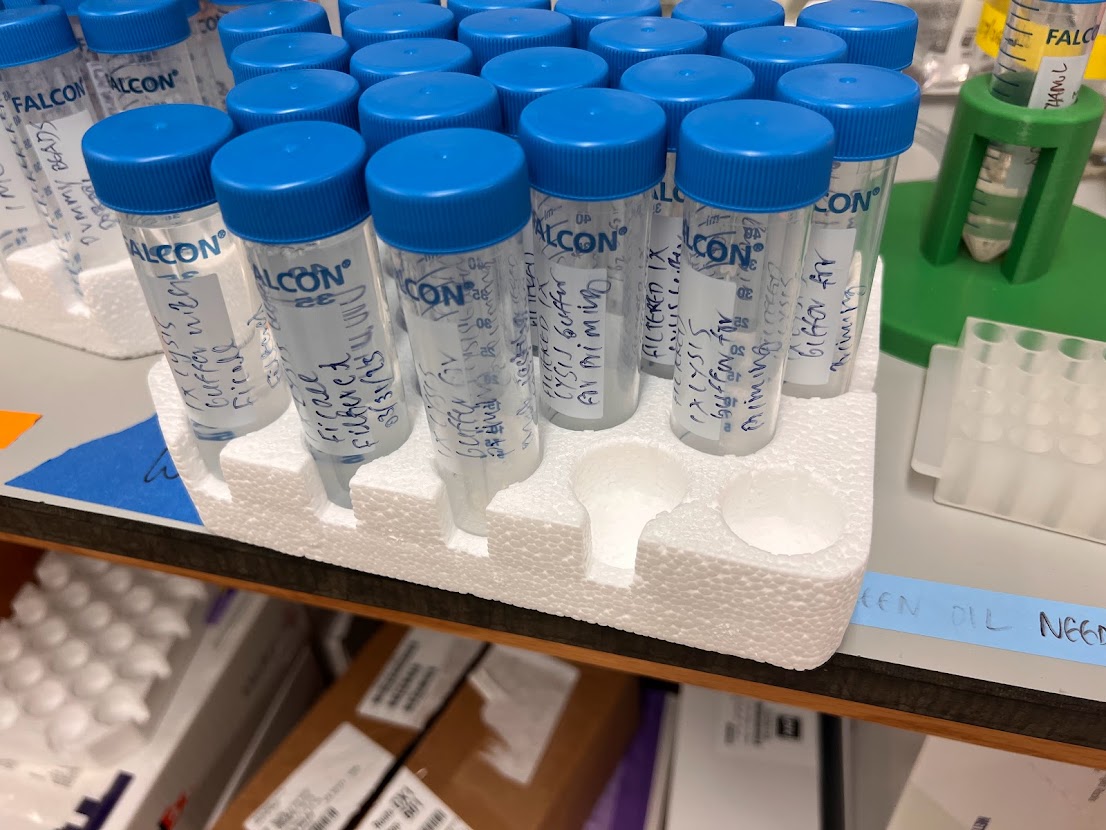

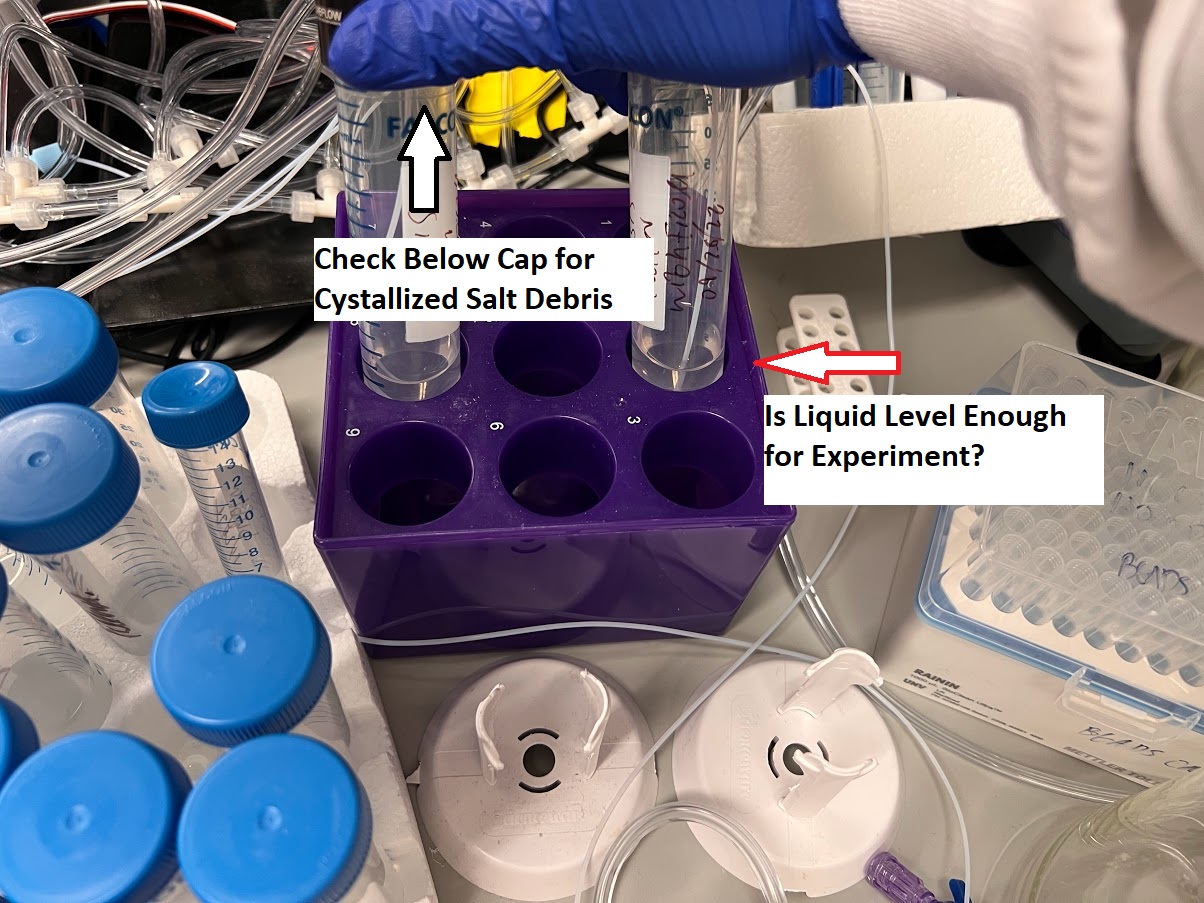

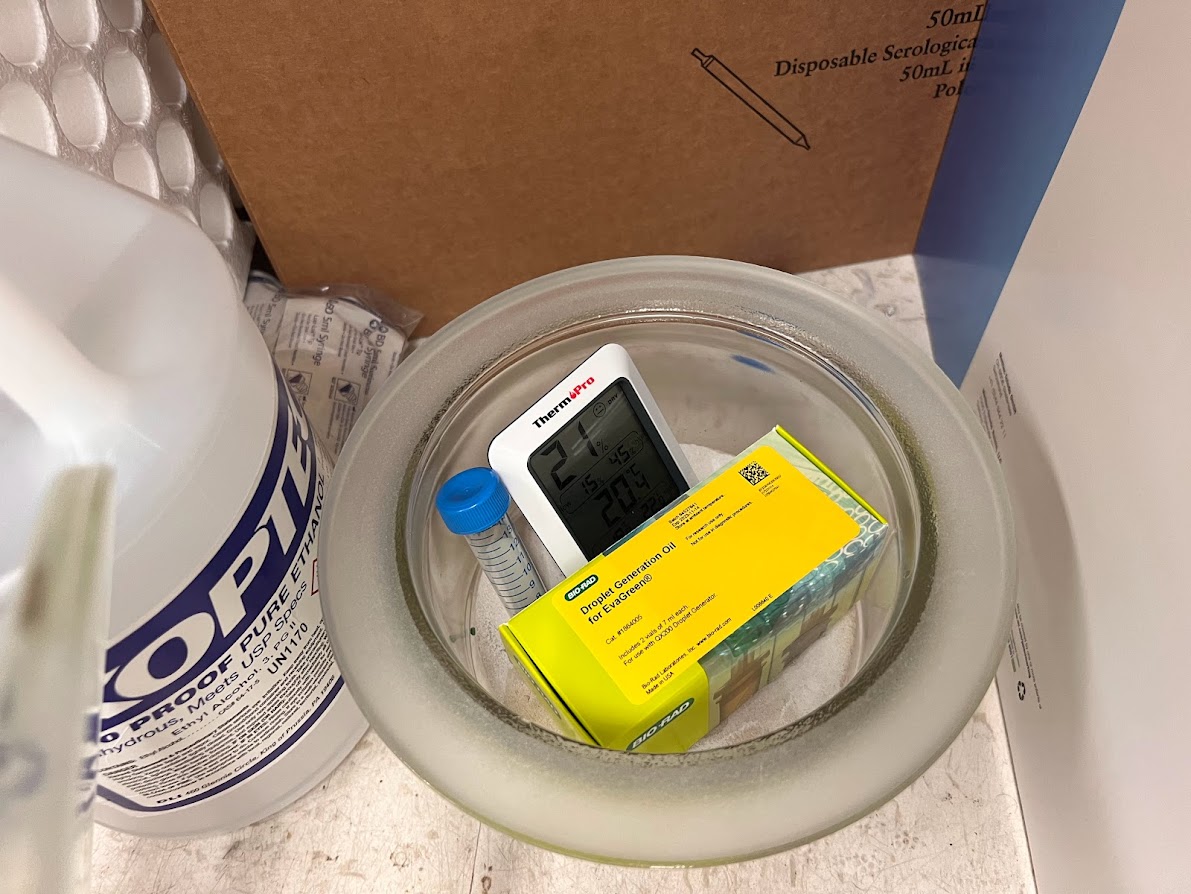

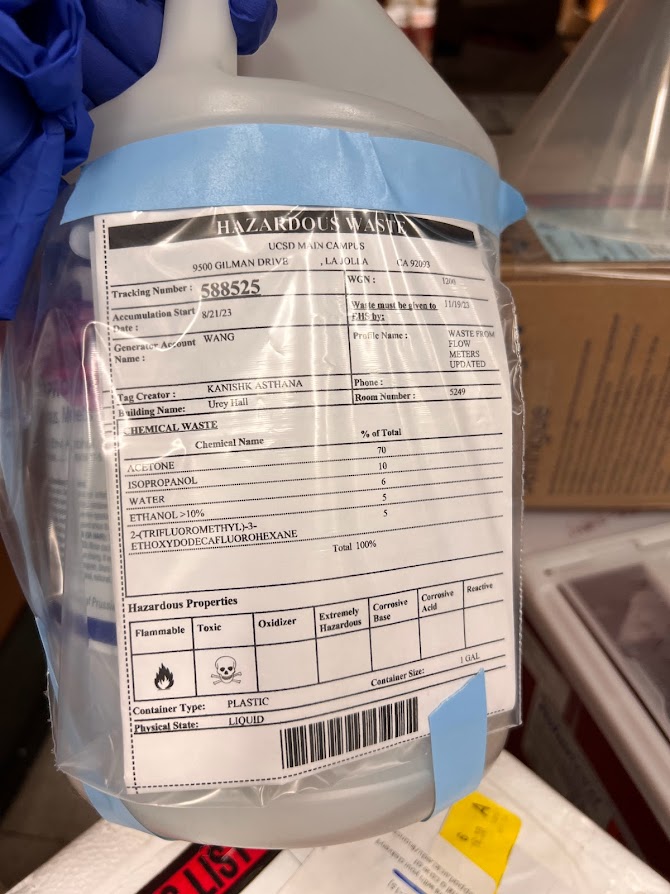

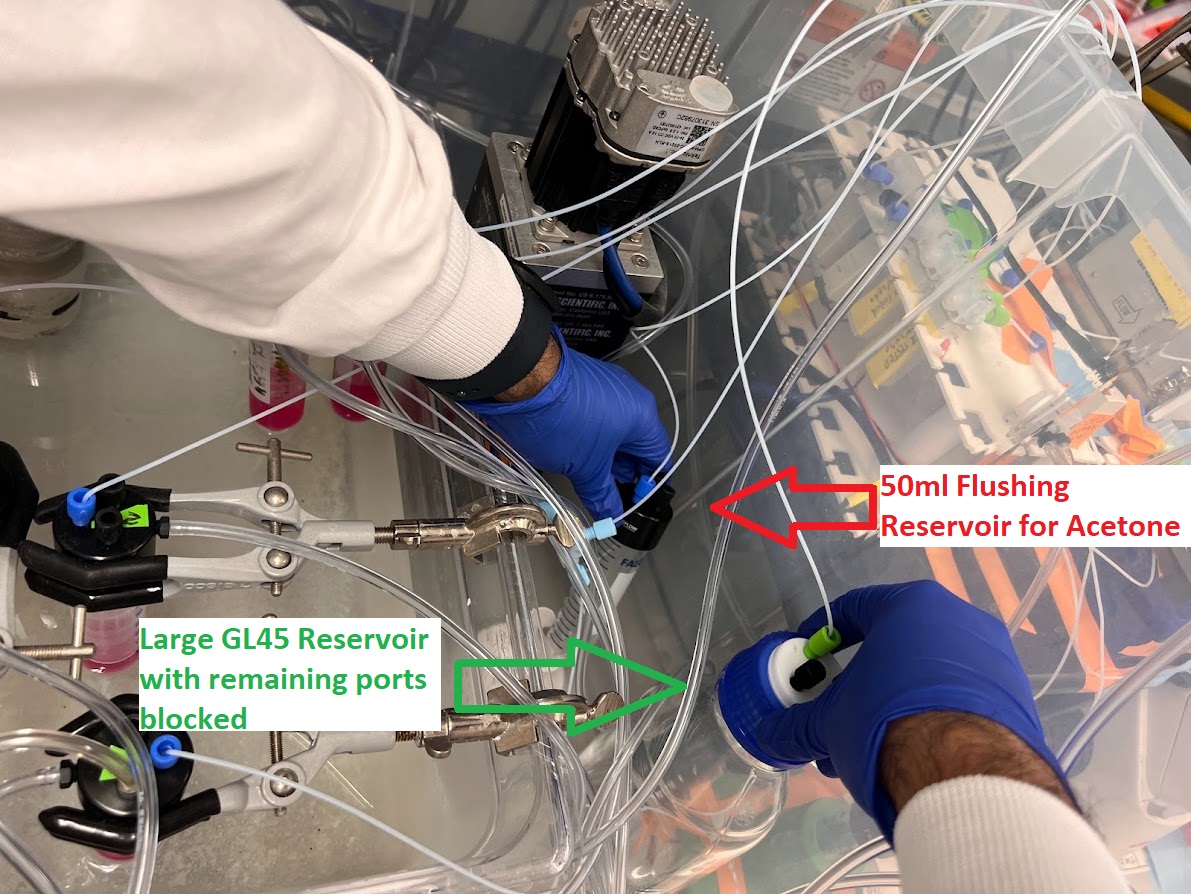

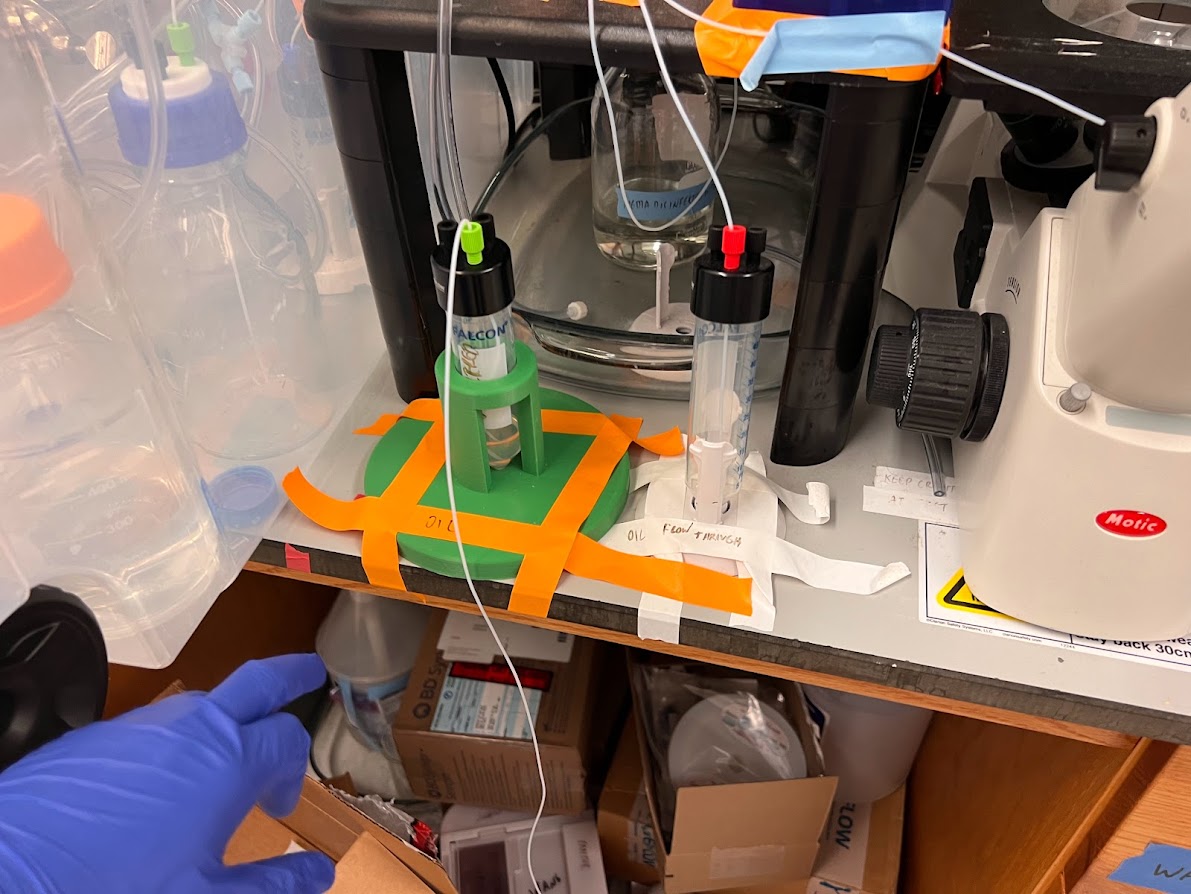

+ Check Lysis buffer volume left in Reservoirs to make sure there is enough for the Experiment.

+ There are two 50ml Reservoirs in Parallel. Make sure Both reservoirs have the Same Volume of Lysis buffer.

+ Typically upto 5ml of buffer might be used per timepoint/injection. Please [see this section for on how to prepare 1X Lysis Buffer](protocol_for_preparing_3.33X_lysis_buffer_stock.ipynb#1X_buffer).

+ Check Lysis buffer volume left in Reservoirs to make sure there is enough for the Experiment.

+ There are two 50ml Reservoirs in Parallel. Make sure Both reservoirs have the Same Volume of Lysis buffer.

+ Typically upto 5ml of buffer might be used per timepoint/injection. Please [see this section for on how to prepare 1X Lysis Buffer](protocol_for_preparing_3.33X_lysis_buffer_stock.ipynb#1X_buffer).

+ **Check below the Lysis Buffer Reservoir Cap for Stuck debris.**

+ **Check below the Lysis Buffer Reservoir Cap for Stuck debris.**

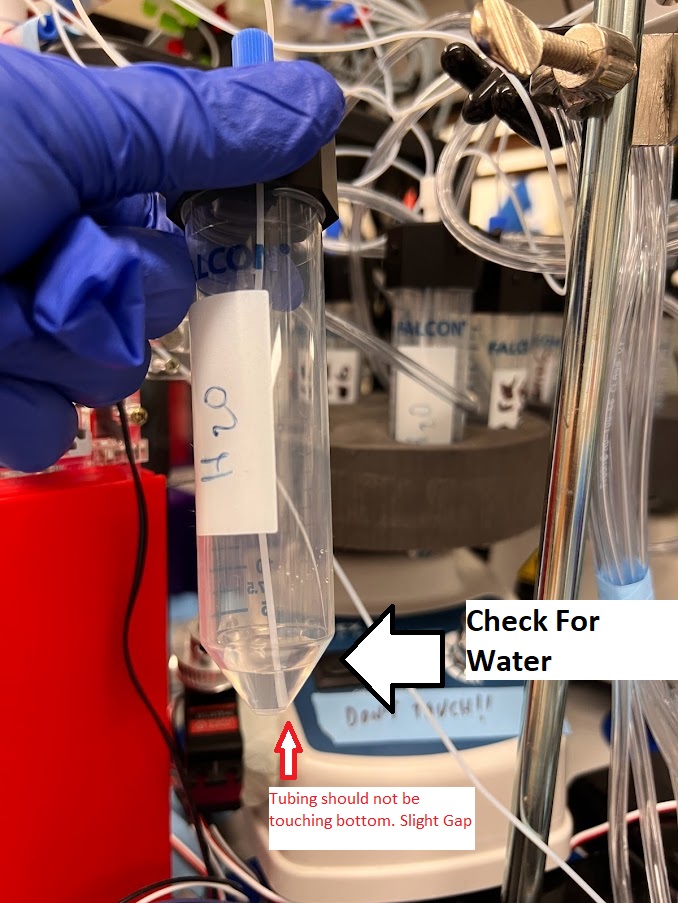

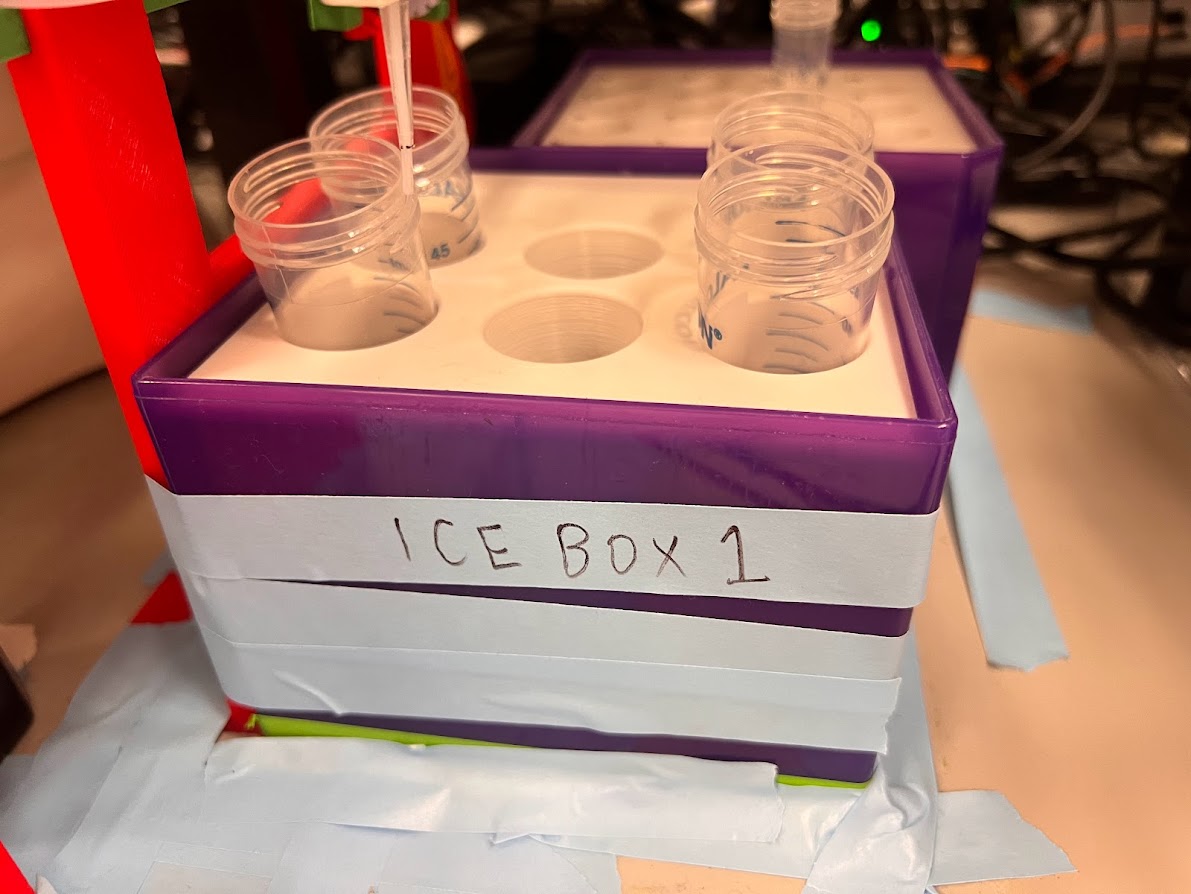

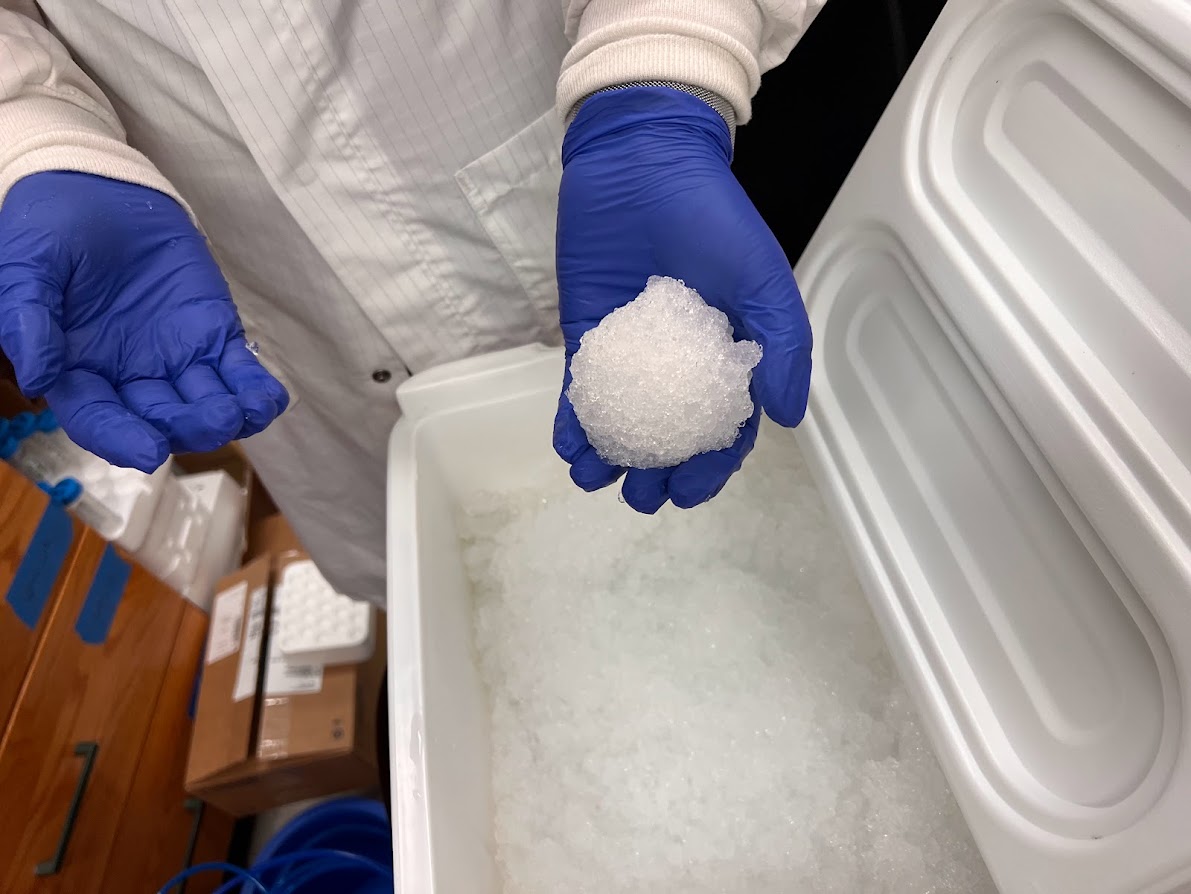

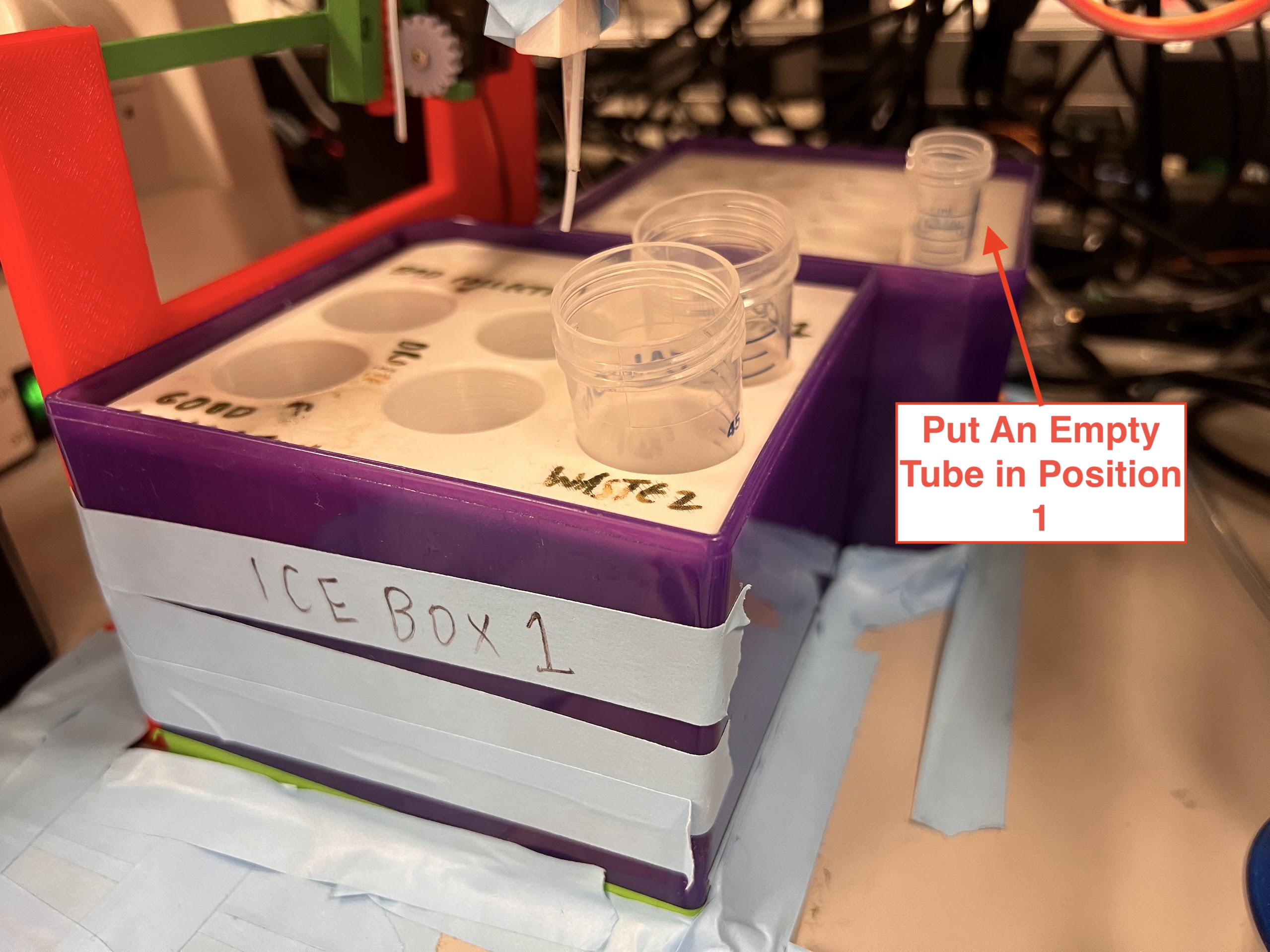

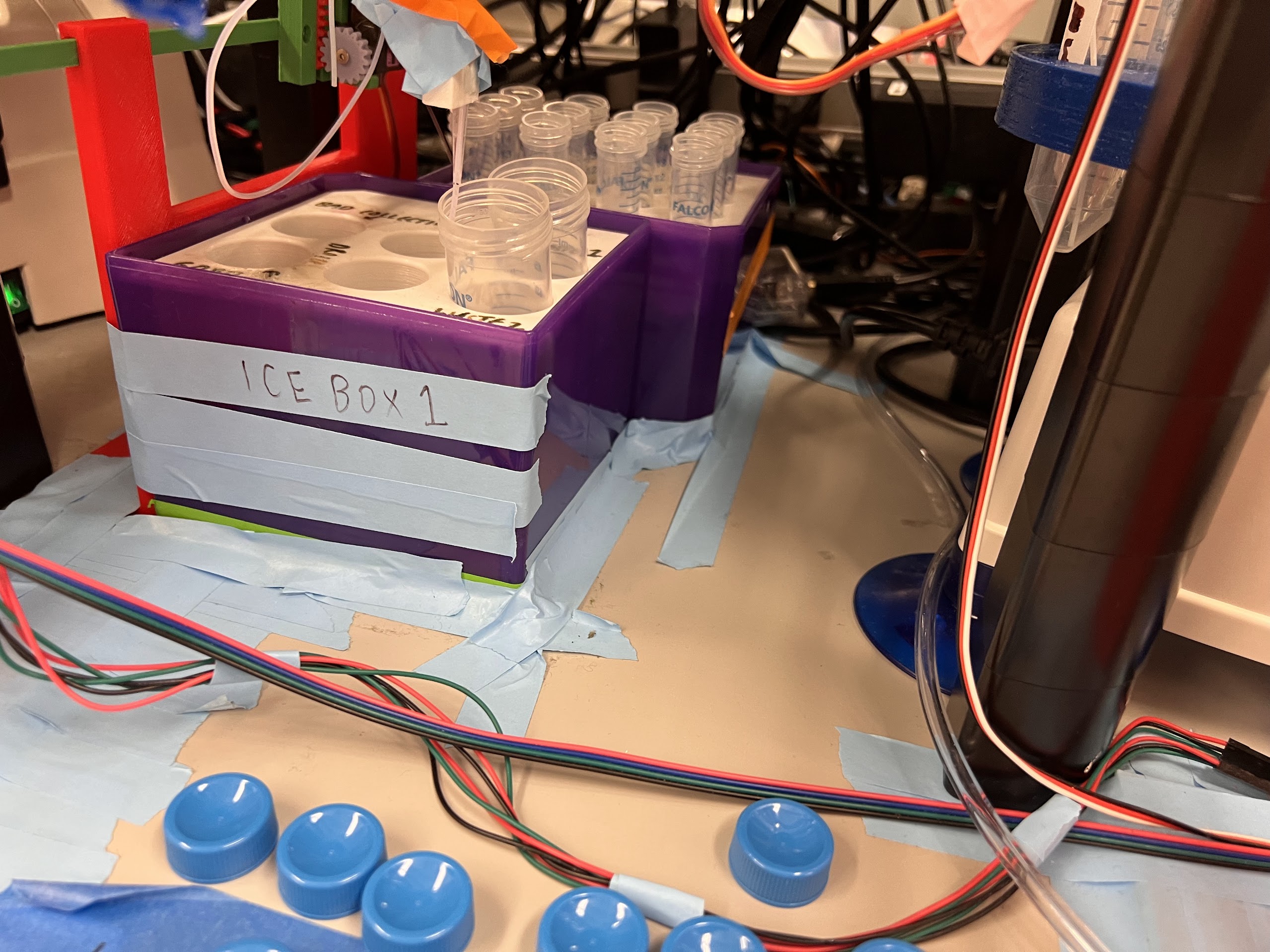

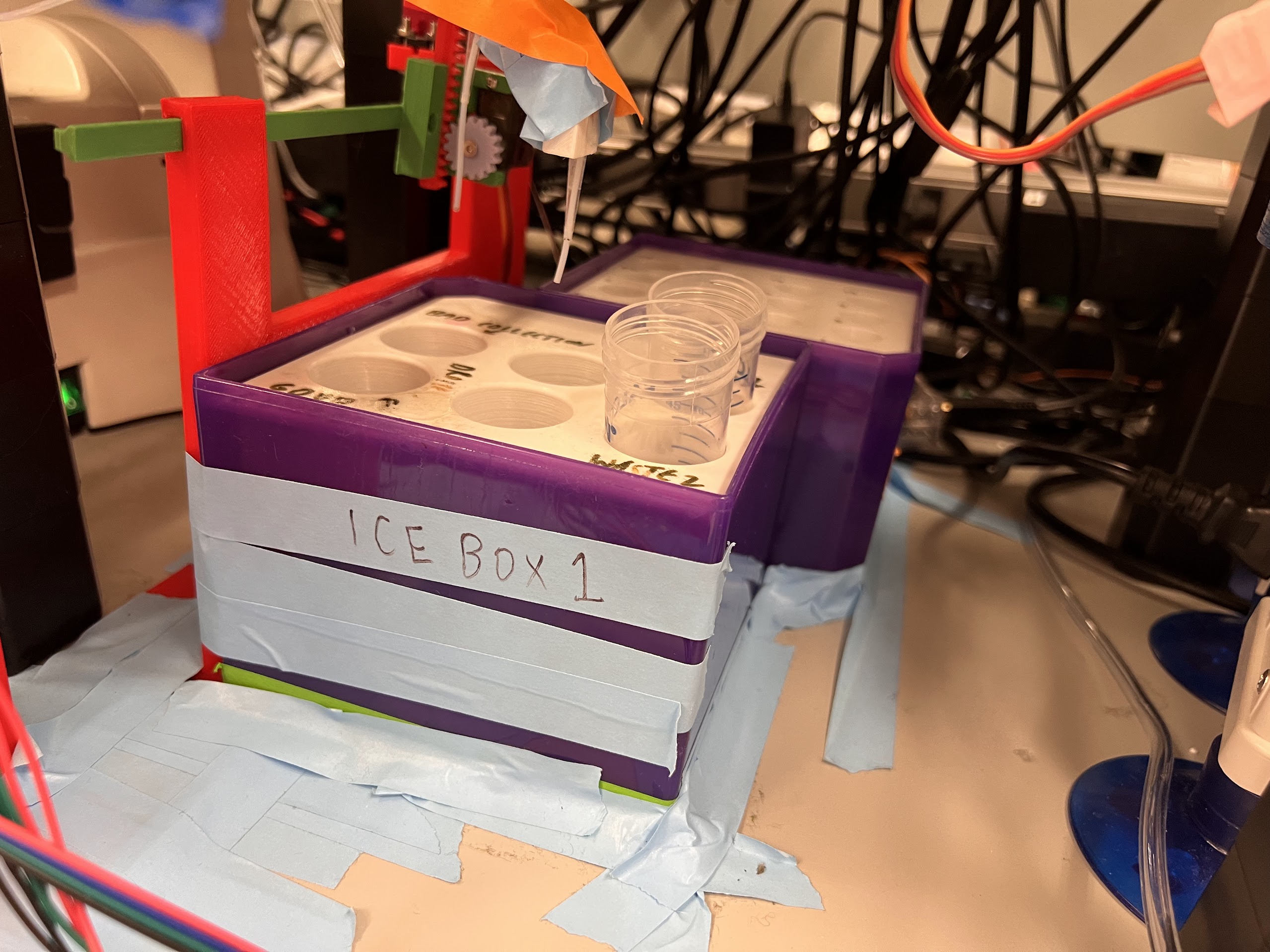

+ #### Check for Water inside the Ice Boxes.

If you did the cleanup correctly there should be no water from the melted ice inside the ice boxes. Use the Vacuum line to suck up any melt water if necessary. Use a wipe to soak up the rest. The Video Below is a demonstration of how to do it.

+ #### Check for Water inside the Ice Boxes.

If you did the cleanup correctly there should be no water from the melted ice inside the ice boxes. Use the Vacuum line to suck up any melt water if necessary. Use a wipe to soak up the rest. The Video Below is a demonstration of how to do it.

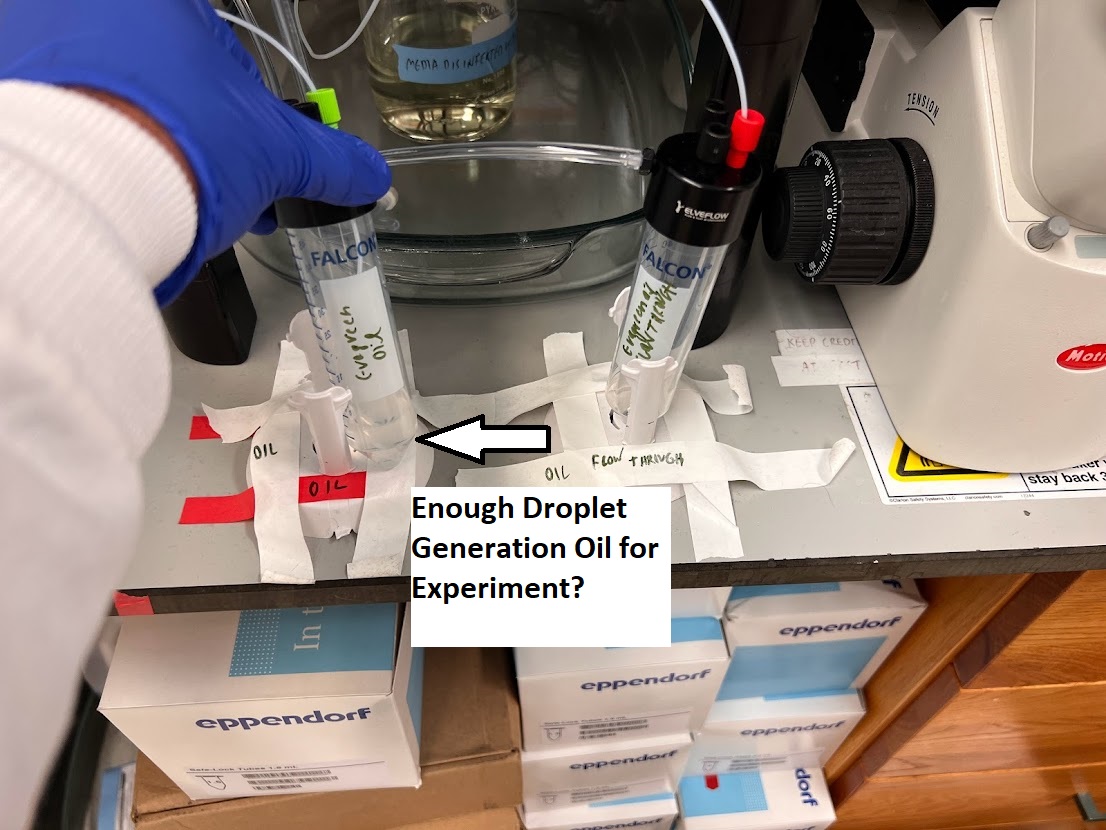

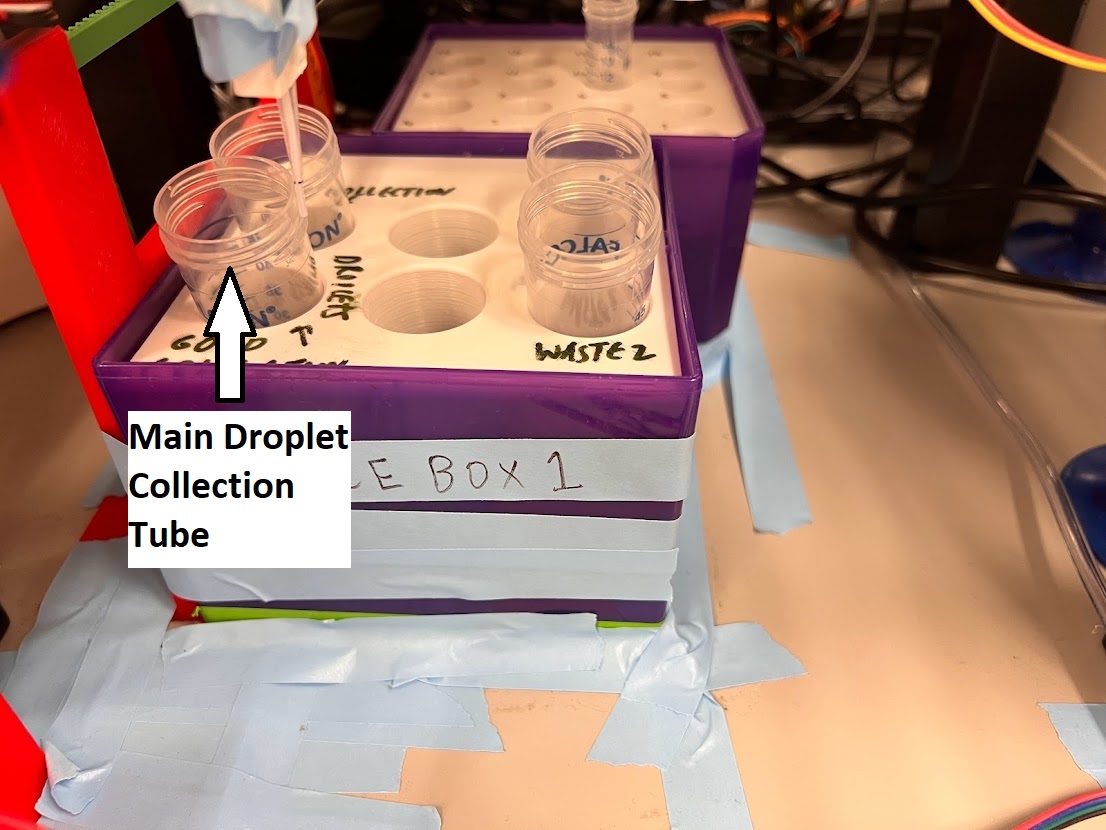

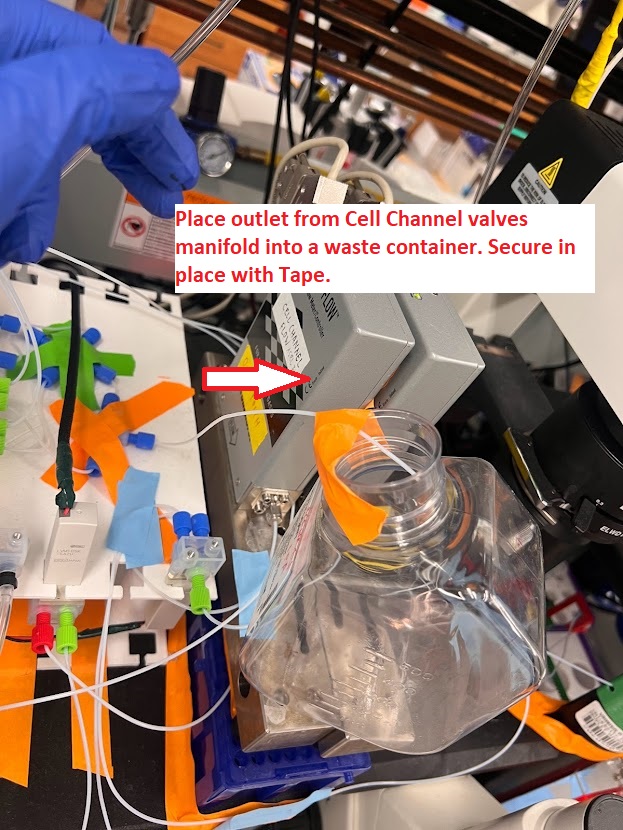

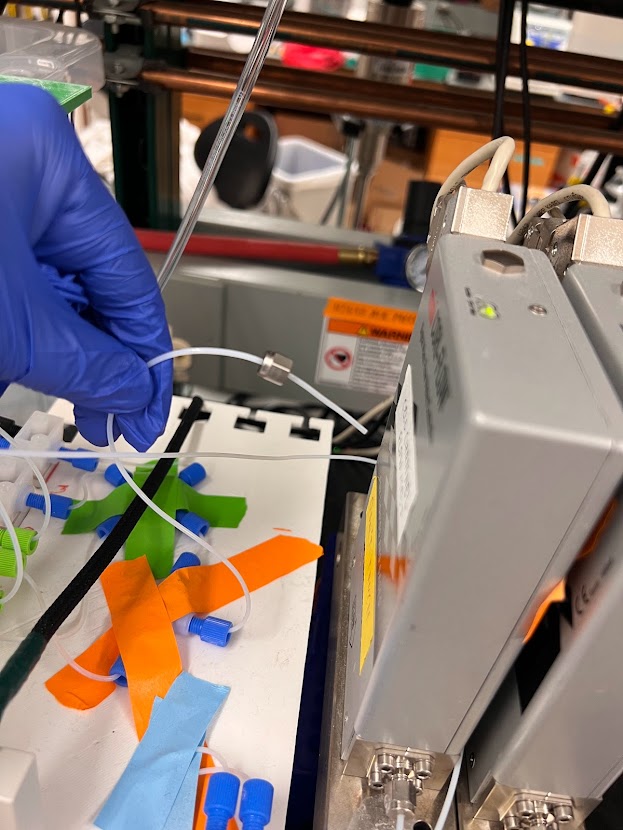

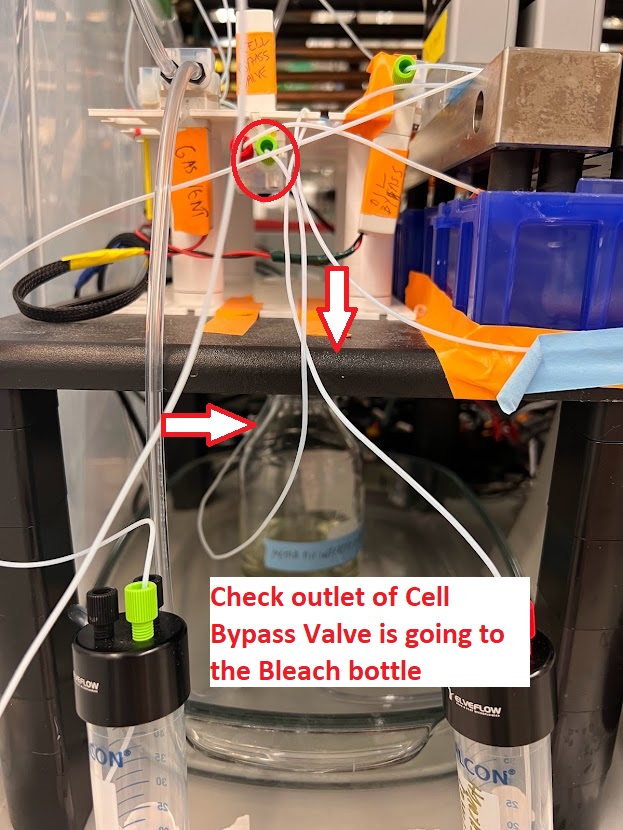

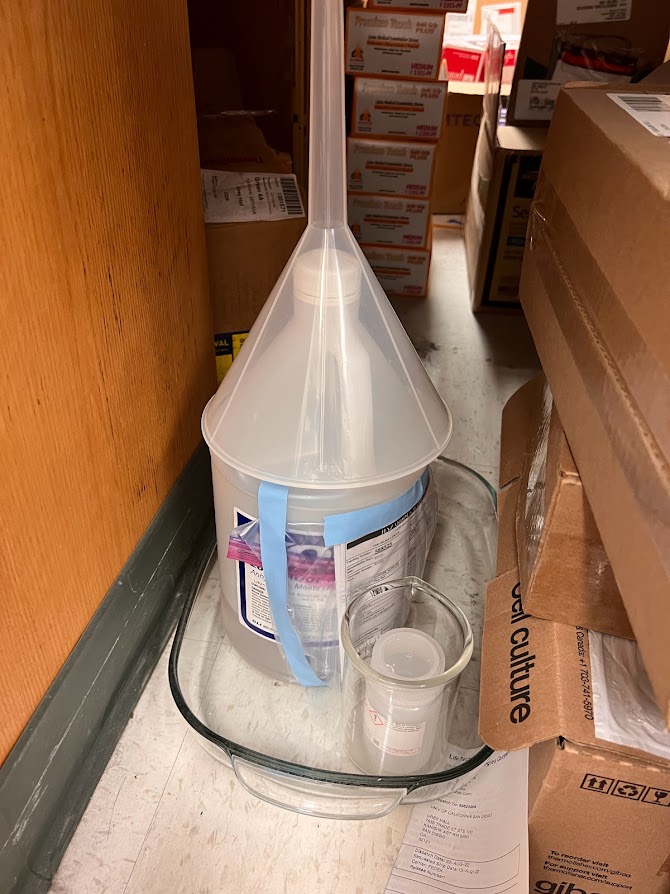

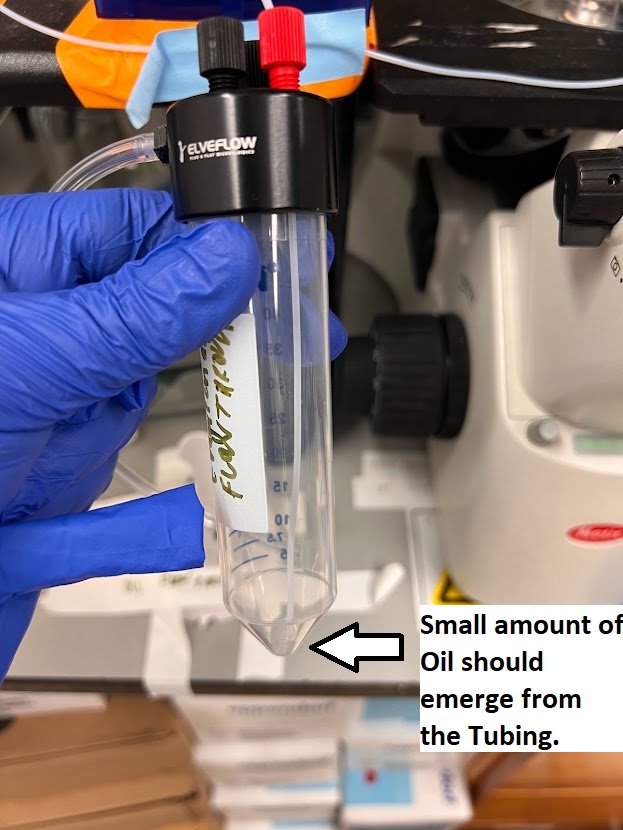

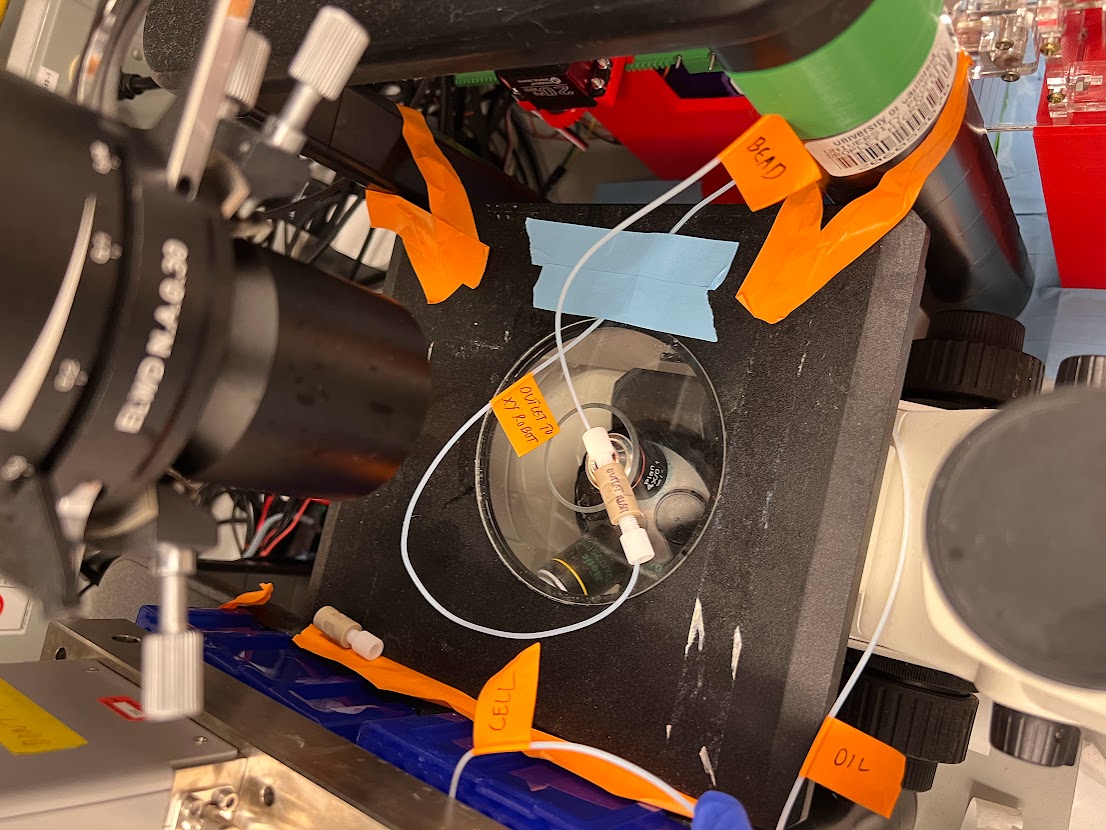

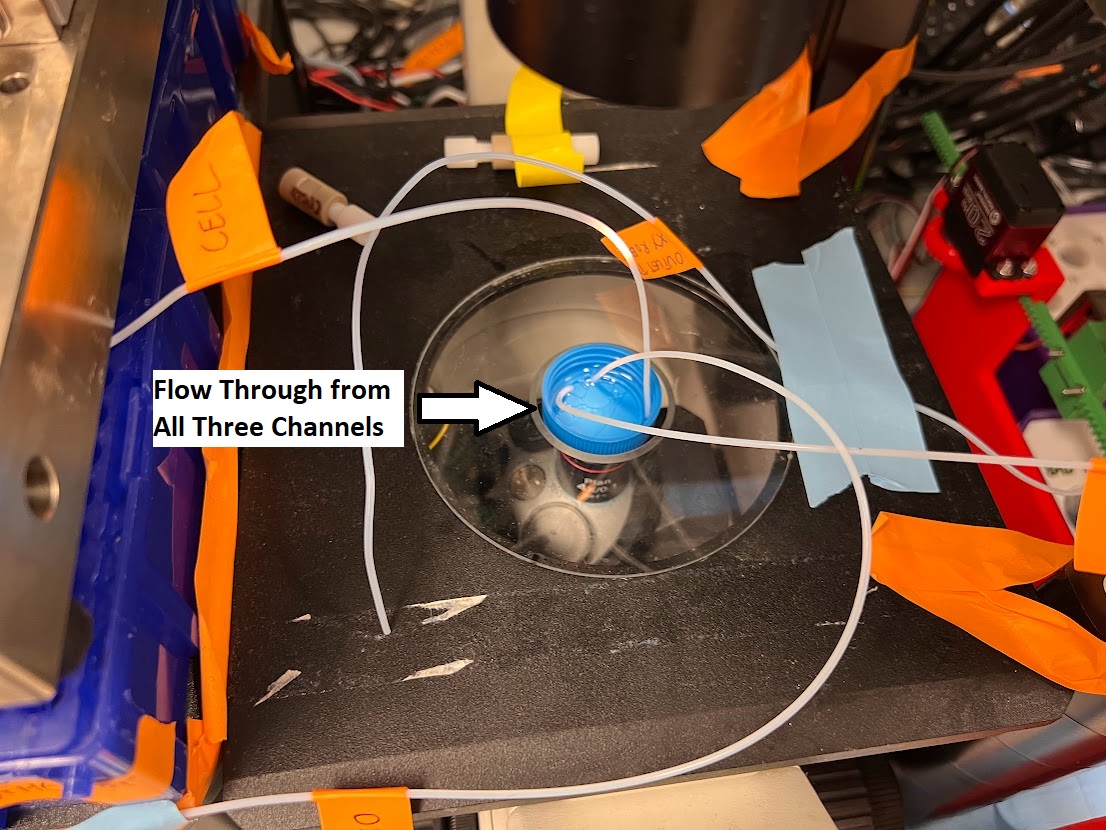

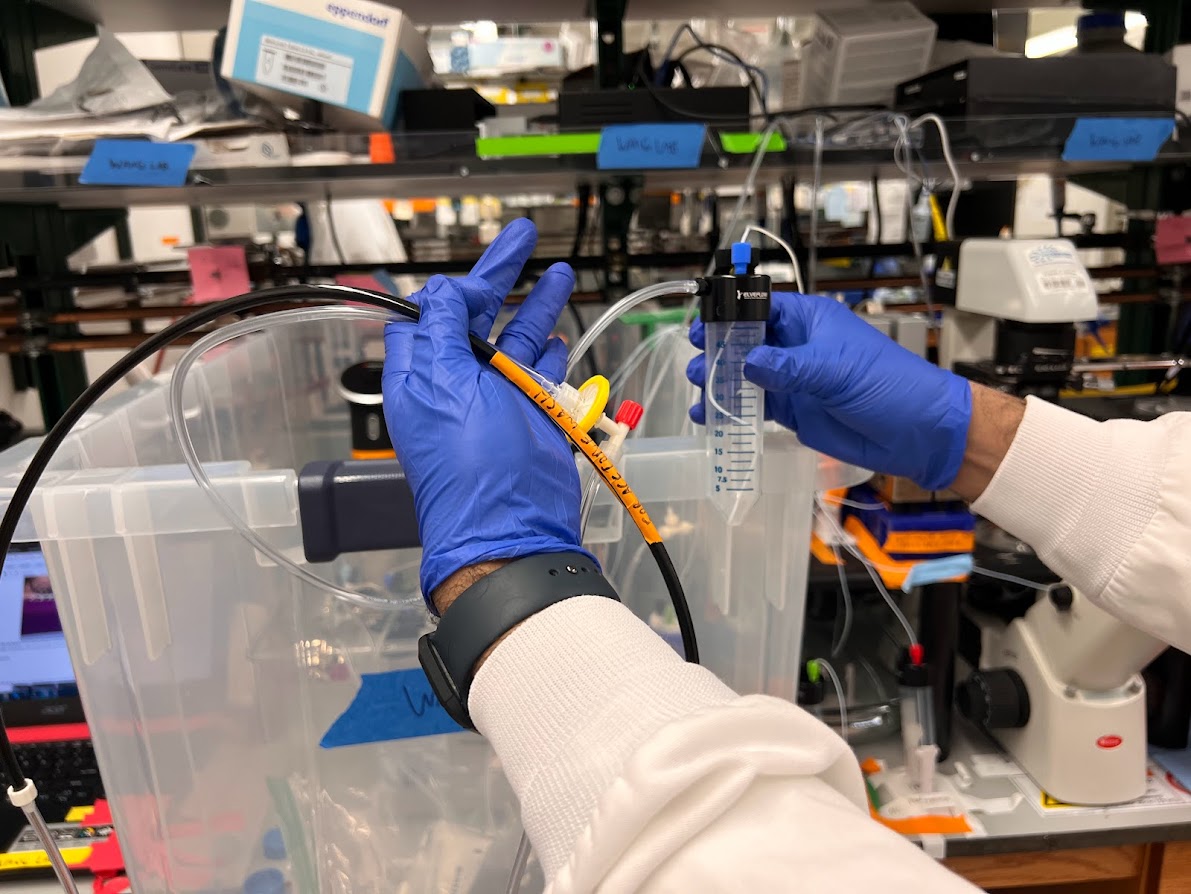

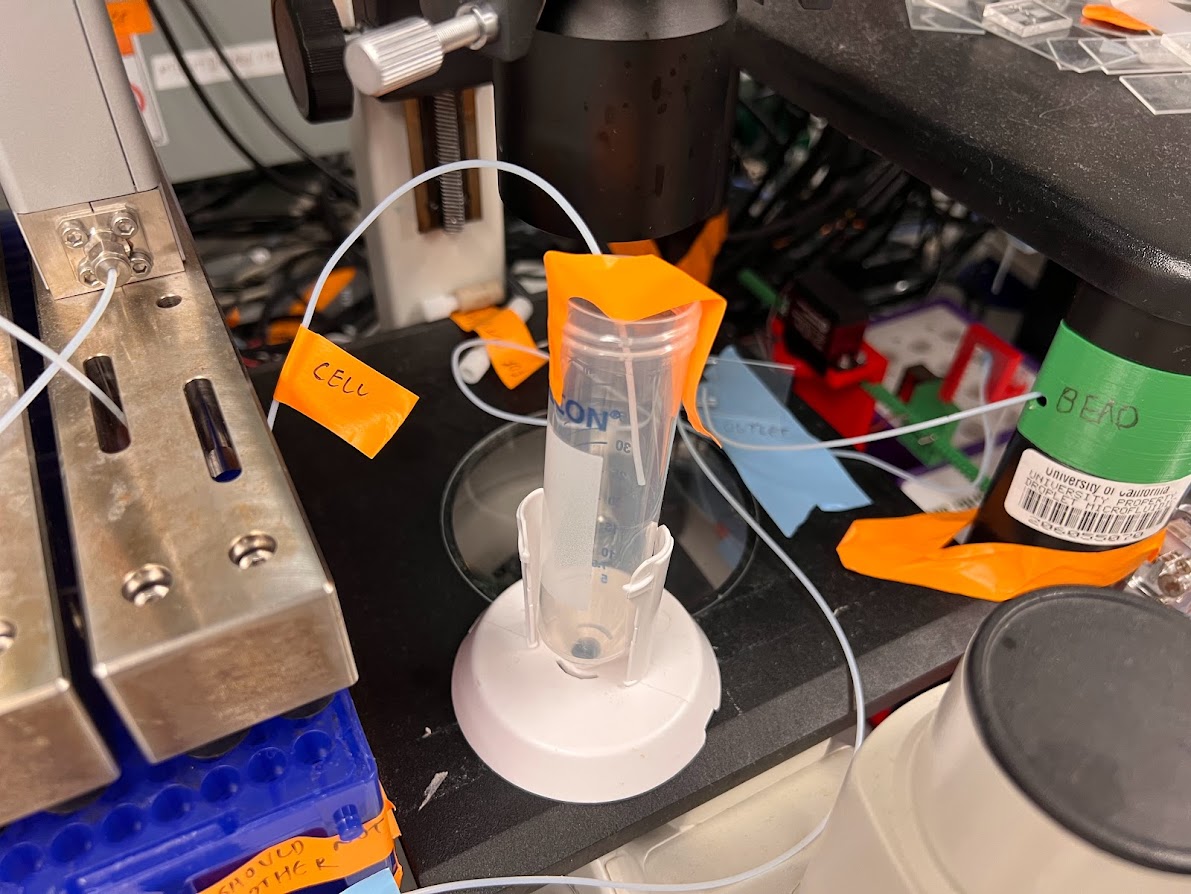

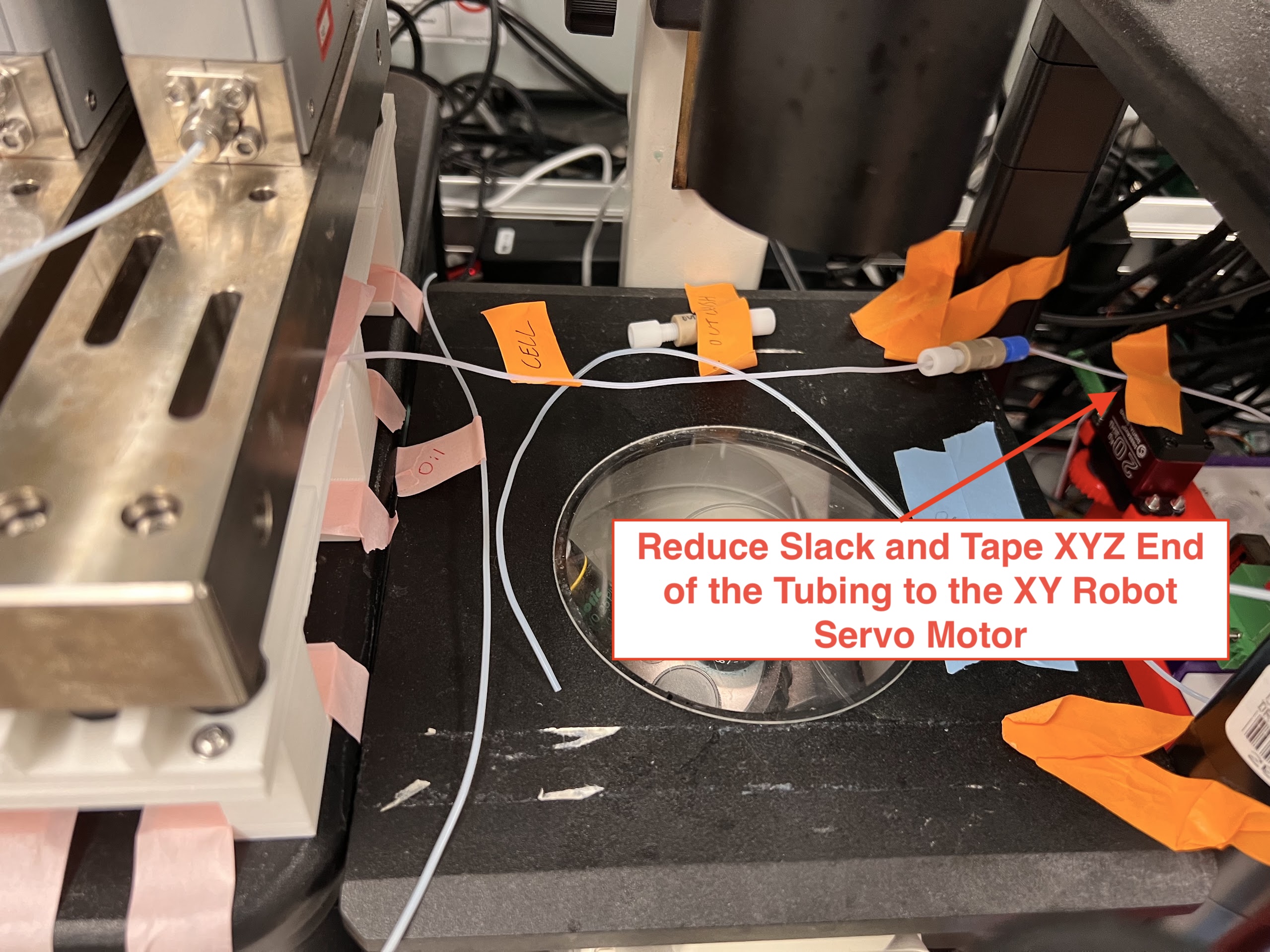

+ Now Execute the Cell Below. A little bit of Oil should emerge into the Oil flow-through Tube (through the Oil-Bypass Valve).

+ Now Execute the Cell Below. A little bit of Oil should emerge into the Oil flow-through Tube (through the Oil-Bypass Valve).

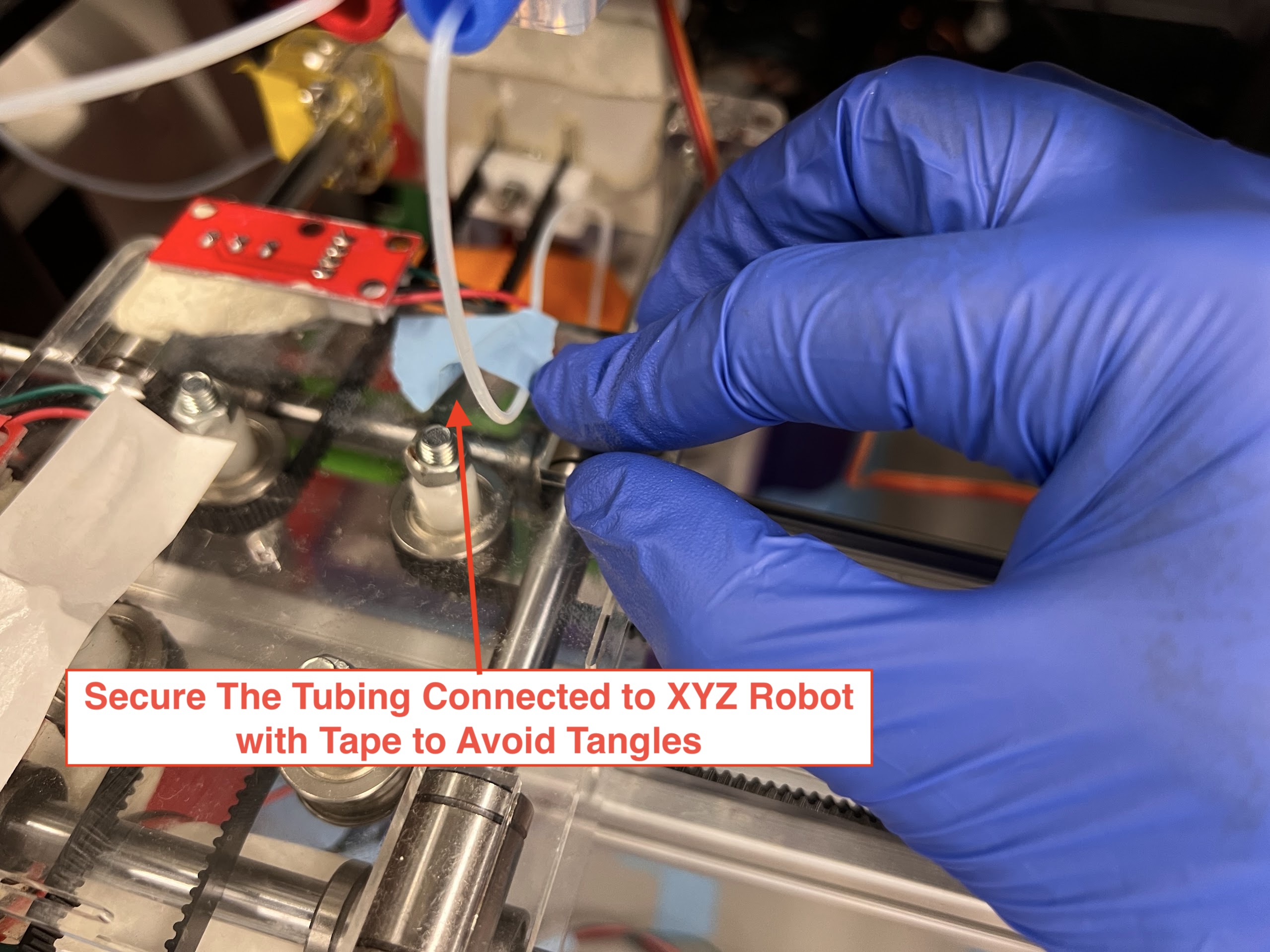

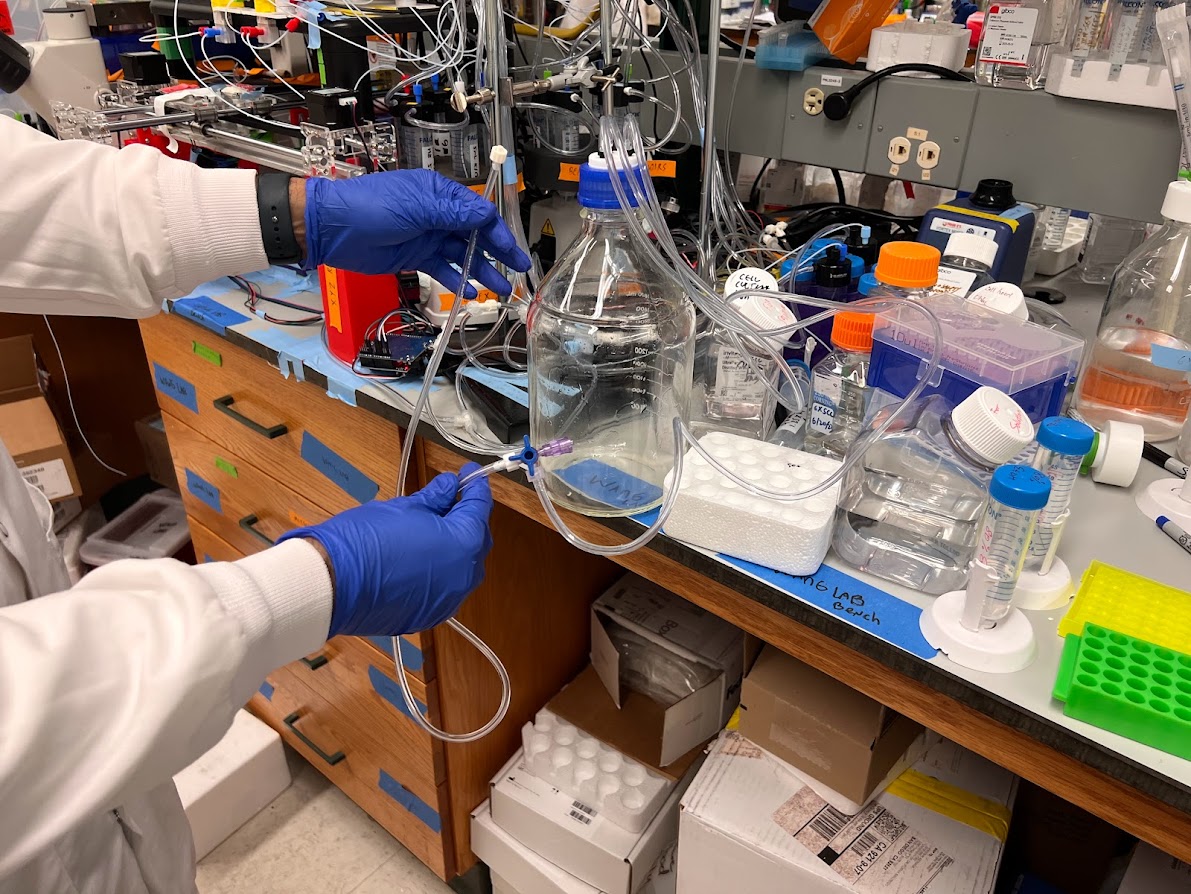

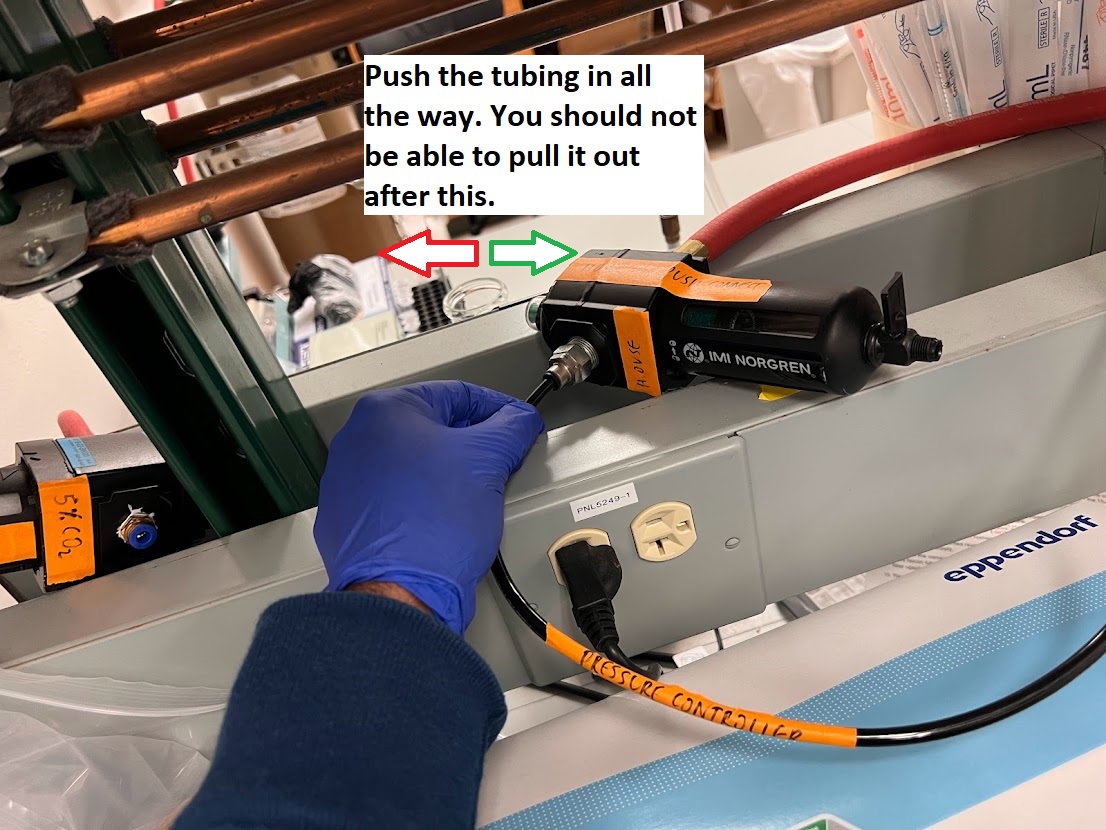

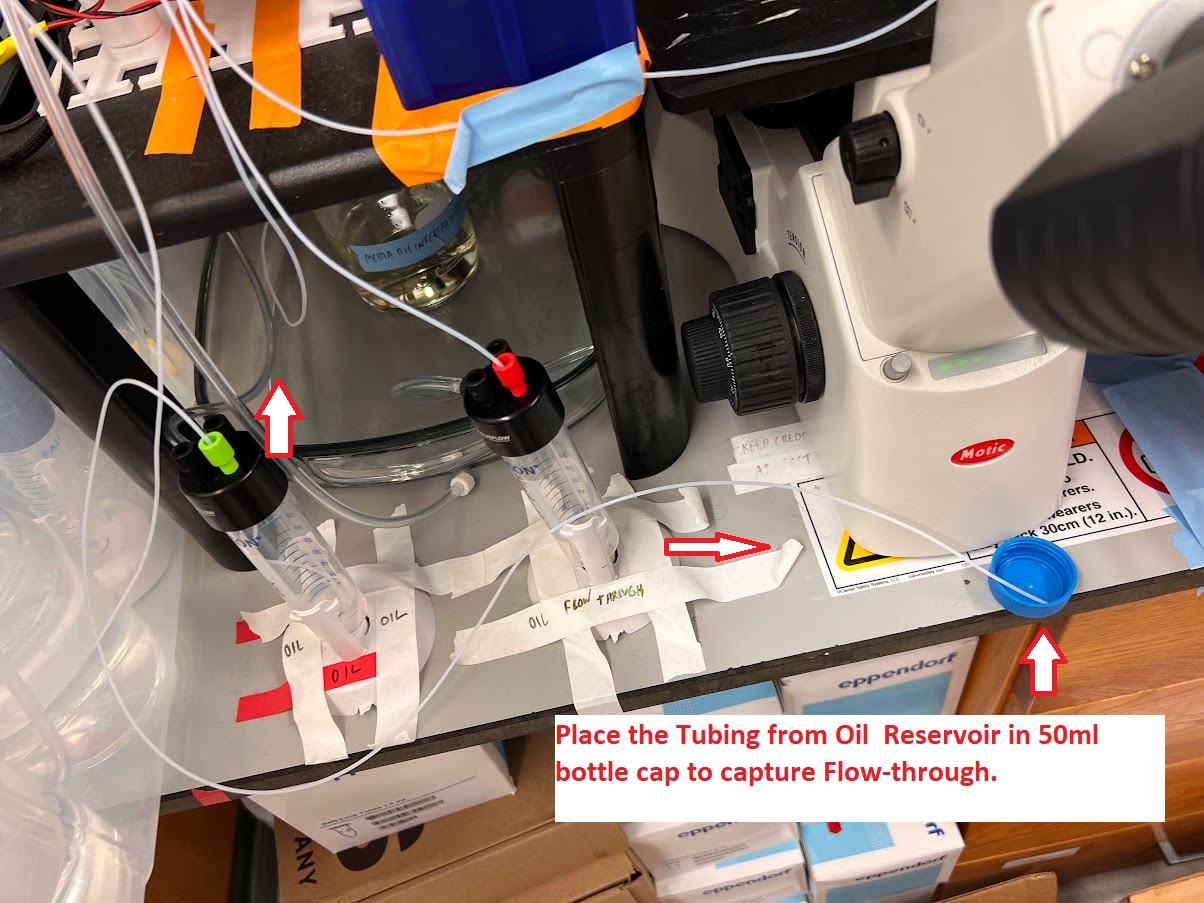

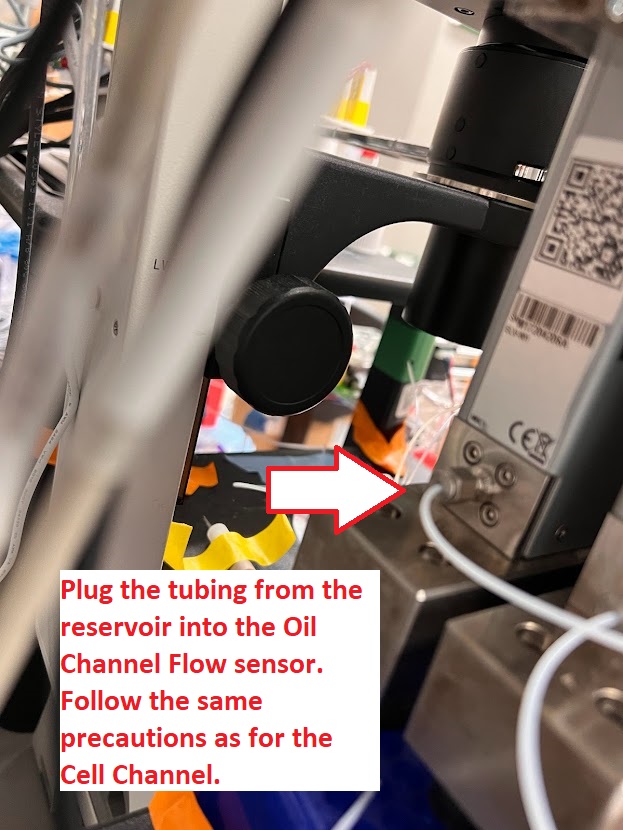

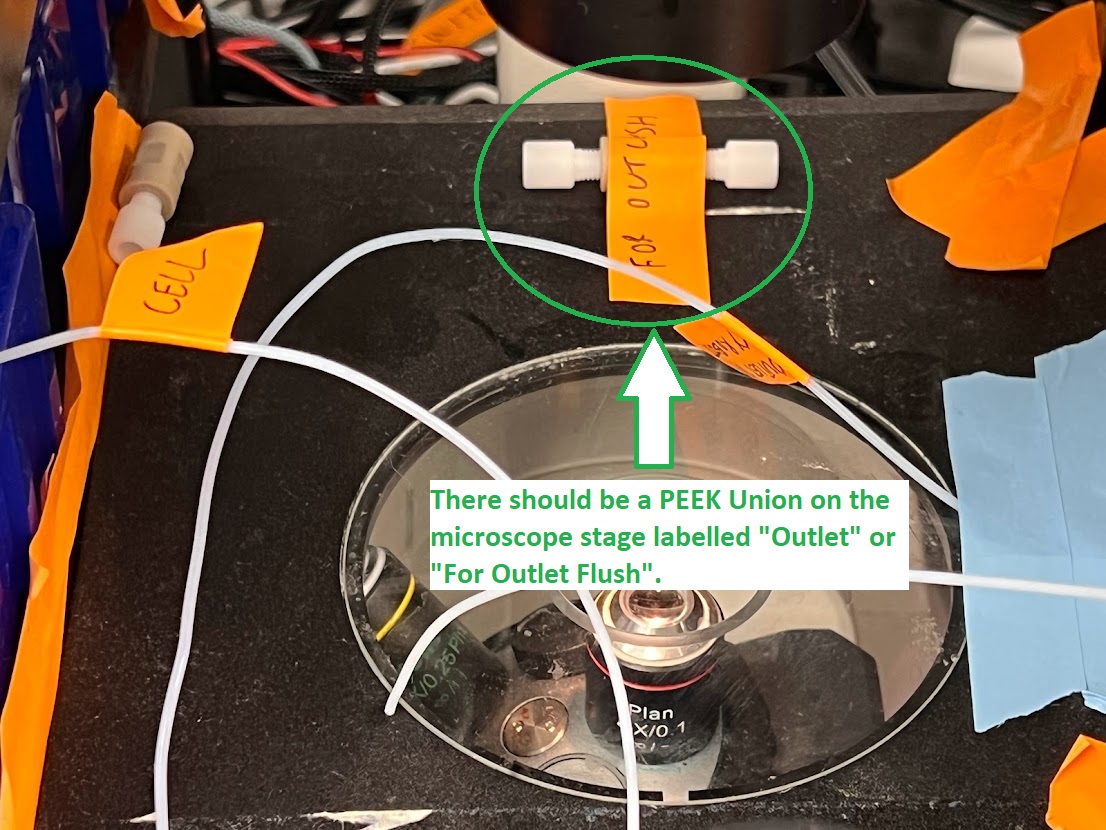

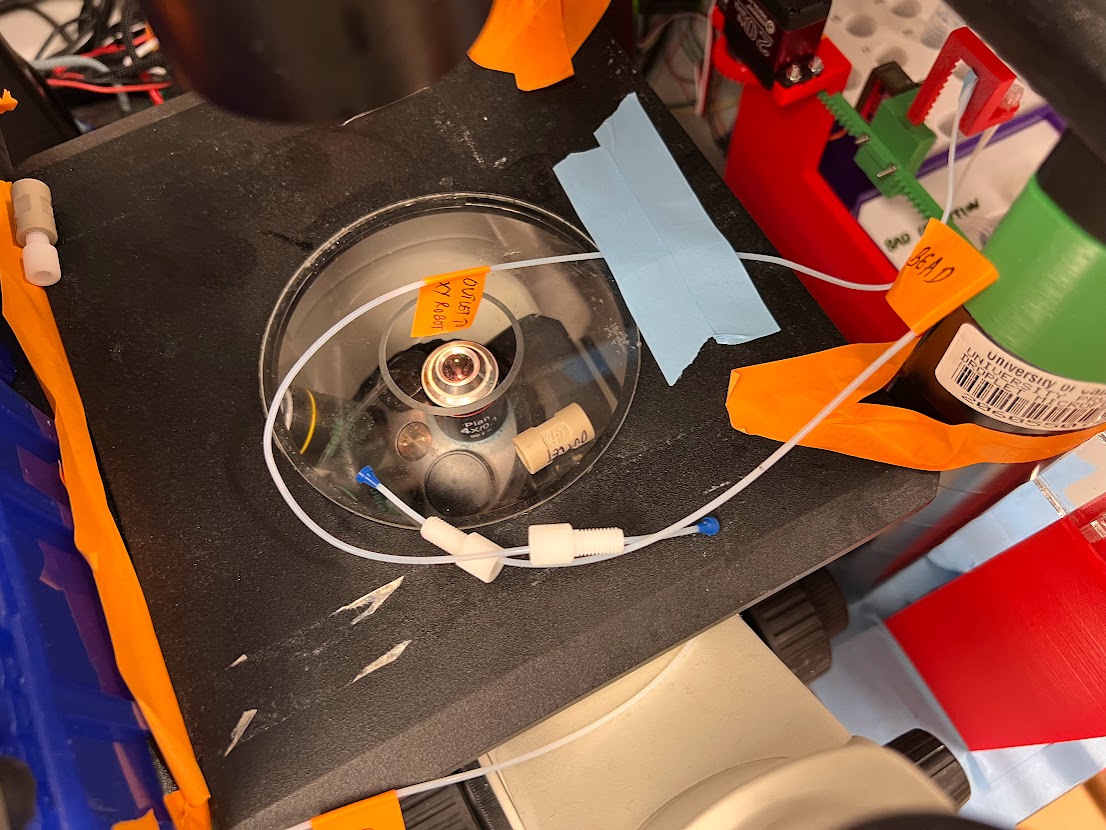

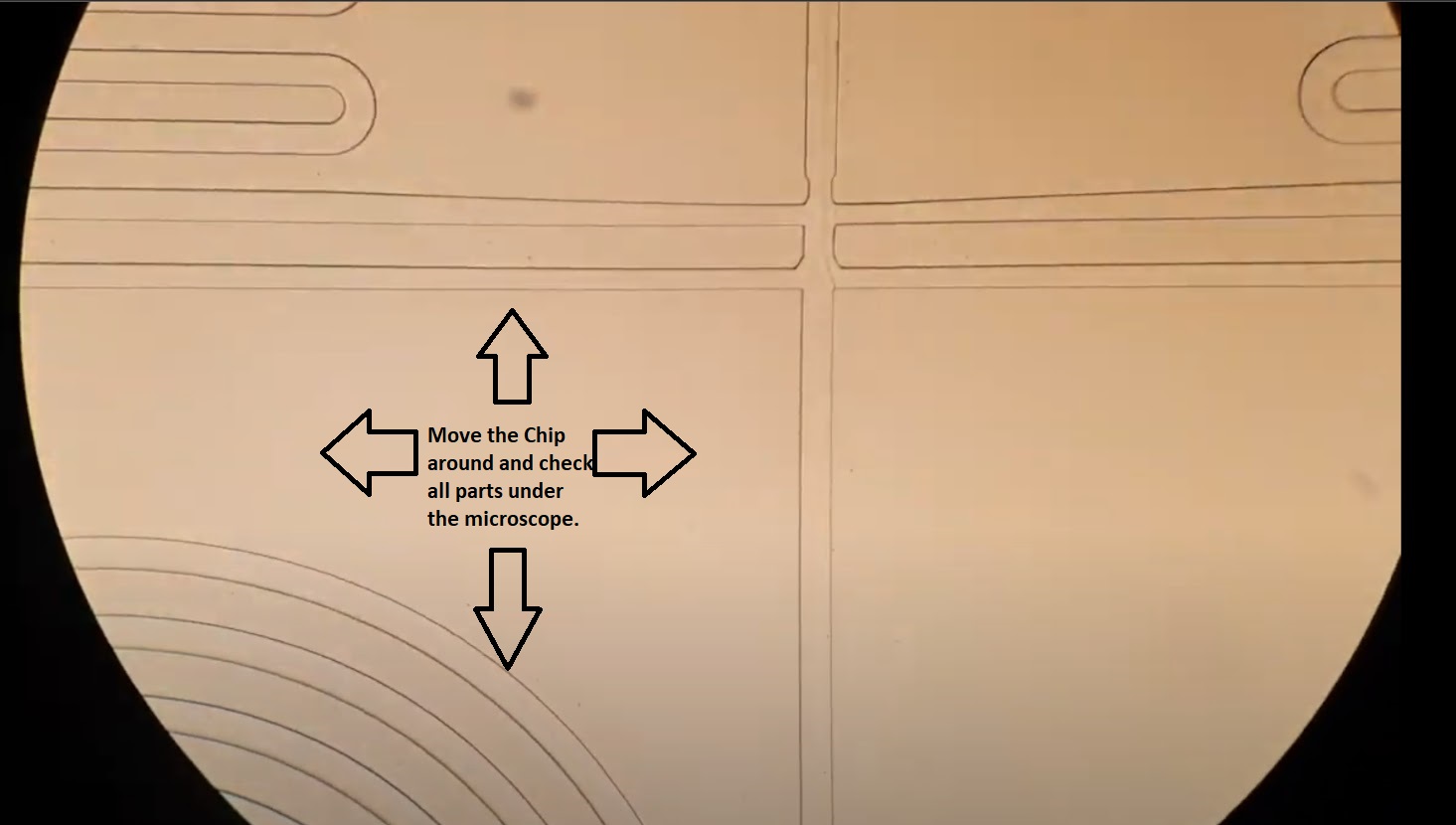

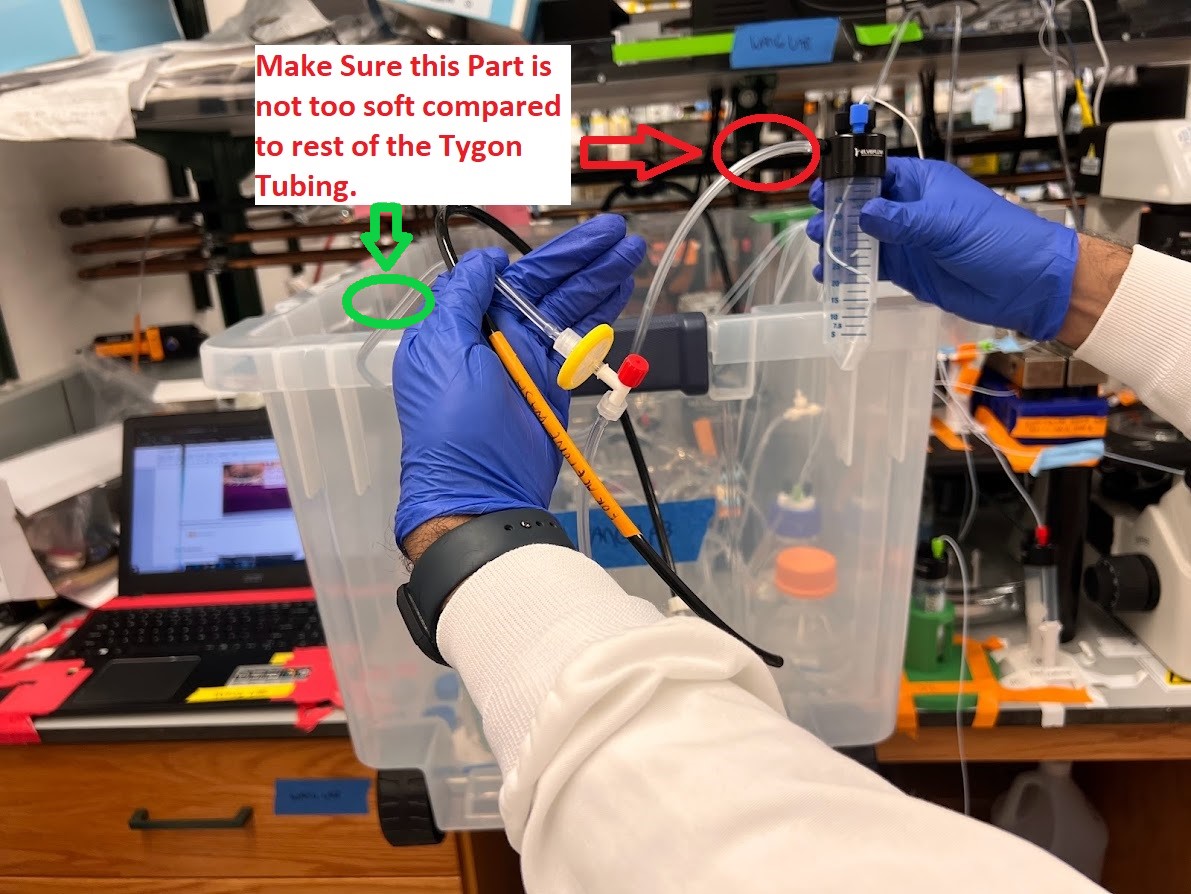

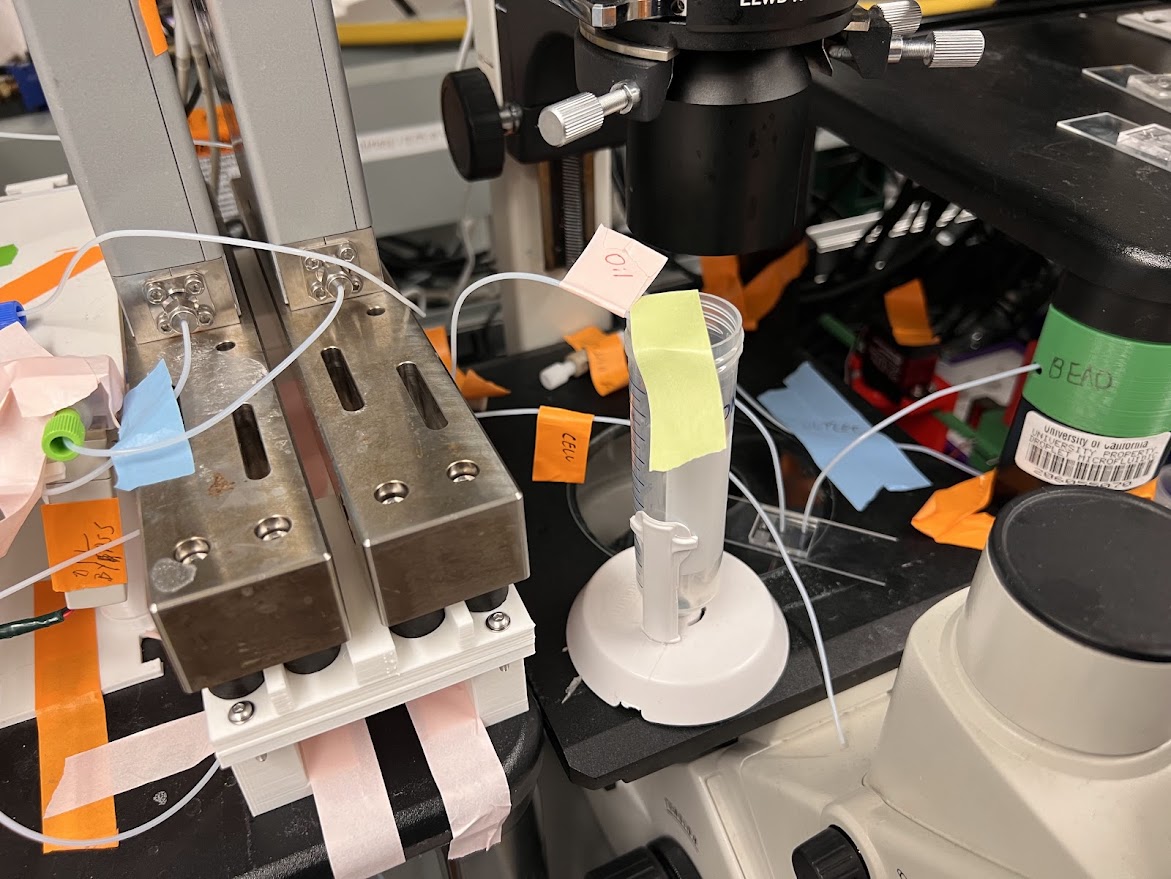

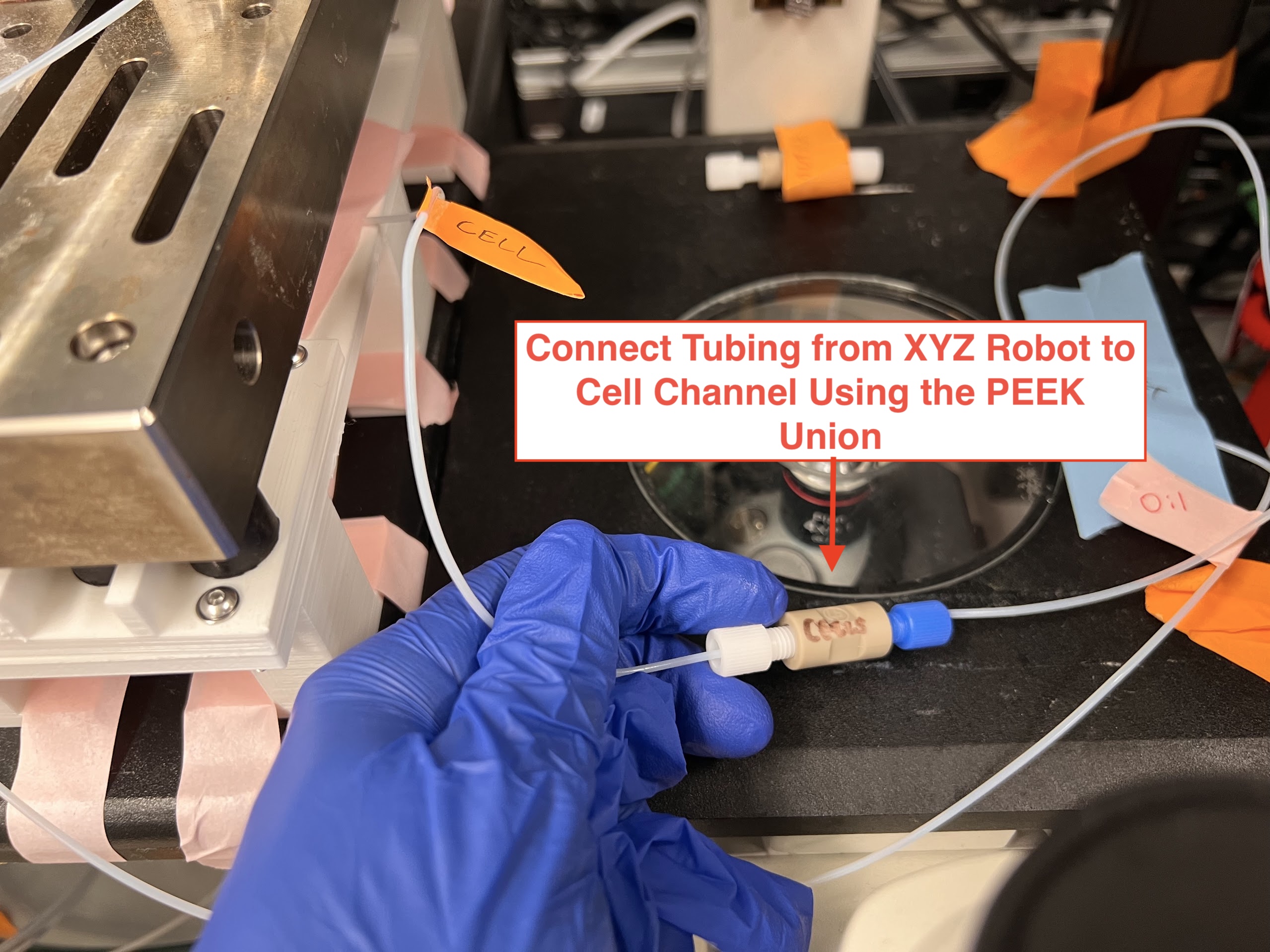

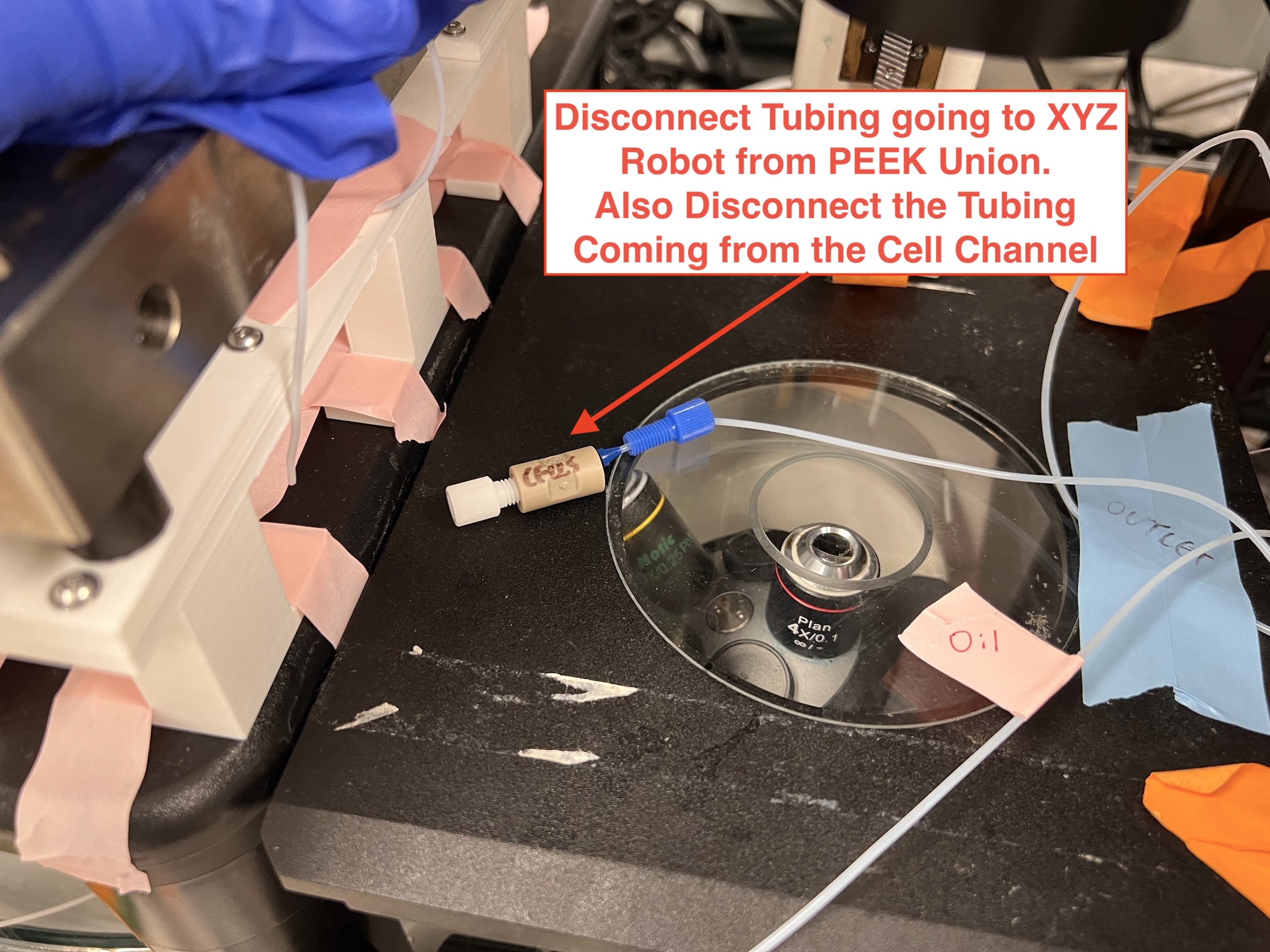

+ We need to prime this tubing that connects to the chip. For this purpose execute

+ We need to prime this tubing that connects to the chip. For this purpose execute

.jpg)